HIP Systems from Avure Technologies

advertisement

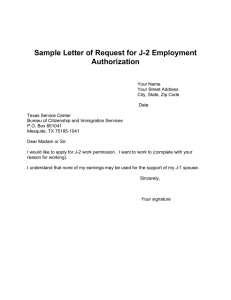

Avure Technologies PM-DK temadag, 2012-11-01 Dr. Anders Eklund Business Unit Director – Advanced Material Densification 1 Avure Confidential, 2012 Outline of Presentation • History of Company • Safety • Cold Isostatic Pressing (CIP) system and it’s Applications • Hot Isostatic Pressing (HIP) system and it’s Applications • Powder and New developments Avure Confidential, 2012 Avure’s Roots: Synthetic Diamonds QUINTUS project - 1953 First successful diamond synthesis by ASEA, Sweden 3 Avure Confidential, 2012 Solid Foundation and History of Excellence Company formation under ASEA (later ABB) ownership 19401950 1953 Sale of Company to Flow International Introduction of isostatic presses 1964 1965 Sale of Company to The Gores Group Introduction of food processing presses 1970 1980 1991 1995 1999 2005 2009 Purchase of Company with Milestone Partners Company produces the world’s first synthetic diamond 4 Introduction of flexform presses First delivery to the automotive industry Introduction of isostatic laminators Avure Confidential, 2012 Supply of the worlds largest HIP Avure Technologies Overview >50 Years of High Pressure Innovation High Pressure Sheet Metal Advance Material Pasteurization Forming Densification $100m+ Sales • 1,800+ Installs 5 ● 190 Employees Avure Confidential 2012 ● Global Footprint Avure Throughout the World - Headquarters in Västerås, Sweden (Industrial Division) - Manufacturing facilities: - Västerås, Sweden - Columbus, OH, USA - Kent. WA, USA Avure offices Sales & Service partners 6 Avure Confidential 2011 Avure Sweden Office Workshop 7 Avure Confidential, 2012 Pressure vessel technology Most Important Considerations for Isostatic Press Installations • Safety • Safety • Safety • Long life • Lowest possible life cycle cost Avure Confidential, 2012 Safety and redundancy in design can never be compromized For example, a large Cold Isostatic Press contains a hugh amount of stored energy when under pressure. Avure Confidential, 2012 System Safety Andover accident 1998-07-26 Accident with a large monoblock vessel in USA (Competitor design) Large monoblock design with a threaded closure No frame was used for the pressure vessel The vessel failed most likely due to thermal stresses that were not taken into account The vessel failed most likely due to crack propagation from the outside of the cylinder The customer replaced the vessel with a QUINTUS® Press Avure Technologies Avure Confidential, 2012 System Safety Mono-block design: Monoblock cylinder The mono-block design has not got the advantages that the wire wound technique provides No pressure Pressure A monoblock vessel will never experience compressive stress on both inner and outer surface Leak before break will not be established Fatal failure will occur in case of a through the wall crack The design requires frequent, extensive and expensive safety related maintenance! Avure Technologies Avure Confidential, 2012 Failure mode: Catastrophic System Safety The mono-block vessel – A non-redundant pressure vessel concept with its roots in WW 1 battle ship gun barrel design The heat treatment of the forging is difficult to control Thick vessel wall Large tensile stresses Built in stress concentrations High risk for crack initiation Avure Technologies Any failure would be catastrophic! Avure Confidential, 2012 System Safety QUINTUS® design: The wire wound technique has got a lot of advantages compared to the mono-block design No pressure Pre-stressed thin-walled cylinder Pressure The pre-stressed vessel will always experience compressive stress on the inner surface A leak before break design secures that no fatal failure will occur in case of a through the wall crack Since the design is both safe and redundant, the need for frequent safety related maintenance is eliminated! Avure Technologies Failure mode: ”Leak rather than break” Avure Confidential, 2012 Avure Cold Isostatic Pressing