Spec Sheet

advertisement

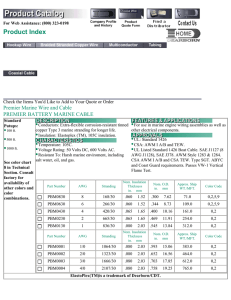

Lead Wire Products Index ITEM STYLE PAGE PVC 1007/1569, 1581/1569 6 1061 7 1015/1230, 1028/1231, 1283/1232, 1284, 1284/1232 8 1015/1230, 1028/1231, 1283/1232, 1284/1232 9 105°C, 600V, UL & CSA PVC-TEW 1056/1275, 1060/1276 10 1316 11 80°C/105°C, 300V, UL & CSA SR-PVC 80°C, 300V, UL & CSA PVC-MTW 90°C /105°C, 600V, UL & CSA PVC-TEW 105°C, 600V, UL & CSA TFFN/THHN-Building Wire 75°C/90°C, 600V, UL & CSA XHHW-Building Wire 12 90°C, 600V SIS-Switchboard 3320, SIS 13 1429, 1534, 1536 14 1430, 3317 15 3265 16 3266 17 3289 18 3271 19 3173, 3195, 3196 20 3321 21 22 105°C, 300V/600V/1000V, UL & CSA 3190, 3192, 3193, 3591, 3309/3591 EPR 3284 23 3340/3374 24 90°C, 600V, UL Irradiated PVC (XL-PVC) 80°C, 150V, UL & CSA Irradiated PVC (XL-PVC) 105°C, 300V, UL & CSA Irradiated Polyethylene (XLP) 125°C, 150V, UL & CSA Irradiated Polyethylene (XLP) 125°C, 300V, UL & CSA Irradiated Polyolefin (XLP) 150°C, 600V, UL & CSA Irradiated Polyethylene (XLP) 125°C, 600V, UL & CSA Polyethylene (XLP) 125°C, 600V, UL & CSA Polyolefin (XLP) 150°C, 600V, UL & CSA Hypalon 125°C, 600V, UL & CSA EPR 125°C/150°C, 600V, UL & CSA 2 Index ITEM STYLE PAGE EPDM 3499 25 3212, 3213, 3214 26 3070, 3101, 3127 27 3071, 3074, 3075, 3125, 3231, 3410 28 200°C, 600V, UL & CSA Mercury Switch 3123, 3135 29 3257 30 3239 31 5256 32 5335 33 1371 34 1213 35 1180 36 1199 37 105°C, 7500V, UL Braidless Silicone 150°C, 600V, UL Braided Silicone 150°C, 600V, UL & CSA Braided Silicone 150°C, 600V, UL Silicone Ignition 250°C, 10 KVAC/25 KVDC Silicone 150°C, 10 to 30 KVDC TGGT 250°C, 600V, UL & CSA MGT 450°C, 600V, UL Polytetrafluroethylene (PTFE) 105°C, UL & CSA, Class I, Group A Polytetrafluroethylene (PTFE) 105°C, UL & CSA, Class I, Group A Polytetrafluroethylene (PTFE) 200°C, 300V, UL & CSA, Class I, Group A Polytetrafluroethylene (PTFE) 200°C, 600V, UL & CSA, Class I, Group A MIL-W-16878/4 Type E 38 200°C, 600V, Teflon MIL-W-16878/5 Type EE 39 200°C, 1000V, Teflon MIL-W-22759/9 and MIL-W-22759/11 200°C, 1000V, PTFE 40 200°C, 600V, PTFE Compound Comparison 41 Insulation Temperature Chart 42 Flame Retardancy 43 3 UL/CSA Index UL Style SIS THHN/TFFN XHHW 1007 1015 1028 1056 1060 1061 1180 1199 1213 1230 1231 1232 1275 1276 1283 1284 1316 1371 1429 1430 1534 1536 1569 1581 3070 3071 3074 3075 3101 3123 3125 3127 3135 3173 3190 3191 3192 3193 CSA Style T90 TR-64/AWM TEW/AWM TEW/AWM TEW/AWM TEW/AWM AWM CLASS 1 GROUP A/B FT1 CLASS 1 GROUP A/B FT1 CLASS 1 GROUP A/B FT1 TEW/AWM TEW TEW TEW TEW TEW TEW TEWN CLASS 1 GROUP A/B AWM REM AWM AWM TR-64/AWM TR-64/AWM SEWF-2 SEW-2 SEW-2 SEW-2 SEWF-2 AWM SEW-2 SEWF-2 AWM CL1251 CL1052 CL1053 CL1052 CL1053 Insulation Type Degrees XLP 90 Nylon 90 CROSSLINKED POLYETHYLENE 90 PVC 80/105 PVC 105 PVC 105 PVC 105 PVC 105 SEMI-RIGID PVC 80 PTFE 200 PTFE 200 PTFE 105 PVC 105 PVC 105 PVC 105 PVC 105 PVC 105 PVC 105 PVC 105 PVC/NYLON 105 PTFE 105 IRRADIATED XL-PVC 80 IRRADIATED XL-PVC 105 