The longer you use the Acera Geospec, the more money you save.

ACERA Geospec Super X and Line-up

17-1, Higashigotanda 2-chome, Shinagawa-ku, Tokyo 141-8626 JAPAN

Tel: +81 (0) 3-5789-2127 Fax: +81 (0) 3-5789-2136

www.kobelco-kenki.co.jp

Photos may contain optional equipment.

60 Pandan Rd., Jurong, Shigapore 609294

Tel: +65-6268-8200 Fax: +65-6261-3719

www.kobelconet.com/shsg/

NEW

The Sandvik Mobiles Doublescreen

Two are better than one

Featuring two independent double or triple deck screen boxes,

the patented Doublescreen system utilises two independent drives

for adjustable amplitudes and combined screen angles resulting in

unsurpassed levels of separation, accuracy and productivity.

EVOLU TI O N I N M OT I ON

www. c o ns t r u c t i o n .s a n d v i k . c o m

CRANE LINE – TELESCOPIC CRAWLER CRANE

VERSATILE:

up to 70 t load 360°, optional

1 t playload working platform

ROBUST BOOM:

full-power, four-stage telescopic

boom for 36 m reach, 15 m folding jib

EFFICIENT:

STABLE AND SAFE:

extendable telescopic crawler tracks,

travel with up to 90° load, optionally

work up to 4 ° inclination sidewards

modern E-Series technology

(Tier IIIB), low maintainance

and easy component access

COMPACT:

easy to transport,

3 m transport width

Best Flexibility - Telescopic Crawler Cranes

Clever investment - long-term savings.

4

2

0

SENNEBOGEN Maschinenfabrik GmbH

Sennebogenstraße 10, 94315 Straubing, Germany

Phone +49 9421 540-144

se

i

t

er nes

p

ex er Cra

f

o awl 2

s

r

a pic Crce 199

e

y co n

20 Teles si

TOGETHER

WE FORGE

AHEAD.

Our mission at Foundation

Associates Engineering

is to provide ultimate

satisfaction and quality

products to our customers.

Foundation associates engineering Pte Ltd

5, Tuas Avenue 1, Singapore 639490 Tel: (65) 6863 1633 Fax: (65) 6863 1455

Email: fnapl@singnet.com.sg Website: www.fnapl.com

ROOTS MATTER.

When it comes to strong growth, nothing beats good roots.

Having mastered the bulldozer, which stands at the top of the construction food chain in terms of sophistry, we seamlessly

grew an entire line of earthmoving, road, concrete handling, public utility and other machines that has blossomed from

the success of our world leading bulldozers. Our rise to become the No. 1 bulldozer maker and seller in the world was no

accident of nature. It’s what we call VALUE THAT WORKS. The Shantui brand now sells in more than 150 countries and

regions round the globe.

Contact your local Shantui dealer today to discover more about our entire product family

tree and our worldwide “Anytime, Anywhere Service” guarantee.

Shantui (Singapore) PTE LTD

Add: 18 Tuas Loop, Singapore 637349

Tel: +65-6863 2567 Hp: +65-8437 7222

Email: robin.wfx@shantui.com

www.shantui.com

TOWER AND LUFFING-JIB CRANES

AMERICA

Construcciones Metálicas COMANSA S.A.

Linden Comansa AMERICA LLC

Hangzhou Comansa JIE Construction Machinery Co. Ltd

Tel. +34 948 335 020 | Fax. +34 948 330 810

export@comansa.com | www.comansa.com

Pol. Urbizkain, Crta. Aoiz Nº 1

31620 - Huarte (Navarra), SPAIN

Tel. +1 704 588 7729 | Fax. +1 704 588 3986

sales@lcacranes.com

www.lcacranes.com

11608 Downs Rd. Pineville NC 28134, USA

Tel. +86 571 8299 5555 | Fax. +86 571 8299 6555

export@comansajie.com.cn

www.comansajie.com.cn

Jingjiang, Xiaoshan, Hangzhou P.C. 311223, CHINA

PASSION FOR

PROGRESS

The future is built into all Bauer machines. We give research and

development top priority. It’s not just our innovative drive that makes

us number one in the world, but also because we offer customized

system solutions that meet the highest quality standards.

www.bauer.de

Bauer. Technology to build the future.

Total lifting

solutions

Manitowoc and JP Nelson’s partnership offers you

the best crawler cranes from one of the world’s

leading crane manufacturers.

Manitowoc crawler cranes

• 80t to 2300t capacity

• Durable & Adaptable

• Available with a wide range of crane

attachments

• Flexible and efficient on the job site

With Manitowoc Crane Care and JP Nelson’s

product support and maintenance service, all

Manitowoc cranes sold through JP Nelson come

with the best after sales service around the clock.

Manitowoc-JP Nelson - a partnership for your total

lift solutions.

