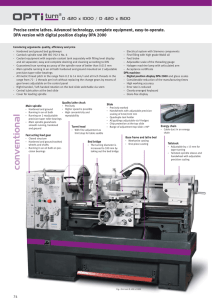

Metal working machines

advertisement

Metal working machines Drilling machines Lathes The OPTIMUM in quality, price-performance and service Milling machines Metal band saw Grinding machines Polishing machines Arbor press Position display Base Accessory Novelties 2015 drill®DX 16V Technology innovation made by Optimum. Bench drill with threading unit and infinitely variable speed control Convincing arguments: quality, efficiency and price ·· Best power transmission by aluminium pulleys ·· Emergency stop push button ·· Drilling spindle with precision ball bearings ·· Thread cutting mode ·· Language selection (all common languages) ·· Digital reference point ·· Digital part counter ·· Acoustic signal when attaining the drill depth Control panel Vario drive Functional keys: ·· Setting to zero ·· Drilling / threading ·· ON button ·· OFF button ·· Turn key Display ·· Digital speed display ·· Depth indication (Nominal/Actual) ·· Part counter Main switch ·· lockable Emergency stop push button LED illumination ·· Left and right drill head integrated ·· Glare-free ·· without disturbing shades Chuck guard ·· Best possible protection of the user ·· Height-adjustable ·· Micro switch Drilling table ·· Precisely worked ·· Transversally running T-slots Base plate ·· Usable as a working surface for higher workpieces due to the rotatable drill table ·· Solid ·· Transversally running T-slots ·· Precisely machined at the surface 2 ·· Reduced speed in the threading mode ·· Softkey panel with contrasting display ·· Control of the core function by means of four keys only and centrally assigned push turn key ·· Large speed range ·· Siemens frequency converter ·· EMV filter (to protect sensitive electronics for override mains-borne signals Class B) Technical data, accessories and dimensions Type Item No DX 16V 3020160 Electrical connection Electrical connection Motor power Drilling capacity Drilling capacity in steel (S235JR) Continuous drilling capacity in steel (S235JR) Thread cutting in steel (S235JR) Spindle seat Throat Spindle seat Spindle stroke Speeds Spindle speeds Number of steps Drilling table Drilling table size Length x Width T-slot size / number / distance Drilling table turnable Distance drill chuck - drilling table Machine foot Working surface machine foot L x W T-slot size / number / distance Distance drill chuck - machine foot Dimensions Column diameter Length x width x height Net weight Standard equipment 230 V / 1 Ph ~50 Hz 1.0 kW 16 mm 13 mm M8 235 mm B 16 54 mm 50 - 4.000 min-1 Electronically adjustable speed 290 x 290 mm 10 mm / 2 / 100 mm 360° 125 mm 290 x 280 mm 14 mm / 2 / 100 mm 300 mm Ø 60 mm 475 x 425 x 910 mm 60 kg Quick-action drill chuck (1 - 13 mm) Accessory Item No. Twist drill kit coated with titanium 13mm 3051010 Clamping tool kit SPW 8 3342015 Clamping tool kit SPW 12 3342017 Universal coolant unit 230 V 3342002 Machine vices Item No. MSO 75 3000075 BMS 85 3000008 Universal substructure Convincing arguments... 3353000 ·· Dimensions L x W x H: 800 x 340 x 420 mm 3 drill® DH 40BV Upright drilling machine with infinitely variable mechanic drive Convincing arguments: quality, efficiency and price ·· Smooth running and powerful electrical motor ·· Sleeve lever made of steel ·· Usable as a working surface for extra high workpieces due to the rotatable drill table ·· ·· ·· ·· Right-handed / left-handed rotation 2 speed stages V-belt cover with safety switch Digital depth gauge VARIO DRIVE made in Germany Vario drive Digital speed display ·· Easy-to-read ·· Integrated in the housing True running accuracy ·· Guaranteed ≤ 0.015 mm measured in the drilling spindle Machine lamp Chuck guard ·· Best possible protection of ·· Integrated in the drill head ·· Halogen lamp the user ·· Height-adjustable ·· Micro switch Drilling spindle ·· Precision ball bearing ·· High-quality quick-action drill chuck as standard Drilling table ·· Precisely worked ·· Transversally running T-slots ·· turnable by 360° Casting column ·· Thick-walled ·· High power absorption and stability Base plate ·· Solid ·· Largely dimensioned ·· Heavily ribbed at the rear side Fig.: Optidrill DH 40BV 4 Technical data and accessories Convincing arguments ... Type Item No DH 40BV 302 0450 Machine data Electrical connection Motor power 400 V / 3 Ph ~50 Hz 1.5 / 2.2 kW Drilling capacity Drilling capacity in steel (S235JR) Continuous drilling capacity in steel (S235JR) Spindle seat Spindle stroke Spindle seat Throat Speeds Ø 34 mm Ø 26 mm 160 mm MT 4 285 mm Spindle speeds 2 stage motor, manual Infinitely variable mechanical gearbox ·· Extremely reliable due to manual speed regulation ·· Powerful smooth running ·· Durable belt with wide groove ·· Speed modification while the motor is running ·· Permanently optimum efficiency degree of the motor ·· Reduction gear 150 - 2.000 min-1 Drilling table Work surface drilling table L x W T-slot size Drilling table turnable Distance spindle - drilling table Distance spindle - machine foot Working surface machine foot L x W Dimensions Column diameter Length x width x height Total weight 420 x 400 mm 14 mm 360° max. 790 mm max. 1.025 mm 390 x 390 mm Ø 115 mm 918 x 595 x 1.960 mm 270 kg OPTIMUM quality quick-action drill chuck (1 - 16 mm) Morse taper MT 4 T-slots Standard equipment ·· Easy tool change due to integrated drill drift Accessory Optidrill DH 40BV Item No. Machine vices Item No. Direct quick action. MT4/1-16 mm 305 0574 BSI 100 300 0210 Reducing bushes MT 4 - MT 3 305 0664 BSI 140 300 0214 Morse taper MT 4 - B16 305 0661 BSI-Q 100 300 0230 Twist drill kit coated with titanium 305 1010 BSI-Q 140 300 0234 Clamping tool kit SPW 12 335 2017 Tapping chuck M5-M12 335 2042 Fig.: BSI Fig.: BSI-Q 5 DH 32GSV Upright drilling machines with gear and infinitely adjustable speed control Convincing arguments: quality, efficiency and price Vario drive ·· ·· ·· ·· ·· ·· High running smoothness thanks to ground multi-toothed follower High true running accuracy due to hardened and ground main spindle Wide speed range Heavy, solid cast iron construction Adjustable drilling depth stop with millimetre scale Low maintenance gear with grease lubrication Integrated drill drift ·· Easy tool change due to ejection mechanism ·· ·· ·· ·· Threading function Automatic spindle sleeve feed High performance coolant pump and chip filter Optional foot switch to actuate the threading function and to switch over right-left handed rotation Automatic spindle sleeve feed ·· For deep drilling or pocket hole drilling, the coupler of the automatic spindle sleeve feed can be opened or closed at any time by actuating the spindle feed switch Right-handed / left-handed rotation Machine lamp ·· Integrated in the drill head ·· Halogen lamp Chuck guard ·· Best possible protection of the user ·· Height-adjustable ·· Micro switch Casting column ·· Thick-walled ·· For high power absorption and stability Front panel ·· User-friendly splash water protected and glare-free membrane keyboard ·· Well readable digital speed display Drilling table ·· ·· ·· ·· ·· Largely dimensioned Solid Precisely worked Transversally running T-slots Heavily ribbed at the rear side Coolant equipment Chip filter ·· according to the machine directive Optional foot switch Functions: ·· Tread cutting ·· Change-over switch right-handed / lefthanded rotation 6 Item No. 3050032 Technical data, accessories and dimensions 6 DH 32GSV 3034245 D Ø 32 mm Ø 29 mm 125 mm MT4 285 mm 0.1 / 0.15 / 0.2 mm 2230 40 - 3.000 min-1 4 steps C 495 400 1115 400 x 420 mm 14 mm 360° max. 820 mm max. 1.280 mm 420 x 644 mm A Ø 115 mm 725 x 450 x 2,200 mm 300 kg 5 Adapter MT4-B16 Transportation packaging flat rate 115 450 6 Standard equipment 4 A 4 TPFR 1 = € 19.00 plus VAT 3 2 B A-A ( 1 : 10 ) Reducing bushes MT 4 - MT 3 3050664 Morse taper MT 4 - B16 3050661 Twist drill kit coated with titanium 13mm 3051010 Clamping tool kit SPW 12 3342017 Tapping chuck M5-M12 3342042 450 395 Item No. 3050574 115 A C 400 285 420 2230 Accessory Quick-action drill chuck MT4/1-16 mm 270 D 660 Number of steps Drilling table Work surface drilling table length x width T-slot size Drilling table turnable Distance spindle - drilling table Distance spindle - machine foot Work surface machine foot length x width Dimensions Column diameter Dimensions Total weight 400 V / 3 Ph ~50 Hz 2.2 kW 100 watts 5 150 Machine data Electrical connection Total connected value Motor coolant pump Drilling capacity Drilling capacity in steel (S235JR) Continuous drilling capacity in steel (S235JR) Spindle seat Spindle stroke Spindle seat Throat Automatic spindle sleeve feed Speeds Spindle speeds Dimensions 155 Type Item No 450 495 90 1115 420 Item No. MSO 125 3000125 MSO 150 3000150 BMS 