12-2499 FIREGUARD Closer-Holder Device

PUSH SIDE INSTALLATION INSTRUCTIONS

®

CAUTION: FAILURE TO INSTALL OR ADJUST PROPERLY MAY RESULT IN INJURY OR DAMAGE

For assistance, contact SARGENT at 800-810-WIRE (9473) or www.sargentlock.com

NOTE: AN AUXILIARY DOOR STOP IS REQUIRED AT HOLD OPEN

! CAUTION:

1. DISCONNECT ALL POWER BEFORE INSTALLATION.

2. ALL WIRING TO BE PERFORMED BY QUALIFIED

PERSONNEL TO COMPLY WITH ALL APPLICABLE

LOCAL CODES.

3. MAXIMUM WIRE SIZE IS 18 AWG.

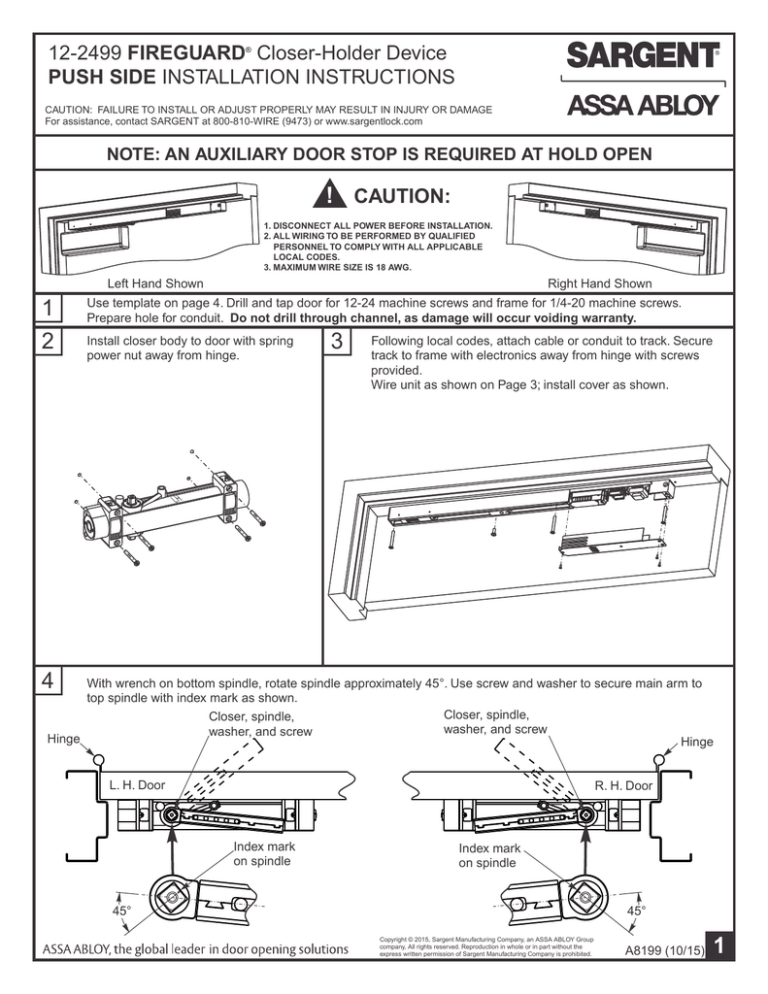

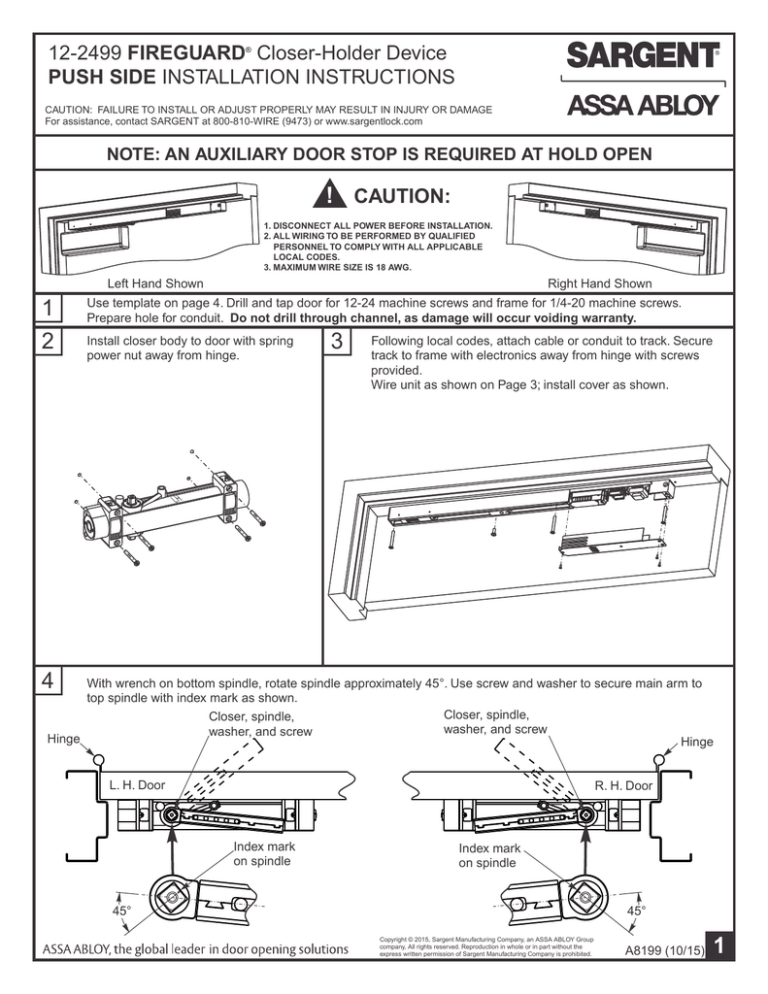

Left Hand Shown

1

2

Right Hand Shown

Use template on page 4. Drill and tap door for 12-24 machine screws and frame for 1/4-20 machine screws.

Prepare hole for conduit. Do not drill through channel, as damage will occur voiding warranty.

Install closer body to door with spring

power nut away from hinge.

3

Following local codes, attach cable or conduit to track. Secure

track to frame with electronics away from hinge with screws

provided.

Wire unit as shown on Page 3; install cover as shown.

LH

4

With wrench on bottom spindle, rotate spindle approximately 45°. Use screw and washer to secure main arm to

top spindle with index mark as shown.

Closer, spindle,

Closer, spindle,

washer, and screw

washer, and screw

Hinge

Hinge

L. H. Door

R. H. Door

Index mark

on spindle

Index mark

on spindle

45°

45°

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group

