www .joskin.com

advertisement

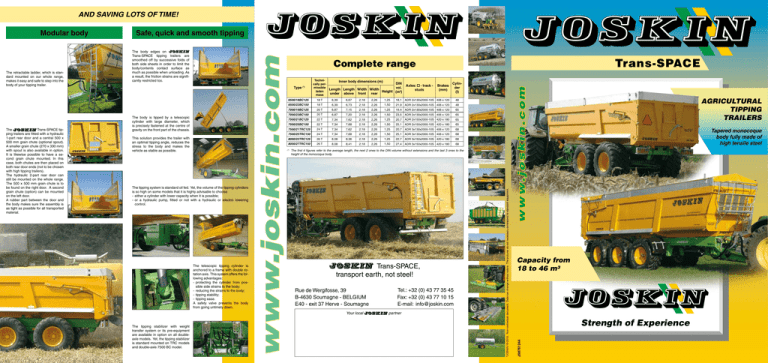

and saving lots of time! The tipping system is standard oil fed. Yet, the volume of the tipping cylinders is so high on some models that it is highly advisable to choose: - either a cylinder with lower capacity when it is possible; -or a hydraulic pump, fitted or not with a hydraulic or electric lowering control. The telescopic tipping cylinder is anchored to a frame with double rotation axis. This system offers the following advantages: -protecting the cylinder from possible side strains to the body; - reducing the strains to the body; - tipping stability; - tipping ease. A safety valve prevents the body from going untimely down. The tipping stabilizer with weight transfer system or its pre-equipment are available in option on all doubleaxle models. Yet, the tipping stabilizer is standard mounted on TRC models and double-axle 7500 BC model. TechniInner body dimensions (m) DIN cally permissible vol. Length Length Width Width laden Height (m³) under above front rear mass Axles: - track studs Brakes (mm) Cylinder (l) 6500/18BC125 18 T 6,39 6,67 2,18 2,26 1,25 18,1 ADR 2x130x2000-10S 406 x 120 48 6500/22BC150 18 T 6,39 6,73 2,18 2,26 1,50 21,9 ADR 2x130x2000-10S 406 x 120 48 7000/19BC125 20 T 6,87 7,15 2,18 2,26 1,25 19,4 ADR 2x130x2000-10S 406 x 120 65 7000/23BC150 20 T 6,87 7,20 2,18 2,26 1,50 23,5 ADR 2x130x2000-10S 406 x 120 65 7500/21BC125 22 T 7,34 7,62 2,18 2,26 1,25 20,7 ADR 2x150x2000-10S 420 x 180 65 7500/25BC150 22 T 7,34 7,68 2,18 2,26 1,50 25,1 ADR 2x150x2000-10S 420 x 180 65 7500/21TRC125 24 T 7,34 7,62 2,18 2,26 1,25 20,7 ADR 3x130x2000-10S 406 x 120 68 7500/25TRC150 24 T 7,34 7,68 2,18 2,26 1,50 25,1 ADR 3x130x2000-10S 406 x 120 68 8000/22TRC125 26 T 8,08 8,36 2,18 2,26 1,25 22,7 ADR 3x150x2000-10S 420 x 180 68 8000/27TRC150 26 T 8,08 8,41 2,18 2,26 1,50 27,4 ADR 3x150x2000-10S 420 x 180 68 The first 4 figures refer to the average length, the next 2 ones to the DIN volume without extensions and the last 3 ones to the height of the monocoque body. (*) JOSKIN Trans-SPACE, transport earth, not steel! Rue de Wergifosse, 39 B-4630 Soumagne - Belgium E40 - exit 37 Herve - Soumagne Tel.: +32 (0) 43 77 35 45 Fax: +32 (0) 43 77 10 15 E-mail: info@joskin.com Your local Joskin partner w w w. j o s k i n . c o m This solution provides the trailer with an optimal tipping angle, reduces the stress to the body and makes the vehicle as stable as possible. Type (*) Agricultural Tipping Trailers Tapered monocoque body fully made of high tensile steel Capacity from 18 to 46 m³ Strength of Experience J98761244 The body is tipped by a telescopic cylinder with large diameter, which is precisely fastened at the centre of gravity on the front part of the chassis. Trans-SPACE Complete range JOSKIN 10-2010. Non contractual document. Data can change without notice. The pictures do not necessary correspond to standard equipment. The JOSKIN Trans-SPACE tipping trailers are fitted with a hydraulic 1-part rear door and a central 500 x 500 mm grain chute (optional spout). A smaller grain chute (270 x 330 mm) with spout is also available in option. It is likewise possible to have a second grain chute mounted. In this case, both chutes are then placed on both rear door ends (not to be chosen with high tipping trailers). The hydraulic 2-part rear door can still be mounted on the whole range. The 500 x 500 mm grain chute is to be found on the right door. A second grain chute (option) can be mounted on the left door. A rubber part between the door and the body makes sure the assembly is as tight as possible for all transported material. The body edges on JOSKIN Trans-SPACE tipping trailers are smoothed off by successive folds of both side sheets in order to limit the body/contents contact surface as much as possible when unloading. As a result, the friction strains are significantly restricted too. © The retractable ladder, which is standard mounted on our whole range, makes it easy and safe to step into the body of your tipping trailer. Safe, quick and smooth tipping www.joskin.com Modular body JOSKIN Trans-space: strong body easy to unload It is for sure that the new JOSKIN Trans-SPACE tipping trailer will never look like its competitors! The Trans-SPACE benefits from the ever increasing quality of contemporary steel types. As it is fully made of high tensile steel with no welded side post nor lower cross-beam, the new Trans-SPACE keeps improving in order to meet everyone’s needs, combining strength and lightness. These ‘‘featherweight’’ trailers are a technical solution to meet the development of European road legislation (40 km/h, limited total load...). Modular body The outer hooks, which are designed to fix a cover, are standard. The front folding cradle or the bolted and galvanized platform at the front of the body are available in option. As a forerunner, the new Trans-SPACE offers the road transport style and design to the farming world. Just have a look at the road trucks and their body form and geometry... there’s no doubt about it! Light and strong body As they are made of a floor sheet in DOMEX WEAR 400 and two or four side sheets (according to the model) in high tensile steel, all of them being 4 mm thick, there is absolutely no cross-weld on the body of all Trans-SPACE tipping trailers. There are merely two lengthwise welds linking both side elements to the body floor. The tensile limit of these steel types is so high