Nashville Electric Service

advertisement

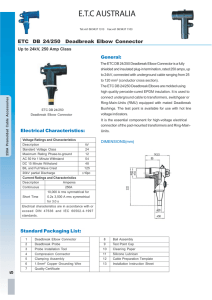

Nashville Electric Service • Specification – ELB-307-3 • Description: Three Phase 25kV Class Load Break Connector 1.0 Scope and Purpose................................................................... 1 2.0 General Requirements .............................................................. 1 3.0 Detailed Requirements.............................................................. 1 4.0 Inspection and Testing .............................................................. 3 5.0 Revision History ........................................................................ 4 The Electric Power Board of the Metropolitan Government of Nashville and Davidson County Specification ELB-307-3 1.0 2.0 3.0 SCOPE AND PURPOSE 1.1 The purpose of this specification is to insure the furnishing of a 25 kV class elbow connector and a bushing insert switch module rated three phase load break. 1.2 It is intended that this specification shall serve as a guide to the manufacturer in preparing the proposal, rather than as a detailed specification. GENERAL REQUIREMENTS 2.1 The connector module shall be suitable for use on a 25 kV class, four wire, multi-grounded or three wire, ungrounded system. Rating shall be 125 kV basic impulse level (BIL), 200 ampere load make/break at 15.2 kV phase-to-ground and 26.3 kV phase-to-phase. The elbow connector and bushing insert switch module shall be interchangeable with other manufacturer’s components complying with industry standards and with ANSI/IEEE 386, latest revision. 2.2 Tensile strengths shall meet ASTM Class No. 35 (35,000 PSI). DETAILED REQUIREMENTS 3.1 Elbow Cable Entrance: The elbow connector shall have a minimum and maximum cable insulation dimension entrance as specified on the invitation to bid, to mate with insulation of shielded cable without use of tape. Dimension range and cable conductor type and size to be specified in invitation to bid. 3.2 Shield: The outer conductive shield for the elbow connector and bushing insert switch module is to be molded. 3.3 Arc Follower: The forward portion of the male contact of the elbow is to be supplied with a thermoplastic arc quenching material that is compatible with the arc snuffer of the bushing insert. 3.4 Hot-Stick Eye: The elbow pulling eye is to be stainless steel capable of withstanding a pull-out force as specified in ANSI/IEEE 386, latest revision. 3.5 Identification Band: The band is to be industry standard to identify the elbow as a three phase load-break device. 3.6 Universal Bushing Well Connection: The bushing insert is to have a 3/816 brass or copper threaded hole in the contact tube and external dimensions that will properly mate with the universal bushing well. 1 Specification ELB-307-3 3.7 Locking Mechanism: The elbow connector is to have a locking ring that mates with the locking groove of the bushing insert to provide a positive latch on the mating. Conductor Compression Connector: The elbow kit to include a copper/aluminum bimetallic friction welded compression aluminum compression barrel). 3.8 Conductor Compression Connector: The elbow kit to include a copper/aluminum bimetallic friction welded compression connector (aluminum compression barrel). 3.9 Movable Contact Assembly: The bushing insert is to have a movable contact assembly that produces a self-closing action under fault-close operation. Minimum fault close rating at rated voltage to be 15,000 amperes RMS symmetrical. Female contact to be silver plated copper and all current carrying components must be copper or copper alloy. 3.10 Gas Restricting Mechanism: The bushing insert is to have a gas trap to control and restrict the expelling of arc-quenching gases during load break operations. 3.11 Male Contact Rod: The contact rod of the elbow connector is to have a pilot to prevent stripping and cross threading of conductor contact. 3.12 Lubrication: All contact parts of the elbow connector and bushing insert are to be provided with proper amount of high viscosity, non-migrating, silicone lubricant. 3.13 Separation Force: Interface tolerances and lubrication of the elbow connector and bushing insert must be such as to allow separation forces within limits prescribed by ANSI/IEEE 386, latest revision. 3.14 Grounding Eye: The elbow connector shall have a convenient eye or tab in molded shield for acceptance of concentric neutral wire for grounding purposes. 3.15 Packaging: The elbow connector and bushing insert shall each be packaged separately. Package shall be dust and moisture proof. Each package shall contain a complete kit for that item with parts, lubricant, applicators, disposable assembly tools and instructions. 3.16 Exclusions: The elbow connector is to be furnished without a test point, and without a hold-down bail. 3.17 This section is to include applicable industry specifications and/or the qualifications of the supplies. 3.18 This is the first paragraph of the scope of the specification. This section describes the range of and limits of the specification. 2 Specification ELB-307-3 4.0 INSPECTION AND TESTING 4.1 All components and parts are to be tested in accordance with the procedures specified in ANSI/IEEE 386, latest edition. 3 Specification ELB-307-3 5.0 REVISION HISTORY I. 11/15/76: Original BDT II. 4/19/77: General revisions BDT III. 8/2/04: Updated ANSI/IEEE number. New formatting, eliminated items taken care of by Procurement S Dunn R Davidson File Locations: Electronic: T:\Specifications (published)\ELB-307-3.doc 4