Manitowoc 8500-1

Manitowoc 11000-1

Manitowoc 16000

Manitowoc 8500-1

JP Nelson Equipment Pte Ltd

No. 30 Benoi Road,

Singapore 629900

Manitowoc Cranes

4 Kwong Min Road

Singapore 628707

Tel: +65 6368 9991

Fax: +65 6367 9991

Tel: +65-62641188

Fax: +65-68624040

www.jpnelson.com.sg

www.manitowoccranes.com

Contents

NEWS

sept/oct 2013

News in Southeast Asia News in Southeast Asia & Australasia

News in East Asia 12

16

18

News in India & the Middle East

20

News in Europe & North America

22

IPAF Highlights

26

EVENTS

Calendar of Events 28

Industry Events 30

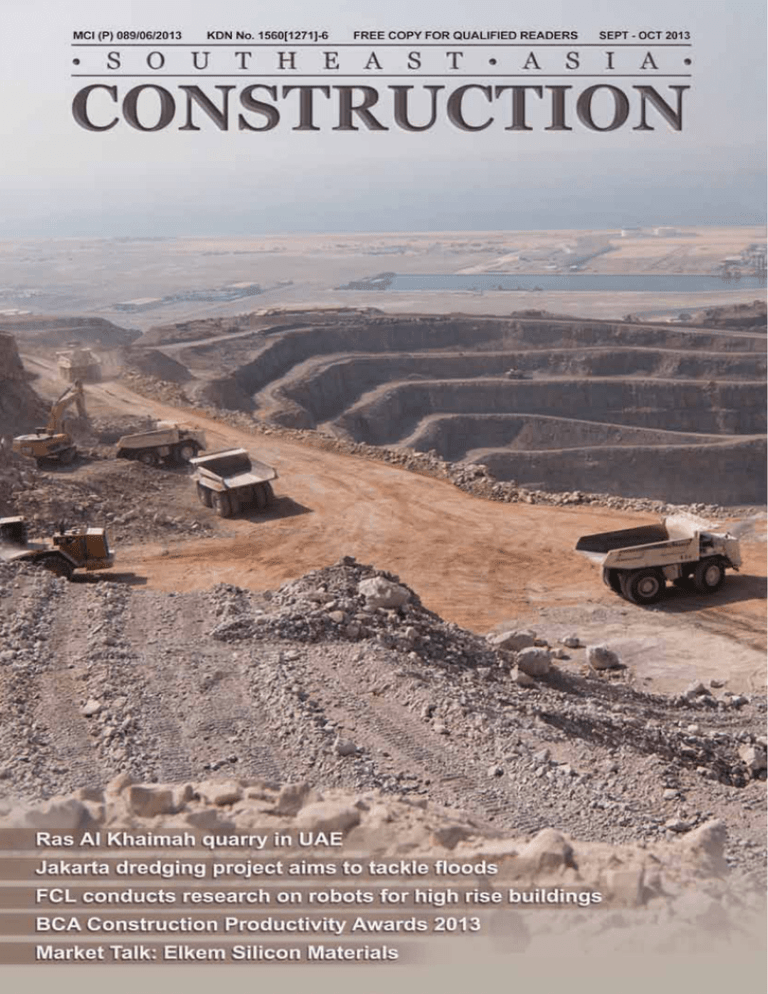

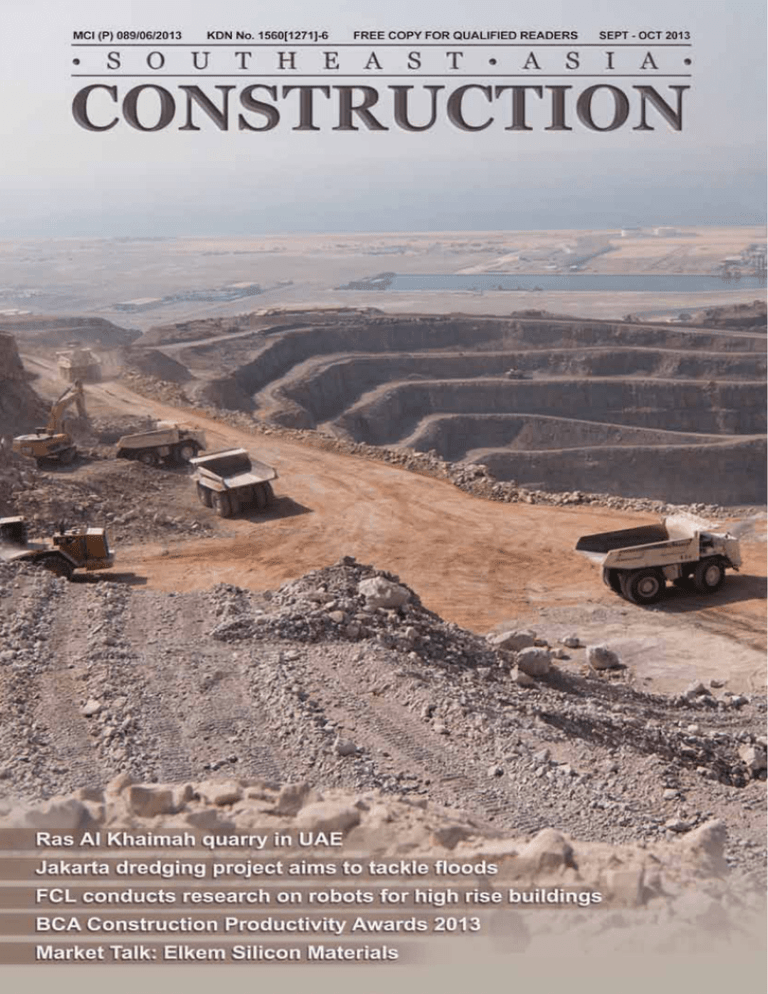

On the cover:

PRODUCTS

Ras Al Khaimah quarry in UAE

(page 98)

Cover designed by Fawzeeah

Yamin

Publisher

Steven Ooi

steven.ooi@tradelinkmedia.com.sg

Editor

Fabia Sugandy

seac@tradelinkmedia.com.sg

Group Marketing Manager

Eric Ooi

eric.ooi@tradelinkmedia.com.sg

New In Industry

Instrumentation

34

52

Earthmovers 54

Road Construction Equipment 56

Cranes

59

Concrete Technology Mixed Category

12

20

34

61

62

66

26

Marketing Manager

Felix Ooi

felix.ooi@tradelinkmedia.com.sg

Assistant Marketing Manager

Jasmine Gan

jasmine.gan@tradelinkmedia.com.sg

37

Head of Graphics Department/

Advertisement Coordinator

Fawzeeah Yamin

fawzeeah@tradelinkmedia.com.sg

56

Graphic Designer

Siti Nur Aishah

siti@tradelinkmedia.com.sg

Circulation

Yvonne Ooi

yvonne.ooi@tradelinkmedia.com.sg

Any other matters : info@tradelinkmedia.com.sg

38

52

58

My Ammann –

A promise well kept.

Plant operator Than Tun Naing with his Uniglobe from Singapore.

Designed as a high - performance production plant with extra - large hot

aggregate storage capacity, you’ll find the Uniglobe wherever there is a

call for low transport costs and maximum production output. Lean dimensions and a powerful 3 or 4 - tonne mixer make it the ‘star turn’ among

our asphalt mixing plants.

For more information on compaction machines, mixing plants and pavers

go to www.ammann - group.com

Ammann South East Asia

The Vida Building, 6th Floor

Jl. Raya Pejuangan Nr. 8, Kebon Jeruk

Jakarta 11530 – Indonesia

Tel. + 62 21 2966 1350, Fax + 62 21 2966 1343

info.aid@ammann-group.com

Contents

72

PROJECTS & SPECIAL FEATURES

Market Talk: Elkem Silicon Materials 24

Applications On Site 70

Research In Construction

80

Dredging Project 86

90

92

94

Quarry Project

98

Product Feature 100

Focus on East Asia 108

BCA Construction Productivity Awards 2013

124

Foundation Project

Airport Runway Project

High Rise Project

80

92

108

124

82

86

100

120

24

SOUTHEAST ASIA CONSTRUCTION is published six times a year by:

Trade Link Media Pte Ltd. RCB Registration no: 199204277K

Address : 101 Lorong 23, #06-04 Prosper House, Singapore 388399

Tel: +65 6842 2580, Fax: +65 6842 2581 /+65 6745 9517

Website: www.tradelinkmedia.com.sg

Email: info@tradelinkmedia.com.sg

The company is a member of Association of Equipment Manufacturers (AEM)

The magazine is available free-of-charge to applicants in the building and construction industries who meet the

publication’s terms of control. For those applicants who do not qualify for free subscription, copies will be made available,

subject to the acceptance by the publisher, of a subscription fee which varies according to the country of residence of

the potential subscriber. Airmail (per year): Europe/USA - S$150; Japan, Australia and New Zealand - S$150; Malaysia

and Brunei - S$80; Singapore - S$40; Rest of Asia - S$120 (Incl. 7% GST Reg.: M2-0108708-2).

Printed in Singapore by Kim Hup Lee Printing Co Pte Ltd. MCI (P) 089/06/2013 • ISSN 0217-4685; KDN NO: 1560

(1271) - (6)

Clause: The Editor reserves the right to omit, amend or alter any press release submitted for publication. The

publisher and the editor are unable to accept any liability for errors or omissions that may occur, although every

effort has been taken to ensure that all information is correct at the time of going to press. No portion of this

publication may be reproduced in whole or part without the written permission of the publisher.

Disclaimer: All advertisers and contributors must ensure all promotional material and editorial information

submitted for all our publications, must be free from any infringement on patent rights and copyright laws in

every jurisdiction. Failure of which, they must be fully liable and accountable for all legal consequences (if any)

that may arise.

International sales office:

T. Asoshina/Shizuka Kondo, ECHO Japan Corporation

Grande Maison Rm 303, 2-2, Kudan-Kita 1-Chome, Chiyoda-ku, Tokyo 102, Japan

Tel: +813 3263 5065, Fax: +813 3234 2064

Email: aso@echo-japan.co.jp

aly

at

,

the Keys to

Partnership Success!

Exclusive Dealership

Aly Energy Singapore Pte Ltd

Aly Lifting & Foundation Pte Ltd

Aly Heavy Equipment Sdn Bhd

Crane Line

Green Line

T: (65) 6266 8558

•

F: (65) 6266 5885

Piling

System

Mobile Load

Control System

• enquiry@aly.com.sg •

www.aly.com.sg

n News in Southeast Asia

BASF recently launched the Master

Builders Solutions brand in Thailand. On

the occasion of the launch, the company also

introduced two solutions that can help make

construction more efficient while enhancing

the quality and reliability of buildings.

Boonchai Opas-iam-likit, chairman

and managing director of BASF Group in

Thailand said, “Familiar names in the Thai

construction market today include MasterTop

for flooring or MasterSeal for waterproofing.

Now, with the full range offered under

the Master Builder Solutions brand, we

can help the Thai construction industry

create their Masterpieces. This simple and

consistent branding represents BASF’s

expertise gained from more than a century of

worldwide operations, with the development

of innovative solutions that contribute to the

sustainable development of construction

industry in Thailand. It gives us the wideranging ability to provide expertise that will

help our customers to be successful and stay

competitive now and in the future.”

BASF launched the global Master

Builders Solutions brand in March of this

year. The global brand is a sign of BASF’s

commitment to the construction industry

© BASF SE

BASF launches new brand for Thailand’s construction industry

Boonchai Opas-iam-likit (second from

left), chairman and managing director,

BASF Group in Thailand.

BASF introduces its Master Builders

Solutions brand and shows its commitment

to the construction industry worldwide.

and represents a wide range of construction

chemical solutions previously sold under a

variety of specialty brands. It also brings all of

BASF’s expertise together to create chemical

solutions for new construction, maintenance,

repair and renovation of structures.

Furthermore, BASF has introduced two

new products to help construction experts in

Thailand enhance efficiency and reliability

of their buildings. BASF’s innovative Smart

Dynamic Concrete (SDC) can upgrade low

and medium strength concrete grades with

outstanding characteristics such as flowability

and self-consolidation without segregation,

thus enhancing the construction efficiency by

eliminating the vibration process. The selfconsolidation characteristic allows building

structures to achieve good construction

quality and prolong life span.

