RUSTIBUS® 20 AIR OPERATION MANUAL

advertisement

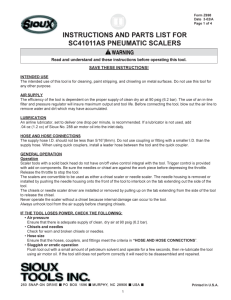

OPERATION MANUAL 020-3000 RUSTIBUS® 20 AIR Needle/Chisel Scaler Machine may vary from pictures Genuine Rustibus® parts only! HELPFUL IDENTIFIERS In addition to information on installation and operation, this instruction manual may contain WARNINGS and CAUTIONS pertaining to user safety, and NOTES on important, useful operating guidelines. A WARNING indicates a potentially hazardous situation, which if not avoided, could result in death or serious injury. A CAUTION indicates a potentially hazardous situation, which, if not avoided may result in minor or major injury. A NOTE is to alert the operator to important operating information. ANSI Z535.5-1997 Definitions IMPORTANT The safeguards and instructions in this manual cannot cover all possible conditions and situations, which may occur. As we cannot control the correct mounting, usage and utilization of this product, we can not be responsible or liable for any injuries, damages, losses or costs, which result from using our products in any way. Do not attempt to operate this tool until you have read and understood all safety precautions and instructions listed in this manual. Incorrect operation of this unit can cause serious injury. Maintain your company’s fire and safety procedures while operating this tool. Machine may vary from pictures Genuine Rustibus® parts only! WARNING De-scaling equipment may cause serious injury – protect hands, feet, eyes and hearing. Debris from scraping action may be scattered. Rustibus® de-scaling Tool may produce sparks. Respiratory protection should be considered depending on material being removed. Before starting Rustibus® de-scaling Tool, ensure that all fixing screws, bolts, clamps, fittings, chain head and locking devices are mounted correctly and securely tensioned. For more information, check the maintenance section of this manual. Never attempt to de-scale areas when its mechanical integrity is in doubt, according to ASME/API specifications or other applicable codes and standards. CAUTION Never install, remove or perform any maintenance on the Rustibus® de-scaling Tool when the air power supply is connected. Always keep both hands on handles when operating the Rustibus® de-scaling Tool. Never use the Rustibus® de-scaling Tool in explosive areas due to potential to produce sparks. Never operate the Rustibus® de-scaling Tool while wearing loose hanging chains, hanging ID/security badges or garments that may be caught in the rotating parts. On vertical sections, work with the Rustibus® de-scaling Tool between knee and shoulder height to avoid strain. If used over prolonged periods for vertical work, lifting assistance should be considered to prevent accidents, fatigue etc. Rustibus® de-scaling Tool should be properly maintained and stored when not in use to avoid damage to parts. Machine may vary from pictures Genuine Rustibus® parts only! SAFETY CONSIDERATIONS • When wearing gloves and operating the tool, always be sure that the gloves will not prevent the trigger from being released! • Wear safety shoes, hardhat, safety goggles, hearing protection, gloves, dust mask and any other appropriate protective clothing while using this tool! • Keep hands and fingers away from the trigger until you intend to operate the tool! • Never rest the tool, needles / chisel on your foot! • Never start the tool when it is lying on the ground! • Never operate the tool with damaged or broken parts! • The operator must keep body and limbs clear of the Needles / Chisel. Should the attachment break the tool may surge forward suddenly! Maintain a balanced and firm body stance and do not over reach. • Air powered tools can vibrate when in use. Vibration and repetitive motions for sustained periods may be harmful to your arms and hands. Stop using any tool if you feel discomfort. • This tool is not designed for use in explosive atmospheres! • This tool is not insulated against electric shock! • Know what is beneath the material being worked on. Be alert for hidden gas, water, and electric lines! • Take care when setting the tool down to prevent accidental operation! • The Needles/ chisel