IRRADIATED XL-PVC 80 IRRADIATED XL-PVC 80 PVC 105 PVC 80 SILICONE 150 SILICONE 200 SILICONE 200 SILICONE 200 SILICONE 150 SILICONE 150 SILICONE 200 SILICONE 150 SILICONE 200 XLP 125 HYPALON 105 HYPALON 105 HYPALON 105 HYPALON 105 4 Voltage Page 600 600 600 300 600 600 600 600 300 300 600 NO VOLTAGE SPECIFIED 600 600 600 600 600 600 600 600 NO VOLTAGE SPECIFIED 150 300 150 150 300 300 600 600 600 600 600 600 600 600 600 600 300 600 600 600 13 11 12 6 8, 9 8, 9 10 10 7 36 37 35 8, 9 8, 9 8, 9 10 10 8, 9 8, 9 11 34 14 15 14 14 6 6 27 28 28 28 27 29 28 27 29 20 22 22 22 22 UL/CSA Index UL Style CSA Style Insulation Type Degrees Voltage 3195 3196 3212 3213 3214 3231 3239 3257 3265 3266 3271 3284 3289 3309 3317 3320 3321 3340 3374 3499 3591 5256 5335 CL1251 CL1251 AWM AWM AWM SEW-2 XLP XLP SILICONE SILICONE SILICONE SILICONE SILICONE SILICONE IRRADIATED XLP IRRADIATED XLP IRRADIATED XLP ETHYLENE PROPOPYLENE-RUBBER IRRADIATED POLYOLEFIN XLP HYPALON IRRADIATED XL-PVC XLP XLP ETHYLENE PROPYLENE-RUBBER ETHYLENE PROPYLENE-RUBBER EPDM HYPALON TEFLON/GLASS/GLASS/TEFLON MICA/GLASS/TEFLON 125 125 150 150 150 200 150 250 125 125 125 125 150 105 105 90 150 125/150 125/150 150 105 250 450 600 600 600 600 600 600 10 KVDC to 30 KVDC 10 KVAC, 25 KVDC 150 300 600 600 600 1 KV 300 600 600 600 600 7500 1000 600 600 AWM AWM AWM CL1254 AWM CL1053 REW AWM CL1503 CL1254 CL1254 CL1053 CLASS 1 GROUP A/B CLASS 1 GROUP A/B Page Disclaimer: The values and data shown in this catalog represent typical values intended to distinguish one material from another and to serve as a guide in selecting the proper material for specific applications or end uses. The information contained herein is given in good faith, but because of the many variables in subsequent manufacturing and installation operations, no guarantees can be made for the performance of these products in service. Users are requested to make their own tests to determine the suitability of these materials for the applications and to be guided by the results of such tests. Data and suggestions made in this publication are not to be construed as recommendations to use any product in violation of existing patents covering any material or its use. 5 20 20 26 26 26 28 31 30 16 17 19 23 18 22 15 13 21 24 24 25 22 32 33 Polyvinyl Chloride (PVC) 80°C/105°C, 300V, UL, CSA Type TR-64 INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 1007/28T07 28 7/36 15 .047 1.6 1007/1569 TR-64 1007/26T07 26 7/34 15 .051 1.8 1007/1569 TR-64 1007/24T07 24 7/32 15 .057 2.4 1007/1569 TR-64 1007/24P07 24 7 PREBOND 15 .056 2.6 1007/1569 TR-64 1007/24T01 24 SOLID 15 .053 2.4 1007/1569 TR-64 1007/22T07 22 7/30 15 .062 3.3 1007/1569 TR-64 1007/22P07 22 7 PREBOND 15 .062 3.7 1007/1569 TR-64 1007/22T01 22 SOLID 15 .058 3.3 1007/1569 TR-64 1007/20T10 20 10/30 15 .067 4.7 1007/1569 TR-64 1007/20P07 20 7 PREBOND 15 .068 5.2 1007/1569 TR-64 1007/20T01 20 SOLID 15 .064 4.5 1007/1569 TR-64 1007/18T16 18 16/30 15 .079 7.1 1007/1569 TR-64 