150 3000015 BMS 200 3000020 BSI 140 3000214 BSI 200 3000220 A 5 Status Änderungen 4 A 725 B A-A ( 1 : 10 ) 7 270 Machine vices 6 Schwerpunkt/ Centre of gravity Datum mill® BF 20 LD Stable drilling milling machines with electronically infinitely variable drive and digital position display DRO Convincing arguments: quality, efficiency and price ·· Feed spindles can be adjusted without clearance due to adjustable spindle nuts ·· Stable dovetail guiding precision ground and scraped with readjustable V-ledges without clearance ·· EMV filter (to protect sensitive electronics for override mains-borne signals Class B) ·· All guideways are ground and sight scrapped (oil pockets for greasing) ·· Precisely manufactured ·· Two-row angular contact bearings in the axis, can be adjusted free of play ·· ·· ·· ·· Safety electrical system of 24 volts type Bellow as guide protection Right-handed / left-handed rotation Drilling milling head tiltable by ± 900for milling and drilling works at different angles ·· Height adjustable protective shield with microswitch against chips and parts flying off for highest possible protection of the user Control electronics ·· Integrated relay control ·· Optional CNC Controller can switch the machine on and off Motor Vario drive ·· Two-stage gear ratio for a powerful transmission of the motor power (850 W) ·· Powerful DC motor with permanent current control Digital position display DRO 5 Speeds ·· Large speed adjustable speed range Z column and X axis ·· Prepared 9 mm slot for the from 90 - 3.000 min-1 subsequent assembly of the magnetic bands by simply gluing them in ·· Easy to read digital speed display Start-stop connection ·· for optional CNC Controller Spindle stroke display ·· Digital ·· Accuracy of the display 0.01 mm ·· Reversible mm/inch Machine lamp ·· Integrated in the drilling-milling head ·· Halogen capsule bulb, 12V - 10W Taper roller bearing ·· High true running accuracy ≤ o.o15 mm measured in the spindle sleeve Column ·· Relocatable by 30 mm to both sides, ·· Longer travels and centric processing of the Z column ·· Rear side with hole ·· Easy oiling of the trapezoid workpiece is possible when the head is slewed spindle or greasing of the recirculating ball screw Cross table ·· ·· ·· ·· Limit stops ·· Mechanic ·· Adjustable Length measuring scale ·· Embedded in the cross table ·· Well readable 8 Fig.: Opti mill BF 20Vario with optional accessory Solid and precise Precisely machined at the surface With T-slots Adjustable V-ledges Technical data, accessories and dimensions Dimensions Type BF 20LD Item No 3338125 Electrical connection Electrical connection Motor power Drilling-milling capacity Drilling capacity in steel (S235JR) Continuous drilling capacity in steel (S235JR) Milling head dimension max. End mill dimension max. Spindle seat Spindle stroke Spindle seat Throat Drilling- milling head Swivel range Spindle speeds Gear stages Cross table Table length Table width T - slot size / distance Load of cross table (max.) Travels X axis Y axis Z axis Dimensions Length Width x Height max. Total weight 230 V / 1 Ph ~50 Hz 850 W Ø 16 mm Ø 12 mm Ø 63 mm Ø 20 mm 50 mm MT 2/M 10 185 mm ± 900 90 - 1.480 min-1 / 150 - 3.000 min-1 2 steps, electrically adjustable speed 700 mm 180 mm 12 mm / 63 mm 55 kg 480 mm 175 mm 280 mm 950 mm 565 x 935 mm 115 kg Standard equipment Taper mandrel MT 2, B16 M10 Draw-in rod M 10 Operating tool Accessory Item No. Add-on adapter "high speed" 3356571 ·· To mount a high speed motor (up to 26.000 min-1) ·· L xWxH: 120 x 195 x 185 mm . Seat: ø 43 mm (without motor) BF 20AV Fig. Add-on adapter high speed Fig. Mounting example 3338129 ·· Milling head and column of the drilling milling machine ·· to be mounted on the lathes TU 2506 and TU 2807 ·· Length x Width x Height max. 470 x 425 x 912 mm ·· Total weight 80 kg Add-on adapter "Lathe" 3356572 ·· To mount columns and milling head onto the machine bed of the lathes: TU 2506 / TU 2807 Universal substructure Fig. Mounting example Fig. Add-on adapter lathe 3353000 ·· Dimensions L x W x H: 800 x 340 x 420 mm Chip tray 3352999 ·· Dimensions L x W x H: 720 x 470 x 30 mm 9 mill® MB 4PV Universal drilling-milling machine with speed-controllable drive and position display as well as the machine base made of cast iron Convincing arguments: quality, efficiency and price ·· ·· ·· ·· Very smooth running due to ground oil-quenched gear wheels One-stage quality electrical motor Automatic sleeve feed with manual fine feed Motor positioning of the Z axis ·· Gear head slewable by ± 60° ·· Drilling / Thread cutting function Vario drive Spindle sleeve feed ·· Automatic Spindle sleeve fine feed ·· Handwheel ·· Easy-to-operate Coolant equipment Safety screen ·· Height-adjustable ·· Largely dimensioned ·· Micro switch Column ·· Solid dovetail guide ·· Manually scraped ·· Highest stability ·· Largest possible precision X axis ·· With motor driven table feed as standard ·· Infinitely variable speed control ·· Rapid feed ·· Right-handed / left-handed rotation Cross table ·· Massive, accurate and largely dimen·· ·· ·· ·· ·· sioned Precisely machined at the surface With T-slots Adjustable V-ledges Integrated length measuring scale Adjustable limit stops Machine base ·· Massive cast pillar ·· Chip channel Fig.: Opti mill MB 4PV 10 Technical data and accessories Type Item No Convincing arguments ... MB 4PV 333 8465 Electrical connection Connection Motor power Drilling-milling capacity Drilling capacity in steel (S235JR) Continuous drilling capacity in steel (S235JR) Milling head dimension max. End mill dimension max. Spindle seat Spindle stroke Spindle seat Spindle sleeve diameter Throat Drilling- milling head Spindle speeds Gear stages Swivel range Cross table Table length Table width Distance spindle - cross table T-slot size / distance / number Automatic spindle sleeve feed Travels Travel X axis automatic Travel Y axis manual Operating panel ·· with integrated switch board to control: ·· Z axis height adjustment ·· Operating mode milling / threading ·· Stage switch drive motor ·· Spindle rotation ·· Machine lamp ·· Coolant pump ·· Emergency stop push button ·· Integrated compact, digital 3-axes position display DRO 5 (X - Y - Z) with speed display ·· User-friendly menu guiding and three-row five segment display 230 V / 1 Ph ~50 Hz 1.5 kW Ø 24 mm Ø 20 mm Ø 63 mm Ø 26 mm 120 mm MT 4 75 mm 258 mm 60 - 2.760 min-1 2 steps ± 450 800 mm 240 mm 420 mm 14 mm / 80 mm / 3 0.1 / 0.18 / 0.26 mm/rev Travel Z axis manual Dimensions Length Width Height max. Total weight 560 mm 195 mm 350 mm 1,250 mm 930 mm 2,110 mm 495 kg Vices Item No. Accessory Item No. FMS 100 335 4100 Kit of parallel packaging plates, 20 pcs 335 4001 FMS 125 335 4125 Copy and planing cutter head MT 4 335 0215 ·· Hardened and ground guide surfaces ·· Hardened and ground clamping jaws, replaceable ·· With turntable, 360° turnable HMS 100 HMS 125 335 5100 335 5127 ·· Booster system, little effort, high pressure output when clamping ·· Large clamping range due to locking bolts with different ·· hole spacings ·· With turntable, 360° turnable Vibration damper SE1 338 1012 Boring drilling head MT 4 335 2084 Arbor for lathe chuck MT4 335 0304 Collet chuck MT 4/M16 335 2094 Tapping chuck M5-M12 335 2042 Height adjustable tailstock RST 1 335 6155 Clamping tool kit SPW 12 335 2017 ·· Metric threads Horizontal vertical circular dividing table RT150 335 6150 End mill kit HSS 20 pcs 338 6200 ·· 10 milling cutter DIN 327 D Type with 2 cutting edges ·· 10 milling cutter DIN 844 B Type with 4 cutting edges Fig.: FMS 100 Fig.: HMS 100 Circular dividing table RT 100 335 6110 Circular dividing table RTE 165 335 6365 11 mill®MH 25SV Stable drilling milling machines with electronically infinitely variable drive and digital speed display DRO Convincing arguments: quality, efficiency and price Vario drive ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· 12 User-friendly keypad Continuously adjustable feed in all axes Rapid X / Y-axis for fast positioning Counterweight facilitates the adjustment of the Z-axis Digital speed display DRO 5 Variable speed control Simple tool change by a rocker arm Feed spindles adjustable by readjustable spindle nuts All guideways are ground and sight scrapped (oil pockets for greasing) Precisely manufactured ·· Precisely manufactured ·· Two-row angular contact bearings in the axis, can be adjusted free of play ·· Safety electronic of 24 volts type ·· Drilling-milling head slewable by ± 900 ·· Right-handed / left-handed rotation ·· Height-adjustable screening grid with micro switch ·· Stable dovetail guiding precision ground and scraped with readjustable V-ledges without clearance Technical data Convincing arguments... Control ·· with touch