CB(1)439/15

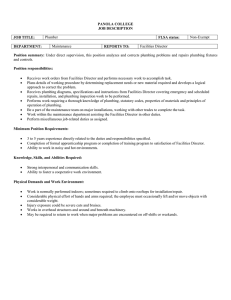

advertisement