1007/18P16 18 16 PREBOND 15 .080 7.3 1007/1569 TR-64 1007/18T01 18 SOLID 15 .073 6.6 1007/1569 TR-64 1007/16T26 16 26/30 15 .094 9.7 1007/1569 TR-64 1007/16T01 16 SOLID 15 .083 9.9 1007/1569 TR-64 1581/14T19 14 19/27 16 .102 16.0 1581/1569 TR-64 1581/14T41 14 41/30 16 .110 18.4 1581/1569 TR-64 1581/12T19 12 19/25 16 .123 23.9 1581/1569 TR-64 RoHS compliant material available upon request. Description: Application: • Soft annealed, solid or stranded, tinned copper, Internal wiring of appliances. Internal wiring of electronic equipment in non-hazardous locations. concentric, compressed concentric or combination unilay stranding per UL 1063, ASTM B-787. • PVC insulated VW-1 compound. • CSA, no voltage specified. • Stripes or print may be added to base colors for additional coding. 6 Semi-Rigid Polyvinyl Chloride (SR-PVC) 80°C, 300V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 1061/28T07 28 7/36 9 .035 1.0 1061 SR-PVC 1061/26T01 26 SOLID 9 .036 1.4 1061 SR-PVC 1061/26T07 26 7/34 9 .039 1.4 1061 SR-PVC 1061/24T01 24 SOLID 9 .041 1.9 1061 SR-PVC 1061/24T07 24 7/32 9 .044 2.1 1061 SR-PVC 1061/24T19 24 19/36 9 .044 2.2 1061 SR-PVC 1061/24P07 24 7 PREBOND 9 .044 2.2 1061 SR-PVC 1061/22T01 22 SOLID 9 .046 2.8 1061 SR-PVC 1061/22T07 22 7/30 9 .050 3.0 1061 SR-PVC 1061/22T19 22 19/34 9 .050 3.2 1061 SR-PVC 1061/22P07 22 7 PREBOND 9 .050 3.2 1061 SR-PVC 1061/20T01 20 SOLID 9 .052 3.9 1061 SR-PVC 1061/20T07 20 7/28 9 .058 4.5 1061 SR-PVC 1061/18T01 18 SOLID 9 .061 5.9 1061 SR-PVC 1061/18T07 18 7/26 9 .069 6.8 1061 SR-PVC 1061/18T19 18 19/30 9 .069 7.2 1061 SR-PVC 1061/16T19 16 19/29 9 .078 9.5 1061 SR-PVC RoHS compliant material available upon request. Description: Application: • Soft annealed, solid or stranded tinned Internal wiring of electronic equipment, bookkeeping, accounting, time recording machines, where protected from mechanic abuse. copper conductor. • Semi rigid PVC insulation, VW-1. • Stripes or print may be added to base colors for additional coding. 7 Polyvinyl Chloride (PVC) Type MTW/CSA TEW 90°C/105°C, 600V, UL Listed & CSA Certified, Moisture Resistant INDUSTRIAL ELECTRIC PART # 1015/22B07* 1015/20B10* 1015/18B19* 1015/18B16* 1015/16B19* 1015/16B26* 1015/14B19* 1015/14B41* 1015/12B19* 1015/12B65* 1015/10B19* 1015/10B105* 1028/08B19* 1028/08B133* 1283/06B19 1283/04B19 1283/02B19 1284/01B19 1284/1/0B19 1284/2/0B19 1284/3/0B19 1284/4/0B19 1284/250B37 1284/300B37 1284/350B37 1284/500B37 SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 22 20 18 18 16 16 14 14 12 12 10 10 8 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 500 7/.0096 10/30 19/.0092 16/30 19/.0117 26/30 19/.0147 41/30 19/.0185 65/30 19/.234 105/30 19/.0295 133/29 19/.0372 19/.0469 19/.0591 19/.0664 19/.0745 19/.0837 19/.0940 19/.1055 37/.0822 37/.0900 37/.0973 37/.1162 30 30 30 30 30 30 30 30 30 30 30 30 45 45 60 60 60 80 80 80 80 80 95 95 95 95 .094 .099 .108 .108 .118 .120 .132 .139 .151 .155 .175 .186 .237 .257 .306 .355 .415 .496 .536 .583 .634 .692 .769 .824 .875 1.007 5.8 7.0 10.7 9.6 13.4 13.6 18.9 18.9 27.0 27.7 40.4 42.0 66.9 67.0 111.2 165.7 250.2 326.0 402.0 496.0 620.0 795.0 904.0 1066.0 1236.0 1728.0 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1028/1231 1028/1231 1283/1232 1283/1232 1283/1232 1284/1232 1284/1232 1284/1232 1284/1232 1284/1232 1284 1284 1284 1284 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C TEW 105°C AWM 105°C AWM 105°C AWM 105°C AWM 105°C AWM 105°C AWM 105°C AWM 105°C AWM 105°C AWM * RoHS compliant material available upon request. Description: • Soft annealed, solid or stranded, bare copper, concentric, compressed concentric or combination unilay stranding per UL 1063, ASTM B-787. • PVC insulated, VW-1 compound, moisture resistant 22-4/0 AWG. • UL Type AWM 105°C 600 volts. • NEC Type MTW 90°C 600 volts. • CSA Type TEW 105°C 600 volts. • CSA Type AWM 105°C 600 volts. • AWG sizes 2-6 also rated 105°C 1000VAC per UL Style 10269. • AWG sizes 8-22 also rated 90°C 1000VAC per UL Style 1032. • AWG sizes 2-16 also rated BC-5W2 per UL Standard 1426 Boat Cable. • AWG sizes 4/0-6 meets or exceeds the requirements of SAE J1127 Battery Cable. Application: For internal wiring of appliances. Suitable for use in transformers, ballasts, switchboard panels, controls, electronic circuits and motors. As machine tool wire, printed Type MTW. FOR TINNED COPPER SEE PAGE 9 8 Polyvinyl Chloride (PVC) Type TEW Appliance, Hook-Up and Motor Lead Wire, 105°C, 600V, UL Listed & CSA Certified, Moisture Resistant INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 1015/24T07 1015/22T07 1015/20T10 1015/18T16 1015/16T26 1015/14T19 1015/14T41 1015/12T19 1015/12T65 1015/10T19 1015/10T105 1028/08T19 1028/08T133 1028/08T168 1283/06T19 1283/06T133 1283/04T19 1283/04T133 1283/02T133 1283/02T665 1284/01T259 1284/1/0T133 1284/1/0T1064 1284/2/0T1330 1284/3/0T1672 1284/4/0T2107 24 22 20 18 16 14 14 12 12 10 10 8 8 8 6 6 4 4 2 2 1 1/0 1/0 2/0 3/0 4/0 7/32 7/.0096 10/30 16/30 26/30 19/.0147 41/30 19/.0185 65/30 19/.0234 105/30 19/.0295 133/29 168/30 19/.0372 133/27 19/.0469 133/25 133/23 665/30 259/25 133/21 1064/30 1330/30 1672/30 2107/30 30 30 30 30 30 30 30 30 30 30 30 45 45 45 60 60 60 60 60 60 80 80 80 80 80 80 .088 .094 .099 .108 .120 .132 .139 .151 .155 .175 .186 .237 .257 .268 .306 .333 .355 .387 .452 .432 .521 .561 .561 .616 .666 .726 4.6 5.8 7.0 9.6 13.6 18.9 19.5 27.7 28.5 41.2 42.4 67.6 74.0 75.0 111.5 117.9 172.0 170.0 262.0 255.0 328.0 421.0 435.0 535.0 638.0 786.0 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1015/1230 1028/1231 1028/1231 1028/1231 1283/1232 1283/1232 1283/1232 1283/1232 1283/1232 1283/1232 1284/1232 1284/1232 1284/1232 1284/1232 1284/1232 1284/1232 TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW TEW RoHS compliant material available upon request. Description: • Soft annealed, solid or stranded, tinned copper, concentric, compressed concentric or combination unilay stranding per UL 1063, ASTM B-787. • PVC