Systems 15 Avure Confidential, 2012 Typical CIP Applications • • • • • • • • • • • • • Tungsten Carbide Products Refractory Ceramic Products Refractory Metal Products Carbon/Graphite pre-forms Heavy Metals Ceramic pre-forms Fine Ceramics Metal Filters Metal Powders Beryllium pre-forms Rare Earth Metals PTFE (Teflon) etc. Avure Confidential, 2012 Cold Isostatic Pressing Principle Compaction of powdered materials with the aid of isostatic pressure resulting in green bodies with isotropic properties Avure Confidential, 2012 Wet Bag Mold Design For Casting Nozzle Rubber Lid Rubber Strap Support Tube Support Tube Rubber Mold Alumina/Graphite Powder Base Plate Avure Confidential, 2012 Wet bag mold design for graphite crucibles Avure Confidential, 2012 Present Industry Trends • Larger CIP (Iso-press) systems – driven by market needs • Higher productivity – Pressurization capacities has increased by an order of magnitude • More automation for faster turn-around between cycles • Energy savings through more energy efficient pressurization systems • Noise control Avure Confidential, 2012 ”State of the art” medium size and large CIP presses should have the following charachteristics: • ”Leak-rather than-break” as defined by the ASME code Section VIII, Div. 3 • Long cyclic life (> 200 000 cycles) • Lowest possible weight • High efficiency high pressure pumping solutions • Accurate decompression control at all pressures • Advanced and operator friendly HMI solutions! Avure Confidential, 2012 Equipment Scope of CIP Press Power Supply and MCC Oil Hydraulic or Direct Drive System with High Pressure Pump(s) Process Fluid (water) Handling System PLC Touch Screen HMI Data Acquisition Unit Loading/Unloading Automation Systems Avure Confidential, 2012 Wire-wound Pre-stressed QUINTUS R Pressure Vessel and Frame Wire-wound yoke frame Closure manipulator Upper closure with air-bleed valve Wire-wound pressure vessel Lower closure with pre-fill valve Vessel support structure Frame traction carriage Base frame Avure Confidential, 2012 Typical Large CIP lay-out Operator’s panel A G B Power supply, MCC, PLC and HMI F Process fluid system E Pressure intensifier(s) C D Oil hydraulic drive system Avure Confidential, 2012 Large 2500 bar Cold Isostatic Press Installation Avure CIP system ID: IH: Pressure: Weight: 1600 mm 2600 mm 2500 bar 250 tonnes Avure Confidential, 2012 Large Avure CIP system ID: 2500 mm IH: 3000 mm Pressure: 2000 bar Weight: 650 tons Avure Confidential, 2012 High Pressure Pumping and Water Handling Systems Vent Valve Water Handling System Fine Decompression Ramping Device 27 Pre-fill Valve High Pressure Let-Down Valves Pressure Intensifier or High Pressure Pump Pre-fill Pumps Avure Confidential, 2012 CIP Cycle Programmable Decompression Rates Very Accurate Feed-back Control Decompression 200-15 (Optional) and 15-0 bar 1-20 min in one or more segments Avure Confidential, 2012 High Pressure Pumping and Water Handling Systems Avure pressure intensifier- Single or double stroke Drive hydraulics and components of standard design and make Direct drive plunger pumps also available Outstanding reliability and service friendliness of high pressure components Skid mounted unit for ease of installation 29 Avure Confidential, 2012 Power Supply and Cycle Control System • Cabinets are IP 54 • PLC and HMI are Siemens S7 or Rockwell Automation Cubicle for Power Distribution and Motor Starters • Standard operating cycles stored in PLC • Rugged application program for trouble free operation • Data transfer to higher level computer over TCP/IP possible • Distributed I/O:s, Proven field bus solutions for safe communication with PLC • Modem for remote diagnostics Avure Confidential, 2012 Control System Cabinet with PLC, HMI and Data Recorder Automated loading/unloading Avure Confidential, 2012 HIP Systems from Avure Technologies Dr. Anders Eklund Business Unit DirectorAdvanced Material Densification HIP Applications Typical HIP Applications 33 • • • • • • • • • • • • • • • • • P/M