panel ·· with holder on the column ·· Keeps off soil substances and liquids Type Item No Electrical connection Electrical connection Total connected value Milling spindle Driving motor Torque driving motor Spindle seat Milling cutter size Milling head dimension max. End mill dimension max. Travels X axis Y axis Z axis Speed range Speeds Milling table Distance spindle - table Table length x width T-slot size / number / distance Load (max.) Dimensions Total weight MH 25SV 3338160 230 V / 1 Ph ~50 Hz 2 kW 1.5 kW 10 Nm BT 30 50 mm Ø 25 mm 400 mm 220 mm 270 mm 200 - 4.000 min-1 305 mm 620 x 180 mm 12 mm / 3 / 50 mm Touchpanel ·· Clear and easy to use ·· Slight contact pressure with the finger is sufficient to activate the touch Limit switch ·· for all three axes Energy chain ·· Cable routing in an energy chain 13 TU 2406 Lathes for do-it-yourselfer. Convincing arguments: quality, efficiency and price ·· Precise machining ·· Hardened and ground guideways ·· Guaranteed true running accuracy of the spindle nose better than 0.009 mm ·· True running accuracy - Lathe chuck better than 0.05 mm ·· With leading spindle for threading or automatic longitudinal turning ·· Right-/left-handed rotation switchable on the control panel ·· ·· ·· ·· ·· Rolled trapezoid spindles Emergency stop push button Comprehensive accessory Acceptance certificate Stable value Conventional Slide ·· Precisely worked ·· Handwheels with adjustable precision scaling of 0.04/0.01 mm ·· Quadruple tool holder ·· All guidings adjustable via V-ledges Change gear kit ·· for threading Taper roller bearing ·· two pieces ·· of P5 quality Thrust bearing Leading spindle ·· run on two porous bearings Prism bed ·· Solid and tempered made of grey cast iron ·· Matured at least for six months ·· Inductively hardened (HRC 42-52) ·· Precision ground Accessory Item No. 14 Machine base 3440409 Fig.: Opti turn TU 2404 with optional machine base OPTIMU M The orig inal Tailstock ·· Adjustable by ± 5 mm for taper turning ·· Tailstock spindle sleeve and handwheel with adjustable precision scaling of 0.02 mm Technical data, accessories and dimensions Type Item No. (230 V) Item No. (400 V) Electrical connection Connection Spindle Driving motor Spindle taper Spindle drilling Spindle seat Quadruple tool holder seat height Machine data Centre height Centre width Turning Ø over machine bed Bed width Speed range Spindle speed Number of steps Travels Travel top slide Travel cross slide Pitches Pitch - Metric in the range of Pitch - Inch in the range of Tailstock Tailstock seat Tailstock - sleeve travel Dimensions Length x width x height Net weight TU 2406 342 0350 342 0353 230 V / 1 Ph ~50 Hz or 400 V / 3 Ph ~50 Hz 750 W MT 3 Ø 21 mm Ø 52 mm 14 x 14 mm 125 mm 550 mm 250 mm 135 mm 125 - 2.000 min-1 6 steps 75 mm 120 mm 0.4 - 3.5 mm/rev 44 - 10 Threads/1“ MT 2 70 mm 1.310 x 520 x 560 mm 125 kg Accessory Three-jaw chuck Ø 125 mm, Speed 3.000 Dimensions Item No. min-1 3442712 Four-jaw chuck Ø 125 mm, Speed 2.750 min-1 3442812 Three-jaw chuck CI3P ø 125 mm cast iron, Speed 3.200 min-1 3442020 Three-jaw chuck CS3C ø 125 mm steel, Speed 4.800 min-1 3442520 Face clamping disc Ø 250 mm 3440552 Steady rest Ø max. 50 mm 3440515 Follow rest Ø max. 34 mm 3441310 Revolving centre MT2 3440702 Collet fixture for collets ER25 3440505 Collet chuck kit ER 25, 1 - 16 mm 3441109 Quick change tool holder SWH 1-A 338 4301 Factory assembly SWH 9000401 Lathe tool kit 10 mm, 11 pcs 3441108 Lathe tool kit 10 mm, 5 pcs 3441664 Lathe tool kit 12 mm, 5 pcs 3441666 Lathe tool kit 12 mm, 5 pcs "Made in Germany" 3441212 Digital position display DRO 5 Workshop assembly 338 3975 9000420 Standard equipment ·· ·· ·· ·· ·· ·· ·· ·· Three jaw chuck Ø 125 mm Steady centre MT 2 Steady centre MT 3 Splash board Chip tray Quadruple tool holder Change gear kit Operating tool 15 TU 3008 / TU 3008V Powerful centre lathe with longitudinal and transversal feed of Vario type with brushless motor Convincing arguments: quality, efficiency and price ·· Precise machining ·· Powerful, maintenance free motor ·· Electronically adjustable speed (Vario-machine) ·· Heavily ribbed prism bed made of grey cast iron, inductively hardened and precision ground ·· Hardened and ground bed guideways ·· Guaranteed true running accuracy of the spindle nose of better than 0.009 mm ·· True running accuracy of the lathe chuck better than 0.04 mm ·· Right-/left-handed rotation switchable on the control panel ·· With leading spindle for threading or automatic longitudinal turning ·· ·· ·· ·· ·· ·· ·· ·· ·· Leading spindle run on two porous bearings Automatic longitudinal/leading spindle drive Centre lathe cover Handwheels on the slide with adjustable precision scaling of 0.04/0.01 mm Change gear kit for threading Thrust bearing Emergency-stop push button and low-voltage release Prepared for measuring system axes Acceptance certificate TU 3008V Powerful Brushless drive Vario drive / Conventional ·· Particularly smooth running ·· Nearly constant torque over the entire speed range ·· High power output Slide ·· Quadruple tool holder ·· All guideways adjustable via V-ledges free of play ·· Chip protection at the top slide Tailstock ·· Adjustable for taper turning ·· Tailstock spindle sleeve and handwheel with adjustable precision scaling of 0.02 mm ·· Rapid and easy adjustment of the tailstock by means of a clamping lever Main spindle ·· Hardened and with readjustable precision taper roller bearings Feed gear ·· Smooth running ·· Rounded toothed wheels ·· running in the oil bath Fig.: Opti turn TU 3008 with optional machine base 16 Technical data, accessories and dimensions Type Item No. TU 3008 342 7200 Type Item No. TU 3008V 342 7205 Electrical connection Connection Connection Vario machine Spindle Driving motor Drive motor Vario machine Spindle taper Spindle seat Spindle drilling, rod passage Quadruple tool holder seat height Machine data Centre height Centre width Turning Ø over machine bed Turning Ø over cross slide Bed width Speed range Spindle speed Number of steps Spindle speed Vario machine Number of steps Vario machine Travels Travel top slide Travel cross slide Feeds and pitches Longitudinal feed in the range of Transverse feed in the range of Pitch - Metric in the range of Pitch - Inch in the range of Tailstock Tailstock seat Tailstock - sleeve travel Dimensions Length x width x height Weight Dimensions 400 V ~50Hz 230 V ~50 Hz 1.1 kW 1.5 kW MT5 Camlock DIN ISO 702-2 No 4 Ø 38 mm Ø 38 mm 180 mm 800 mm 300 mm 180 mm 180 mm 150 - 2.000 min-1 6 steps 3 - 3.000 min-1 5 steps; electrically adjustable speed Accessory 65 mm 190 mm 0.085 - 0.832 mm/rev 0.01 - 0.1 mm/rev 0.2 - 3.5 mm/rev 56-8 threads/1“ MT 3 70 mm 1.500 x 720 x 690 mm 260 kg Item No. Three-jaw chuck Camlock cast iron Ø 200 mm 3442762 Three-jaw chuck CI3P Camlock cast iron Ø 200 mm 3442045 Four-jaw chuck CI4P Camlock cast iron Ø 200 mm 3442145 Three-jaw chuck CS3C Camlock steel Ø 200 mm 3442545 Four-jaw chuck CS4C Camlock steel Ø 200 mm 3442645 Follow rest 3441460 Steady rest 3441461 Factory assembly SWH 9000400 Lathe tool kit 16 mm, 11 pcs 3441508 Lathe tool kit 16 mm, 5 pcs "Made in Germany" 3441216 Vibration damping machine foot SE 2 Measuring system Newall DP700 Complete add-on kit 338 1016 339 0420 17 TH 4610 / TH 4615 / TH 4620 New precision centre lathe - unique in precision and operation. With digital position display DPA 21 Convincing arguments: quality, efficiency and price Conventional ·· Hardened and ground bed guideways ·· Spindle seat Camlock DIN ISO 702-2 No. 6 ·· Coolant equipment with separate coolant tank, filling level display and oil separator; easy and complete draining and cleaning according to DIN ·· Guaranteed true running accuracy of the spindle nose better than 0.015 mm ·· Right-handed / left-handed rotation on the bed slide switchable via stem ·· Mechanic longitudinal feed switch-off of the bed slide with four adjustable eccentric ·· Cover for leading spindle ·· Foot operated emergency-stop equipment ·· Electrical system with Siemens components Main spindle ·· Hardened and ground ·· Running in an oil bath ·· Running on 2 readjustable precision taper roller bearings of 0.04/0.02 mm ·· All guidings adjustable via V-ledges ·· Shafts and wheels running in the oil bath ·· Range of adjustment top slide ± 90° ened and ground wheels and shafts ·· Running in an oil bath on precision bearings Adjustable scale of the threading gauge Central lubrication at the bed slide Acceptance certificate Quick change tool holder SWH 5-B 1 tool holder 25 x 120 type D for square tools Digital position display DPA 21 –– Speed display –– Considerable reduction of the manufacturing times –– High working accuracy –– Error rate is reduced –– Glass scales Slide ·· Precisely