insulated VW-1 compound, moisture resistant. • UL Type AWM 105°C 600 volts. • NEC Type MTW 90°C 600 volts. • CSA Type TEW 105°C 600 volts. • CSA Type AWM 105°C 600 volts. • Topcoat Conductor available upon request in AWG sizes 14-22. • Solid Conductor available upon request in AWG sizes 10-22. • Prebond conductor available in AWG sizes 16-22. • AWG sizes 4/0-6 also rated 105°C 1000VAC per UL Style 10269. • AWG sizes 8-24 also rated 90°C 1000VAC per UL Style 1032. • AWG sizes 4/0-16 also rated BC-5W2 per UL Standard 1426 Boat Cable. • AWG sizes 4/0-6 meets or exceeds the requirements of SAE J1127 Battery Cable. Application: For internal wiring of appliances, switchboard panels, controls, electronic circuits and motors. As machine tool wire, printed Type MTW. • For bare copper see page 8. 9 Polyvinyl Chloride (PVC) Type TEW Appliance, Hook-Up, Refrigeration and Air Conditioning Lead Wire, 105°C, 600V, UL Listed & CSA Certified, Moisture Resistant INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT 1056/18 1056/16 1056/14 1056/12 1056/10 1060/14 1060/12 1060/10 18 16 14 12 10 14 12 10 16/30 26/30 41/30 65/30 105/30 41/30 65/30 105/30 60 60 60 60 60 80 80 80 .168 .181 .192 .212 .225 .234 .252 .270 18.0 22.0 27.7 38.0 55.2 34.2 49.1 64.5 UL STYLE 1056/1275 1056/1275 1056/1275 1056/1275 1056/1275 1060/1276 1060/1276 1060/1276 RoHS compliant material available upon request. Description: Application: • Soft annealed stranded bare or tinned copper conductor. • Moisture resistant PVC. • PVC insulated VW-1 compound. Internal wiring of electric refrigeration equipment, room air conditioners, room cooler units or internal wiring of remote outdoor condensing units for domestic cooling systems. 10 C.S.A. TYPE TEW TEW TEW TEW TEW TEW TEW TEW TFFN/THHN Building Wire 90°C, 600V, C(UL) T90 Nylon INDUSTRIAL ELECTRIC PART # TFN18B01* TFN16B01* TFFN18B16* TFFN16B26* THHN14B01 THHN12B01 THHN10B01 THHN14B19 THHN12B19 THHN10B19 THHN08B19 THHN06B19 THHN04B19 THHN03B19 THHN02B19 THHN01B19 THHN1/0B19 THHN2/0B19 THHN3/0B19 THHN4/0B19 THHN250B37 THHN300B37 THHN350B37 THHN400B37 THHN500B37 SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. PVC NYLON 18 16 18 16 14 12 10 14 12 10 8 6 4 3 2 1 1/0 2/0 3/0 4/0 250 300 350 400 500 SOLID SOLID 16 26 SOLID SOLID SOLID 19 19 19 19 19 19 19 19 19 19 19 19 19 37 37 37 37 37 15 15 16 16 15 15 20 15 15 20 30 30 40 40 40 50 50 50 50 50 60 60 60 60 60 5 5 5 5 4 4 4 4 4 4 5 5 6 6 6 7 7 7 7 7 8 8 8 8 8 DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT .083 .094 .090 .103 .104 .121 .152 .112 .131 .164 .216 .253 .322 .350 .381 .443 .483 .528 .579 .636 .704 .758 .808 .855 .938 8 11 8 12 16 24 38 17 26 40 66 100 159 191 241 305 377 468 581 722 860 1018 1180 1342 1661 NEC** AMPACITY 75°C 90°C THWN THHN 0 0 0 0 15 20 30 15 20 30 50 65 85 100 115 130 150 175 200 230 255 285 310 335 380 6 8 6 8 15 20 30 15 20 30 55 75 95 110 130 150 170 195 225 260 290 320 350 380 430 RoHS compliant material available