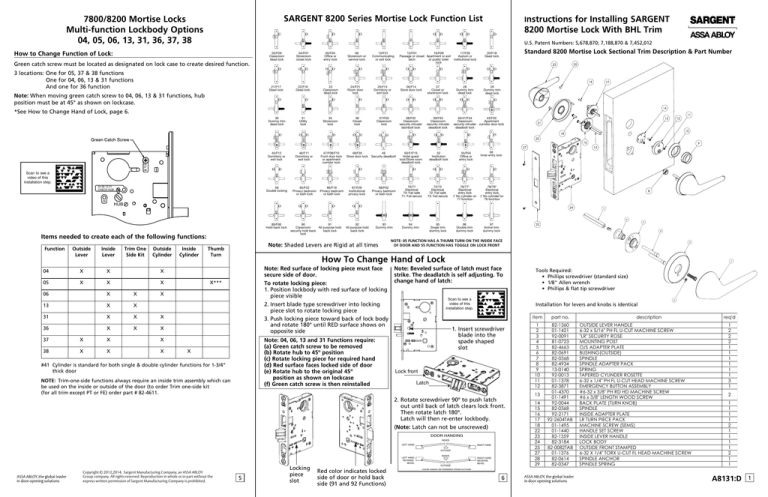

SARGENT 8200 Series Mortise Lock Function List

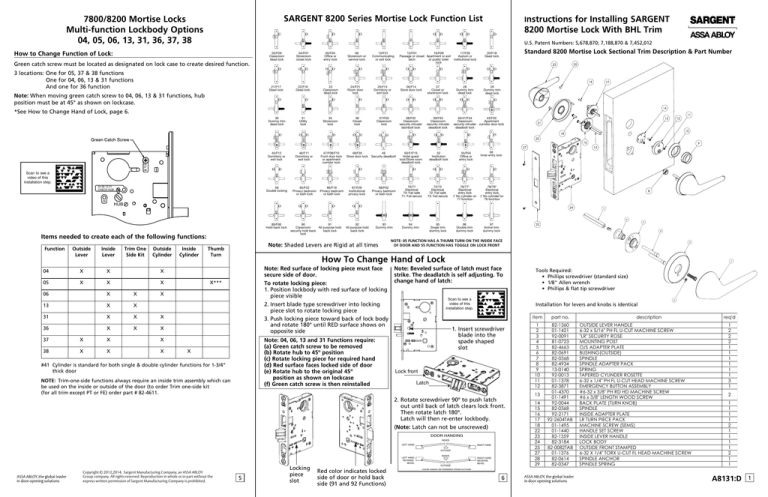

7800/8200 Mortise Locks

Multi-function Lockbody Options

04, 05, 06, 13, 31, 36, 37, 38

Instructions for Installing SARGENT

8200 Mortise Lock With BHL Trim

U.S. Patent Numbers: 5,678,870; 7,188,870 & 7,452,012

How to Change Function of Lock:

Green catch screw must be located as designated on lock case to create desired function.

3 locations: O

ne for 05, 37 & 38 functions

One for 04, 06, 13 & 31 functions

And one for 36 function

03/F29

Classroom

dead lock

04/F07

Storeroom

closet lock

05/F04

Office or

entry lock

06

Storeroom or

service lock

21/F17

Dead lock

22/F16

Dead lock

23

Classroom

dead lock

24/F21

Room door

lock

30

Dummy trim

dead lock

31

Utility

lock

35

Storeroom

lock

45/F12

Dormitory or

exit lock

46/F11

Dormitory or

exit lock

59

Double locking

65/F22

Privacy bedroom

or bath lock

Note: When moving green catch screw to 04, 06, 13 & 31 functions, hub

position must be at 45° as shown on lockcase.

