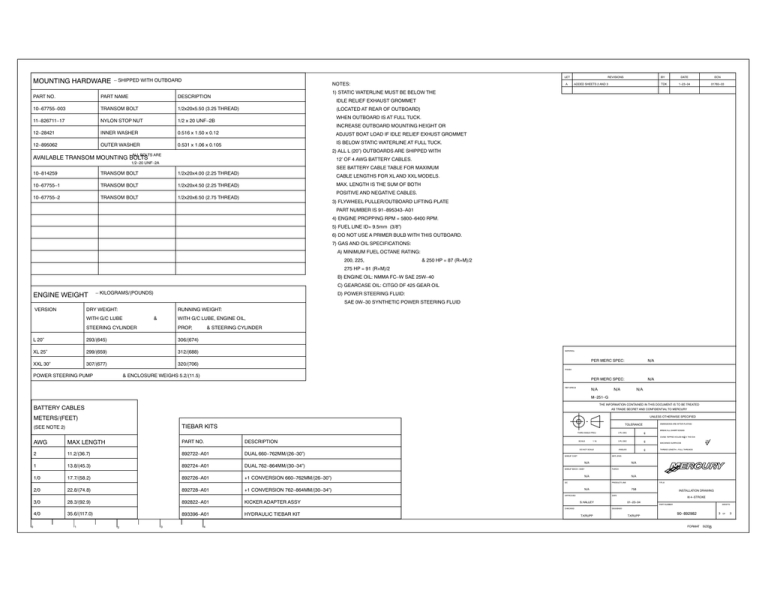

available transom mounting bolts battery cables meters/(feet) awg

advertisement

MOUNTING HARDWARE LET – SHIPPED WITH OUTBOARD NOTES: PART NO. PART NAME DESCRIPTION 10–67755–003 TRANSOM BOLT 1/2x20x5.50 (3.25 THREAD) 11–826711–17 NYLON STOP NUT 1/2 x 20 UNF–2B 12–28421 INNER WASHER 0.516 x 1.50 x 0.12 12–895062 OUTER WASHER 0.531 x 1.06 x 0.105 A REVISIONS BY ADDED SHEETS 2 AND 3 TDK DATE ECN 1–23–04 01760–03 1) STATIC WATERLINE MUST BE BELOW THE IDLE RELIEF EXHAUST GROMMET (LOCATED AT REAR OF OUTBOARD) WHEN OUTBOARD IS AT FULL TUCK. INCREASE OUTBOARD MOUNTING HEIGHT OR ADJUST BOAT LOAD IF IDLE RELIEF EXHUST GROMMET IS BELOW STATIC WATERLINE AT FULL TUCK. 2) ALL L (20”) OUTBOARDS ARE SHIPPED WITH – ALL BOLTS ARE AVAILABLE TRANSOM MOUNTING BOLTS 12’ OF 4 AWG BATTERY CABLES. 1/2–20 UNF–2A 10–814259 TRANSOM BOLT 1/2x20x4.00 (2.25 THREAD) 10–67755–1 TRANSOM BOLT 1/2x20x4.50 (2.25 THREAD) 10–67755–2 TRANSOM BOLT 1/2x20x6.50 (2.75 THREAD) SEE BATTERY CABLE TABLE FOR MAXIMUM CABLE LENGTHS FOR XL AND XXL MODELS. MAX. LENGTH IS THE SUM OF BOTH POSITIVE AND NEGATIVE CABLES. 3) FLYWHEEL PULLER/OUTBOARD LIFTING PLATE PART NUMBER IS 91–895343–A01 4) ENGINE PROPPING RPM = 5800–6400 RPM. 5) FUEL LINE ID= 9.5mm (3/8”) 6) DO NOT USE A PRIMER BULB WITH THIS OUTBOARD. 7) GAS AND OIL SPECIFICATIONS: A) MINIMUM FUEL OCTANE RATING: 200, 225, & 250 HP = 87 (R+M)/2 275 HP = 91 (R+M)/2 B) ENGINE OIL: NMMA FC–W SAE 25W–40 C) GEARCASE OIL: CITGO DF 425 GEAR OIL ENGINE WEIGHT – KILOGRAMS/(POUNDS) D) POWER STEERING FLUID: SAE 0W–30 SYNTHETIC POWER STEERING FLUID VERSION DRY WEIGHT: RUNNING WEIGHT: WITH G/C LUBE & WITH G/C LUBE, ENGINE OIL, STEERING CYLINDER PROP, L 20” 293/(645) 306/(674) XL 25” 299/(659) 312/(688) XXL 30” 307/(677) 320/(706) & STEERING CYLINDER MATERIAL PER MERC SPEC: N/A FINISH POWER STEERING PUMP & ENCLOSURE WEIGHS 5.2/(11.5) PER MERC SPEC: REF SPECS N/A N/A N/A N/A M–251–G THE INFORMATION CONTAINED IN THIS DOCUMENT IS TO BE TREATED BATTERY CABLES AS TRADE SECRET AND CONFIDENTIAL TO MERCURY METERS/(FEET) UNLESS OTHERWISE SPECIFIED TIEBAR KITS (SEE NOTE 2) TOLERANCE DIMENSIONS ARE AFTER PLATING BREAK ALL SHARP EDGES THIRD ANGLE PROJ 2 PL DEC CHAM. TAPPED HOLES 90 X THD DIA AWG MAX LENGTH PART NO. DESCRIPTION 2 11.2/(36.7) 892722–A01 DUAL 660–762MM/(26–30”) 1 13.8/(45.3) 892724–A01 DUAL 762–864MM/(30–34”) 1/0 17.7/(58.2) 892726–A01 +1 CONVERSION 660–762MM/(26–30”) 2/0 22.8/(74.8) 892728–A01 +1 CONVERSION 762–864MM/(30–34”) 3/0 28.3/(92.9) 892822–A01 KICKER ADAPTER ASSY SCALE: 1:16 DO NOT SCALE MANUF CAST MANUF MACH / ASSY 0 1 2 3 4 HYDRAULIC TIEBAR KIT N/A PURCH N/A N/A PRODUCT LINE N/A TITLE 758 INSTALLATION DRAWING DATE S.HALLEY CHECKED 893396–A01 THREAD LENGTH = FULL THREADS MATL ENG APPROVED 35.6/(117.0) MACHINED SURFACES ANGLES N/A QC 4/0 125 3 PL DEC I6 4–STROKE 01–23–04 PART NUMBER SHEETS DESIGNED T.KRUPP T.KRUPP 90–892982 FORMAT 3 SIZEB OF 3