may continue to impact momentarily after trigger is released! • Do not clean or flush this tool with Diesel fuel or other flammable fluids, as this could ignite in the tool when the tool is operated! • When cleaning the tool use only proper cleaning solvents that meet current health and safety standards! • Compressed air is Dangerous! Never point an air hose at yourself or fellow workers and never blow clothes free of dust with compressed air! • Make sure all hose connections are in good condition and tight. A loose or damaged air hose may not only leak but also can become detached from the tool, whip around and injure not only the operator but also others in the area. To prevent injure in the event of a broken airline, attach safety cables to all hoses! • You should never disconnect a pressurized airline. Always turn off the air supply and bleed the tool for air before you disconnect an airline! • Do not fool around with this tool or compressed air! Distraction can cause accidents and injury. • READ, UNDERSTAND AND FOLLOW ALL SAFETY WARNINGS! Genuine Rustibus® parts only! Machine may vary from pictures PLEASE READ THE WARNINGS BEFORE OPERATION WARNINGS: When connecting, changing, or repairing the Rustibus® needle scaler, the air supply MUST ALWAYS be disconnected. IMPORTANT: • It is recommended to connect the Rustibus® needle scaler to a filtered air, lubricator and regulator system. (Rustibus® Air Pro.) • Fill some drops of Air-tool oil into the air motor once a day and after use. • Ear & face protection should be used for your own safety. It is recommended to use a safety screen when operating the Rustibus® 20. Wear protective gloves and safety shoes. WORKING SAFELY WITH THIS MACHINE IS POSSIBLE ONLY WHEN THE OPERATING AND SAFETY INFORMATION ARE READ COMPLETELY AND THE INSTRUCTIONS CONTAINED THEREIN ARE STRICTLY FOLLOWED. IN ADDITION, THE GENERAL SAFETY INSTRUCTIONS IN THE ENCLOSED BOOKLET MUST BE FOLLOWED. BEFORE USING FOR THE FIRST TIME, TAKE A LOOK AT THE MACHINE TO UNDERSTAND THE PRACTICAL WORKINGS OF IT. Machine may vary from pictures Genuine Rustibus® parts only! INSTALLATION AND SETUP RUSTIBUS® 20 AIR NEEDLE/CHISEL SCALER Before you begin. Step 1: VERIFY THE COMPLETENESS OF YOUR RUSTIBUS® 20 NEEDLE SCALER. • Check that all components are attached properly and in a proper / safe working order. (Check that there are no loose wires, guards or parts on the machine) Step 2: ASSOCIATED EQUIPMENT. • Ensure that you have available required Air Pressure & volume. (12CFM /340lts min // 6-8 bar/ 87-116 psi.) • Ensure that you have available Air tool oil to lubricate the machine. • It is recommended that you connect the Rustibus® 20 needle scaler to a filtered air, lubricator and supply regulator. (Rustibus® Air Pro.) Step 3: BEFORE COMMENCING THE OPERATION. • Locate the section to be cleaned / de-scaled and determine if the area needs to be cleaned. Excessive grease, dirt and other hazardous material may need to be cleaned from the surface area before operation of the Rustibus® 20 machine. • Ensure needles are properly connected to motor • Confirm the correct air pressure before connecting hose supply. • The Needles deliver 4600 BPM, show outmost care when connecting Air hose and when operating machine. ALWAYS THINK SAFETY FIRST! • Connect your machine to its power source. • Make sure the air hose is properly connected and safely located for your operation. Apply safety wires on hose. • Start and Stop the machine and check that action is correct according to machine. Step 4: OPERATION OF RUSTIBUS® 20 MACHINE. • For the best results from your Rustibus® machine you should run the machine over the area until appropriate result is achieved • Your machine will last longer if operated with care. Step 5: MAINTENANCE OF RUSTIBUS® MACHINE. • ALWAYS stop the machine and disconnect it from its power source before carrying out any maintenance on the machine. • To maintain your needle scaler in a good working order, the air-tool should be lubricated 3-4 times a day during operation using 3cc of air tool oil, if an airline lubricator (Rustibus® Air Pro.) isn’t used. • When the machine is due for storage, please lubricate the air-tool by using 3cc