worked ·· Handwheels with adjustable precision scaling ·· Gearwheels smooth running, hardFast acting feed gear ·· Closed structure ·· Hardened and ground toothed ·· ·· ·· ·· ·· ·· Energy chain ·· Cable duct in an energy chain Quality lathe chuck ·· Precisely ·· Higher speed is possible ·· High concentricity and Chip protection ·· Largely dimensioned ·· Integrated LED lamp Tailstock ·· Adjustable by ± 15 mm for taper turning repeatability ·· Tailstock spindle sleeve and handwheel with adjustable precision scaling of 0.025 mm Fig.: Opti turn TU 4615 18 Technical data and accessories Type TH 4610 TH 4615 TH 4620 Item No. 3462110 3462120 3462130 Electrical connection Connection Total connected value Spindle Driving motor Spindle taper Spindle seat Spindle drilling, rod passage Height of quadruple tool holder Coolant-lubricant system Power of the coolant pump Machine data Centre height Centre width Turning Ø over machine bed Turning Ø over cross slide Turning Ø in the bed bridge Length of bed bridge Bed width Speed range Spindle speed Number of steps Travels Travel top slide Travel cross slide Feeds and pitches Longitudinal feed in the range of Transverse feed in the range of Pitch - Metric in the range of Pitch - Inch in the range of Diametrical pitch in a range of Modular thread in the range of Tailstock Tailstock seat Tailstock - sleeve diameter/travel Dimensions Length Width x Height Net weight 400 V / 3 Ph ~50 Hz 5.8 kW 5.5 KW MT 6 Camlock DIN ISO 702-2 No 6 Ø 58 mm max. 25 x 25 mm 100 W 230 mm 1,500 mm 465 mm 270 mm 690 mm 240 mm 300 mm 1,000 mm 2,000 mm 25 - 2.000 min-1 12 steps 128 mm 285 mm 0.031 - 1.7 mm/rev; 0.014 - 0.784 mm/rev; 0.1 - 14 mm/rev; 112 - 2 threads/1“; 4 - 112; 0.1 - 7; 42 feeds 42 feeds 41 thread pitches 41 thread pitches 50 threads 34 modular thread MT 4 Ø 60 mm / 130 mm 2.200 mm 1.645 kg 2.750 mm 1.245 x 1.568 mm 1.810 kg 3.250 mm 1.945 kg Lathe chu ck do not forg et Accessory Item No. Three-jaw chuck CI3P Ø 250 mm cast iron, Speed 2.000 min-1 3442055 Four-jaw chuck CI4P Ø 250 mm cast iron, Speed 2.500 min-1 3442155 Three-jaw chuck CS3C Ø 250 mm steel, Speed 3.500 min-1 3442555 Four-jaw chuck CS4C Ø 250 mm steel, Speed 3.500 min-1 3442655 Universal collet attachment 5C 3444006 Collet chuck kit 3 - 25 mm, 5C, 17 pcs. 3441509 Position limit stop with fine adjustment 3444022 Revolving centre MT 4 3440704 Spare tool holder 32 x 130 type H for round tools 3384324 Lathe tool kit HM 20 mm, 5 pcs 3441670 Lathe tool kit HM 20 mm, 5 pcs 3441617 Vibration damping machine foot SE 3 3381018 Standard equipment ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· Reducing bush MT 6/MT 4 2 steady centres MT 4 Micro stop Digital position display DPA 21 Glass scales Follow rest Passage Ø max. 100 mm Steady rest Passage Ø max. 160 mm Quick change tool holder SWH 5-B Tool holder 25 x 120 type D for square tools Threading gauge Coolant equipment Machine lamp Change gear kit Operating tool 19 TH 4615V Heavy centre lathe completely equipped, particularly smooth running, low-vibration with Siemens inverter Vario drive and digital position display DPA 21 Convincing arguments: quality, efficiency and price ·· Hardened and ground bed guideways ·· Spindle seat Camlock DIN ISO 702-2 No. 8 ·· Speed monitoring according to machine directive ·· EMC filter also for the use in mixed-use areas ·· Coolant equipment with separate coolant tank, filling level display and oil separator; easy and complete draining and cleaning according to DIN ·· Guaranteed true running accuracy of the spindle nose better than 0.015 mm ·· Right-handed / left-handed rotation on the bed slide switchable via stem ·· Mechanic longitudinal feed switch-off of the bed slide with four adjustable eccentric ·· Cover for leading spindle ·· Foot operated emergency-stop equipment ·· Electrical system with Siemens components ·· Adjustable scale of the threading gauge ·· Central lubrication at the bed slide ·· Acceptance certificate Vario drive Converter SINAMICS G120D More information about: „Converter SINAMICS G120D“ see main catalogue Main spindle ·· Hardened and ground ·· Running in an oil bath ·· Running on 2 readjustable preci- Slide ·· Precisely worked ·· Handwheels with adjustable precision scaling sion taper roller bearings ·· Gearwheels smooth running, hardened and ground of 0.04/0.02 mm ·· All guidings adjustable via V-ledges ·· Shafts and wheels running in the oil bath ·· Range of adjustment top slide ± 90° Fast acting feed gear ·· Closed structure ·· Hardened and ground toothed wheels and shafts ·· Running in an oil bath on precision bearings ·· Quick change tool holder SWH 5-B ·· 1 tool holder 25 x 120 type D for square tools ·· Digital position display DPA 21 –– Speed display –– Considerable reduction of the manufacturing times –– High working accuracy –– Error rate is reduced –– Glass scales Quality lathe chuck ·· Precisely ·· Higher speed is possible ·· High concentricity and repeatability Chip protection ·· Largely dimensioned ·· Integrated LED lamp Energy chain ·· Cable duct in an energy chain Tailstock ·· Adjustable by ± 15 mm for taper turning ·· Tailstock spindle sleeve and handwheel with adjustable precision scaling of 0.025 mm 20 Type Item No. Electrical connection Electrical connection Total connected load Spindle Driving motor Spindle taper Spindle seat Spindle drilling, rod passage Height of quadruple tool holder Coolant-lubricant system Power of the coolant pump Machine data Centre height Centre width Turning Ø over machine bed Turning Ø over cross slide Turning Ø in the bed bridge Length of bed bridge Bed width Speed range Spindle speed Number of steps Travels Travel top slide Travel cross slide Feeds and pitches Longitudinal feed in the range of Transverse feed in the range of Pitch - Metric in the range of Pitch - Inch in the range of Diametrical pitch in a range of Modular thread in the range of Tailstock Tailstock seat Tailstock - sleeve diameter/travel Dimensions Length x width x height Net weight TH 4615V 3462125 400 V / 3 Ph ~50 Hz 8.5 kW 7.5 KW MT 7 Camlock DIN ISO 702-2 No 8 Ø 80 mm max. 25 x 25 mm 100 W 230 mm 1,500 mm 465 mm 270 mm 690 mm 240 mm 300 mm 30 - 400 min-1 / 160 - 2000 min-1 2 steps; electrically adjustable speed 128 mm 285 mm 0.031 - 1.7 mm/rev; 0.014 - 0.784 mm/rev; 0.1 - 14 mm/rev; 112 - 2 threads/1“; 4 - 112 D.P.; 0.1 - 7; MT 4 Ø 60 mm / 130 mm 2.720 x 1.080 x 1.370 mm 2.750 kg Lathe chu ck do not forg et Accessory Three-jaw chuck CI3P Ø 250 mm cast iron, Speed 2.000 Standard equipment Item No. min-1 3442055 Four-jaw chuck CI4P Ø 250 mm cast iron, Speed 2.500 min-1 3442155 Three-jaw chuck CS3C Ø 250 mm steel, Speed 3.500 min-1 3442555 Four-jaw chuck CS4C Ø 250 mm steel, Speed 3.500 min-1 3442655 Universal collet attachment 5C 3444006 Collet chuck kit 3 - 25 mm, 5C, 17 pcs. 3441509 Position limit stop with fine adjustment 3444022 Revolving centre MT 4 3440704 Spare tool holder 32 x 130 type H for round tools 3384324 Lathe tool kit HM 20 mm, 5 pcs 3441670 Lathe tool kit HM 20 mm, 5 pcs 3441617 Vibration damping machine foot SE 3 3381018 ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· Reducing bush MT 6/MT 4 2 steady centres MT 4 Micro stop Digital position display DPA 21 Glass scales Follow rest Passage Ø max. 100 mm Steady rest Passage Ø max. 160 mm Quick change tool holder SWH 5-B Tool holder 25 x 120 type D for square tools Threading gauge Coolant equipment Machine lamp Change gear kit Operating tool 21 TH 5615 / TH 5620 / TH 5630 Heavy centre lathes with new digital position display D DPA 21. Precision for lifetime. Convincing arguments: quality, efficiency and price ·· Hardened and ground bed guideways ·· Spindle seat Camlock DIN ISO 702-2 No. 8 ·· Coolant equipment with separate coolant tank, filling level display and oil separator; easy and complete draining and cleaning according to DIN ·· Guaranteed true running accuracy of the spindle nose better than 0.015 mm ·· Clearly arranged gear selector levers to switch the feed speeds ·· Emergency-stop push button, protective motor switch, lockable main switch ·· Right-handed / left-handed rotation on the bed slide switchable via stem ·· Central lubrication at the bed slide ·· Mechanic longitudinal feed switch-off of the bed slide with four adjustable eccentric ·· Cover for leading spindle ·· Foot operated emergency-stop equipment ·· Electrical system with Siemens components ·· ·· ·· ·· ·· Adjustable scale of the threading gauge Acceptance certificate Quick change tool holder SWH 7-C 1 tool holder 32 x 150 type D for square tools Digital position display DPA 21 –– Speed display –– Considerable reduction of the manufacturing times –– High working accuracy –– Error rate is reduced –– Glass scales Fast acting feed