In addition, BASF’s MasterSeal

M820 is a unique high performance

PU based waterproofing solution, aimed

for applications to both underground

and superstructures. It maximises speed

of construction while ensuring quality

assurance on site. It is spray applied,

seamless, tough and sets in 20 seconds, and

is a Green Label certified product. n

Vinci to design and build office tower in Malaysia

With this new contract, Vinci Construction

Grands Projets has reinforced its operations in

Malaysia, where it handed over the 700,000

sq m Berjaya Times Square project in Kuala

Lumpur in 2003, said to be the largest

contiguous residential and shopping complex

in Asia, and is currently building the 185,000

sq m Berjaya Central Park project. n

Vinci has won a contract to design and

build an office tower in Kota Kinabalu.

PINAI Fund supports wind power project in the Philippines

The Philippine Investment Alliance for Infrastructure (PINAI),

a fund that is partly financed by the Asian Development Bank

(ADB), is investing up to US$85 million for a wind farm project in

the northern part of the Philippines.

The 81 MW project – PINAI’s first investment ever – is a joint

venture with AC Energy Holdings Inc, a wholly owned subsidiary

of Ayala Corporation, and UPC Renewables Partners (UPC) through

UPC Philippines Wind Holdco BV. PINAI will own 32 percent of

the project, while AC Energy and UPC will own 64 percent and

4 percent respectively. The project will have two phases, with the

first phase generating at least 54 MW, to be connected to the grid

by June 2014.

12

sept/oct 2013

PINAI is a US$625 million private equity fund focused

exclusively on Philippine infrastructure projects. It was launched

in July 2012 to capitalise on the various public-private partnership

opportunities in the Philippines. PINAI should spur more private

equity funds that will catalyse additional long-term capital into the

country, and further development of domestic capital markets.

According to the Philippine Development Plan, around 12 percent

of the country’s US$120 billion investment requirements need to come

from the private sector. PINAI is managed by Macquarie Infrastructure

and Real Assets. It is jointly financed by ADB, Philippines’ stateowned pension fund Government Service Insurance System, Dutch

pension fund asset manager APG, and the Macquarie Group. n

© UIG

Vinci Construction Grands Projets has

signed a €60 million contract with Akal

Megah Sdn Bhd to design and build an office

tower in Kota Kinabalu, Malaysia.

The contract covers design and

construction of a four-level carpark, a

three-storey podium of shops and a 10storey office tower with a total surface

area of 65,000 sq m. The work is set to get

under way in August 2013 and handover is

scheduled for 31 March 2015.

n News in Southeast Asia

Ammann strengthens in Southeast Asia

Ammann is strengthening its presence

in the Southeast Asia region with a new

representative office in Jakarta, Indonesia,

from where the company will coordinate

activities across all ASEAN markets. In

addition, Ammann has appointed a new

distributor in Singapore, Teesin Machinery

(Pte) Ltd, which will focus on the company’s

light equipment line including forward,

reverse and hydrostatic vibratory plates,

trench rollers, walk-behind rollers, rammers

and add-on compactors for a wide range of

excavators.

“As Singapore moves forward, we

are seeing a trend towards increased

mechanisation of many road construction,

repair and maintenance applications, so it

is essential for light compaction equipment

to cater to specific site jobs,” said James

Tan, managing director of Teesin Machinery

(Pte) Ltd.

“Ammann’s remote controlled trench

rollers, for example, are ideal for working

in confined spaces in total safety while the

ARW65 walk-behind rollers provide a good

compromise between mechanising the task

and having an operator to ensure the good

quality of the resulting road work.”

The AFW150 G paver.

The ARW65 walk-behind roller.

Mr Tan also highlighted Ammann’s new

AFW150 paver. “It is the smallest paver

with a paving width of 1.5 m, designed

specifically for all the walkways, paths,

cycling lanes, pavements and small alleys

where it would be impossible to work with

a standard paver designed to work on much

wider stretches of road. The AFW150 is an

ideal machine for these applications, and

one that will deliver a much better finish to

the small surfaces being paved.”

Sergio de Rinaldini, general manager of

Ammann Southeast Asia, said that Singapore

is an important market for Ammann.

“Singapore is now firmly on Ammann’s map;

we are establishing ourselves more and

more here. We have a second new asphalt

mixing plant being erected right now at

Samwoh specifically designed to produce

asphalt using a high percentage of reclaimed

asphalt, which is then recycled in the plant,

therefore reducing the environmental impact

and essentially delivering a greener finished

product.” Mr de Rinaldini added that

Ammann plants also have the lowest fuel/gas

consumption per ton on the market. n

New integrated construction and precast hub in Singapore

SEF Group Ltd is currently building its first integrated construction

and precast hub (ICPH) at Kaki Bukit, Singapore. The ICPH is

the first to be awarded under a public tender by the Building and

Construction Authority (BCA), as part of the government’s initiatives

to transform the industry to one that adopts highly productive

technology and mechanisation.

The ICPH is scheduled to start its production next year. Upon

completion, the facility will be equipped with modern automated

production line using advanced European technologies, which will

have an annual production capacity of more than 100,000 cu m

of precast components. This is said to be three times more than a

conventional open precast yard. The factory setting not only speeds

up the production process but also provides better quality control of

the precast concrete products. The ICPH is also capable of producing

more than 25 types of components, both structural, architectural as

well as prefinished, preassembled products for use in public and

private sectors projects.

In land scarce Singapore, the concept of an integrated hub will

allow a more efficient use of land. Besides the production of precast

components, the 32,608 sq m five-storey building will also be used

for related purposes such as offices and dormitories for the workers.

The SEF’s ICPH is believed to be the first in Singapore to make use

of a multi-tiered fully automated storage system. This storage system

is capable of storing more than 100 trailers worth of completed

components including bulky 3-D components such as household

shelters. In addition, the system for tracking of inventory of precast

components as well as the preparation prior to delivery, is fully

14

sept/oct 2013

automated. SEF will be integrating advanced Building Information

Modelling (BIM) software with the control and management software

to gather installation updates from project sites to achieve a just-intime production, in order to cut down on storage space.

“With our productivity drive towards off-site production,

mechanisation and standardisation, the demand for precast

components will increase significantly in the next few years,”

said Dr John Keung, CEO of BCA. “The concept of the integrated

construction and precast hub is suitable for Singapore as it allows us

to intensify land use while ensuring production of high quality precast

components. Such facilities will be the next step forward for our local

precasters towards automation, process integration, improved quality

and significant productivity improvement.” BCA plans to roll out

more tenders for new ICPHs - about two to three more this year - to

boost the industry’s capability and capacity in this area.

Despite having a large production capacity, the ICPH will be

adopting environment-friendly practices to cut down on water

consumption, such as by recycling and treating rainwater and grey

water (collected from wash basin and shower area) to industrial

water for production use. The recycled water is expected to be

able to fulfil daily production needs. Furthermore, there will be a

high efficient low energy heater, reducing energy consumption and

boiling time by up to 50 percent, to produce hot water for production

use. SEF will also be employing a more productive suspension

concrete in its production, on top of normal concrete, which can

help cut down the amount of cement, aggregate and water used by

up to 30 percent. n

n News in Southeast Asia & Australasia

Trimble acquires Actronic

Technologies

Trimble has acquired Auckland, New Zealand-based Actronic

Holdings Limited, one of the leading providers of weighing technology

and payload information systems for construction, aggregates, mining

and waste markets.

Actronic Technologies produces the Loadrite weighing system for

wheel loaders, excavators, conveyors and waste collection vehicles.

Loadrite systems provide equipment operators, site foremen and

project managers with accurate payload weights and allow them to

ensure that machines are loaded to optimal capacity and that loads

are accurately recorded. Weight information combined with fleet

dynamics and cycle time tracking provides metrics for monitoring

and improving both machine and project performance.

Loadrite extends Trimble’s Connected Site portfolio by adding

weight as an element of information collected at the machine.

This extended capability will better enable contractors to use the

Trimble Connected Site to achieve improved comprehensive realtime intelligence on asset and site productivity for the contractors’

mixed fleet. Trimble’s Connected Site is an extensive information

architecture that optimises and integrates operations across the

construction site and the office, thereby enabling improved planning,

more advanced monitoring, and significantly greater productivity.

“The acquisition of Actronic Technologies empowers machine

operators, foremen, supervisors and project managers to understand

machine performance and progress across the entire site within

the aggregate, construction, mining and waste industries,” said

Roz Buick, vice president and general manager of Trimble’s Heavy

Civil Construction Division. “Loadrite weighing systems expand the

richness of the Connected Site information we collect from machines

and complements the productivity and reporting capabilities we

already provide our customers.”