of air tool oil. Machine may vary from pictures Genuine Rustibus® parts only! SET UP TOOL APPLICATIONS • De-rusting and cleaning metals. • Removing paint, rust and dirt. • Peening of welded joints. • Cleaning castings. • Cleaning welding slag. • Removing barnacles. Rustibus® 20 Needle scaler is pneumatically driven and requires 12 CFM / 340 litres per minute/6-8 Bar 87-116 psi. The machine is easy to operate and leaves the surface clean to St 3+++ (SSPC-SP11+++). The machine is adjusted to a proper BPM when it leaves the Rustibus® factory. If maintenance is done on the air motor, make sure the BPM is not exceeding 4600 BPM. Always disconnect the air supply before dismantling the Rustibus® 20 machine. NEEDLE / CHISEL INSTALLATION Always close the air supply to your Rustibus® 20 and disconnect the airline before you install, remove or adjust the needles / chisel or before carrying out any maintenance. Installing the needles into your Rustibus® 20 could not be easier and is done in a few simple steps. 1. Lift up the lever of the Retainer on the side of the Rustibus® 20. 2. Slide in / pull out the Needle Driver into / from the Rustibus® 20 making sure the cut--out notch in the Needle Driver is facing upwards. 3. You can then release the Lever on the side of the Rustibus® 20. The lever on the side of the Rustibus® 20 is connected to the Retainer. This in turn ‘Retains’ holds the Needle Driver / Chisel is place. The Retainer rests in the cut-out notch of the Needle Driver / Chisel when they are installed in the Rustibus® 20. On the side of the Needle Tube there is a cut –out section with a series of notches. The cut—out on the Needle Tube is meant to fit over the lever of the Retainer. The lever then fits into the first of these notches and the following notches allow you to adjust the length of the needles as they ware down during use. Machine may vary from pictures Genuine Rustibus® parts only! RUSTIBUS® 20 - DISASSEMBLY 1. Disconnect your air supply and remove all attachments. THE NEEDLE ATTACHMENT 2. Holding the Needle Tube (020-779) in one hand and the Backhead in the other. Push and twist the Needle Tube until the lever of the Retainer (020-956) is free from the Needle Tube. 3. Slide the internal parts of the Needle attachment out of the Needle Tube. 4. Pull the tab on the Retainer up on the tool and remove the Needle Driver (020-045) THE SCALER BODY 5. Using a vice, clamp the Rustibus® 20 in an upright / vertical position with the front of the tool, facing upward. Clamp using the flats on the Backhead. 6. Using a pair of internal expanding pliers, expand the Retainer clip. 7. Remove both the Retainer Buffer (020-527) and the Retainer (020-956) 8. You should now remove the Rustibus® 20 from the vice and clamp the Barrel assembly in the vice in a downward facing position, Making sure you clamp the tool using the flats on the side of the Barrel. 9. Using a wrench you must then loosen the Backhead lock ring. This will allow you to remove the entire Backhead Assembly. 10. Removing the Barrel unit from the vice you are now able to slide the Valve assembly and Plunger (020-373) from the Barrel. 11. Should you wish to check the Throttle valve, remove the Throttle valve cap (020-207 and Cap Gasket (020-636). Lift out the Valve Spring (020-078) and Valve (020-782). Replace the ‘O’ ring if worn or damaged. Machine may vary from pictures Genuine Rustibus® parts only! RUSTIBUS® 20 - ASSEMBLY 1. When assembling your Rustibus® 20 make sure that all parts are clean and free of any abrasives. THE SCALER BODY 2. 3. 4. 5. 6. 7. 8. 9. 10. Support the Valve Block (020-508) under an arbor press. Take both V.B. Dowel pins (020-126) and fit them into the ‘blind holes’ in the Valve Block until they are fully in, they should press against a should at the bottom of the holes. The Flutter Valve (020-196) can then be placed in the recessed centre of the Valve Block. You are now able to fit the Valve Block Button (020-173) on to the Valve Assembly. Make sure the Blind holes of the V.B. Button (This are the holes that are parallel to the axis of the part) line up with the Dowel pins. With the Valve Block facing upwards, place the Valve assembly on a small round support