cuprofin-E - Wieland Industrierohre

advertisement

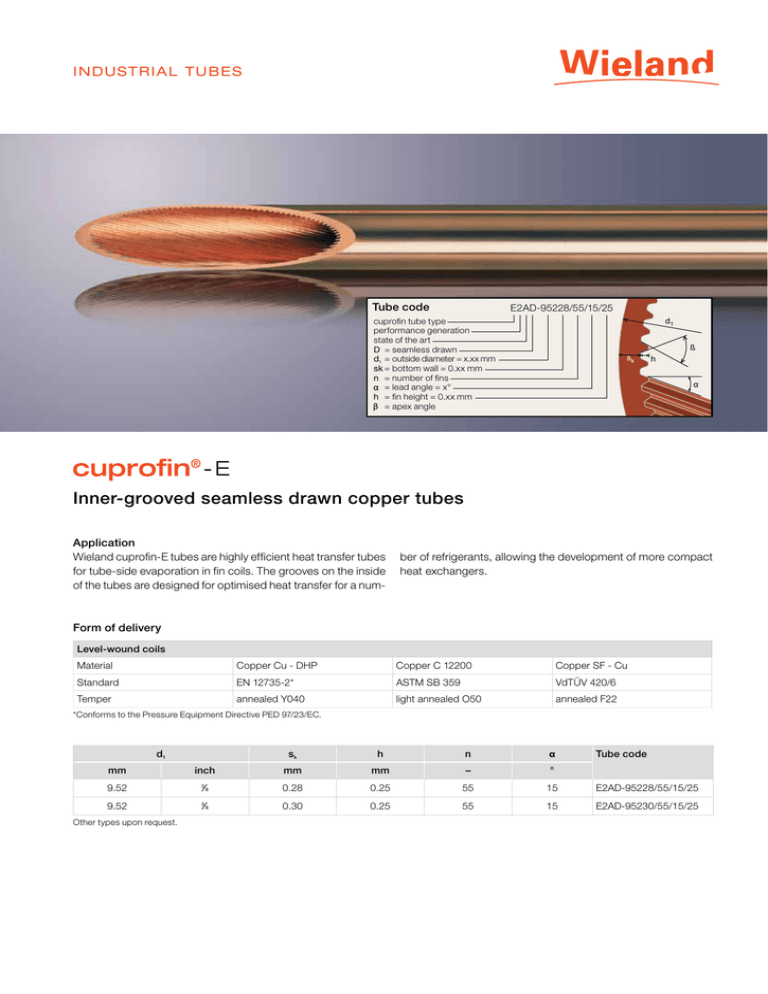

I NDUSTRIA L TUBES Tube code E2AD-95228/55/15/25 d1 cuprofin tube type performance generation state of the art D = seamless drawn d1 = outside diameter = x.xx mm sk= bottom wall = 0.xx mm n = number of fins = lead angle = x° h = fin height = 0.xx mm = apex angle sk ß h α -E Inner-grooved seamless drawn copper tubes Application Wieland cuprofin-E tubes are highly efficient heat transfer tubes for tube-side evaporation in fin coils. The grooves on the inside of the tubes are designed for optimised heat transfer for a num- ber of refrigerants, allowing the development of more compact heat exchangers. Form of delivery Level-wound coils Material Copper Cu - DHP Copper C 12200 Copper SF - Cu Standard EN 12735-2* ASTM SB 359 VdTÜV 420/6 Temper annealed Y040 light annealed O50 annealed F22 *Conforms to the Pressure Equipment Directive PED 97/23/EC. d1 mm sk h n inch mm mm – ° Tube code 9.52 3 /8 0.28 0.25 55 15 E2AD-95228/55/15/25 9.52 3 /8 0.30 0.25 55 15 E2AD-95230/55/15/25 Other types upon request. -E E VA P O R AT I O N Heat transfer performance Pressure drop 32 R407C (no oil) 7000 R407C (no oil) 28 6000 24 Pressure drop [kPa] Heat transfer coefficient [W/m²K] 8000 5000 4000 3000 20 16 12 2000 8 1000 4 0 0 0 50 100 150 200 250 300 350 0 50 100 Mass flow rate [kg/m2s] 14000 200 250 300 350 10 R410A (no oil) R410A (no oil) 9 12000 8 10000 7 Pressure drop [kPa] Heat transfer coefficient [W/m²K] 150 Mass flow rate [kg/m2s] 8000 6000 4000 6 5 4 3 2 2000 1 0 0 0 50 100 150 200 250 300 0 50 Mass flow rate [kg/m2s] Test conditions Tube Type Tube Application Process Application Material Evaporation – 9.52 mm tubes t0 = 0 °C superheat ~5 K, inlet quality 20 % tube length 2 m Standard evaporation condensation fin coils shell & tube copper 100 150 200 250 300 Mass flow rate [kg/m2s] cuprofin E cuprofin standard plain tube This leaflet E EDX C evaporation evaporation condensation fin coils shell and tube evaporators fin coils copper copper copper G single phase heat transfer highly viscous liquids L10 evaporation condensation copper cupro nickel seawater Wieland-Werke AG www.wieland.com Graf-Arco-Str. 36, 89079 Ulm, Germany, Phone +49 (0)731 944-0, Fax +49 (0)731 944-6330, info@wieland.de This printed matter is not subject to revision. No claims can be derived from it unless there is evidence of intent or gross negligence. The product characteristics are not guaranteed and do not replace our experts' advice. 03.15 Rg (GSW/Ri) W W W.W I E L A N D - I N D U S T R I A LT U B ES .C O M