upon request. * Listed as 105°C Appliance Wiring Material and 90°C MTW, also as Type TFFN (stranded conductor) and TFN (solid conductor) 90°C, CSA approved as Type TEWN. ** Ampacity in accordance with NEC. As THHN 90°C, conductor temperature at 30°C ambient in dry locations. As THHN 75°C, conductor temperature at 30°C ambient in wet or dry locations. Description: Application: • Conductor of soft drawn bare copper, concentric, General purpose wiring in accordance with the NEC, maximum conductor temperature of 90°C in dry locations and 75°C in wet locations, 600 volts for installation in conduit or other recognized race way. For wiring of machine tools, appliances and control circuits not exceeding 600 volts. compressed concentric, or combination unilay. • Primary insulation of PVC with NYLON jacket. • Listed by Underwriters Laboratories under standards 83 and 1063 as: Type THHN 90°C in dry locations. Type THWN 75°C in wet locations. Gasoline and oil resistant II. Type MTW 90°C Machine Tool Wire (stranded only). 105C AWM, 80°C where exposed to oil. • TFFN is UL 1316, 105°C approved & CSA TEWN approved. 11 XHHW-2 Building Wire 90°C, 600V INDUSTRIAL ELECTRIC PART # XHHW14B07 XHHW12B07 XHHW10B07 XHHW08B07 XHHW06B07 XHHW04B07 XHHW02B07 XHHW01B19 XHHW1/0B19 XHHW2/0B19 XHHW3/0B19 XHHW4/0B19 XHHW250B37 XHHW300B37 XHHW350B37 XHHW500B37 SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX NET WEIGHT #/1000 FT 14 12 10 8 6 4 2 1 1/0 2/0 3/0 4/0 250 300 350 500 7 7 7 7 7 7 7 19 19 19 19 19 37 37 37 37 30 30 30 45 45 45 45 55 55 55 55 55 65 65 65 65 .133 .152 .175 .235 .28 .32 .35 .44 .48 .52 .58 .63 .70 .75 .80 .93 18 26 39 66 99 151 232 300 372 461 573 714 846 1005 1166 1624 NEC AMPACITY* 75°C 90°C 15 20 30 50 65 85 115 130 150 175 200 230 255 285 310 380 RoHS compliant material available upon request. * Ampacity in accordance with NEC for not more than three conductors in raceway. 90°C conductor temperature at 30°C ambient in dry locations. 90°C conductor temperature at 30°C ambient in wet locations. Description: Application: • Conductor of soft drawn bare copper, concentric, General purpose wiring in accordance with the NEC, maximum conductor temperature of 90°C in wet or dry locations, 600 volts for installation in conduit or other recognized raceway. compressed concentric, or combination unilay. • Cross-linked polyethylene insulation. • Listed by Underwriters Laboratories as Type XHHW-2 per UL standard 44. • Suitable for use in low leakage circuits requiring a dielectric constant of 3.5 or less. 12 25 30 40 55 75 95 130 150 170 195 225 260 290 320 350 430 Chemically Cross-Linked Polyethylene Type SIS 90°C, 600V, UL Listed, CSA Type SIS INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX NET WEIGHT #/1000 FT UL TYPE SIS18T16 18 16/30 30 .111 10 3320 SIS16T26 16 26/30 30 .121 13 3320 SIS14T07 14 7/.0242 30 .140 17 SIS SIS14T41 14 41/30 30 .140 20 SIS SIS12T07 12 7/.0305 30 .160 23 SIS SIS12T65 12 65/30 30 .160 23 SIS SIS10T105 