that there is now only one reinforcement on each side of the body, and two on the 7500 (with 1.50 m body) and 8000 models. Thanks to this new fabrication concept, the empty weight of this new generation of agricultural tipping trailers is significantly lower and therefore allows to transport still higher pay loads. The underside of the Trans-SPACE is meant for the most constraining works: two imposing stringers support the body with unmatched stability. The first one links both side reinforcements to each other while the other is placed on the level of the anchoring point of the tipping cylinder. The shot-blasting (2.400 kg/min) and drying (60°C) process leads to a perfect adhesion of the primer paint coat, on which a 2-component finishing lacquer is applied in order to ensure the long-lasting character of the treatment. Tapered body The body of any JOSKIN TransSPACE tipping trailer is designed in such a way as to make the rear part 8 cm wider than the front part. The transported material is therefore easy to unload when tipping. + 8 cm JOSKIN Trans-space: foolproof running gear! Hitching Lighting and protection The rear truck-type lights are standard mounted on the whole range. They are protected and can pivot backwards (thanks to the silentblocks) when striking an obstacle. The lateral lights (compulsory for certification in some countries) are available in option. On the contrary, the bolted and galvanized mudguards are standard on the whole range whereas the thermoplastic mudguards are available in option on BC models and standard on TRC models. All models are fitted with a D.A. hydraulic skid that is completely built in the drawbar. The whole JOSKIN TransSPACE range includes 4 standard sight windows with perspex closing plate (width: 21 cm - height: 38 cm on 1,25 m body and 63 cm on 1,50 m body). These features stand for enhanced visibility! Nothing escapes from your sight! These sight windows can be fitted with rods in option. Steering axles JOSKIN Roll-Over boggie The JOSKIN Trans-SPACE tipping trailers are fitted with a bolted fixed eyelet (Ø 40 mm Röckinger in Germany) that is easy to replace by a swivel or knee-joint eyelet in option (Scharmüller in Germany). Truck-type extensions (profiled in aluminium or galvanized with rods) are available in option too. These 25 or 50 cm extensions are stackable. The front extension can be replaced by a mechanical or hydraulic headboard in option. Flexible running gears The free or self steering axle is available in option on the whole TransSPACE range. The well-known JOSKIN ‘‘RollOver’’ boggie (24 cm clearance) is part of the double-axle JOSKIN Trans-SPACE tipping trailers (BC). Its parabolic-type leaves offer an unfailing suspension and carriage stability. Unlike the traditional boggies, which tend to bury their front wheels, the JOSKIN ‘‘Roll-Over’’ design has an upwards thrust line. In this way, the front wheels are literally pushed over the obstacle. Consequence: less traction power needed, less ground compaction, less damage to the ground and less wear to the tyres. The self steering axle is an important safety component as it keeps your trailer in the tractor driving line (the TRC models are standard fitted with a double self steering system). Hydro-Tandem hydraulic suspension • flashing beacon; The axle cylinder is operated by a sensor cylinder linked to the tractor by a hitching rod with quick coupling. This one is anchored to the drawbar by means of a knee-joint and controls the hydraulic circuit operating the steering cylinder. • rear working lights built in the chassis; The system is balanced by the compensated cylinders that apply the same force in both directions. Other optional fittings: On all double-axle Trans-SPACE models (BC), the hitching suspension is ensured by a cross-spring (parabolic leaves). In option too, one single sight window with rods (width: 1,77 m - height: 52 cm on 1,25 m body and 76 cm on 1,50 m body) can be mounted on your Trans-SPACE tipping trailer. It can also be covered by a perspex closing plate. The hydropneumatic hitching suspension is available in option on all models. • side lights; • rear and/or side bumpers (compulsory for certification in some countries); • hitching yoke with or without 12 V electric plug. In option on double-axle models, the JOSKIN Roll-Over boggie can be replaced by the Hydro-Tandem hydraulic suspension, which leads to outstanding clearance and unexpected road stability (standard on models 7500 BC). The Hydro-Tandem can go along with another option, i.e. the automatic suspension height adjustment. As far as the TRC models are concerned, they are standard fitted with the Hydro-Tridem hydraulic suspension. The circuit is fitted with a one-piece set-up unit including a pressure gauge, two nitrogen accumulators, an aligning valve and a calibrating circuit. Braking system The BC models are fitted with hydraulic brakes, unlike the TRC models that are fitted with air brakes (optional on BC models). The braking power of any tipping trailer fitted with air brakes can also be proportional to the load. In option, it is also possible to choose dual (hydraulic and air) brakes. In Germany, the air braking system is still compulsory for all our JOSKIN Trans-SPACE models, while the dual braking system is forbidden. CARGO Concept The CARGO TSM and TRM multi-module carriers are ready to transport your monocoque tipping body... as well as your future slurry tank, silage box or spreading box.