A Status Report

advertisement

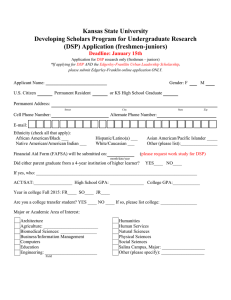

Advanced Technology Group Radiation Hardened Microelectronics Program: A Status Report Presented at the Annual Microelectronics Reliability and Qualification Workshop 11-12 December 2012 RHM Branch Mission, Objectives & Applications Mission: Develop both evolutionary and revolutionary microelectronics technologies to enhance satellite electronic systems capabilities • • Objectives: • Onboard Processing (OBP) Enhancements: • Provide heterogeneous OBP capability to support TFLOP performance & TB storage at reduced SWaP • Provide high performance analog/mixed-signal technologies to support communications and intelligence applications • Electronically Steerable Array (ESA) Enablement: •Very high SFDR low power CNT FET technology for LNA, mixer and ADC designs • UDSM technology for elemental digital beam-forming • Applications: •System survivability •Pre-planned program upgrades by providing improvements in performance, reliability & SWaP • New mission capabilities Near Term Technology Program Objective: • Productization & Qualification of RH Electronics Technologies (250nm to 150nm) • 10X improvement in OB processing performance Tasks: • • • • • • • • • • • RH15F Process Class V Qualification L2 Cache MCM/Synchronous SRAM Qualification 4Mb CRAM Qualification RH18/RAD750 200MHz/400MIPS Processor Qualification 100 MHz Bridge ASSP Development RAD750/250MHz 500 MIPS processor RH SERDES Development Structured Array Development Optimized SERDES Development Advanced Packaging Development HX-5000 SEE Characterization Near Term Program Status Balanced design to support > 400 MIPS Throughput Spacecraft Front-end & Processing L2 CACHE Memory Class Q Qualification Completed RAD750 200MHz/400MIPS Class Q Qual 4QCY12 100MHz Bridge Chip Class Q Qual 4QCY12 RH 16Mb (X32) SRAM Class Q Qual 4QCY12 SERDES Test Chip X BAE SYSTEMS RH SERDES Pass 2 Completed Class Q Qual 4QCY12 RH15F Class V Qual Completed RH 4Mb NVRAM Class Q & V Quall Completed RH15 Class V Qual Complete Structured Array Complete FPGA Replacement 5Gbps SERDES Design Complete Demo 2QCY13 Mid/Far Term Technology Program Objective: • Demonstration of technology to provide a heterogeneous, flexible > TFLOP OBP architecture to support full range of processing needs (MIPS to TIPS) Adaptation of Commercial Processes & IP for Space Applications >1000X in OB processing performance; > TFLOP OBP performance • Demonstration of high performance AMS technology GSPS wide-band ADC/DAC Tasks: • • RHBD 90nm & 45nm 70/250GFLOP DSP • RHBD 45nm Next Generation multi-core GPP Family • RHBD 45nm ASIC Design, Demonstration and Qualifcation • RHBD 45nm/32nm Next Generation Analog/Mixed-Signal Technology Development • RHBD 90nm Reliability Investigation & QML Qualification Support • RHBD Next Generation FPGA Investigation RHBD Vector Processor Host Bridge RHBD 45nm ASIC Development Technical Approach In production since 2009 Freescale 45nm Physical IP • Combinational and sequential standard cells • LVCMOS I/O • 5 Gbps multi-protocol, multirate SerDes • Single Port SRAM compiler • Dual Port SRAM compiler • PLL • SSTL I/O • DDR3 I/O • CML I/O • USB phy • Register File • ROM • CAM Freescale and BAE Systems High Level IP BAE Systems 45nm Physical IP + • SEU/SET hardened sequential cells • SEU hardened PLL / SerDes • LVDS I/O • Upgrades to EM for 15 year missions at 125°C • Upgrades to Vth for low leakage + • Multiple memory controllers: SRAM, SDRAM, DDR2/3, DDR3/3L, Flash • 32-bit Embedded microcontroller (EMC) • Pattern matching engine • Multiple I/O protocols: Serial RapidIO (sRIO), SpaceWire, PCI 32/64, UART, JTAG, I2C • On-Chip Bus Proven on multiple ASICs Ready for space… …and long missions. • Optimal system size, weight and power through 45nm SOI technology • Lower program risk through reuse of proven library elements • High reliability for 15 year missions through enhancements • Excellent radiation tolerance through direct proton ionization immunity and selective SEU/SET hardening The combination of a SOC proven 45nm ASIC library and improvements for radiation and reliability provide an extensive capability for demanding space missions Mid/Far Term Program Status RHBD < 90nm technology to support ESA, Signal Conversion, Data Storage & OBP Applications RH OBP Board 4- 70/250GFLOP DSPs + Host Bridge Spacecraft Front-end & Processing ~ 1TLOP Performance/BD (> TFLOP/Box ) RHBD 90/45nm GFLOP DSP 70/250 GFLOP RHBD 90nm devices in test RHBD 45nm DSP Host Demo 4QFY14 Next Gen RH Reprogrammable FPGA FY12 Architecture Investigation RHBD 45nm GPP RAD55XX Family RHBD 45nm Mixed-Signal technology for SIGINT,ESA & COMM Applications RHBD 45nm ASIC Design & Demonstration and Qualification Effort 4QFY14 RHBD 90nm/45nm Onboard Processing & Control Technology Development & Demonstration Program • Program Objectives • Design, development, demonstration and verification of a RH, flexible and heterogeneous architecture onboard processing capability to meet the full range of satellite payload processing and control function needs (MIPS to TIPS) • Technical Approach • Combines advanced commercial DSP & GPP IP with RHBD 45nm technology to achieve program objectives • Develop and demonstrate: • GFLOP DSP (90nm mid term& 45nm far term) • Host Bridge to support TFLOP SBC capability • MIPS to GIPS GPP family • GPP SBC • RH DDRX Controller RHBD 90nm RADSPEED™ SIMD DSP The RADSPEED DSP is a radiation hardened variant of the CSX700 digital signal processor (DSP) from ClearSpeed Technology RADSPEED DSP features @ 90nm • 160 (152 + 8 spare) processing elements (PE) in two multi-threaded array processors (MTAP) • Throughput: 70 GFLOPS @ 15 W power dissipation • Each PE incorporates double precision floating point hardware as well as integer processing • Single instruction, multiple data (SIMD) architecture • Dual ClearConnect™ bridges (CCBR) Each with ~ 30 Gb/s throughput Supports direct connection between DSPs or to a backplane using a bridge • Dual DDR2 DRAM interfaces A DDR2 interface is dedicated to each MTAP, avoiding bottlenecks Throughput: ~30 Gb/s each Supported by mature commercial software development kit Software prototyping hardware available now RADSPEED DSP block diagram with detailed PE The RADSPEED DSP chip includes two independent cores, each with 76 parallel processing engines, and dual high performance memory and I/O ports RADSPEED-HB™ host / bridge ASIC architecture Dual CCBR interfaces to RADSPEED DSP chips (30 Gb/s each) • Full duplex double data rate wide parallel point to point connection Four “x4” serial 3.125/5 GHz RapidIO 2.1 interfaces plus a spare x4 (40-64 Gb/s total) Control Plane provided through SpaceWire interface DDR2/3 SDRAM memory controller with SECDED ECC (up to 50 Gb/s) Startup ROM and Flash controllers for interfacing with boot and non-volatile memory Multiple 64-bit RAD5500™ Power Architecture processor cores: • • • Setup RADSPEED DSP operations Control data transfers to/from Serial RapidIO backplane Supplement data processing where more efficient Host debug port to RADSPEED DSP and JTAG interface for debug and test Real time trace provides access to internal nodes Preliminary block diagram RADSPEED-HB status: In design now Prototypes: 2014 • The RADSPEED-HB is built upon Freescale QorIQ™ architecture The RADSPEED-HB ASIC sets up the RADSPEED DSP, provides a high speed path to and from a RapidIO backplane, and provides high performance general purpose processing Processor Family Development – RAD 5545 – 32/64bit multi-core Processor Processor Family Development RAD 5510 – 32/64bit Processor DSP Flight Board Block diagram & Model RAM Dual DSP RAM RADSPEED DSP RADSPEED DSP RAM RADSPEED-HB NVRAM ASIC ASSP RAM ASIC sRIO backplane RHM Program Satellite Processing & Control Systems (MIPS to TIPS) RAM FPGA Solid State Recorder RAM RAM