Tool Steel Aerospace castings (SA and Ti) Aluminium castings (Densal with Bodycote) Body implant castings (Ti and Co-Cr-Mo) Body implant ceramics (Alumina and Zirkonia) Advanced engineering ceramics Armour ceramics Composite P/M materials Near net shape (NNS) alloy steel products Super alloy billets and NNS P/M products Diffusion bonding of dissimilar materials Sputtering targets Metal matrix diamond tools Metal matrix composites HIP brazing Carbon/Carbon HIP impregnation etc. Avure Confidential, 2012 HIP Applications Aerospace and Industrial Gas Turbine Castings (Titanium and Super-alloys) Today around 60% of the worldwide HIP capacity in number of HIP systems is used for this application 34 P/M Tool Steels, NNS Steel Products and Various Composite Products Today around 5% of world-wide HIP installations but probably > 50% of the HIPped through-put tonnage. This application has a hugh growth potential Avure Confidential, 2012 HIP Applications • HIPped MPIF’s P/M part of the year 2007 – A good example of the possibilities of near net shape HIPping of stainless steel (316 LN) Curved Surface Grand Prize Cryomagnetic End Cover – Part weight is approx. 114 kg and finished part weight 70 kg – Material properties are equal or better as compared with wrought 316 LN Courtesy of Bodycote Hot Isostatic Pressing AB Surahammar, Sweden 35 Avure Confidential, 2012 HIP Applications Medical Implants and Other Highly Stressed Precision Castings Medical implants and other highly stressed precision castings 36 Metal Matrix Composites (WC-Co and Diamond Tools etc) Growing application (diamond tools) WC-Co market may come back-new high performance low Co grades Avure Confidential, 2012 HIP Applications P/M Superalloys, Jet Engine Turbine Hardware Small but established application. Parts can be HIPped to Near Net Shape. Sometimes a billet is HIPped followed by extrusion and isothermal forging 37 Advanced Ceramics and Ceramic Armor (Silicon Nitride, Silicon Carbide, Boron Nitride, Boron Carbide, Titanium Boride, Spinels, Alumina and others) Avure Confidential, 2012 HIP Applications Sputtering Targets Small and growing application. HIPing of target materials and bonding of target material to substrate 38 Automotive Aluminum Castings (Engine blocks, turbocharger rotors, oil trays etc.) Avure Confidential, 2012 HIP Applications Advanced Materials and Structures • • • • • • 39 Fuel cells Super conductor materials Piezoelectric materials Specific diffusion bonding applications Nano-powder compaction Post densification of MIM and PIM parts for demanding applications Avure Confidential, 2012 HIP Systems from Avure Technologies QUINTUS Hot Isostatic Pressing Systems Main customer values: • Superior safety ”Leak before break” as defined by the ASME code • Unmatched cost of ownership • Unmatched performance and reliability • Practically no limitations in size of presses • Backing all the way by Avure Technologies-The world’s leading high pressure company 40 Avure Confidential, 2012 HIP System Scope Equipment Scope of HIP Press HIP Furnace and Cooling (URC) System Power Supply, VRT:s and MCC Gas Compressor System Closed loop cooling System PLC Scada type HMI Data Acquisition 41 Avure Confidential, 2012 HIP System The Pressure Vessel is the Backbone of any HIP System Leak before break No built-in stress concentrations No real size and pressure limitations 42 for vessels and frames Efficient cooling of the cylinder The need for frequent safety related maintenance is eliminated All QUINTUS® vessels are based upon design criteria given in ASME B&PV Code, Section VIII, Division 3 All CE-marked QUINTUS® vessels meet the European Pressure Equipment Directive Avure Confidential, 2012 HIP System Installation 2.05 m dia x 4.3 m tall HIP System 43 Avure Confidential, 2012 HIP System Installation 2.05 m dia x 4.3 m tall HIP System for Japan 44 Avure Confidential, 2012 HIP System Furnaces HIP Furnaces If the pressure vessel is the backbone of every HIP system then the furnace is the