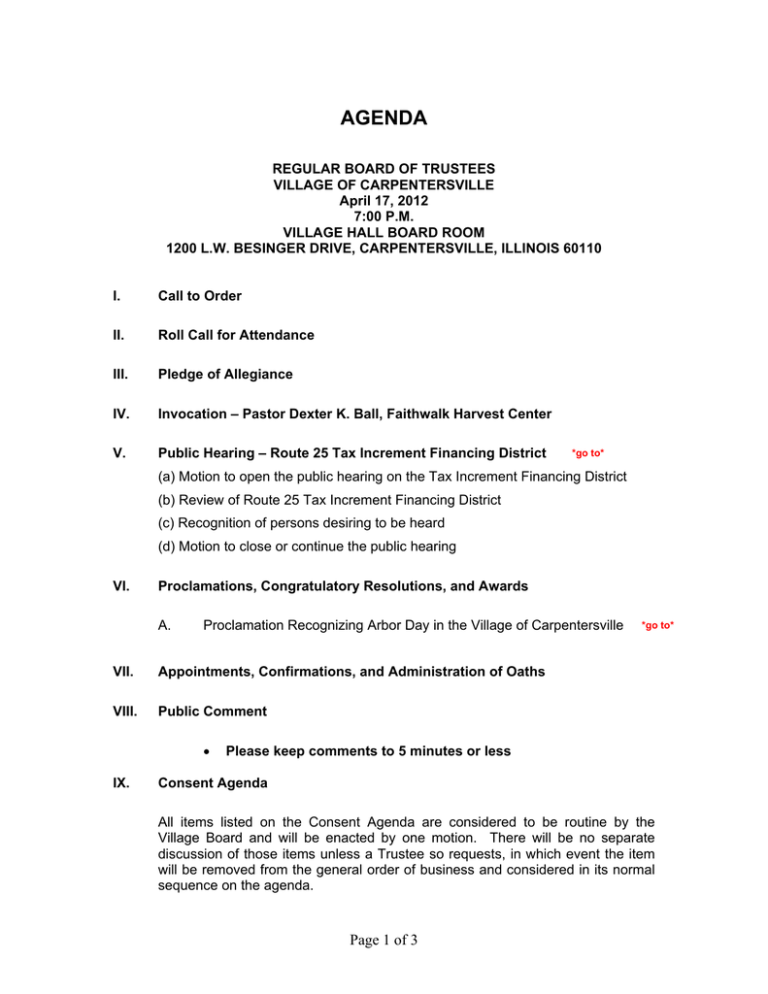

Board of Trustees Regular Meeting - April 17, 2012

advertisement