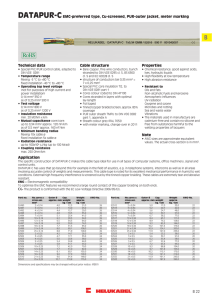

HELUKABEL MULTISPEED 500-C-PVC UL/CSA - Hi

advertisement

HELUKABEL MULTISPEED 500-C-PVC UL/CSA Safety against high bending in drag chain systems, low torsion, UL/CSA approved Technical data Cable structure Application – Special drag chain cables for high mechanical stress in adapted to DIN VDE 0281 part 13 and E DIN VDE 0245 and UL-Std. 758 AWM Style 21179 – Temperature range flexing – 58 C to +808 C fixed installation –308 C to +808 C – Nominal voltage U0/U 300/500 V UL 600 V – Test voltage 3000 V – Insulation resistance min. 100 MOhm x km – Minimum bending radius 7,5 x cable 1 – Coupling resistance max. 250 Ohm x km – Radiation resistance up to 80 x 106 cJ/kg (up to 80 Mrad) – Bare copper, fine wire conductors, Unilay with short pitch length – Special TPE core insulation – Black cores with continuous white numbering – Green-yellow earth core (3 cores and above) – Stranding: * < 7 cores: cores stranded in a layer with optimal lay-length around a filler as per construction * $7 cores: cores stranded with optimal lay-length to bunch-construction with low torsion strength, optimal selected short lay-length around a filler – Special-PVC inner sheath YM2 extruded as filler with pressure grey (RAL 7001) – Screen of Cu braid bare, coverage 85% max., with optimal bunch – Special-PVC outer sheath, especially resistant against fatigue strength, sheath colour pine green (RAL 6028) low adhesion, oil resistant – PVC self-extinguishing and flame retardant according to DIN VDE 0482 part 265-2-1/EN 50265-2-1/IEC 60332-1 (equivalent DIN VDE 0472 part 804 test method B), VW1, FT1 UL/CSA approved HELUKABEL MULTISPEED 500-C-PVC are installed there, where the extreme requirements for the cables are necessary. Designed for the export-orientated machinery manufacturer, specifically for USA and Canada. The selected materials and lay-up technique permit these high flexible cables for permanent application in drag chains for long distances, high and slow speed of movements. These high flexible PVC control cables are suitable for shift- and bending stresses in machines and machine tool constructions. These are installed in dry and moist rooms with free movement without tensile stress or forced movements. These screened cables are particularly suitable for the interference-free transmission in instrumentation and control engineering applications. – The materials used in manufacture are cadmium-free and contain no silicone and free from substances harmful to the wetting properties of lacquers. * EMC = Electromagnetic compatibility Note To optimise the EMC features we recommend a large round contact of the copper braiding on both ends. Specific advantages – High property of alternating bending strength – Long life durability due to low frictionresistance – Better chemical resistance – Oil resistance – High stability – Higher economical solution – Reduced 1 , results low weight of moving materials = The product is conformed with the EC Low-Voltage Directive 73/23/EEC and 93/68/EEC. No. cores x cross-sec. mm2 Outer 1 ca. mm 24335 OZ 24336 24337 24338 24339 24340 24341 24342 24343 2 x 0,5 3G 0,5 4G 0,5 5G 0,5 7G 0,5 9G 0,5 12G 0,5 18G 0,5 25G 0,5 6,3 6,8 7,3 7,7 10,3 10,5 12,4 14,7 16,9 24344 OZ 24345 24346 24347 24348 24349 24350 24351 2 x 0,75 3G 0,75 4G 0,75 5G 0,75 7G 0,75 12G 0,75 18G 0,75 25G 0,75 6,9 7,4 8,0 8,5 12,5 13,3 16,1 18,5 Part No. Cop. weight kg / km Weight ca. kg / km AWGno.*) 30,0 36,0 42,0 48,0 64,0 80,0 105,0 137,0 210,0 89 104 119 150 189 223 280 379 552 20 20 20 20 20 20 20 20 20 40,0 48,0 55,0 66,0 85,0 135,0 190,0 275,0 96 111 142 161 237 317 486 651 19 19 19 19 19 19 19 19 *) Note AWG sizes are approximate equivalent values. The actual cross-section is in mm2 – see page T 15. Part No. No. cores x cross-sec. mm2 Outer 1 ca. mm Cop. weight kg / km Weight ca. kg / km AWGno.*) 24352 24353 24354 24355 24356 24357 24358 3G 1 4G 1 5G 1 7G 1 12G 1 18G 1 25G 1 7,7 8,3 9,1 13,3 14,4 17,3 19,4 59,0 70,0 84,0 106,0 174,0 240,0 332,0 131 164 198 264 410 550 749 18 18 18 18 18 18 18 24359 24360 24361 24362 24363 24364 24365 3G 1,5 4G 1,5 5G 1,5 7G 1,5 12G 1,5 18G 1,5 25G 1,5 8,6 9,4 10,4 15,2 16,6 20,3 22,6 75,0 90,0 108,0 157,0 240,0 355,0 448,0 166 199 229 324 502 709 939 16 16 16 16 16 16 16 24366 24367 4G 2,5 5G 2,5 11,2 12,2 134,0 175,0 270 335 14 14 G = with green-yellow earth core X = without green-yellow earth core (OZ) Further technical details see selection table for drag chain cables (pages 24ff). A 63 A