16/F09

15/F01

Passage or closet Apartment or exit

or public toilet

latch

lock

13/F31

Communicating

or exit lock

17/F30

Asylum or

institutional lock

20/F18

Dead lock

28

Dummy trim

dead lock

29

Dummy trim

dead lock

Standard 8200 Mortise Lock Sectional Trim Description & Part Number

25/F13

Dormitory or

exit lock

26/F14

Store door lock

27

Closet or

storeroom lock

36

Closet

lock

37/F05

Classroom

lock

38/F32

Classroom

security intruder

latchbolt lock

39/F33

Classroom

security intruder

deadbolt lock

47/F08/F10

Front door lock

or apartment

corridor lock

48/F35

Store door lock

49

Security deadbolt

50/51F15

Hotel guest

lock/Store room

deadbolt lock

52

Institution

deadbolt lock

66/F19

Privacy bedroom

or bath lock

67/F26

Institutional

privacy lock

68/F02

Privacy bedroom

or bath lock

70/71

Electrical

70: Fail safe

71: Fail secure

72/73

Electrical

72: Fail safe

73: Fail secure

76/77*

Electrical

entry lock

(* No cylinder on

77 function

78/79*

Electrical

entry lock

(* No cylinder on

79 function

92

All purpose hold

back lock

93

Dummy trim

95

Single trim

dummy lock

96

Double trim

dummy lock

97

Active trim

dummy lock

*See How to Change Hand of Lock, page 6.

05

37

38

Scan to see a

video of this

installation step.

04 06 13 31

CHECK HUB

36

HUB

89/F06

Hold back lock

Items needed to create each of the following functions:

Function

Outside

Lever

Inside

Lever

Trim One

Side Kit

04

X

X

X

05

X

X

X

06

X

X

13

X

X

31

X

X

36

X

X

Outside

Cylinder

Inside

Cylinder

Note: Shaded Levers are Rigid at all times

Thumb

Turn

X

38

X

X

X

NOTE: 05 FUNCTION HAS A THUMB TURN ON THE INSIDE FACE

OF DOOR AND 55 FUNCTION HAS TOGGLE ON LOCK FRONT

Note: Red surface of locking piece must face

secure side of door.

X***

To rotate locking piece:

1.Position lockbody with red surface of locking piece visible

Note: Beveled surface of latch must face

strike. The deadlatch is self adjusting. To

change hand of latch:

Scan to see a

video of this

installation step.

.Insert blade type screwdriver into locking 2

piece slot to rotate locking piece

3.Push locking piece toward back of lock body

and rotate 180° until RED surface shows on

opposite side

X

X

56

Inner entry lock

If shaded, knob or

lever rigid at all times

X

X

94

Dummy trim

55/F04

Office or

entry lock

How To Change Hand of Lock

X

37

90

91

Classroom

All purpose hold

security hold back

back lock

lock

43/F20

40/41/F34

Apartment

Classroom

security intruder corridor door lock

deadbolt lock

Note: 04, 06, 13 and 31 Functions require:

(a) Green catch screw to be removed

(b) Rotate hub to 45º position

(c) Rotate locking piece for required hand

(d) Red surface faces locked side of door

(e) R

otate hub to the original 45º

position as shown on lockcase

(f) Green catch screw is then reinstalled

X

#41Cylinder is standard for both single & double cylinder functions for 1-3/4”

thick door

NOTE: Trim-one-side functions always require an inside trim assembly which can

be used on the inside or outside of the door (to order Trim one-side kit

(for all trim except PT or FE) order part # 82-4611.

Installation for levers and knobs is identical

1. Insert screwdriver

blade into the

spade shaped

slot

Lock front

Latch

2. R

otate screwdriver 90º to push latch

out until back of latch clears lock front.

Then rotate latch 180º.

Latch will then re-enter lockbody.

(Note: Latch can not be unscrewed)

DOOR HANDING

INSIDE

LEFT HAND

RIGHT HAND

OUTSIDE

Copyright © 2012,2014, Sargent Manufacturing Company, an ASSA ABLOY

Group company. All rights reserved. Reproduction in whole or in part without the

express written permission of Sargent Manufacturing Company is prohibited.

5

Locking

piece

slot

LEFT HAND

REVERSE

BEVEL

Red color indicates locked

side of door or hold back

side (91 and 92 Functions)

INSIDE

OUTSIDE

Tools Required:

• Phillips screwdriver (standard size)

• 1/8" Allen wrench

• Phillips & flat tip screwdriver

RIGHT HAND

REVERSE

BEVEL

item

part no.