RAM RAM RAM RAM RAM RAM RAM Communications I/F Golden Gate Bridge RAD5545 processor RAM NVRAM RapidIO ASIC Single Board Computer RAD750 CPU + RAM L2 cache NVRAM Golden Gate Bridge RAM RADSPEED-HB NVRAM ASIC SpaceWire Router ASIC Payload I/O Sensor RAM RAD5545 NVRAM processor Sensor Sensor Serial RapidIO ClearConnect bridge Analog Sensor D/A converter Analog Actuator SpaceWire endpoint ASIC w/PCI I/F Golden Gate Bridge NVRAM NVRAM NVRAM NVRAM NVRAM NVRAM Instrument Control 45nm Front End Processor ASIC Payload Processor Golden Gate Bridge A/D converter Non-volatile Memory Single Board Computer RAD750 NVRAM CPU + RAM L2 cache RadRunner FPGA Programmable I/O SpaceWire Analog IMU Analog Sensor GNC I/F Bus Electronics Sensor 45nm Comm ASIC Antenna Switch Fabric RAD5510 processor RAM NVRAM Digital Sensor Star Tracker A/D converter Analog Sensor D/A converter Analog Actuator 1553 PCI The Rad Hard By Design 45nm Library Development program provides the technology required for low power, high performance, high density ASIC solutions. RHBD 45nm ASIC Development, Demonstration & Qualification Program Program Objectives • Development, demonstration, and Class Q/V qualification of a RHBD 45nm ASIC technology. Program Tasks • Radiation & Reliability Technology Assessment & Characterization Reliability assessment and remediation RHBD library development & demonstration Radiation effects modeling and simulation • RHBD ASIC Design and Demonstration Design, fabrication and test of two ASICs Package development and demonstration • ASIC & Technology Qualification QML Class V qualification QML Class Q ASIC qualification Design flow qualification RH45 ASIC Library Description Reliability Enhancements to RH45 ASIC library and custom circuitry – Selective metal width updates and modifications for electro-migration (EM) – Lower VDD (0.95V nominal) to limit NBTI/GOI effects – Enhanced design methodology (e.g. power aware placement) for reduction of hot spots – Power grid segmenting to control power and thermal profile – Avoiding (and identifying / updating) circuit topologies that may impact reliability (e.g. voltage stacks) – Limiting I/O ranges – Package / image co-design (board / package / image when applicable) Combinational Cells • I/O • Full family : INV, AND, NAND, OR, NOR, BUF, AO, AOI, – LVCMOS with programmable voltage OA, OAI, XOR, XNOR, FA, HA, MUX2, MUX4, TIE and drive • Data-path enhancement family: ADDRs, MAJs, MUXs, – Low power LVCMOS others – SSTL (DDR2 and DDR3 support) Clock Cells – LVDS – Schmitt Trigger • INV, NAND, NOR designed for radiation hardness – PCI • Proper EM consideration for 20 year lifetime • Glitch-less hardened clock gates for power reduction • Support Cells Sequential Cells − Voltage island isolation • D Flip-flops (DFFs) and Latches − Delay cells − Antenna cells • Scan or non-scan, set, reset, set-reset − Filler cells • With or without Single Event Transient (SET) filters − ESD structures • Soft latches and DFFs available for non-hardened paths − E-fuse RHBD AMS Design, Development & Demonstration Program Program Objective • Investigate the use of < 45nm technology to support AMS requirements to include: • Very high sample rate (> 25 Gsps) moderate ENOB • High sample rate (> 1.5 Gsps) high ENOB • Very high sample rate & very low power elemental digital beam forming (eDBF) applications Technical Approach • Test and analysis through • Critical circuit (e.g., PLL, S/H, etc) design, fabrication, test and characterization • Analog to Digital Converter architecture (ADC) Analysis • 1-3 bit/ > 20 Gsps W-ADC Arch. Design • 10/14 bit/1.5 Gsps W-ADC Evaluation • Commercial ADC Benchmark/Qualification • High sample rate ADC and digital filter architecture investigation Mid/Far Term RHM Program Roadmap 2011 2012 2013 2014 2015 2016 2017 2018 2019 3 2 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q Q 90nm GLOP DSP Prototype Complete 90nm DSP GLOP T&E Complete 