heart HIP furnaces can be supplied as either multi-zone radiation furnaces or single level heated (patented) convection furnaces Elaborate designs and experience are necessary in order to satisfy insulation, temperature accuracy, rapid cooling and reliability requirements Avure’s furnaces are outstanding in all respects and offer great value to HIP system users HIP furnaces are mainly built of steel, molybdenum or graphite depending on operating temperature 45 Avure Confidential, 2012 HIP System Efficiency URC Uniform Rapid Cool 46 HIP furnaces must have excellent insulation capacity to protect the pressure vessel from overheating URC means interrupting the insulating capacity of the furnace in a controlled manner to shorten cycle time or to achieve some kind of heat treatment as an add on to the HIP cycle During URC vast amounts of energy are trans-fered out of the HIP vessel in a short period of time Only thin-walled vessels will allow URC URC at rates of 100 Deg C/min or more can be achieved Avure Confidential, 2012 HIP System Efficiency URC Uniform Rapid Cool HIP Cycle: Conventional Cooling Versus URC Typical HIP Cycle with and without URC 1 Vacuum 2 Equalization 3 Pumping 47 4 Heating 5 Holding 6 Cooling 7 Equalization 8 Backpumping 9 Release Avure Confidential, 2012 HIP System Efficiency URC Uniform Rapid Cool URC Conditions Furnace dia., 1250 mm Ditto height, 2100 mm Load weight, 2500 kg Temp Time 48 Avure Confidential, 2012 HIP System Auxiliary Equipment Gas Compressor System The object of the gas compressor system is to pump the process gas (argon or nitrogen) in and out of the pressure vessel. A typical gas handling cycle consists of: • Evacuating air out of the pressure vessel • Gas inlet (equalisation) from a gas storage • Pumping (while heating) to the maximum pressure in the vessel • Decompression of gas into the gas storage • Recovery pumping to approx. 40 bar in the vessel • Dumping of the gas into the atmosphere 49 Avure Confidential, 2012 HIP System Auxiliary Equipment Closed Loop Cooling System The object of the closed loop cooling system is to cool the pressure vessel during the HIP cycle The system is provided with necessary pumps, valves heat exchanger and flow meters The system normally also is provided with a water tank that will take up the surge of energy coming out of the system during rapid cooling 50 Avure Confidential, 2012 HIP System Auxiliary Equipment Power Supply System The object of the power supply system is to provide motors, actuators and furnace with power The furnace power is controlled either over SCRs and single phase transformers or with the aid of VRTs For large HIP systems the installed power is several MVA and massive busbar systems are required to transfer the power to the furnace 51 Avure Confidential, 2012 HIP System Auxiliary Equipment Control System And Scada Type HMI PLC The object of the control system is to provide functionality for: • Control logic and interlocks • Furnace power control (cascade) • Temperature control during URC • Human/machine interface for system status and HIP cycle data visualisation as well as cycle recipe down loads • Data acquisition and communication with higher level computers • Modem “dial in” for remote system diagnostics 52 Control Cubicle HMI HMI Ethernet Dial In Switch TPC/IP Field Bus Communication Distributed I/O:s Switch Gear/MCC Avure Confidential, 2012 Gas Compressor Cooling System TC Inputs What does Powder do for all of us? • Powder opens new markets: – Cuts end customer lead time & cost – Increases quality and execution – New markets for existing HIPs – New markets for small/medium sized HIPs – New markets for very large HIPs 53 HIP is the ultimate heat treatment equipment ! 