gear ·· Closed structure ·· Hardened and ground toothed Conventional wheels and shafts ·· Running in an oil bath on precision bearings Main spindle ·· Hardened and ground ·· Running in an oil bath ·· Running on 2 readjustable precision taper roller bearings ·· Gearwheels smooth running, hardened and ground Digital position display ·· DPA 21 Slide ·· Precisely worked ·· Handwheels with adjustable precision scaling of 0.04/0.02 mm ·· All guidings adjustable via V-ledges ·· Shafts and wheels running in the oil bath ·· Range of adjustment top slide ± 90° Quality lathe chuck ·· Precisely ·· Higher speed is possible ·· High concentricity and repeatability Chip protection ·· Largely dimensioned ·· Integrated LED lamp Energy chain ·· Cable duct in an energy chain Tailstock ·· Adjustable by ± 15 mm for taper turning ·· Tailstock spindle sleeve and handwheel with adjustable precision scaling of 0.025 mm 22 Technical data and accessories Type Item No. Electrical connection Connection Total connected value Spindle Driving power spindle motor Spindle taper Spindle seat Spindle drilling, rod passage Tool holder seat height (max.) Machine data Centre height Centre width Turning Ø over machine bed Turning Ø over cross slide Turning Ø in the bed bridge Length of bed bridge Bed width Speed range Spindle speed Number of steps Travels Travel top slide Travel cross slide Feeds and pitches Longitudinal feed in the range of Transverse feed in the range of Pitch - Metric in the range of Pitch - Inch in the range of Diametrical pitch in a range of Modular thread in the range of Tailstock Tailstock seat Tailstock - sleeve diameter/travel Dimensions Length x width x height Net weight TH 5615 3462160 TH 5620 3462170 TH 5630 3462180 400 V / 3 Ph ~50 Hz 8.5 KW 7.5 kW MT 7 Camlock DIN ISO 702-2 No 8 Ø 80 mm 25 x 25 mm 280 mm 2,000 mm 560 mm 355 mm 790 mm 270 mm 350 mm 1,500 mm 3,000 mm 25 - 1.600 min-1 12 steps 130 mm 316 mm 0.059 - 1.646 mm/rev; 0.020 - 0.573 mm/rev; 0.2 - 14 mm/rev; 112 - 2 threads/1“; 4 - 112; 0.1 - 7; 35 feeds 35 feeds 47 thread pitches 60 thread pitches 50 threads 34 modular thread MT 5 Ø 75 mm / 180 mm 2.840 x 1.150 x 1460 mm 2.302 kg 3.340x 1.150 x 1460 mm 2.720 kg 4.340x 1.150 x 1460 mm 3.000 kg Lathe chu ck do not forg et Accessory Item No. Three-jaw lathe chuck CI3P Ø 315 mm, D1 - 8” cast iron, Speed 1.500 min-1 3442065 Three-jaw lathe chuck CS3C Ø 315 mm, D1 - 8” steel, Speed 2.800 min-1 3442565 Four-jaw lathe chuck CI4P Ø 315 mm, D1 - 8” cast iron, Speed 1.500 min-1 3442165 Four-jaw lathe chuck CS4C Ø 315 mm, D1 - 8” steel, Speed 2.800 min-1 3442665 Revolving centre MT 5 3440705 Position limit stop with fine adjustment 3444023 Spare tool holder 40 x 160 type H for round tools 3384326 Lathe tool kit HM 20 mm, 5 pcs 3441670 Lathe tool kit HM 20 mm, 5 pcs 3441617 Vibration damping machine foot SE3 3381018 Standard equipment ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· Reducing bush MT 7/MT 5 2 steady centres MT 5 Micro stop Digital position display DPA 21 Glass scales Follow rest Passage Ø max. 165 mm Steady rest Passage Ø max. 95 mm Quick change tool holder SWH 5-B Tool holder 32 x 150 type D for square tools Threading gauge Coolant equipment Machine lamp Change gear kit Operating tool 23 TH 5620V Heavy centre lathe with Siemens Inverter-Vario drive, which distinguish themselves by high flexibility, accuracy and operating efficiency. With new digital position display DPA 21. Convincing arguments: quality, efficiency and price ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· Hardened and ground bed guideways Spindle seat Camlock DIN ISO 702-2 No. 8 Speed monitoring according to machine directive EMC filter also for the use in mixed-use areas Coolant equipment with separate coolant tank, filling level display and oil separator; easy and complete draining and cleaning according to DIN Guaranteed true running accuracy of the spindle nose better than 0.015 mm Clearly arranged gear selector levers to switch the feed speeds Emergency-stop push button, protective motor switch, lockable main switch Right-handed / left-handed rotation on the bed slide switchable via stem Central lubrication at the bed slide Mechanic longitudinal feed switch-off of the bed slide with four adjustable eccentric Cover for leading spindle Foot operated emergency-stop equipment ·· ·· ·· ·· ·· ·· Electrical system with Siemens components Adjustable scale of the threading gauge Acceptance certificate Quick change tool holder SWH 7-C 1 tool holder 32 x 150 type D for square tools Digital position display DPA 21 –– Speed display –– Considerable reduction of the manufacturing times –– High working accuracy –– Error rate is reduced –– Glass scales Vario drive Fast acting feed gear ·· Closed structure ·· Hardened and ground toothed wheels and shafts ·· Running in an oil bath on precision bearings Main spindle ·· Hardened and ground ·· Running in an oil bath ·· Running on 2 readjustable preci- Converter SINAMICS G120D More information about: „Converter SINAMICS G120D“ see main catalogue Slide ·· Precisely worked ·· Handwheels with adjustable precision scaling of 0.04/0.02 mm ·· All guidings adjustable via V-ledges ·· Shafts and wheels running in the oil bath ·· Range of adjustment top slide ± 90° Energy chain ·· Cable duct in an sion taper roller bearings ·· Gearwheels smooth running, hardened and ground Quality lathe chuck ·· Precisely ·· Higher speed is possible ·· High concentricity and repeatability Chip protection ·· Largely dimensioned ·· Integrated LED lamp energy chain Tailstock ·· Adjustable by ± 15 mm for taper turning ·· Tailstock spindle sleeve and handwheel with adjustable precision scaling of 0.025 mm 24 Technical data and accessories Type Item No. Electrical connection Connection Total connected value Spindle Driving motor Spindle taper Spindle seat Spindle drilling, rod passage Tool holder seat height (max.) Machine data Centre height Centre width Turning Ø over machine bed Turning Ø over cross slide Turning Ø in the bed bridge Length of bed bridge Bed width Speed range Spindle speed Number of steps Travels Travel top slide Travel cross slide Feeds and pitches Longitudinal feed in the range of Transverse feed in the range of Pitch - Metric in the range of Pitch - Inch in the range of Diametrical pitch in a range of Modular thread in the range of Tailstock Tailstock seat Tailstock - sleeve diameter/travel Dimensions Length x width x height Net weight TH 5620V 3462175 400 V / 3 Ph ~50 Hz 8.5 kW 7.5 kW MT7 Camlock DIN ISO 702-2 No 8 Ø 105 mm 25 x 25 mm 280 mm 2,000 mm 560 mm 355 mm 785 mm 170 mm 350 mm 25 - 200 min-1 / 200 - 1600 min-1 2 steps; electrically adjustable speed 130 mm 316 mm 0.059 - 1.646 mm/rev; 0.020 - 0.573 mm/rev; 0.2 - 14 mm/rev; 112 - 2 threads/1“; 4 - 112; 0.1 - 7; MT 5 Ø 75 mm / 180 mm 3.340x 1.150 x 1460 mm 2.985 kg Lathe chu ck do not forg et Accessory Item No. Three-jaw lathe chuck CI3P Ø 315 mm, D1 - 8” cast iron, Speed 1.500 min-1 3442065 Three-jaw lathe chuck CS3C Ø 315 mm, D1 - 8” steel, Speed 2.800 min-1 3442565 Four-jaw lathe chuck CI4P Ø 315 mm, D1 - 8” cast iron, Speed 1.500 min-1 3442165 Four-jaw lathe chuck CS4C Ø 315 mm, D1 - 8” steel, Speed 2.800 min-1 3442665 Revolving centre MT 5 3440705 Position limit stop with fine adjustment 3444023 Spare tool holder 40 x 160 type H for round tools 3384326 Lathe tool kit HM 20 mm, 5 pcs 3441670 Lathe tool kit HM 20 mm, 5 pcs 3441617 Vibration damping machine foot SE3 3381018 Standard equipment ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· Reducing bush MT 7/MT 5 2 steady centres MT 5 Micro stop Digital position display DPA 21 Glass scales Follow rest Passage Ø max. 165 mm Steady rest Passage Ø max. 95 mm Quick change tool holder SWH 5-B Tool holder 32 x 150 type D for square tools Threading gauge Coolant equipment Machine lamp Change gear kit Operating tool 25 Lathe tool kits Lathe tool kit HM 8 mm Lathe tool kit HM 8 mm ·· 5 pcs. ·· With HM reversible carbide tips ·· TiN-coated ·· Aluminium box 1 2 3 4 5 2 3 4 5 HM spare inserts (5 pcs each) h1 ISO No 1 3441662 3441758 3441761 3441760 3441761 3441759 h1 ISO SWGC L0808 D05 8 mm No SSDC N0808 D06 8 mm SWGC R0808 D05 8 mm STGC R0808 D09 8 mm SDJC R0808 D07 8 mm 1/3 2 4 5 WCMT050308 SCMT060204 TCMT090204 DCMT070204 D1 D2 B1 S1 Re Item No. 7.94 6.35 5.56 6.35 3.2 2.8 2.5 2.8 80° 90° 60° 55° 3.18 2.38 2.38 2.38 0.8 0.4 0.4 0.4 3441759 3441761 3441760 3441758 Lathe tool kit HM 10 mm Lathe tool kit HM 10 mm ·· 5 pcs. ·· With HM reversible carbide tips ·· TiN-coated ·· Aluminium box 6 h1 7 8 9 10 HM spare inserts (5 pcs each) 3441759 ISO No 6 7 8 9 10 3441664 3441760 3441761 3441758 h1 ISO SWGC L1010 E05 10 mm No SSDC N1010 E06 10 mm SWGC R1010 E05 10 mm STGC R1010 E09 