“The Loadrite system is widely recognised as setting the standard

for our industry, a result of over 30 years industry expertise gained by

working closely with machine owners and operators,” said Gottfried

Pausch, general manager for Actronic Technologies. “I believe the

addition of the Loadrite system to Trimble’s leading portfolio of

positioning and automation technology solutions extend our collective

ability to deliver more powerful and robust solutions designed to

improve operational efficiency and reporting and allow our customers

to maximise their profits.” n

Royal HaskoningDHV joins forces with DBI to support

growth in Indonesian market

International consultancy, engineering and project management

service provider Royal HaskoningDHV is strengthening its presence

in Indonesia by acquiring PT Dwira Bangun Indonesia (DBI). All

DBI staff is integrated in the existing Royal HaskoningDHV Industry

& Logistics Advisory Group. DBI, which provides mechanical and

electrical services for buildings and process utilities, has been a

dedicated partner of Royal HaskoningDHV since 1986.

During the past 27 years DBI and Royal HaskoningDHV have

delivered many prestigious projects together, such as the L’Oréal

factory in Jababeka, Bekasi on West Java last year. Both companies

are currently involved in the design and installation management of

the mechanical and electrical works for a large pharmaceutical plant

for B. Braun in Karawang, Indonesia. n

16

sept/oct 2013

Raman Joshi to head Manitowoc’s

operations in Greater Asia Pacific region

Raman Joshi (left) will head Manitowoc

Cranes’ operations in the Greater Asia Pacific

(GAP) region - which covers much of Asia

and Australasia, but excludes China. He

takes over as executive vice president of GAP

from Gilles Martin, who has left the company

to pursue other interests. Mr Joshi will

report directly to Eric Etchart, president and

general manager of Manitowoc Cranes.

Mr Joshi’s most recent role, which he will continue to occupy

in conjunction with the new EVP position, was as vice president

of Manitowoc Cranes India. In this role he oversees the company’s

factory for Potain tower cranes in Pune, as well as its five sales

offices and network of local dealers. Before moving to India, he

was marketing director of Asia Pacific, and prior to that he served

as global product manager for Manitowoc crawler cranes, his first

role at the company that he assumed in 2006.

Mr Joshi will continue to be based in India, but will also

spend much of his time at Manitowoc’s regional headquarters in

Singapore. He commented, “India has been an exciting market

to work in for the past five years and it will continue to occupy a

large amount of my time as I continue my duties there. But I’m

also looking forward to re-introducing myself to our customers and

dealers across the rest of Asia, and in Australia and New Zealand.

This part of the world offers such a diverse range of customers

and industries, with so many varied needs that every day will be

a challenge. But I’m confident that the structure we have and the

team we’ve got will deliver. I want us to build on the strong position

we’ve attained and work even harder to deliver cranes and support

solutions that are perfect for this part of the world.”

Prior to joining Manitowoc, Mr Joshi worked for Japanese

bearing manufacturer NSK Ltd, latterly as sales and marketing

manager for the company’s US operations. n

TJHD to deliver first major construction for North

West Rail Link

A joint venture between Thiess, John Holland and Dragados

(TJHD) has been chosen by the New South Wales government

to construct the tunnels and excavate new underground stations

for Sydney’s visionary North West Rail Link in Australia. Under

the A$1.15 billion tunnel and station civil works contract, TJHD

will construct twin 15 km tunnels, which will run between Bella

Vista and Epping. These are believed to be the longest rail tunnels

ever built in Australia.

The project also includes civil works for five of the eight new

stations and two service facilities. Four custom-made tunnel

boring machines (TBMs) will be used to construct the 6 m

diameter tunnels with the first of the TBMs to be in the ground

by the end of next year.

TJHD is hitting the ground running and expects to place orders

for the TBMs within the next few weeks. The team is also gearing

up for a proactive community engagement effort to limit disruption

and inconvenience while providing information on the long term

benefits of the project. Work will start shortly to prepare the three

major tunnelling sites at Bella Vista, Showground and Cherrybrook

with contract completion scheduled for first quarter 2017. n

n News in East Asia

LiuGong and ZF produce first prototype

LiuGong and ZF have jointly developed their first prototype, AP3000

axle, which was produced by their new joint venture company, ZF

Liuzhou Axle Co Ltd.

LiuGong and ZF started their long-term relationship in 1995

by setting up Liuzhou ZF Machinery to produce construction

transmissions and spare parts. It has been successfully serving

joint venture partner LiuGong and third parties with high quality

construction machinery transmissions for years.

After the continued success of the first JV with ZF, LiuGong and

ZF built a new joint venture together last September, focussing on

wheel loader axles that are specially tailored to the requirement of

developing markets. Located in the same city together with LiuGong,

the new ZF Liuzhou Axle is targeting an increase in annual volume

to more than 30,000 units by 2018.

“Liuzhou ZF Machinery has been a win-win example in the

industry for years. Today, we come to another milestone with our

new JV company, ZF Liuzhou Axle,” said Wang Xiaohua, chairman

of the board for LiuGong, “I am very pleased to be here to unveil

the brand new AP3000 axle. It marks a new level of our excellent

cooperation with ZF, the world’s leading automotive industry

supplier, demonstrating our determination in the heavy machinery

industry.”

AP3000 was developed through the joint efforts of research

teams from ZF headquarters in Germany, ZF China and LiuGong. It

can be assembled with dry or wet brakes, and is mainly designed for

5- and 6-t wheel loaders. LiuGong’s 855N will be the first machine

equipped with the new axle, acquiring higher reliability, excellent

load capacity, optimised cost and lubrication condition. n

Atkins to develop eco-low carbon urban planning guidance in China

Atkins has won an important new commission to develop guidance for

eco-low carbon (ELC) urban planning in China. Funded by the UK’s

Foreign and Commonwealth Office (FCO) Prosperity Fund and led

by Atkins’ sustainable planning team in Beijing, the project involves

working with both national government agencies and city governments

and is aimed at providing a key, high profile reference point for ELC

urban planning in China. The Prosperity Fund brings together Chinese

and British experts to develop low carbon policies, practices and

regulations, with a growing focus on sustainable urbanisation.

China’s emerging ELC urbanisation initiative forms a key

component of the government’s 12th Five Year Plan, which places

strong emphasis on energy and resource efficiency, reducing GHG

emissions and environmental protection. To date the emphasis has been

more on developing demonstration areas, ELC technologies and, more

recently, establishing sustainable planning evaluation frameworks.

Hydronix opens sales and service office in China

UK-based Hydronix Limited, a world leader in the field of microwave

moisture measurement, has opened a new sales and service office

in China. The new company, Shanghai Haodun Electro-Mechanical

Technology Co Ltd, will represent Hydronix in China.

With this new facility, Hydronix can offer better support, service

and training to its automation OEM resellers in China as well as advice

and support to all resellers and users of its equipment in the country.

The new office does not affect any existing trading relationships

between automation suppliers and batch plant producers or endusers. Hydronix said the new office is primarily aimed to service,

support, train and educate, but it will also welcome new direct sales

to automation companies and suitably qualified resellers. n

Hydronix

Limited is

headquartered

in the UK.

18

sept/oct 2013

With the vast scale and scope of urbanisation in China, there is an

unprecedented opportunity to build knowledge and experience of ELC

urban planning approaches and methodologies. The project team will

work in particular in partnership with local government in China to

help achieve this.

Supported by China’s Ministry of Housing and Urban-Rural

Development (MOHURD), which has responsibility for green

building and urban planning administration, the project team

will work closely with two selected city governments to develop,

test and apply the ELC guidance. The guidance will be designed

to be closely integrated with China’s statutory urban planning

requirements, and cross-referenced to current ELC urban planning

indicator systems. The project outputs will be strongly focused on

hands-on use as an everyday working tool in a practical, ‘on the

ground’ urban planning setting. n

Gammon wins contract for Hong Kong’s TM-CLKLsouthern connection viaduct section

Gammon Construction Limited has been awarded by HKSAR

Highways Department a HK$8.66 billion design and build

contract for the construction of the southern connection viaduct

section of the Tuen Mun-Chek Lap Kok Link (TM-CLKL) in

Hong Kong. This is the largest solo contract ever awarded to

Gammon Construction.

The southern connection viaduct section, which is part of the

9 km long TM-CLKL, mainly includes the design and construction

of a dual two-lane sea viaduct of approximately 1.6 km long

between the Hong Kong-Zhuhai-Macao Bridge Hong Kong

Boundary Crossing Facilities and North Lantau. It also includes

construction of nine approach viaducts and other associated

works including slope improvement, environmental protection

and mitigation measures.

Work is scheduled to be substantially completed by the end of

2016 and fully completed by April 2017. The project is expected

to create more than 1,500 jobs in Hong Kong.

The TM-CLKL, together with the proposed Tuen Mun

Western Bypass, is a strategic road link between North West New

Territories, North Lantau, the Hong Kong-Zhuhai-Macao Bridge

Hong Kong Boundary Crossing Facilities and the Hong Kong

International Airport at Chek Lap Kok. n

n News in India & the Middle East

AECOM wins contract for Delhi Mumbai Industrial Corridor

AECOM has been awarded a programme management contract for

the Dholera Special Investment Region (DSIR) in Gujarat, India, for

the Delhi Mumbai Industrial Corridor (DMIC). The US$30 million

contract has a base period of five years, with an option to extend

for additional five-year terms.