company, All rights reserved. Reproduction in whole or in part without the

express written permission of Sargent Manufacturing Company is prohibited.

A8199 (10/15)

1

5

Adjust hold open angle by adjusting arm length:

Range of 85° to 110° is obtainable. A) Place slider in

hold-open setting, B) open door, C) insert slide insert

into main arm. Open door to desired hold-open

position and D) secure arms with 9/64” hex screw.

Main Arm

6

To adjust holding

tension:

Insert 9/64” allen

wrench thru hole in

track end cap into cap

screw in spring

mechanism. Rotate

allen wrench for

desired tension.

C

D

A

Slide Insert

B

FINAL ADJUSTMENT AND REGULATING PROCEDURES

Closing and latching speed:

Turn valves clockwise to slow down or counterclockwise to speed up door movement.

Backcheck:

Turn valve clockwise to increase or counterclockwise to decrease.

CAUTION: SET VALVE FOR SLIGHT CUSHIONING EFFECT. NEVER USE THE BACKCHECK AS A DOOR STOP.

ALWAYS USE A DOOR STOP TO STOP THE DOOR.

Delayed action feature (optional):

When provided, turn valve clockwise to slow down or counterclockwise to speed up door movement.

Delayed Action

Range

Backcheck

Valve

Closing Speed

Range

Delayed Action

Valve (optional)

Back

Check

Range

Closing Speed

Valve

Latching Speed

Valve

Latching Speed

Range

NOTE: If adjustments are

ineffective, check

indexing from step 5

Install cover as shown.