10 105/30 30 .190 36 SIS SIS08T133 8 133/29 45 .270 62 SIS SIS06T133 6 133/27 60 .330 99 SIS SIS04T133 4 133/25 60 .388 200 SIS SIS02T133 2 133/.0226 60 .453 292 SIS Description: Application: • Soft annealed stranded tinned copper conductor. • Chemically cross-linked polyethylene insulation, Type SIS per the NEC, for instrument and control wiring of switchboards, annunciator circuits and industrial control panels. For use at 600 volts 90°C maximum operation in dry locations per NEC, article 384 paragraph 310. Not useable in conduit duct or pipe per article 384-4. VW-1 rated. • IEEE 383 flame tested material available in many sizes. Shielded constructions available in many sizes. CSA available in most sizes and colors. 13 Irradiated Polyvinyl Chloride (XL-PVC) 80°C, 150V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE 1429/28T07 28 7/36 10 .036 1.08 1429 AWM(XLPVC) 1429/26T07 26 7/34 10 .040 1.51 1429 AWM(XLPVC) 1429/26T19 26 19/38 10 .040 1.64 1429 AWM(XLPVC) 1429/24T07 24 7/32 10 .045 2.14 1429 AWM(XLPVC) 1429/24T19 24 19/36 10 .045 2.24 1429 AWM(XLPVC) 1429/22T07 22 7/30 10 .051 3.04 1429 AWM(XLPVC) 1429/22T19 22 19/34 10 .052 3.21 1429 AWM(XLPVC) 1429/20T07 20 7/28 10 .059 4.61 1429 AWM(XLPVC) 1429/20T19 20 19/32 10 .060 4.95 1429 AWM(XLPVC) 1429/18T07 18 7/26 10 .070 6.94 1429 AWM(XLPVC) 1429/18T19 18 19/30 10 .072 6.94 1429 AWM(XLPVC) 1429/16T19 16 19/29 10 .078 8.80 1429 AWM(XLPVC) 1534/14T19 14 19/27 10 .096 13.82 1534 AWM(XLPVC) 1534/14T41 14 41/30 10 .098 14.00 1534 AWM(XLPVC) 1536/12T19 12 19/25 10 .114 22.85 1536 AWM(XLPVC) Description: • Soft annealed, stranded tinned copper conductor. • Irradiated PVC insulated, VW-1 compound. • UL 1534 & 1536 have no voltage specified. • Meets Military type MIL-W-16878/1 type B C.S.A. TYPE Application: For internal wiring of appliances. Internal wiring of electronic equipment where not subjected to undue mechanical abuse. 105°C, 600 volts, 26-12 AWG. • Stripes or print may be added to basic colors for additional coding. 14 Irradiated Polyvinyl Chloride (XL-PVC) 105°C, 300V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 1430/28T07 28 7/36 16 .049 1.54 1430 REW(XLPVC) 1430/26T07 26 7/34 16 .051 1.94 1430 REW(XLPVC) 1430/26T19 26 19/38 16 .053 2.10 1430 REW(XLPVC) 1430/24T07 24 7/32 16 .056 2.64 1430 REW(XLPVC) 1430/24T19 24 19/36 16 .057 2.84 1430 REW(XLPVC) 1430/22T07 22 7/30 16 .062 3.62 1430 REW(XLPVC) 1430/22T19 22 19/34 16 .063 3.74 1430 REW(XLPVC) 1430/20T07 20 7/28 16 .070 5.25 1430 REW(XLPVC) 1430/20T19 20 19/32 16 .071 5.61 1430 REW(XLPVC) 1430/18T07 18 7/26 16 .082 7.69 1430 REW(XLPVC) 1430/18T19 18 19/30 16 .082 8.05 1430 REW(XLPVC) 1430/16T19 16 19/.0117 16 .092 9.97 1430 REW(XLPVC) 3317/14T19 14 19/.0147 16 .107 14.93 3317 REW(XLPVC) 3317/12T19 12 19/.0185 16 .124 23.16 3317 REW(XLPVC) 3317/10T105 10 105/30 16 .156 37.66 3317 REW(XLPVC) Description: Application: • Soft annealed, stranded tinned copper conductor. • Irradiated PVC insulated, VW-1 compound. • Meets military type MIL-W-16878/2 Type C For internal wiring of appliances. 