AECOM will provide full programme management services for

the DSIR as part of the DMIC Development Corporation’s new cities

infrastructure programme. The programme aims to transform India’s

manufacturing and service base by developing a number of smart,

sustainable and industrial cities along the DMIC - a 921 mile long

corridor between Delhi and Mumbai. The 347 sq mile DSIR township

will be the first city implemented under the programme.

The Dholera region comprises 22 villages that will be

incorporated as part of the master plan. AECOM’s project scope

consists of implementing all base infrastructure, including

water supply, sewerage, roads, highways, power, information and

communications technology (ICT) and rail; performing extensive

flood-control and drainage measures to protect the future city;

and overseeing the development and execution of all publicprivate partnership delivered projects, such as the rail connecting

Land use

master

plan for

Dholera

Special

Investment

Region.

Ahmedabad to Dholera, industrial (tertiary) wastewater treatment

and potable water treatment plant.

The DSIR will be built in three phases with the estimated

construction value for the Phase 1a (2013-2018) base infrastructure

to be worth more than US$2 billion. n

Sandvik to manufacture construction equipment for Indian market

Sandvik Asia has acquired 50 acres of

land at Chakan, near Pune, India, for the

establishment of a new plant that will

manufacture construction equipment for the

Indian market. The facility is expected to be

up and running by 2015. This development

further highlights Sandvik’s commitment

to India and Southeast Asia as a whole,

and follows on from Sandvik Construction’s

recently launched new surface rock drill that

has been designed and manufactured in India

from components sourced locally.

According to Olof Faxander, president

and CEO of Sandvik, there are also plans to

design and make products for the domestic

construction and mining sector. He added

that the company will also source components

from India for export to its other plants

globally, as well as stating that Sandvik

will make significant investment in India,

including in its R&D centre over the next

two years.

Ajay Sambrani, managing director of

Sandvik Asia, said of the development, “We

have identified mining and construction as a

major growth area in India, which will make

significant contribution to the company’s top

line and would become the largest business

area in Sandvik.”

24x7 service programme

In another development, Sandvik Construction

India has recently designed a customised

service solution programme as part of its

continued aftermarket development. The

24x7 service programme ‘went live’ in June

2013, and is considered to be the first of

its kind in the industry. Key features of

the programme include 24x7 customer

call handling, focused end-to-end service

delivery, enhanced visibility and launch of

‘Sandvik Solitaire Club’.

The ‘Sandvik Solitaire Club’ aims to give

customers priority service, while delivering

Olof Faxander (left), president and CEO of

Sandvik, and Ajay Sambrani, managing

director of Sandvik Asia.

cost savings through enabling customers

to choose between two types of services premium or classique - depending on their

specific requirements and the orientation of

their business. n

Bechtel-led consortium selected for major rail project in Saudi Arabia

A consortium led by Bechtel has been awarded by the High

Commission for the Development of ArRiyadh to design and build

two rail lines of the Riyadh Metro network in Saudi Arabia. The

team will be responsible for the approximately US$10 billion

development of Lines 1 and 2, which will be part of the six-line

metro system that will form the backbone of Riyadh’s public

transportation network. The consortium, which includes Bechtel,

20

sept/oct 2013

Almabani General Contractors, Consolidated Contractors Company

and Siemens (BACS) will be responsible for the design, construction,

train cars, signalling, electrification and integration of the new

lines to the system. Line 1 will run north to south across Riyadh

from Olaya to Batha Corridor and Line 2 will run east to west along

King Abdullah Road. The new lines will feature stations powered

by renewable energy and fully automatic trains. n

n News in Europe & North America

Turner & Townsend to work on

Russia’s major residential project

Turner & Townsend will soon be working on one of the most extensive

residential developments in Russia. The £10 billion, 15-year project

takes in 22 sites across St Petersburg, involving the construction of

1,200 new buildings and the redevelopment of over 900 ha. Turner &

Townsend was chosen by SPb Renovation, which aims to replace the

city’s Soviet-era buildings to create a more modern and sustainable

living environment, while also upgrading the standard of new-build

accommodation within the city.

Providing new apartments for 450,000 residents – about 10

percent of the population – this is a substantial commission, for

which Turner & Townsend is providing consultancy services for the

commercial infrastructure needed to support the new neighbourhoods.

The company will be offering cost modelling, option appraisal,

procurement support and systems development on behalf of SPb

Renovation and its development partners throughout the programme’s

15-year period. n

SDLG to enter North American market

Shandong Lingong Construction

Machinery plans to introduce

its SDLG branded equipment

to customers in North America.

The company expects to enter

the market in the second half of

2013 by launching two models

from its popular range of wheel

loaders, the LG938L – a 1.8

cu m loader with a rated load

of 3 US t, and the LG959 – a

3.1 cu m loader with a rated

SDLG LG959.

load of 5 US t.

The entry into North America is the latest phase of the company’s

ambitious international expansion programme. Recent introductions

have seen SDLG enter markets such as Latin America, Russia,

Oceania, Africa, the Middle East and much of Asia. The company’s

products attract customers who are looking for new machines that

are reliable, simple and with a more competitive price point than

premium, features-led equipment.

Initially the SDLG products will undergo an introduction phase

with select dealers before being rolled out to a wider customer base

across North America in the coming months. n

LiuGong branches out to Stockholm

Peters Lastmaskiner AB, LiuGong’s exclusive dealer for Sweden,

has opened a new branch office in Stockholm. The company, which

also relocated its head office in Karlstad to a new facility with fully

equipped workshop, parts warehouse and showroom in November

2012, is already a well-known name in Sweden for the sales of

secondhand forestry machines. “We chose Stockholm for our new

branch because most brands are represented in the capital. It offers

the greatest potential because it’s simply the largest market in Sweden,

so this new branch should be great for LiuGong,” said Teuvo Vanha,

Peters’ sales manager. “We also believe we’ll be able to help the

market here by bringing information to improve specific problems

with machinery that can occur in a cold climate.” n

22

sept/oct 2013

Tognum to expand R&D centre at

MTU Aiken plant

Tognum will expand

its research and

development centre at

the MTU Aiken Plant in

the US. The company’s

investment of US$22.5

million will result in 10

new jobs at the facility

and is expected to double

the centre’s development

MTU Aiken plant in South Carolina.

capacity with the addition

of two new test cells for off-highway diesel engines. “The expansion

of our MTU Aiken Plant is part of our global growth strategy to

invest in our plants and in R&D,” said Dr Ulrich Dohle, CEO of

Tognum. “In the medium term, the plant expansion enables us

to prepare for the planned volume growth.”

The investment, which will be made with the support of Aiken

County, South Carolina, follows Tognum’s previous commitment

of US$40 million to build the research and development centre,

which officially opened in April 2013. The company’s ongoing

plans to increase its footprint in North America have resulted in

an overall investment of approximately US$100 million in Aiken

County since 2010. The company also maintains facilities and

offices throughout the US, and is in the midst of an international

plant expansion programme.

“This new expansion project will enable us to enhance our

engine development capabilities and will result in the completion

of one of the most advanced diesel engine development facilities

in North America,” said Joerg Klisch, VP of North American

operations at Tognum America Inc.

The research and development centre at the MTU Aiken Plant

features advanced technologies that aid in the design of cleaner,

more efficient and more powerful versions of the MTU Series 2000

and Series 4000 off-highway diesel engines. Construction of the

new engine test cells is scheduled to begin soon. It is anticipated

that the project will be completed by March 2015. n

Sales of Oshkosh’s access equipment segment

increases 15.6 percent

Sales of Oshkosh Corporation’s access equipment segment,

led by JLG, increased 15.6 percent to US$941.5 million

for the third quarter of fiscal 2013 compared to the prior

year third quarter. This increase was principally the result

of higher replacement-driven demand in North America,

the realisation of previously announced price increases

and higher aftermarket parts & service sales, which

more than offset lower sales volume in Australia. In the

third quarter of fiscal 2013, access equipment segment

operating income increased 5.1 percent to US$154.5

million (16.4 percent of sales) compared to prior year

third quarter operating income of US$88.2 million (10.8

percent of sales). The increase in operating income was

primarily the result of higher sales volume, the realisation

of previously announced price increases, as well as product

and process cost reductions. n

n Market Talk

Elkem sets up regional service hub for Southeast Asian market

Headquartered in Norway, Elkem Silicon Materials - a division of

Elkem AS - is one of the world’s pioneers in the development of

microsilica (silica fume). The product has been used extensively

around the globe to produce high performance concrete, providing

benefits in many aspects, including strength, durability and rheology.