10 mm SDJC R1010 E07 10 mm 6/8 7 9 10 WCMT050308 SCMT060204 TCMT090204 DCMT070204 D1 D2 B1 S1 Re Item No. 7.94 6.35 5.56 6.35 3.2 2.8 2.5 2.8 80° 90° 60° 55° 3.18 2.38 2.38 2.38 0.8 0.4 0.4 0.4 3441759 3441761 3441760 3441758 14 15 Lathe tool kit HM 12 mm Lathe tool kit HM 12 mm ·· 5 pcs. ·· With HM reversible carbide tips ·· TiN-coated ·· Aluminium box 26 11 h1 12 13 HM spare inserts (5 pcs each) 3441762 3441759 ISO No 11 12 13 14 15 3441666 3441758 h1 SWGC L1212 H 05 12 mm SSDC N1212 H 09 12 mm SWGC R1212 H 05 12 mm STGC R1212 H 11 12 mm SDJC R1212 H 07 12 mm No 11/13 12 14 15 ISO WCMT050308 SCMT09T304 TCMT110204 DCMT070204 D1 D2 B1 S1 Re Item No. 7.94 6.35 3.2 2.8 80° 90° 60° 55° 3.18 2.38 0.8 0.4 3441759 3441763 3441762 3441758 6.35 2.8 6.35 2.8 2.38 0.4 2.38 0.4 Lathe tool kit HM 16 mm Lathe tool kit HM 16 mm ·· 5 pcs. ·· With HM reversible carbide tips ·· TiN-coated ·· Aluminium box 21 22 23 24 25 HM spare inserts (5 pcs each) h1 3441752 ISO No 21 22 23 24 25 3441668 3441754 3441755 3441750 h1 PWLN R1616 H06 16 mm No PWLN L1616 H06 16 mm PSDNN 1616 H09 16 mm CKJN R1616 H16 16 mm MDJN R1616 H11 16 mm 21/22 23 24 25 ISO WNMG060408 SNMG090304 KNUX160405R DNMG110408 D1 D2 B1 S1 Re 9.252 9.252 9.252 9.525 3.81 3.81 80° 90° 55° 55° 4.76 3.18 4.76 4.76 0.8 0.4 0.5 0.8 3.81 L1 Item No. 3441752 3441755 3441754 3441750 16.15 Lathe tool kit HM 20 mm Lathe tool kit HM 20 mm ·· 5 pcs. ·· With HM reversible carbide tips ·· TIN-coated ·· Aluminium box h1 37 38 39 40 HM- spare inserts 3441756 3441753 ISO No 36 37 38 39 40 36 3441670 3441754 3441750 h1 PWLN R2020 K08 20 mm PWLN L2020 K08 20 mm PSDN N2020 K12 20 mm CKJN R2020 K16 20 mm MDJN R2020 K11 20 mm No ISO 36/37 WNMG080408 38 39 40 SNMG120408 KNUX160405R DNMG110408 D1 D2 B1 S1 Re 9.252 3.81 80° 4.76 0.8 12.7 9.252 9.525 5.16 90° 55° 55° 4.76 4.76 4.76 0.8 0.5 0.8 3.81 L1 Item No. 3441752 3441756 3441754 3441750 16.15 Lathe tool kit HM 25 mm 51 Lathe tool kit HM 25 mm ·· 5 pcs. ·· With HM reversible carbide tips ·· TIN-coated ·· Aluminium box h1 53 54 55 HM- spare inserts 3441754 3441752 3441757 ISO No 52 3441672 3441751 h1 51 PWLN L2525 M08 25 mm No 52 PSDN N2525 M15 25 mm 53 PWLN R2525 M08 25 mm 54 CKJNR R2525 M16 25 mm 55 MDJN R2525 M15 25 mm 51/53 52 54 55 ISO WNMG080408 SCMG150608 KNUX160405R DNMG150408 D1 D2 B1 S1 Re 9.252 15.875 9.252 12.7 3.81 6.35 80° 90° 55° 55° 4.76 6.35 4.76 4.76 0.8 0.8 0.5 0.8 5.16 L1 16.15 Item No. 3441752 3441757 3441754 3441751 27 Lathe tool kits Lathe tool kit HM 32 mm 56 Lathe tool kit HM 32 mm ·· 5 pcs. ·· With HM reversible bide tips ·· TIN-coated ·· Aluminium box car- h1 58 59 60 HM- spare inserts 3441754 3441751 3441752 3441757 ISO No 57 3441674 h1 56 PWLN L3232 P08 32 mm No 57 PSDN N3232 P15 32 mm 58 PWLN R3232 P08 32 mm 56/58 57 59 CKJN R3232 P16 32 mm 60 MDJN R3232 P15 32 mm 59 60 Clamping block with 2 blades and carbide cutting tips Kit 16-05 3440653 ISO D1 D2 B1 S1 Re WNMG080408 SCMG150608 9.252 15,875 3.81 6.35 80° 90° 4.76 6.35 0.8 0.8 KNUX160405R DNMG150408 9.252 12.7 5.16 55° 55° 4.76 4.76 0.5 0.8 L1 Item No. 3441752 3441757 16.15 3441754 3441751 Kit of carbide cutting tips (10 pcs.) for carbide cutting tips GTN 2 3440663 For the lathes: D320/TU3209/ D330/D360/TU3610V for carbide cutting tips GTN 3 3440664 ·· 1 pc. Clamping block SLTBN 16-05 for carbide cutting tips GTN 4 3440665 ·· 1 pc. Blade SLIH 26-2 ·· 1 pc. Blade SLIH 26-3 ·· 5 pc. Carbide cutting tips GTN2 (widths 2.2 mm) ·· 5 pc. Carbide cutting tips GTN3 (widths 3.1 mm) ·· Aluminium box Kit 20-05 3440654 For the lathes: D420/TU4210V/D460/TU4615/D560/TU5620 ·· 1 pc. Clamping block SLTBN 20-05 ·· 1 pc. Blade SLIH 26-3 ·· 1 pc. Blade SLIH 26-4 ·· 5 pc. Carbide cutting tips GTN3 (widths 3.1 mm) ·· 5 pc. Carbide cutting tips GTN4 (widths 4.1 mm) ·· Aluminium box Kit 25-05 Carbide cutting tip block incl. cutting chisel 3440655 Clamping block 16-05 20-05 25-05 For the lathes: D 660/TU 8020/TU 8030 L x W x H (mm) 88 x 38 x 42 88 x 38 x 43 100 x 42 x 43.5 ·· 1 pc. Clamping block SLTBN 25-05 C 16 mm 20 mm 25 mm ·· 1 pc. Cutting chisel SLIH 26-3 D 4 mm 5 mm 5 mm ·· 1 pc. Cutting chisel SLIH 26-4 ·· 5 pc. Carbide cutting tips GTN3 (widths 3.1 mm) ·· 5 pc. Carbide cutting tips GTN4 (widths 4.1 mm) Reducing bush ·· Aluminium box Edge finder ·· with rotating spindle ·· Probing Ø 10 mm 28 335 1171 MT3-MT2 / M12 335 0313 7.90 MT4-MT3 / M16 335 0314 12.90 Accessory Steady rest Follow rest for TU 3008 3441461 for TU 3008 3441460 Precision boring drilling head kit Kit of reversible carbide tips ·· 8 pc. Drill rods: BJ2008-32L/BJ2010-40L/BJ2014-53L/BJ2016-68L/ BJ2020-83L/BJ2025-96L/BJ2030-115L/BJ20-L20-100L 8 1 2 3 4 Kit of reversible carbide tips (10 pcs.) for tool (for drill rods No. 8 and 7) for aluminium (for drill rods No. 8 and 7) for tool (for drill rods No. 6 and 5) for aluminium (for drill rods No. 6 and 5) for tools (for drill rods No. 4, 3, 2 and 1) for aluminium (for drill rods No. 4, 3, 2 and 1) Universal-substructure BF 16/BF 20 Steel ·· Including drill rods, bolts, circle extensions, tools, box Alu ·· without reversible carbide tips ISO 30 5 6 335 2127 ISO 40 335 2128 ISO 50 335 2129 7 335 2136 335 2141 335 2137 335 2142 335 2138 335 2143 335 3000 ·· Dimensions L x W x H: 340 x 420 x 800 mm Chip tray BF 16/BF 20 335 2999 ·· Dimensions L x W x H: 720 x 470 x 30 mm 29 DPA 21 The versatile 3+1 axis digital position display with speed display. High quality technique and durable industrial quality for the rought use in the shop Measuring blocks ·· Fully enclosed path measuring systems with highly precise glass measuring rod ·· Accuracy 5 µm ·· Scanning carriage with miniature ball bearings guided and connected via a coupling in the mounting stand ·· Protected against dust, chips and splash water by a rubber sealing lip ·· Flexible metal protection hose protects a 3 of 4 m long connection cable (from ML 620 on - 4 m) ·· Without assembly ML 80 mm 338 4108 ML 100 mm 338 4110 ML 120 mm 338 4112 ML 170 mm 338 4117 ML 220 mm 338 4122 ML 270 mm 338 4127 ML 320 mm 338 4132 ·· User-friendly splash water protected closed and glare-free membrane keyboard ML 370 mm 338 4137 ·· Switchable for milling machines and lathes, freely selectable input signal (sine/rectangle) to be used e.g. for glass measuring rods and/or magnetic tape systems ML 420 mm 338 4142 ML 470 mm 338 4147 ML 520 mm 338 4152 ML 570 mm 338 4157 ML 620 mm 338 4162 ML 670 mm 338 4167 ML 720 mm 338 4172 ML 770 mm 338 4177 ML 820 mm 338 4182 ·· High quality aluminium housing ML 870 mm 338 4187 ·· Display: X, Y/Z0, Z axis with 8-digit LED display each (the sign is the first digit) ML 920 mm 338 4192 ML 970 mm 338 4197 ·· Three evaluable measuring inputs with seven correction memories for tools each ML 1020 mm 338 4202 ML 1250 mm 338 4225 ·· Dimensions L x W x H: 280 x 70 x 185 mm ML 1400 mm 338 4240 ·· Weight: 2.6 kg ML 1520 mm 338 4252 ML 1670 mm 338 4267 Possible functions ML 1940 mm 338 4294 ·· Calculator ML 2010 mm 338 4295 ·· Speed display ML 3000 mm 338 4300 ·· Sub D plugs sockets Factory assembly ML 9000410 ·· Absolute/incremental operation ·· Per measuring block Digital position display DPA 21 3384020 ·· Magnetic tape to be mounted on machines on which there is not sufficient space for magnetic measuring rods ·· Sensors to capture the spindle speed are included in the delivery ·· High working accuracy ·· Considerable reduction of the manufacturing times ·· Error rate is reduced ·· Axis coupling (sum Z) ·· Conversion inch/metric thread ·· Pitch circle calculator (chain dimension) Magnetic tape MB 100 ·· Coordinates in the circle (pitch circle) ·· Price per 1 cm ·· Holes in the circle (pitch circle) ·· Measured values radius/diameter can be switched over ·· With steel protecting strip Factory assembly magnetic tape ·· Zeroing/data pre-setting ·· Each axis 338 3941 9000412 ·· Self-diagnosis ·· Reference point Reading head activated ·· Linear error correction ·· for magnetic tape 338 3932 ·· 7 tool memories 30 Scope of delivery Perforated disc ·· Speed sensor ·· for speed sensor ·· Bracket ·· Lathe D 320 up to D 360 338 3926 ·· Power supply unit 24V ·· Lathe D 420 up to D 660 338 3927 DRO 5 Digital 3 axes positioning magnetic measuring system for milling machines and lathes with speed display Digital magnetic measuring system DRO 5 338 3975 Item No. ·· including magnetic sensor ·· including 3 reading head ·· including Power supply unit ·· Digital 3-axes position display for milling machines (X - Y - Z) and lathes (X, Z, Z0) ·· Stable aluminium housing ·· To measure positions ·· Speed display ·· 3 inputs ·· Four-row LCD display ·· Front programming Magnetic tape ·· Lenght 1.100 mm Item No. 338 3978 Magnetic tape ·· Lenght 2.000 mm Item No. 338 3979 Workshop assembly 9000420 Add-on kit - Turning Kit 1 3390405 ·· Digital position display DP700 ·· Display bracket ·· Add-on part for the mounting of a measuring bar 1 axis Spherosyn and 1 axis Microsyn larger than 300 mm Add-on kit - Turning Kit 2 3390406 ·· Digital position display DP700 ·· Display bracket ·· Add-on part for the mounting of a measuring bar 1 axis Spherosyn and 1 axis Microsyn less than 300 mm 31 saw®SP 11V / SP 13V Transportable mitre band saws with high cutting precision particular low noise and infinitely variable cutting speed Convincing arguments... Convincing arguments: quality, efficiency and price ·· Ball bearing mounted 2 point saw band guiding providing outstanding band run and thus optimum cutting results ·· Saw bow from 0° to +60° (SP 13V) or from 0° to +45° (SP 11V) slewable in order to allow angular saw cuts ·· With high-grade bimetallic saw band supplied as standard ·· Adjustable material stop for series productions ·· Base plate equipped with anti-skid feet ·· Vibration and wear-resistant thanks to special drive with two toothed wheels made of hardened steel ·· Vario drive motor with low speed and carbon brushes for one to 10-times longer service life Mitre angle ·· Scale good read for angle adjustment Push button "Manual saw band running" ·· Switches the run of the saw band Saw band guiding ·· Ball bearing; for outstanding belt run and thus optimum cutting results Vario drive ·· Infinitely variable saw band speed from 30 to 80m/min. Fig.: Optisaw SP13V Optional accessories Machine pedestal ·· L x W x H: 500 x 470 x 780mm Item No. 363 0000 Type Item No. Machine data Electrical connection Motor power General information Saw band speed Saw band dimensions Cutting angle Dimensions Length Width without / with material stop Height bottom / upper stop position of saw bow Net weight Standard equipment SP 11V 330 0070 SP 13V 330 0075 230 V / 1 Ph ~50 Hz 850 W 230 V / 1 Ph ~50 Hz 1 kW 30 - 80 m/min 1.330 x 13 x 0,65 mm 0° - 60° 30 - 80 m/min 1.440 x 13 x 0,65 mm 0° - 60° 650 mm 290 / 670 mm 720 mm 300 / 650 mm 450 / 630 mm 19 kg Bi-metal saw band Material stop 420 / 680 mm 19.5 kg Bi-metal saw band Material stop The saw complies with the standard DIN EN 55011:2011-04 Class C2 - (to be used only in industrial areas) 32 SP 11V Cutting range 0 ° Ø 105 mm Ø 125 mm Cutting range 0 ° 125 x 125 mm 100 x 100 mm SP 13V Cutting range 45° Ø 85 mm Cutting range 45 ° 85 x 85 mm 60 x 65 mm SP 13V SP 11V SP 13V Ø 65 mm Cutting range 60 ° 50 x 50 mm Cutting range 60° Ø 50 mm Saw bands HSS bi-metal M 42 6 - 10 tpi 0° 335 1546 10 - 14 tpi 0° 335 1547 saw® S 275N/ S 275NV Metal band saws with slewable saw bow and 2 saw band speeds. Optisaw S 275NV with infinitely variable cutting speed Convincing arguments: quality, efficiency and price ·· ·· ·· ·· ·· Low-noise running Solid casting type High cutting accuracy due to vibration-free running Two switchable speeds Lowering of the saw bow by means of the hydraulic cylinder with infinitely variable throttle valve ·· Micro switch for automatic limit stop ·· Scale good read for angle adjustment ·· With high-grade bimetallic saw band supplied as standard ·· Adjustable material stop for series productions ·· Completely equipped machines; the user can immediately work productive after commissioning S 275NV ·· Infinitely variable saw band speed 20 - 90 m/min. ·· It is easily possible to change the speed during operation Saw band guiding ·· Ball bearing 5-point saw band guiding ·· Outstanding band run and thus optimum cut ·· Chip brush ·· EMC filter Control panel ·· Clearly-arranged keyboard for simple operation ·· Emergency stop push button ·· Switch coolant pump ·· Speed selector switch ·· for Vario: Potentiometer Quick-action vice ·· Adjustable via handwheel ·· Clamping the workpiece by means of the handy quick action lever Machine base ·· Robust Cutting ranges 0° Ø 225 mm Type Item No. S 275N 330 0260 Type Item No. S 275NV 330 0265 Machine data Electrical connection Total connected value Electrical connection NV Total connected value NV General information Lifting the saw bow Feed Saw band speed Saw band speed NV Saw band dimensions Cutting angle Net weight Standard equipment 400 V / 3 Ph ~50 Hz 1.1 kW 230 V / 1 Ph 1.5 kW Manual continuously adjustable 45/90 m/min 20 - 90 m/min 2'480 x 27 x 0.9 mm from 0° up to 60° 185 / 200 kg Bi-metal saw band Material stop Machine base 235 x 150 mm 45° Ø 155 mm 210 x 155 mm 60° Ø 90 mm 120 x 90 mm Saw bands HSS bi-metal M 42 Teeth per inch Tooth angle Item No. 5 - 8 tpi 0° 335 7511 6 - 10 tpi 0° 335 7524 5 - 8 tpi 6° 335 7512 Saw band kit ·· Saw band HSS bi-metal 5 - 8 TPI; 00 ·· Saw band HSS bi-metal 6 - 10 TPI; 00 ·· Saw band HSS bi-metal 5 - 8 TPI; 60 S 275N/ S 275NV 335 7504 90.00 33 saw® SD 280V Metal band saw with slewable saw bow and infinitely variable saw band speed Convincing arguments: quality, efficiency and price ·· ·· ·· ·· ·· Low-noise running Solid casting type High cutting accuracy due to vibration-free running Two switchable speeds Lowering of the saw bow by means of the hydraulic cylinder with infinitely variable throttle valve ·· Micro switch for automatic limit stop ·· ·· ·· ·· Scale good read for angle adjustment With high-grade bimetallic saw band supplied as standard Adjustable material stop for series productions Completely equipped machines; the user can immediately work productive after commissioning ·· EMC filter (electromagnetic compatibility) Control panel ·· Clearly-arranged keyboard for simple operation ·· Emergency stop push button ·· Switch coolant pump ·· Speed selector switch ·· Potentiometer Hard metal guideway ·· avoids rapid wear Quick-action vice ·· Adjustable via handwheel ·· Clamping the workpiece by means of the handy quick action lever Coolant equipment ·· Powerful Machine base ·· Robust Cutting ranges 0° Ø 225 mm Type Item No. Machine data Electrical connection Total connected value General information Lifting the saw bow Feed Saw band speed Saw band dimensions Cutting angle Net weight Standard equipment 34 SD 280V 3300280 45° 400 V / 3 Ph ~50 Hz 1.1 kW Manual continuously adjustable 20 - 90 m/min 2'480 x 27 x 0.9 mm from 0° up to 60° 200 kg Bi-metal saw band Material stop Machine base 245 x 180 mm Ø 160 mm 160 x 160 mm 60° Ø 100 mm 100 x 100 mm Saw bands HSS bi-metal M 42 Teeth per inch Tooth angle Item No. 5 - 8 tpi 0° 3357511 6 - 10 tpi 0° 3357524 5 - 8 tpi 6° 3357512 MSR 4H / MSR 7H / MSR 10H Height adjustable material stand MSR-H as manual aid for supporting and moving the workpieces for metal saws infinitely variable to 1.050 mm Convincing arguments... Convincing arguments: quality, efficiency and price ·· ·· ·· ·· Optimum aids to support long and heavy workpieces Universally applicable for e.g. metal band saws, circular saws, etc. Infinitely height adjustable roller support Safe workpiece support due to steel rollers which are massive high-capable of bearing ·· Infinitely extendable ·· Mounting option of the distance measuring system LMS Frame ·· Stable type ·· Solid special profile Load-bearing rollers ·· Steel ·· Ball bearings on both sides Fig.: MSR 10H Layer height ·· Infinitely variable from 650 - 1.050 mm Fig.: MSR 7H Fig.: MSR 4H Type Item No. Technical data Diameter of support rollers Width of support rollers Static table load Dimensions Length x Width Height Height H-version Net weight Standard equipment Accessories Item No. MSR 4H 335 7001 MSR 7H 335 7002 MSR 10H 335 7003 60 mm 360 mm 500 kg 60 mm 360 mm 700 kg 60 mm 360 mm 700 kg 1.000 x 440 mm 650 - 950 mm 650 - 1.050 mm 33 kg 2.000 x 440 mm 650 - 950 mm 650 - 1,050 mm 61 kg Fixing material for elongation 3.000 x 440 mm 650 - 950 mm 650 - 1,050 mm 78 kg Table elongation MSR 1 335 7004 Accessories PVC rolls ·· Additionally mountable ·· Made of anti-skid PVC ·· To avoid scratches ·· Simply mount rolls into the existing mounting brackets ·· In practical wall bracket Table elongation ·· Additionally mountable ·· Mountable in both directions 35 LMS 10 - LMS 40 distance measuring system to be attached to the Optimum material stand MSR for perfect distance measurement and exact positioning Convincing arguments... Convincing arguments: quality, efficiency and price ·· ·· ·· ·· Magnetic measuring system with magnetic tape For recurring measuring tasks with high precision of 0.1 mm Automatic switching on of the display During longer standstills the measuring system switches off and keeps the last measurement saved ·· Measuring accuracy: ±(0.025 + 0.02 x measuring length [m]) ·· Battery life of up to 10 years Material stop ·· For large diameters ·· Stop for small pieces with elongation ·· ·· ·· ·· ·· ·· ·· Display: LCD Switching functions: Zeroing display Reset Direction indicator ± Measuring unit 0.01 mm Absolute measurement and