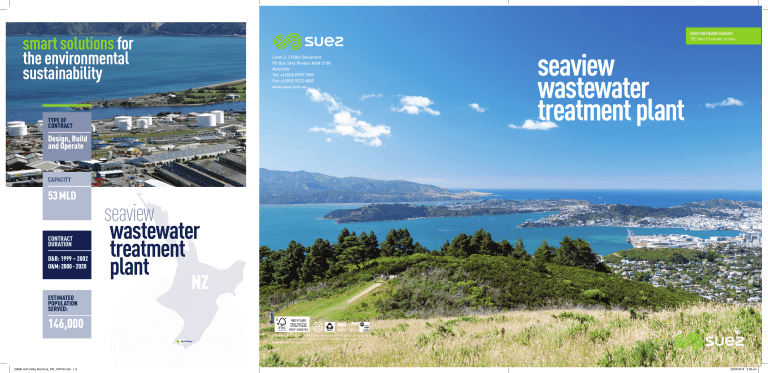

seaview wastewater treatment plant

advertisement

Smart and reliable solutions SUEZ water & treatment solutions smart solutions for the environmental sustainability Level 3, 3 Rider Boulevard PO Box 3246 Rhodes NSW 2138 Australia Tel: +61(0)2 8759 7900 Fax:+61(0)2 9332 6882 www.suez.com.au TYPE OF CONTRACT seaview wastewater treatment plant Design, Build and Operate CAPACITY 53 MLD CONTRACT DURATION D&B: 1999 – 2002 O&M: 2000 - 2020 seaview wastewater treatment plant NZ ESTIMATED POPULATION SERVED: 146,000 Printed on 100% recycled paper created entirely from post consumer waste, using vegetable oil based inks and an alcohol-free ISO 14001 certified printing process. 00896 Hutt Valley 00896 Hutt Valley Brochure_FIN_APR16.indd 1-3 22/04/2016 2:09 pm improving marine and coastal environment TECHNICAL INFORMATION In the 1990s, Hutt City Council investigated the improvement of the marine and coastal environment of Wellington’s southern coast. To achieve this, it was identified that the existing Wainuiomata Wastewater Treatment Plant needed to be replaced and wastewater from Wainuiomata Valley needed to be transferred to a new plant through a pipeline connecting the two valleys. Microscreen > 3ADWF > 2ADWF Primary SedimentationTanks Contact Stabilisation Secondary Clarifiers UV Disinfection Effluent Pumping Pencarrow Head SEWERAGE SYSTEM - HUTT VALLEY The new wastewater treatment plant needed to meet stringent effluent quality requirements to cleanse Wellington’s southern coast and reduce discharge to Wainuiomata River. In 1999 Hutt Valley Water Services (HVWS), a subsidiary of New Zealand Water Services (fully owned by SUEZ Australia & New Zealand) alongside OMI Beca, was engaged to design, build, operate and maintain the new Seaview Wastewater Treatment Plant for 20 years. Return Activated Sludge Primary Sludge WAINUIOMATA VALLEY Through listening to the client’s needs and drawing on our experience in wastewater treatment, SUEZ developed smart solutions to help improve the coastal areas. Since the plant was commissioned in 2002, the marine and coastal environment of the south coast and harbour entrance has vastly improved. In addition, discharge to the Wainuiomata River has ceased, returning the water to its natural state. Waste Sludge Gravity Thickener TO LANDFILL Dissolved Air Flotation Storm Tank Scum Odour Treatment Biofilters providing water solutions for the seismic area ADWF PST GT BT DW TD Air From Process Units (PSTs, GT, BT, DW, TD) Wellington lies along an active seismic fault in the south of New Zealand’s North Island. It is a dextral strike-slip fault with variable amounts of vertical movement causing uplift to the northwest. Therefore, a design enabling the plant to continue to operate under stress conditions was required. Average Dry Weather Flow Primary Sedimentation Tank Gravity Thickener Blend Tank Dewatering Thermal Dryer Blend Tank Listening and understanding the client’s concern, SUEZ and our partners designed wastewater tanks to remain intact during an earthquake, reducing the chance of wastewater spilling into the harbour and minimising operational disruptions. Thermal Dryer DRIED BIOSOLIDS TO BENEFICIAL USE Centrifuge Dewatering community - the heart of our design The plant is situated in a semi-industrial area which is close to commercial properties, therefore the odour emission from the facilities was a key focus from the start of the project. Tanks and equipment that release odours are covered and ventilated, as well as the odour treatment facility to help ensure that the health and safety of the neighbours and environment in the area are not affected. WATER CHARACTERISTICS The sludge from the wastewater treatment line is treated through a drying facility to produce a pathogen-free pelletised product for horticultural reuse. flexibility for continuity Dextral strike-skip fault In preparation for future population growth and to help ensure the continuity of operation, the plant is designed to be flexible for upgrading capacity of up to 50% to serve more residents. Population served 146,000 residents Average flow (MLD) 53 Average dry weather flow (MLD) 42 Typical wet weather flow (MLD) 65 INLET OUTLET BOD (g/m ) 180 8 Total suspended solids (mg/L) 200 14 Faecal coliforms (CFU/ml) 1 x 106 100 3 The plant design allows process units to work independently, enabling the plant to continue operation if one unit is taken offline. BOD = Biochemical Oxygen Demand SUEZ Water & Treatment Solutions 00896 Hutt Valley Brochure_FIN_APR16.indd 4-6 SUEZ Water & Treatment Solutions MLD = mega litres per day SUEZ Water & Treatment Solutions 22/04/2016 2:09 pm