The Elkem Microsilica consists of microsilica powder, microsilica

slurry and microwhite (for coloured concrete), which can be applied

in various applications and projects including shotcrete; high strength

and ultra high strength concrete; triple blend with fly ash; low-heat

concrete; tunnels; marine concrete; tall buildings; dams; floors and

pavements; mortars and grouts; and self-compacting concrete.

In 2011, Elkem AS was bought by China National Bluestar Group

Co Ltd from Orkla ASA. Bluestar is an international chemicals and

new materials company based in Beijing; it is 80 percent owned by

the Chinese state-owned company ChemChina, with the remaining

20 percent owned by the US private equity firm Blackstone Group.

The acquisition reaffirms Elkem’s commitment to the Asia Pacific

market, while it allows Bluestar to strengthen its competitiveness in

the silicone industry and broaden its footprint in adjacent markets.

Following this takeover, Elkem established a legal entity in

Singapore in March 2012. In the past, the company managed its

Southeast Asia operations from Orkla’s office in Singapore. The

new Elkem Singapore Materials Pte Ltd will continue to develop

the business segments for well-drilling products, construction,

refractory and polymers. For the construction business unit,

Elkem Singapore is responsible for all countries in Southeast Asia,

Oceania, Korea and Taiwan.

Southeast Asia Construction met up with Erik Bergsmo, Asia

regional director of Elkem Silicon Materials, and Saptak Roy, general

manager of Elkem Singapore, to find out the company’s direction and

progress in Southeast Asia and what it has in store for the region.

1. Elkem Silicon Materials has undergone a significant change with Bluestar

as the new owner. How does the acquisition affect Elkem’s strategies for

the Asia Pacific market?

EB: There is no major shift in Elkem’s main structure or operations.

Bluestar are very supportive of our strategy, they encourage us to

work independently. Through this acquisition, Bluestar will have

access to our management experience and technological know-how.

It is also complementary - we produce silicon for them, and therefore

the acquisition expands Bluestar’s silicone industry chain.

As for Elkem, it means financial stability. Bluestar has a solid

financial capacity and will be able to support our continued growth

globally, especially in Asia Pacific. The company has the best

attributes to take advantage of the potential of Elkem’s technological

strength and competence.

An aerial view of Elkem Silicon Materials’ main facility in Fiskaa,

Kristiansand, Norway. The larger circle is the company’s office in

the Fiskaa industrial park, and the smaller circle is the company’s

Fiskaa plant. Elkem’s main headquarters is located in Oslo.

24

sept/oct 2013

Left: Erik Bergsmo, Asia regional director of Elkem Silicon

Materials.

Right: Saptak Roy, general manager of Elkem Singapore.

Left: Elkem Microsilica was used

for the grade 70 MPa concrete

(cylinder) on the Keangnam Hanoi

Landmark Tower in Vietnam, which

was completed in 2010. The

complex consists of a 72-storey

office tower measuring 350 m and

two 48-storey residence towers. It

is said to be the tallest building in

Vietnam.

Inset: Elkem Microsilica has been

used extensively around the world

to produce high performance

concrete, providing benefits in

many aspects, including strength,

durability and rheology.

2. The establishment of Elkem Singapore also represents the growth of

Elkem in Southeast Asia. Could you share with us the company’s progress

in the region?

EB: Elkem Singapore is a regional service hub, where the company

manages and provides services in logistics distribution, sales and

marketing, finance, applications and projects for the customers in

the Southeast Asia region. It also serves as a major distribution hub,

which ensures more efficient, reliable and faster delivery of goods from

Elkem’s worldwide and Asia plants to these customers at competitive

costs. Products for the Asia Pacific market currently come from our

sources in Thailand, China, Norway and Iceland.

SR: Elkem has been growing significantly in Southeast Asia.

Since we started our Singapore operations in 2005 until last year,

our microsilica sales increased by around 15 percent per annum.

Numerous key developments in the region have used high performance

concrete containing Elkem Microsilica. For high-rise buildings, we’ve

supplied to the Comfort Towers in Tokyo (Japan), ICC building and

City Plaza in Hongkong, Keangnam Hanoi Landmark Tower in Hanoi

(Vietnam), and The Sail @ Marina Bay in Singapore, to name a few.

In infrastructure projects, like tunnels and bridges, our microsilica

have been applied to the Penang Bridge in Malaysia, Marina Coastal

Expressway (MCE) in Singapore, and most of Singapore’s underground

MRT lines. Elkem Microsilica is also extensively used in shotcreting

mines in Indonesia and Australia.

Other noteworthy projects in Asia, such as the Tsing Ma Bridge in

Hong Kong (completed in 1997) and the Lotte World Tower in Korea

(under construction), have also chosen Elkem Microsilica. Overall, we

have about 40 percent market share in Southeast Asia and Oceania.

n Market Talk

3. What sort of challenges are you facing in Southeast Asia?

EB: The initial cost of high performance concrete is still not favoured

by many, as it is higher than that of conventional concrete. However,

high performance concrete works out to be economical in the end,

because it enhances the service life of the structure (up to 100 years,

depending on the concrete specification) and the structure suffers

less damage, which would reduce overall costs.

Another challenge is to do with maintaining customers’ perception

of microsilica. There are companies that produce microsilica with

poor quality; this would affect the image of the product. It could also

harm our reputation, as the name ‘microsilica’ is highly associated

with Elkem. The bottom line is, we want customers to use the right

microsilica as per ASTM or EN standard specifications.

SR: To address these issues, education is our key marketing tool.

We regularly conduct seminars and training programmes in the

region to inform customers on the benefits of microsilica and the

importance of choosing the right one. We also work closely with

consultants, architects and owners (developers). Our strategy focuses

on growing in the market we’re in. We also intend to venture out into

new upcoming developing countries such as Myanmar, and look into

new areas of application.

4. Did the global financial crisis in 2008 and China slowdown last year

have a considerable impact on Elkem?

EB: Not when it comes to infrastructure projects, such as bridges

and roads. They have not slowed down much in Asia Pacific, because

most of them are government funded. Since the global financial

crisis, we notice there has been a shift of priority from housing to

infrastructure projects worldwide.

Elkem Singapore Materials Pte Ltd was set up in March 2012,

serving as a regional service hub. Mr Roy is seen here with the

other staff members of the company.

5. Infrastructure projects in Southeast Asia are expected to rise within

the next years. Do you plan to invest more in the market to keep pace

with this development?

EB: Elkem plans to develop another silicon manufacturing facility

for the global market, in addition to the company’s existing sources

in Thailand and China. We still don’t know where but Southeast Asia

is one of the main locations we are looking into. This plan is hoped

to be realised in the next five years. We will also keep strengthening

ourselves in countries like Indonesia, Vietnam, Laos and Cambodia.

Hopefully Myanmar will follow after that. n

TIGER is the most innovative and versatile manufacturer of concrete products machinery in the world.

TIGER produces the most complete and varied product line of any manufacturer in the world today;

with multiple series of concrete products manufacturing machines and their corresponding handling

equipment for every industry application conceivable. No other supplier of this type of machinery can

claim the variety of equipment, its versatility and its quality. Since our inception 63 years ago we strive to

design and manufacture high quality innovative and unique equipment, especially designed to meet our

customer’s specific needs. TIGER is the leading “custom” manufacturer in the world.

At our company we say to our customers and prospective new customers:

“Discuss your project with TIGER.”

No project is too small nor too big.

TIGER MACHINE CO., LTD. /TIGER INTERNATIONAL, INC. 2327 Abe, Ochicai-cho, Takahashi-shi, Okayama 716-0061 JAPAN

PHONE: +81-866-22-8812 FAX: +81-866-22-9320 e-mail: TIGER@TIGER-MACHINE.com Website: www.tigermachine.com

25

sept/oct 2013

n IPAF Highlights

IPAF’s first MEWPs for Managers course held in Singapore

The inaugural IPAF’s MEWPs for Managers

course was successfully held in Singapore in

April 2013. The course was led by IPAF’s

technical officer Chris Wraith at the Galmon

facility. Nine attendees were successfully

trained, including representatives from the

Singapore’s Ministry of Manpower (MOM),

Singapore Institution of Safety Officers

(SISO), the Singapore’s Access & Scaffold

Industry Association (ASIA), Lighthouse

Club Singapore, Bovis Lend Lease and

MEWP rental companies.

MEWPs for Managers is a one-day

course for those who plan, supervise and

manage the use of mobile elevating work

platforms (MEWPs) in the workplace. The

course does not qualify attendees to operate

MEWPs. Attendees receive instruction and

training to prepare for and safely coordinate

the use of MEWPs on site. Attendees who

successfully pass the written test at the

end of the course receive a certificate of

completion. More details are at www.ipaf.

org/m4m. n

The inaugural IPAF’s MEWPs for Managers

course took place at the Galmon facility.