that has a smaller diameter than the inside of the Barrel. You can now place the Plunger (020-373) on to the Valve Block. The protrusion on one end of the Plunger should now also be facing upwards. The Cylinder Sleeve can now be set in place over the plunger. This is then followed by the Tool Nose (020-363), do not forget to set in place the Tool Nose Key. (020-801) The Barrel (020-343) can now be slipped over the entire assembly, until the assembly sits firmly in inside the Barrel. With a firm grip on the support fixture and Barrel, turn the whole unit over. (If you assemble the units in this way it will ensure that the Value assembly does not separate during installation. With the front of the tool in a downward facing position, clamp the Barrel unit vertically in a vice. Using the flat clamp points. Remembering to fit the Backhead Positioning Spacer (020-947), screw the Backhead Lock Ring on to the (020-882) Backhead Assembly (020-851). (Make sure that the taper of the lock ring is facing the front of the front of the Backhead Assembly. The Backhead Assembly can now be screwed on to the back of the Barrel Assembly. Use a wrench to tighten the Backhead Assembly. Screw down and tighten the lock ring against the Barrel. Turning the whole unit up side down in the vice so that the front of the unit now faces upwards, place the Retainer (020-956) and Retainer Buffer (020-527), in the cut out section at the front end of the Barrel unit. You are now able to expand the Retainer Clip (020-554) and place in position over the Retainer Buffer and Retainer. THE NEEDLE ATTACHMENT 11. Begin by sliding the correct number of needles into the Needle Holder (020-046). The large ends of the Needles will fit into the recessed holes in the back of Needle Holder. Slide the Needle Spring (020-044) over the needles and up to the needle holder. 12. Place the needle unit into the rear of the Needle Tube (020-779). 13. Lift the lever of the Retainer (020-956) up on the Rustibus® 20 and then slide in to place the Needle Driver (020-045). 14. Holding the Needle Tube unit in one hand and the Backhead Unit in the other, push and twist the Needle Tube unit until the lever of the Retainer is set in a notch on the Needle Tube. Machine may vary from pictures Genuine Rustibus® parts only! TOOL SPECIFICATION WEIGHT: 7 lbs / 3.1kg LENGTH W NEEDLES OR CHISEL: 17 in w 5” Needles /43cm w/13 cm Needles CFM CONSUMED: 12 cfm / 340 Cu.Lts/min WORKING PRESSURE: 6-8 BAR / 87-116 psi BORE: 1” / 2.54cm STROKE: 1 1/8” / 2.85cm BPM: 4600 INLET: 1/4” NPT / 0.635 cm MIN. HOSE SIZE: 3/8” / 0.375 cm WARNING: When connecting, changing, or repairing the Rustibus® Needle scaler, the air supply MUST ALWAYS be disconnected. Please note the following: • For best maintenance of the air-tool, please lubricate 3-4 times a day during operation. • When machine is due for storage, please lubricate air-tool by using 3cc of air tool oil. Genuine Rustibus® parts only! Machine may vary from pictures SPARE PART LIST – RUSTIBUS® 20 AIR NEEDLE/CHISEL SCALER PARTS TO RUSTIBUS® 20 020-024 NEEDLES 3,2MM x 180MM (100 PCS) 020-044 NEEDLE SPRING 020-045 NEEDLE DRIVER 020-046-2MM NEEDLE HOLDER - 2MM (For 55 2MM Needles) 020-046-3MM NEEDLE HOLDER - 3MM (For 19 3MM Needles) 020-046-4MM NEEDLE HOLDER - 4MM (For 14 4MM Needles) 020-057 NEEDLES 2MM x 180MM (100 PCS) 020-058 NEEDLES 3MM x 180MM (100 PCS) 020-059 NEEDLES 4MM x 180MM (100 PCS) 020-078 THROTTLE VALVE SPRING 020-109 VALVE BLOCK ASSEMBLY 020-126 VALVE BLOCK DOWEL PIN 020-173 VALVE BLOCK BUTTON 020-196 FLUTTER VALVE 020-207 THROTTLE VALVE CAP 020-302 THROTTLE VALVE “O” RING 020-313 BARREL 020-373 PLUNGER 020-508 VALVE BLOCK 020-527 RETAINER BUFFER 020-554 RETAINER CLIP 020-632 FLAT CHISEL 20MM X 180MM 020-633 WIDE CHISEL 35MM X 180MM 020-634 ANGLE CHISEL 35MM X 180MM 020-636 THROTTLE VALVE CAP GASKET 020-700 CYLINDER SLEEVE 020-735 BAREL ASSEMBLY 020-779 ROUND NEEDLE TUBE 020-780 THROTTLE LEVER 020-781 BARE LEVER TYPE BACKHEAD 020-782 THROTTLE VALVE INCL. “O” RING 020-801 TOOL NOSE KEY 020-848 THROTTLE LEVER PIN 020-851 LEVER THROTTLE BACKHEAD ASSEMBLY 020-882 BACKHEAD LOCK RING 020-947 BACKHEAD POSITIONING SPACER 020-956 RETAINER 020-963 TOOL NOSE Machine may vary from pictures Genuine Rustibus® parts only! SCENARIOS POTENTIAL REASONS SOLUTIONS part list – Rustibus® 2000-3000. - Spare Dirt, foreign materials 1)Check that there are no restrictions on - Internal corrosion / rust the hose. - Misalignment 2) Check the PSI meter on the Air Lubriction - Poor lubrication System for adequate pressure. - Jammed machine 3) Check air supply. 