45nm Reliability Assessment 45nm IP Library Transfer Initiate GPP Design Complete Start 90nm 45nm GFLOP DSP GLOP DSP Qualification Complete 45nm RHBD ASIC Demo Complete GPP Design & Initiate Fabrication Complete ESA moon-bit ADC study Complete Initial COMM ADC study Complete 45nm RHBD ASIC Qualification 45nm GLOP DSP Prototype Complete 45nm GLOP DSP GLOP T&E RHBD 45nm ASIC Demonstration & Qualification Complete 45nm GFLOP DSP Qualification RHBD GLOP DSP Demonstration & Qualification RHBD 45nm Host Bridge & GPP Demonstration & Qualification Complete GPP (5545) Qualification Complete Complete SBC HB Qualification Qualification Complete SIGINT ADC Qualification Complete COMM Demo RHBD < 45nm AMS Demonstration & Qualification Complete Complete COMM AMS ESA moon-bit Qualification ADC Demo Complete SIGINT AMS Qualification Disruptive Technologies Program Objective: • Develop and demonstrate Disruptive Technologies for Space Applications • High SFDR @ low power CNT FET LNA, Mixer & ADC • RH non-volatile & low power memory Tasks: • CNT Non-volatile Memory 4Mb/64Mb NRAM 1G DDRX SDRAM • CNT FET Technology Low power mixer High SFDR ADC Disruptive Technologies Program Status Spacecraft Front-end & Processing CNT FET LNA +Mixer + ADC 2 Spectrum 1 1000X reduction in power @ > 40dbm SFDR When compared to traditional semiconductor technologies CNT 4M NRAM Demo 2QFY12 64M NRAM FY14 1G SDRAM FY16 Improvement in the Frequency Performance of CNT FETs 4.2 GHz 3.8 GHz Hero Device F max (GHz) 4 3 Average Device 8 µm Channel 3 µm Channel 2 1.3 GHz 2 GHz 0.95 GHz 1 1 GHz 0.5 GHz 0.4 GHz 2009 2010 2011 2012 Time (Year) 21 CNT Microelectronics Technology Roadmap 2007 NRAM™ Fully Integrated Circuit 2008 2009 2010 2012 2014 2016 4Mb RT NRAM™ Design & Production 4Mb RH NRAM™ Design Why CNT Technology? •Rad hard • Non-volatile storage • High switch speed • Highly scalable • Easily integrated into silicon technology • ~ zero leakage current • Low interconnect resistance • Highly linear operation @ low power for mixers & LNA applications 4M NRAM Fully functional NRAM Demonstrated 4QFY12 4Mb RH NRAM™ Fabrication Space Qual 64Mb RH NRAM™ e-NRAM™ RH FPGA 256Mb NRAM/ 1Gb RH SDRAM/ Embedded CNT NRAM technology Development CNT FET Technology to support memory demonstrations (w/ ~ 30% increase in density) and analog mixed-signal circuit development 4Mb NRAM® Description Fabricated on 8” wafer 67 usable die per wafer for wafer-scale testing and/or packaging 4Mb test chips 8-1Mb NRAM® arrays with up to 4-1Mb arrays used for error detection and correction 32 databit I/O architecture Test register implementation to accommodate standard and multiple special test and debug modes Significant enhancements to improve operability and function from 1Mb test chip predecessor LBL LSL LWL CNT NRAM CNT Memory Cell Schematic First packaged parts in testing UNCLASSIFIED NRAM functional verification 64 NRAM® bits tested per data point Multiple die and array tested to verify NRAM® operability Consistent 100% w0 yield (OFF) performance D31 … … … D0 1Mb array w1 yield (ON) performance; > 95% yield across die D31 … LOCKHEED MARTIN PROPRIETARY INFORMATION … … D0 Memory Development Tasks DDR2 SDRAM Design In-progress CNT NRAM 64Mb NRAM Design Complete Summary The RHM Program is addressing DoD and IC RH microelectronics needs through a variety of technical thrusts: • Near term P&Q, Yield enhancement and optimization tasks are underway to exploit 250nm, 180nm and 150nm technologies at BAE Systems and Honeywell • Mid-term efforts to adopt advanced commercial technologies, e.g., DSP, FPGA, microprocessors, for space system applications, i.e., redesign to address radiation effects, power restrictions and reliability. • Mid to Far term investigate and demonstrate the use of highly scaled & disruptive technologies, e.g., CNT, to support various spacecraft applications, e.g., OBP, ESA enablement, DSU. CLASSIFY AS APPROPRIATE ON MASTER SLIDE