chain measurement function ·· Right end/left end stop Slide ·· Easily moveable ·· Precisely guided ·· Replaceable durable dry bearings ·· Easy installation by the client Positioning slide ·· Right end/left end stop ·· Folding upwards Fig.: Material stand MSR 4 with distance measuring system LMS 10 36 Type Item No. LMS 10 338 3851 LMS 20 338 3852 LMS 30 338 3853 LMS 40 338 3854 Technical data Rail length Travel 1,000 mm 830 mm 2,000 mm 1,830 mm 3,000 mm 2,830 mm 4,000 mm 3,830 mm Linear guide rails ·· Lubricant-free ·· Very smooth running ·· Wear resistant ·· Corrosion-resistant ·· Little friction values ·· High static bearing capacity grind®GU 17 / GU 20 / GU 25 Robust double grinding machines to process metals Convincing arguments: quality, efficiency and price ·· Heavy long-life industrial type with maintenance-free motor for permanent use ·· Housing made of aluminium die casting ·· Balanced rotor with quality ball bearings ensures long service life and very smooth running ·· Spark protection on each grinding wheel reduces flying sparks ·· Solid, adjustable workpiece support ·· Inspection glasses made of break-proof material ·· Vibration-absorbing rubber feet Convincing arguments... ·· Two universal corundum grinding wheels in the standard scope of delivery Fig.: Opti grind GU20 Type Item No. Item No. Machine data Electrical connection Motor power Grinding wheels Dimensions Speeds Dimensions Length x width x height Net weight GU 15 3101505 - GU 18 3101510 - GU 20 3101515 (230 V) 3101520 (400 V) GU 25 3101525 230 V / 1 Ph ~50 Hz 450 W 230 V / 1 Ph ~50 Hz 450 W 230 V or 400V 600 W 400 V / 3 Ph ~50 Hz 1.5 kW Ø 150 x 20 Ø16 mm 2.850 min-1 Ø 175 x 25 Ø32 mm 2.850 min-1 Ø 200 x 30 Ø32 mm 2.850 min-1 Ø 250 x 40 Ø32 mm 2.850 min-1 410 x 200 x 265 mm 12 kg 456 x 220 x 291 mm 14 kg 461 x 246 x 310mm 20 kg 542 x 304 x 365 mm 37 kg Grinding wheel regular corundum rough K 36 Grinding wheel regular corundum fine K 80 Standard equipment Universal grinding machines with grinding tool made by OPTIMUM speak for functionality Type Item No. GU 20S 3101570 (230 V) 3101575 (400 V) GU 25S 310 1580 (400 V) 37 GZ 20D/GZ 20DD / GZ 25D/GZ 25DD / GZ 30D/GZ 30DD Premium double grinding machines. GZ - DD types with substructure and integrated suction system Substructure Convincing arguments: quality, efficiency and price ·· 10-year Optimum warranty* GZ 20D ·· Heavy industrial grinding machine absorbs due to its high dead weight and little vibrations ·· Also suitable for very strong thrust forces on the grinding wheels ·· Maintenance-free, durable induction motor running smoothly ·· Two-sided turned grinding wheel locking flange ·· Housing made of cast iron ·· Spark protection ·· Solid, adjustable workpiece support GZ-DD types: ·· Integrated suction system with fan made of aluminium and self-cleaning blades ·· Dust bag made of self-extinguishing fabric ·· Stable substructure including water tray 309 1120 ·· L x W x H: 400 x 370 x 760 mm ·· Weight 33 kg GZ 25D 309 1122 ·· L x W x H: 460 x 430 x 760 mm ·· Weight 40 kg GZ 30D 309 1124 ·· L x W x H: 460 x 430 x 760 mm ·· Weight 52 kg Grinding wheel ·· Fused aluminium oxide grinding wheel ·· Hardness M - white ·· Made in Germany Grinding wheel GZ 20D/DD K 36 309 8021 K 60 309 8023 K 80 309 8025 Grinding wheel GZ 25D/DD K 36 309 8031 K 60 309 8033 K 80 309 8035 Grinding wheel GZ 30D/DD K 36 309 8041 K 60 309 8043 K 80 309 8045 309 1099 Electronic brake ·· Controlled stopping PREMIUM ·· Including factory assembly „Optimum warrenty please see main catalogue Type Item No. GZ 20D 309 1010 GZ 25D 309 1015 GZ 30D 309 1020 Type Item No. GZ 20DD 309 1040 GZ 25DD 309 1045 GZ 30DD 309 1050 400 V / 3 Ph ~50 Hz 750 W 400 V / 3 Ph ~50 Hz 1.1 kW 400 V / 3 Ph ~50 Hz 1.8 kW Ø 200 x 25 Ø20 mm 2,800 min-1 Ø 250 x 30 Ø25 mm 1,400 min-1 Ø 300 x 35 Ø30 mm 1,400 min-1 550 x 290 x 360 mm 800 x 710 x 1.300 mm 25 kg 63.7kg 670 x 340 x 410 mm 800 x 710 x 1.300 mm 44.8 kg 91 kg 810 x 420 x 560 mm 800 x 1.200 x 1.300 mm 64.5 kg 124 kg Machine data Electrical connection Motor power Grinding wheels Dimensions Speeds Dimensions L x W x H GZ types L x W x H GZ-DD types Net weight GZ types Net weight GZ-DD types 38 Fig.: GZ 25DD with optional grinding wheels GZ 20C / GZ 25C Premium combined grinding machines for shops, steel working companies Convincing arguments: quality, efficiency and price Base ·· 10-year Optimum warranty* GZ 20C ·· Heavy industrial combined grinding machine absorbs due to its high dead weight and little vibrations ·· Also suitable for very strong thrust forces on the grinding wheel and brush ·· Maintenance-free, durable induction motor running smoothly ·· Housing made of cast iron ·· Solid, adjustable workpiece support ·· Optionally available zero balanced grinding wheel for rough grinding and brush for polishing 309 1120 ·· L x W x H: 400 x 370 x 760 mm ·· Weight 33 kg GZ 25C 309 1122 ·· L x W x H: 460 x 430 x 760 mm ·· Weight 40 kg Grinding disc ·· Fused alu oxide grinding wheel ·· Hardness M - white ·· Made in Germany Grinding wheel GZ 20D/DD K 36 309 8021 K 60 309 8023 K 80 309 8025 Grinding wheel GZ 25D/DD PREMIUM Fig.: GZ 20C with optional grinding wheel and brush Type Item No. Machine data Electrical connection Motor power Grinding wheels Dimensions Speeds Dimensions Length x width x height Net weight K 36 309 8031 K 60 309 8033 K 80 309 8035 Round brush ·· Multi-purpose wire brush made of high-strength steel wire available in the accessories in different strengths ·· Slewable brush protection housing with suction nozzle to connect a suction unit „Optimum warrenty please see main catalogue GZ20C 309 1070 GZ25C 309 1075 400 V / 3 Ph ~50 Hz 750 W 400 V / 3 Ph ~50 Hz 1.1 kW Ø 200 x 25 Ø20 mm 2.800 min-1 Ø 250 x 30 Ø25 mm 1.400 min-1 650 x 300 x 360 mm 26.5 kg 850 x 340 x 410 mm 40.7 kg ·· High-strength steel wire ·· Made in Germany GZ 20C 0.35 mm 309 8081 0.5 mm 309 8082 GZ 25C 0.3 mm 309 8086 0.5 mm 309 8087 Electronic brake 309 1099 ·· Controlled stopping ·· Including factory assembly 39 polish GU 20P / GU 25P Polishing machines for the finest surface treatment of metal workpieces Convincing arguments: quality, efficiency and price ·· Heavy, long-life industrial type with maintenance-free motor ·· Housing made of aluminium die casting ·· Balanced rotor with quality ball bearings ensures long service life and very smooth running ·· Vibration-absorbing rubber feet ·· Two wide polishing discs Balanced rotor ·· Long service life ·· High smooth running ·· Quality ball bearings Type Item No. (230 V) Item No. (400 V) Machine data Electrical connection Motor power Technical data Speed Dim. polishing disc Dimensions Length Width Height Weight Standard equipment 40 Standard equipment ·· Polishing wheel smooth ·· Polishing wheel hard GU 20P 3101540 3101545 GU 25P 3101550 230 V/1 Ph o 400V/3Ph 600 W 400 V / 3 Ph ~50 Hz 1.5 kW 2.850 min-1 Ø 200 x 20 Ø 16 mm 2.850 min-1 Ø 250 x 25 Ø 20 mm 200 mm 550 mm 250 mm 630 mm 260 mm 320 mm 18 kg 23 kg Polishing wheel smooth Polishing wheel hard DDP 50 Precision arbor press of robust and solid type. For mechanic shops and repair companies Convincing arguments: quality, efficiency and price ·· For pressing-in and grouting of bearings, arbors, connectors, spindles, pins ·· Solid construction ·· Body made of high quality grey cast iron Type Item No. Technical data Height of workpiece max. Throat Dimensions Length x Width x Height max Ram dimensions (L x W x H) Weight Standard equipment ·· Variably adjustable lever rod ·· Quadruple positionable base plate ·· To be fixed on a workbench DDP 50 335 9015 Force effect 459 mm 226 mm 650 x 350 x 785 mm 50 x 50 x 647 mm 140 kg DDP 50 Manual force F1 Length of lever arm S1 Force effect F2 392.4 N 589 N (40 kg) (60 Kg) 850 mm 10251 15372 (1045 kg) (1567 kg) 41 Notizen 42 Notizen 43 Our variety is your advantage CNC catalogue www.optimum-maschinen.de OPTIMUM Cap Item No. 9000072 € 9.90 plus VAT. www.schweisskraft.de OPTIMUM Maschinen Germany GmbH Dr.-Robert-Pfleger-Str. 26 D-96103 Hallstadt/Bamberg Fax.: +49/ 9 51 - 96 555 - 888 e-mail: info@optimum-maschinen.de www.aircraft-kompressoren.com Sales Germany: Sales Austria Stürmer Maschinen GmbH Dr.-Robert-Pfleger-Str. 26 D-96103 Hallstadt/Bamberg AIRCRAFT Kompressorenbau und Maschinengrosshandel GmbH Gewerbestraße Ost 6 A-4921 Hohenzell / Austria Phone: +43 - (0) 77 52 - 70 929 - 0 Fax.: +43 - (0) 77 52 - 70 929 - 99 e-mail: info@aircraft.at Phone: +49/ 951 - 96 555 - 74 Fax.: +49/ 951 - 96 555 - 55 e-mail: info@stuermer-maschinen.de Your specialized dealer: www.finikompressoren.de www.unicraft.de www.holzkraft.de The machine is built according to CE guidelines www.optimum-maschinen.de © OPTIMUM MASCHINEN GERMANY GMBH. 09/2015 / WMD 0,1 K www.metallkraft.de