4) Disconnect air power supply from Rustibus® machine - Dirt, foreign materials machine / tool, remove the screen and runs at reduced - Internal corrosion / rust chain Drum unit from Machine / tool and speed. - Misalignment check if main drive shaft rotates freely. - Insufficient air pressure / flow - Air hose or compressor is to small 5) Too much dust may have accumulated in the tool. Clean the tool. - Restricted exhaust 6) Check the bearings to make sure they are - Poor lubrication spinning freely in their track. - Air hose between machine and Air motor failure (handle part) such as compressor is to long main gear not engaging. Contact Rustibus® machine - Dirt, foreign materials supplier for service. runs with low torque. - Internal corrosion / rust 7) Lubricate the machine and rotate the - Misalignment chain head or drive shaft in both - Insufficient air pressure / flow directions a few times. - Poor lubrication - Jammed machine Machine reduces - Misalignment speed during opera- - Restricted exhaust tion - Jammed machine 1) Disconnect machine from air power - Compressor is to small supply and check that exhaust is not - Air hose between machine and restricted. compressor is to long 2) Check air supply is not restricted and that it is adequate. Machine runs warm - Misalignment - Poor lubrication 1) Disconnect the air supply from the machine / tool. 2) Check oil in the lubricator oil system. 3) Check that there are no restrictions on the hose. 4) Check that bearings are spinning freely. Not getting good - Machine running to slow 1) Check that air supply is free of enough de-scaling - Chain drum is worn out restrictions and that it has the adequate performance PSI. Rustibus® machine Does not run. 2) Disconnect the air supply and check if the chain drum is worn and replace if necessary. Unfamiliar smells or - Misalignment sounds coming from - Poor lubrication machine. - Jammed machine - Dirt, foreign materials 1) Disconnect machine from air power supply. 2) Carefully inspect machine / tool. Genuine Rustibus® parts only! Machine may vary from pictures RUSTIBUS ANGLE DE-SCALER WARRANTY/REPLACEMENT PLAN DALSEIDE SHIPPING SERVICES WILL REPLACE OR REPAIR ANY TOOL OR COMPONENT THAT FAILS DUE TO DEFECTS IN MATERIAL OR WORKMANSHIP FOR A PERIOD OF ONE (1) YEAR (12 MONTHS) FROM THE DATE OF SHIPMENT OF THIS PRODUCT FROM OUR FACILITY. A WARRANTY CLAIM WILL NOT BE HONOURED IF DEFECTS ARE NOT REPORTED WITHIN THE WARRANTY PERIOD, OR IF DALSEIDE SHIPPING SERVICES DETERMINES THAT DEFECTS OR DAMAGES ARE DUE TO NORMAL WEAR, MISAPPLICATION, LACK OF MAINTENANCE, ABUSE, IMPROPER INSTALLATION, ALTERATION, OR ABNORMAL CONDITIONS. Dalseide Shipping Services will always seek to improve the Rustibus® machines design, specifications and production. Therefore, alterations may take place at any time. While every effort is made to produce up-todate literature, the descriptions, specifications, illustrations and photographs in this manual should not be regarded as the definitive guide to current specifications; though all manuals are considered concise at the time of their production. Machine may vary from pictures Genuine Rustibus® parts only! CONTACT INFORMATION NORWAY: Dalseide Shipping Services AS Bekkjarviksundet 1 NO - 5397 Bekkjarvik Norway Tel: + 47 5618 1200 Fax: + 47 5618 1201 E-mail: bergen@rustibus.com ANTWERP: Rustibus N.V. Noordersingel 7 2140 Antwerpen Belgium Tel: + 32 3227 2096 Fax: + 32 3227 2097 E-mail: antwerp@rustibus.com SINGAPORE: Rustibus PTE LTD 18 Boon Lay Way #08-145 TradeHub 21 Singapore 609966 Phone: +65 62 62 52 26 Fax: +65 62 66 69 55 E-mail: singapore@rustibus.com HOUSTON TX: Rustibus INC. 2901 West Sam Houston Pkwy North Suite E-325 Houston, TX 77043 USA Tel: + 1 832 203 7170 Fax: + 1 832 203 7171 E-mail: houston@rustibus.com sales@rustibus.com w w w.rustibus.com