1

2

3

4

5

6

7

8

9

10

11

12

82-1360

01-1421

92-0091

81-0723

82-4663

82-0691

82-0368

82-4934

13-0140

92-0013

01-1378

82-3871

01-4370

01-1491

92-0044

82-0368

92-2171

92-2604TAB

01-1495

01-1440

82-1359

82-3184

82-0082TAB

01-1376

82-0614

82-0347

13

14

15

16

17

18

22

23

24

25

27

28

29

description

OUTSIDE LEVER HANDLE

6-32 x 5/16" PH FL U-CUT MACHINE SCREW

"LR" SECURITY ROSE

MOUNTING POST

O/S ADAPTER PLATE

BUSHING(OUTSIDE)

SPINDLE

SPINDLE ADAPTER PACK

SPRING

TAPERED CYLINDER ROSETTE

6-32 x 1/4" PH FL U-CUT HEAD MACHINE SCREW

EMERGENCY BUTTON ASSEMBLY

#6-32 x 3/8" PH RD HD MACHINE SCREW

#6 x 3/8" LENGTH WOOD SCREW

BACK PLATE (TURN KNOB)

SPINDLE

INSIDE ADAPTER PLATE

LR TURN PIECE PACK

MACHINE SCREW (SEMS)

HANDLE SET SCREW

INSIDE LEVER HANDLE

LOCK BODY

OUTSIDE FRONT STAMPED

6-32 X 1/4" TORX U-CUT FL HEAD MACHINE SCREW

SPINDLE ANCHOR

SPINDLE SPRING

req'd

1

2

2

2

1

1

1

1

1

1

3

1

2

1

1

1

1

2

1

1

1

1

2

1

1

DOOR HANDS DETERMINED FROM OUTSIDE

6

A8131:D

1

5. Insert spindle (E) into inside trim of lockbody hub.

6. Slide adapter plate assembly (F) over spindle & secure with two #8-32

screws (G).

Important: Check template A7057 to prep door for function

holes, size and location. Verify strike location according to

template. Clean door pocket and verify hand of lock.

1. Slide lock body in door pocket.

7. Tighten rose (J) firmly onto adapter plate assembly (F). Align holes

and install security set screw (K) to plate assembly (F) with security torx

screwdriver.

8. Attach inside lever and secure with security torx screwdriver. Verify lock

is operating correctly prior to closing door.

9.Slide cylinder (A) through spring (B) & collar (C) and thread into lock until

cylinder face is flush with collar (C). Pull the key slightly out of the cylinder

to help thread.

Note: SARGENT logo must be horizontal & in an upright position.

10. Tighten cylinder clamp screw and wood screws by hand with #2 Phillips

screwdriver.

11. Assemble thumbturn/emergency release according to instructions on bag.

12. Attach outside front plate (H) with two #8-32 x 1/4" flat head screws (I).

13. Check for proper operation.

2. Secure lock in door with two wood screws #12 x 1-1/4" or

machine screws #12-24 x 1/2" (D).

Inside of

door

3.Insert spindle adapter into lockbody on the

outside trim, as shown in image at right.

Note: To check for proper lock operation by function number see catalog

(www.sargentlock.com).

Note: Spindle adaptor only goes on the

outside trim.

4.Slide outside lever & rose assembly (or lever &

escutcheon assembly) onto the door and lock body.

Note: Keep door open while installing lock.

Note: If installing trim one side, see separate instruction sheet.

When the spindle adaptor is installed correctly the lever will

free wheel up.

J

J

Inside of

door

Outside of

door

Cylinder

Clamp

Screw

K

K

H

R/C & I/C cylinder cores require Control key

(stamped ”C”) to install. Must request

separately. If 1 bitted—specify 11311 cut.

RH Door Shown

I

H

I

Scan to see a

video of this

installation step.

Scan to see a

video of this

installation step.

Scan to see a

video of this

installation step.

2

3

Copyright © 2012, 2014, Sargent Manufacturing Company, an ASSA ABLOY

Group company. All rights reserved. Reproduction in whole or in part without the

express written permission of Sargent Manufacturing Company is prohibited.

4

A8131:D