SISO and IPAF hold joint forum on MEWP safety

The first forum on MEWP safety jointly

organised by IPAF and the Singapore

Institution of Safety Officers (SISO) was held

in April 2013. The theme was ‘Can MEWPs

provide a safer way of working at height?’

and the guest of honour was Go Heng Huat,

deputy director for major hazard installation,

OSH specialist department, occupational

safety and health division, Singapore’s

Ministry of Manpower (MOM). Speakers

included Desmond Ong, CEO of Galmon;

Nick Snowden, president of Snorkel Asia

and director of supply chain for Snorkel; and

Gilbert Decruz, IPAF-approved instructor

from BS Technology. n

Some of the attendees and speakers at the

IPAF-SISO’s first forum on MEWP safety.

MEWP delivery drivers at risk

Target your delivery drivers for training and

safety initiatives on the safe and effective use

of MEWPs. Watch out for slips/trips/falls at

the same level and pay attention to manual

handling when working at height. These

were some of the initial findings following

the commitment by IPAF rental company

members in the UK to report any known

MEWP accidents involving their staff via

the IPAF accident database.

A total of 303 MEWP-related incidents

were reported by IPAF UK rental company

members involving their employees and

those of their customers where they have

been made aware of incidents, from the time

the project was voluntary in January 2012

until the end of April 2013.

Of these incidents, 46.2 percent (140)

resulted in injury, 43.2 percent (131)

resulted in damage, and 10.6 percent (32)

were near misses.

Loading and unloading of MEWPs

is potentially one of the most dangerous

activities, and is an area that IPAF is focusing

on. About a third of the incidents involved

drivers (34.3 percent, 104). Industry sources

estimate that there are approximately one

million movements of MEWPs (delivery and

collection) by road every year in the UK.

Other incidents involved engineers (25.1

percent, 76), customers (22.4 percent, 68)

and operators (18.2 percent, 55).

Closer analysis of the 140 incidents

resulting in injury reveals certain patterns.

The main causes of injuries were slips/trips/

falls at the same level (23.6 percent, 33),

manual handling (16.4 percent, 23) and

use of hand tools (15 percent, 21). Further

down the list were stranded in equipment (10

percent, 14), fall from height (7.1 percent,

10), walked/bumped into equipment (6.4

percent, 9) and injury while using the upper

The loading and unloading of MEWPs is

a potentially risky activity.

controls of a scissor lift while walking beside

the machine, sometimes referred to as dog

leading (6.4 percent, 9).

To register and to report an accident

involving a MEWP or an MCWP (mast

climbing work platform), go to www.ipaf.

org/accident. n

IPAF Singapore members:

Access & Scaffold Industry Association (Affiliated Association)

Lighthouse Club Singapore (Affiliated Association)

Aly Energy Singapore Pte Ltd

APPS Machinery Pte Ltd

Aver Asia (S) Pte Ltd

A&G Equipment Pte Ltd

BMS Environmental Services Pte Ltd

BS Technology Pte Ltd

Bestlink Machinery Pte Ltd

26

sept/oct 2013

CDP Access Asia Pte Ltd

Galmon (S) Pte Ltd

Genfor Lease Pte Ltd

Haulotte Singapore Pte Ltd

JH Equipment & Services Pte Ltd

JP Nelson Equipment Pte Ltd

LGS Prospect Resources Pte Ltd

LH Construction and Machinery Leasing Pte Ltd

Manitou Asia Pte Ltd

Modern (Singapore) Access & Equipment Pte Ltd

Sin Heng Aerial Lifts Pte Ltd

Spiderlift Asia Pte Ltd

ST Aerospace Ltd

Tat Hong Training Services Pte Ltd

Terex (Singapore) Pte Ltd

Trust Equipment Services Pte Ltd

n IPAF Highlights

IPAF appoints UAE representative

Get solid data to back business

decisions

IPAF has appointed Jason Woods as its new

representative for the United Arab Emirates

(UAE), reflecting the Federation’s steadily

growing presence in the Middle East where

IPAF currently has 15 members across

Jordan, Qatar, Saudi Arabia and the UAE.

Mr Woods has over 20 years’ experience

in the powered access industry. He started in

sales and rental and was based in the UK from

1990 to 2002, holding positions with Building

Services Plant Hire, Hewden Stuart and Euro

Towers. He has been involved in work at

height training since 1996 and is a certified

IPAF instructor and a PASMA instructor. He

ran his own training and sales business from

2008 and 2011, and was also vice chairman

of the PASMA training committee. In 2011,

Mr Woods joined Instant Access in the Middle

East as training manager, and has since

focused on promoting safety and training

standards, and developing the mobile tower

and powered access business in the Gulf

region. He is based in Dubai.

“My new duties with IPAF will include

working alongside existing and new members

How many platforms are there in the

worldwide rental fleet? How much of

the US fleet is Tier 4 compliant? Get the

answers to these questions and more in the

IPAF US Powered Access Rental Market

Report 2013 and the IPAF European

Powered Access Rental Market Report

2013, now ready to order.

These reports are the definitive guide

to the powered access rental markets in

the US and Europe. Useful facts and

figures give insight into the industry

and help managers plan for future

investments.

The US report includes Canada and

Brazil. The European report includes

seven individual country/regional sections

- France, Germany, Italy, the Netherlands,

Nordic/Scandinavian countries (covering

Denmark, Finland, Norway and Sweden),

Spain and the UK.

View the list of contents and order

the 2013 reports at www.ipaf.org/reports.

Some older reports are now available for

free download. n

27

sept/oct 2013

Jason Woods (centre) is seen here at a

meeting with IPAF CEO Tim Whiteman

(left) and Dr Ali Salem Al Qaiwani,

director of occupational health and

safety, UAE Ministry of Labour.