54 TeraPi - QIH 3.14 x 5.0-1050-1250 MURC Mezzanine plan for easy operation – Upper floor for production operation – Lower floor for maintenance operation 55 Avure Confidential, 2012 Tera-HIP’s Background • PM production of Gas Atomized Powder (GAP) increases roughly 15% per year – Within 3 years the yearly production of gas atomized powder will increase by 25,000 tons! • Erasteel – increases production with 8,000 ton/year…2012 • Carpenter – increases production with 10,000 ton/year…2014 • Atmix – increases production with 7,000 ton/year…2013 – Equaling 5 HIPs of Surahammer size (1,75 ID x 3,3 H) • Water atomized powder (+3-5% p.a.) – Total production 1.5 Mton/year – Targeting 10% for conversion to HIP • Equaling 20-30 HIP’s of Surahammer size • The market requires larger HIP’s with increased throughput Tera HIP 56 Avure Confidential, 2012 TeraPi – Some interesting facts Each frame = 50 tons (4 frames) • • • • • • • • Cylinder weight = 158 tons Wire = 14.3 m/kg Totaling: 5100 km of wire - Distance from Seattle, WA to Orlando, FL - Kiruna to Gibraltar - Moscow to Irkutsk Elongation ~ 0.3% meaning = about 16 km 57 Avure Confidential, 2012 Objects for TeraPi HIPed impellers for desalting and hydro power production Superduplex cast stainless steel impeller for seawater desalination system Martensitic stainless steel hydro energy turbine blade 58 Avure Confidential, 2012 Remove Welds in Current Large Pipe Flange Designs 59 PM/HIP Offshore Deep Sea Manifolds 60 Power Plant Components • Reactor coolant pumps • Reactor vessels • Pressurizers 61 Forged Parts Reactor Pressure Vessel Reactor Pressure Vessel Reactor Pressure Vessel Core Region Shell Bottom Petal Integrated Type Closure Head Dimension: 295” od X 156” H (mm) 62 Dimension: 300” od X 63” H (mm) Dimension: 158” od X 67” H (mm) Weight: 127 ton Weight: 80 ton Weight: 38 ton Material: ASME SA508, CL.3EQ. Material: ASME SA508, CL.3EQ. Material: ASME SA508, CL.3EQ. Avure Technologies Thank you for your attention! How can we help you grow and be more successful in your business? 63 Avure Confidential, 2012 Avure HIP References Out of the some 30 HIP systems with a hot zone diameter > 1000 mm sold in the world, Avure has delivered or has on order ~26 Avure has delivered approx. 65 % of all production HIP units in the world Avure is the only supplier who has delivered hot unload convection furnaces Avure has supplied the largest HIP system in the world with useful dia. 2.05 m 64 Avure Confidential, 2012 Avure HIP References Avure—The Low Risk/High Value Supplier Superior safety ”Leak before break” Longest cyclic life and lowest weight Unmatched HIP furnace performance Wide variety of HIP furnace options e.g. molybdenum, 65 graphite, stainless steel and “black steel” Un-paralleled rapid cool performance due to thin-walled pressure vessel design Cold or hot load/unload furnaces Advanced system control with cascade control of furnace temperature Advanced and operator friendly HMI solutions Outstanding documentation Modem “dial in” remote diagnostics Avure Confidential, 2012 Avure HIP References Avure—The Low Risk/High Value Supplier Broadest competence base in the business 50 years of un-interrupted high-pressure 66 business history More resources than any competitor ( > 150 people devoted to High Pressure Technology) Widest product range Most references Technology leader Market leader Global company Devoted to partnership relations with customers and suppliers Global service organization Strong emphasis on service, retro-fit and up-grading Avure Confidential, 2012 System Safety Incident 2004-06-28 Incident with an Avure Cold Isostatic Press in Germany A QUINTUS Cold Isostatic Press had been delivered 1967 and had been operated between 400 and 600 MPa with an average pressure of 530 MPa Due to mechanical damage (most likely scratching of the vessel wall) the cylinder cracked in a controlled manner as anticipated The total number of cycles were approximately 50 000, which was beyond the calculated (fracture mechanics) life of the vessel The customer replaces theforging vessel with a new No parts broke loose. The cracked was safely containedQUINTUS by the wire ® mantle Cold Isostatic Press The multi layer redundant wire package was intact Avure Technologies Avure Confidential, 2012