Adjust power to allow door to close and latch

Number of Turns of Spring Power Adjusting Nut

Door Width

(inches)

24 - 30

30 - 36

36 - 42

42 - 48

Exterior Doors

1 - 3 CCW

Factory Set

1 - 4 CW

7 - 9 CW

Increase

Interior Doors

1 - 3 CCW

Factory Set

1 - 4 CW

4 - 6 CW

Adjusting door to close due to high draft conditions may exceed

ADA standards. Consult local ordinances when fire doors are involved.

Decrease

5/8”

Adjusting Nut

Insert is removable.

Place in unused opening.

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group

company, All rights reserved. Reproduction in whole or in part without the

express written permission of Sargent Manufacturing Company is prohibited.

A8199 (10/15)

2

INSTALLER: LEAVE INSTRUCTIONS WITH BUILDING OWNER

CAUTION

1. Disconnect all power before beginning

installation to prevent electrical shock

and equipment damage.

2. Installer must be a trained, experienced

service person.

12- Smoke Detector Unit

(120VAC shown)

3. All wiring must comply with

applicable local electrical codes,

ordinances and regulations.

4. Maximum wire size is 14AWG.

Smoke Detector

Unit

Header for Solenoid

Connection

Red LED/

Reset Switch

Test Swtich

Fuse (PTO120V)

125V / 1/2A

- Wire stand alone unit to appropriate power supply and fire

system.

- Refer to data sticker on back of hook-up box for proper input

power voltage and current specifications.

- Solenoid Connector must be attached to Header on circuit board

before hold open will function.

- Energize power supply. Current draw of .074Amps max per unit.

- Open door to hold open point. Door should hold open.

- Depress Test Switch. Door should close and latch.

- Test Switch is a momentary switch. Once released, hold open

should re-energized.

- Adjust closer spring power to insure proper latching.

Terminal Strip for

Power Input Connection

Opening for Concealed

Wiring

Smoke

Detector

120VAC Circuit Board

3

2

1

SOL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Wiring Diagram for Master to Companion

To Solenoid

Companion Unit - 24v ONLY

(2499 / 9-2499)

Field Wiring Provided by Others

Wire Nut or Splice Connector (Provided)

Master Unit -120v or 24v Input

(12-2499)

To Solenoid

87654321

4

1

7654321

- Companion units are designed to work with 12- smoke detector

units.

- Wire companion unit to smoke detector unit as shown on wiring

diagram.

- Do not disconnect any existing wires on smoke detector unit’s

terminal strip.

- Energize power supply. Current draw of .074Amps max per unit.

- Open door to hold open point. Door should hold open.

- Depress Test Switch on master unit. Doors should close and latch.

- Test Switch is a momentary switch. Once released, hold open

should re-energized.

- Adjust closer spring power to insure proper latching.

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group

company, All rights reserved. Reproduction in whole or in part without the

express written permission of Sargent Manufacturing Company is prohibited.

A8199 (10/15)

3

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group

company, All rights reserved. Reproduction in whole or in part without the

express written permission of Sargent Manufacturing Company is prohibited.

A8199 (10/15)

4

2

(51)

3-7/8

(98)

35-13/16

(910)

29-1/2

(749)

9

2

2-7/16

(227)

(51)

(62)

2-15/16

(4) #12 x 3” Wood Screws

(75)

or #12-24 x 2-1/4” Flat head

machine screws

CL Hinge: Butts, center hung

or offset pivots

1-1/8 (29) hole

for Conduit

(1) 1/4-20 x 5/8”

Pan head machine screws

35-5/16

(897)

34-3/16

(868)

(3) 1/4-20 x 2”

Flat head machine screws

12

(305)

NOTES:

1. Reinforced metal doors and frames per ANSI

A250.8 & SDI-100, 12 gauge recommended.

2. Left hand door shown, right hand opposite.

3. For narrow rail doors (minimum 3”), use 351-D

drop plate.

Bottom

of stop

2-7/16

(62)

3-1/8

(79)

19

(486)

1-1/2

(38)

Edge of

stop

1

(25)

2-3/16

(56)

2” Min

stop

1-1/2

(38)

5-15/16

(151)

Edge of

stop