and training centres to give full guidance,

advice and support,” said Mr Woods. “My

key aim is to boost the safe use of powered

access and to grow the number of IPAF PAL

Cards (Powered Access Licences) within

the GCC, working with the UAE Ministry

of Labour.” [The Gulf Cooperation Council

(GCC) is the political and economic alliance

of six Middle East countries including

Bahrain, Kuwait, Oman, Qatar, Saudi Arabia

and the UAE]. n

Enquiry: uae@ipaf.org

n Calendar of Events

Date

Events in Asia

Organiser & Contact

9 to 15 Sept 2013

World Engineers Summit

Sands Expo and Convention Centre

Marina Bay Sands

Singapore

The Institution of Engineers, Singapore

Tel: +65 6588 3832

Email: wes2013@reedexpo.com.sg

Website: www.wes2013.org

10 to 12 Sept 2013

Cambuild 2013

Diamond Island Convention & Exhibition Centre

Phnom Penh

Cambodia

AMB Events (Cambodia) Pte Ltd

Tel: +855 23 217 290, Fax: +855 23 210 806

Email: richard@ambexpo.com

Website: expocambodia.com

19 to 21 Sept 2013

Constech 2013

IMPACT Exhibition Centre

Bangkok

Thailand

IMPACT Exhibition Management Co Ltd

Tel: +66 2833 5208, Fax: +66 2833 5127-9

Email: pasinc@impact.co.th

Website: www.thailandconstech.com

9 to 12 Oct 2013

OneBuild 2013

Putra World Trade Centre

Kuala Lumpur

Malaysia

One International Exhibition Sdn Bhd

Tel: +603 8943 7488, Fax: +603 8943 7599

Email: info@oneinternational.com.my

Website: www.oneinternational.com.my/onebuild

15 to 18 Oct 2013

BICES 2013

Beijing Jiuhua International Exhibition Centre

Beijing

China

China Construction Machinery Co Ltd

Tel: +86 10 5222 0922, Fax: +86 10 5118 3612

Email: info@e-bices.org

Website: www.e-bices.org

24 to 26 Oct 2013

Concrete Show Southeast Asia 2013

Jakarta International Expo, Kemayoran

Jakarta

Indonesia

UBM

Tel: +44 20 7560 4225

Email: matt.wilson@ubm.com

Website: www.concreteshowseasia.com

6 to 9 Nov 2013

Philconstruct 2013

SMX Convention Centre and World Trade Centre

Metro Manila

The Philippines

Global-Link Exhibitions Specialist Inc

Tel: +632 750 8588-92, Fax: +632 750 8585

Email: philconstruct@globallinkmp.com

Website: www.globallinkmp.com

20 to 24 Nov 2013

Excon 2013

Bangalore International Exhibition Centre

Bangalore

India

Confederation of Indian Industry

Tel: +91 44 42 444 555, Fax: +91 44 42 444 510

Email: excon@cii.in

Website: www.excon.in

26 to 28 Nov 2013

Myanbuild 2013

Tatmadaw Hall

Yangon

Myanmar

AMB Events Sdn Bhd

Tel: +603 4041 9889, Fax: +603 2770 5301

Email: myanbuild@ambexpo.com

Website: www.myanbuild.net

7 to 9 May 2014

OS+H Asia 2014

Suntec Singapore

Singapore

Messe Duesseldorf Asia Pte Ltd

Tel: +65 6332 9620, Fax: +65 6337 4633

Email: osha@mda.com.sg

Website: www.osha-singapore.com

25 to 28 Nov 2014

bauma China 2014

Shanghai New International Expo Centre

Shanghai

China

Messe München International

Tel: +49 89 949 20251, Fax: +49 89 949 20259

Email: info@bauma-china.com

Website: www.bauma-china.com

15 to 18 Dec 2014

bC India 2014

India Expo Centre

Greater Noida, Delhi

India

Messe München International

Tel: +49 89 949 20255, Fax: +49 89 949 20259

Website: www.bcindia.com

Date

18 to 21 Sept 2013

28

Events outside Asia

bauma Africa 2013

Gallagher Convention Centre, Johannesburg

Gauteng

South Africa

sept/oct 2013

Organiser & Contact

Messe München International

Tel: +49 89 949 11478, Fax: +49 89 949 11479

Email: info@bauma-africa.com

Website: www.bauma-africa.com

n Calendar of Events

25 to 28 Nov 2013

PMV Live at The Big 5

Dubai World Trade Centre

Dubai

UAE

DMG Events

Tel: +971 4 4380 355, Fax: +971 4 4380 356

Email: joseffwilliams@dmgeventsme.com

Website: www.pmvlive.com

14 to 16 Jan 2014

Intermat Middle East 2014

Abu Dhabi National Exhibition Centre

Abu Dhabi

UAE

Comexposium & Clarion Events Middle East

Tel: +33 1 7677 1208

Email: asmaa.cherraf@comexposium.com

Website: www.intermatme.com

21 to 24 Jan 2014

World of Concrete 2014

Las Vegas Convention Centre

Las Vegas, Nevada

USA

Hanley Wood Exhibitions

Tel: +1 972 536 6300, Fax: +1 972 536 6301

Email: contactus@worldofconcrete.com

Website: www.worldofconcrete.com

4 to 8 Mar 2014

ConExpo-Con/Agg 2014

Las Vegas Convention Centre

Las Vegas, Nevada

USA

Association of Equipment Manufacturers

Tel: +1 414 298 4167, Fax: +1 414 272 2672

Email: international@conexpoconagg.com

Website: www.conexpoconagg.com

1 to 5 Apr 2014

Smopyc 2014

Zaragoza Exhibition Centre

Zaragoza

Spain

Feria de Zaragoza

Tel: +34 976 764 700, Fax: +34 976 330 649

Email: comunicacion@feriazaragoza.es

Website: www.smopyc.com

8 to 11 May 2014

Samoter 2014

Verona Exhibition Centre

Verona

Italy

Veronafiere

Tel: +39 045 8298111, Fax: +39 045 8298288

Email: info@veronafiere.it

Website: www.samoter.com

YCK TOOLS PTE LTD

CONSTRUCTION DIAMOND PRODUCTS

Diamond Segment

Manufacturer in

Singapore

Your one-stop-destination

for supreme quality

diamond cutting tools

and diamond blade

products at the most

competitive prices.

Newly Patented Epoxy

Injector - SealTech!

10, Ubi Crescent, #06-06, Ubi Techpark, Lobby A, Singapore 408564

t: 65-6748 2532 f: 65-6748 2547 w: www.ycktools.asia e: ycktools@gmail.com

29

sept/oct 2013

n Industry Events

Entries open for 4th International Holcim Awards

The Holcim Awards is one of the most significant competitions in

its field in terms of reputation and international scope. The fourth

cycle of the competition offering a total of US$2 million in prize

money is now open for entries, which must be submitted online by

24 March 2014.

The Holcim Awards (main category) is open to architects,

planners, engineers, project owners, builders and construction firms

that showcase sustainable responses to technological, environmental,

socioeconomic and cultural issues with contemporary building

and construction. Projects must have reached an advanced stage

of design, have a high probability of execution, and may not have

started construction before 1 July 2013.

The competition also seeks visionary projects and bold ideas for

the ‘next generation’ (young professionals and students category). All

authors must be aged between 18 and 30 years of age (date of birth

between 2 July 1982 and 24 March 1996), and the project may not

have started construction before 1 July 2013.

Organised by the Swiss-based Holcim Foundation for Sustainable

Construction, the competition is conducted in parallel in five regions

of the world during 2013-2014 followed by a global phase in 2015.

Regional winners will be announced at Holcim Awards ceremonies

in late 2014 in Moscow (for region Europe), Toronto (North America),

Medellín (Latin America), Beirut (Africa Middle East) and Jakarta

(Asia Pacific).

Taking part in the competition has been streamlined by an

interactive online entry form. Entries must be made in English using the

web-based form to provide information on authors, a project summary

and response to the ‘target issues’ for sustainable construction,

technical details, as well as project images or illustrations.

Independent jury panels of experts evaluate all entries against the

five ‘target issues’ for sustainable construction, which cover economic,

social and environmental performance as well as contextual/aesthetic

impact, and innovation/transferability. The juries are headed by JeanPhilippe Vassal (for region Europe), Toshiko Mori (North America),

Bruno Stagno (Latin America), Howayda Al-Harithy (Africa Middle

East) and Rahul Mehrotra (Asia Pacific).

The Holcim Awards is conducted in partnership with some of

the world’s leading technical universities that host the jury meetings.

The Swiss Federal Institute of Technology (ETH Zurich) leads the

Technical Competence Centre of the Holcim Foundation. Other

partner universities include Massachusetts Institute of Technology

(USA), Tongji University (China), Universidade de São Paulo

(Brazil), University of the Witwatersrand (South Africa), Universidad

Iberoamericana (Mexico), Ecole Supérieure d’Architecture de

Casablanca (Morocco), Indian Institute of Technology (IIT Bombay),

American University of Beirut (Lebanon), Tsinghua University

(China) and University of Melbourne (Australia). n

Website: www.holcimawards.org

Conexpo-Con/Agg 2014 tapped for international buyer programme

Conexpo-Con/Agg has once again earned international buyer programme

(IBP) status from the US Department of Commerce (DOC). The IBP

helps qualified international buyers, representatives and distributors

attend the show more easily and connect with export-minded exhibitors

looking to boost sales and establish global connections.

The next Conexpo-Con/Agg will be held from 4 to 8 March

2014 at the Las Vegas Convention Centre in Las Vegas, USA. The

co-located IFPE 2014 exposition will also offer its attendees the IBP

services and benefits.

Under the IBP, the US government promotes shows through its

worldwide network of embassies and consulates. It also recruits

official trade delegations to attend and assists delegations with travel,

housing and registration. The IBP also provides exhibitors with

practical, hands-on assistance such as export counselling, market

analysis and matchmaking services.

Conexpo-Con/Agg and IFPE 2014 will produce a special show

export opportunities guide (print and electronic) to help attendees

locate exhibitors interested in doing business globally through

export sales, agency relationships, distributor investment and joint

ventures. The guide will be available at the shows and distributed to

DOC international posts. An on-site international trade centre (ITC),

staffed by experienced DOC trade specialists and show management

staff, will operate during the run of the shows with multi-lingual

interpreters fluent in several world languages, a message centre,

phone/fax/e-mail access and private meeting rooms.

Conexpo-Con/Agg has won recognition as the most global of all

shows in North America, with international attendance of 24 percent

in 2011, from more than 150 countries. For 2014, show management

will expand and refine its already-robust international marketing

outreach, especially to emerging markets.

Show management will establish more matchmaking

opportunities and country roundtables to bring together buyers

30

sept/oct 2013

and sellers. Show management will also work closely with incountry DOC commercial service officers and exhibitors’ regional

representatives to pinpoint specific needs and actions to ensure

optimum use of IBP services. n

Website: www.conexpoconagg.com

BEI Asia Awards launched in Singapore

Creative Group Pte Ltd has launched the BEI Asia Awards,

believed to be the first award for enterprises in the built

environment industry (BEI) in Singapore. It aims to celebrate the

outstanding performances of enterprises in developing successful

businesses and acknowledge their contributions towards the

development of people, society and the environment; thereby

driving sustainable growth in Singapore and beyond.

Under the banner of ‘Recognising the Finest Enterprises in

the Built Environment Industry’, the BEI Asia Awards 2013 will

accept nominations from all sectors of the built environment

industry including building, architectural & engineering and

civil & landscape contractors, manufacturers, designers,