Conductix-Wampfler Cables for Reeling Systems Catalog

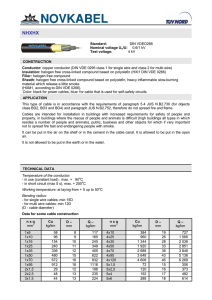

advertisement