105°C, 1000 volts, 26-12 AWG. • Stripes or print may be added to basic colors for additional coding. 15 Irradiated Cross-Linked Polyethylene (XLP) 125°C, 150V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 3265/26T07 26 7/34 10 .040 1.49 3265 AWM 3265/24T07 24 7/32 11 .044 2.0 3265 AWM 3265/24T19 24 19/36 11 .045 2.1 3265 AWM 3265/22T07 22 7/30 11 .050 3.0 3265 AWM 3265/22T19 22 19/34 11 .052 3.1 3265 AWM 3265/20T07 20 7/28 11 .058 4.6 3265 AWM 3265/20T19 20 19/32 11 .060 4.8 3265 AWM 3265/18T07 18 7/26 11 .068 6.8 3265 AWM 3265/18T19 18 19/30 11 .070 7.8 3265 AWM Description: Application: • Soft annealed, solid or stranded, tinned copper For internal wiring of appliances where not subjected to undue mechanical abuse. 300 volts peak, for electronic use only. conductor. • Irradiated cross-linked polyethylene insulation. • VW-1 compound available. • Prefused material available upon request. • Stripes or print may be added to base colors for additional coding. 16 Irradiated Cross-Linked Polyethylene (XLP) 125°C, 300V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE 3266/24T07 3266/24T19 3266/22T01 3266/22T07 3266/22T19 3266/20T01 3266/20T07 3266/20T19 3266/18T01 3266/18T07 3266/18T16 3266/18T19 3266/16T19 3266/16T26 3266/14T19 3266/14T41 3266/12T19 3266/10T37 24 24 22 22 22 20 20 20 18 18 18 18 16 16 14 14 12 10 7/32 19/36 SOLID 7/30 19/34 SOLID 7/28 19/32 SOLID 7/26 16/30 19/30 19/.0117 26/30 19/.0147 41/30 19/.0185 37/.0167 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 .056 .057 .059 .062 .064 .066 .070 .072 .074 .080 .080 .082 .089 .092 .106 .107 .127 .151 2.55 2.69 3.14 3.67 3.85 4.50 5.12 5.46 6.55 7.58 7.00 7.80 10.33 10.46 15.58 15.52 23.98 36.18 3266 3266 3266 3266 3266 3266 3266 3266 3266 3266 3266 3266 3266 3266 3266 3266 3266 3266 C.S.A. TYPE CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 CL1252 Description: Application: • Soft annealed, solid or stranded, tinned copper For internal wiring of appliances where not subjected to undue mechanical abuse. 600 volts for peak electronic use only. conductor. • Irradiated cross-linked polyethylene insulation. • VW-1 compound available. • Prefused material available upon request. • Stripes or print may be added to base colors for additional coding. 17 or or or or or or or or or or or or or or or or or or AWM AWM AWM AWM AWM AWM AWM AWM AWM AWM AWM AWM AWM AWM AWM AWM AWM AWM Irradiated Cross-Linked Polyolefin (XLP) 150°C, 600 Volt, UL3289 CSA Type AWM INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 3289/22T07 22 7/30 30 .095 5.8 3289 AWM 3289/20T07 20 7/28 30 .103 7.85 3289 AWM 3289/18T16 18 16/30 30 .105 9.52 3289 AWM 3289/16T26 16 26/30 30 .122 13.3 3289 AWM 3289/14T41 14 41/30 30 .136 19.0 3289 AWM 3289/12T65 12 65/30 30 .150 27.1 3289 AWM 3289/10T65 10 65/28 30 .172 40.5 3289 AWM 3289/08T84 8 84/27 45 .238 69.2 3289 AWM 3289/06T84 6 84/25 60 .305 111.5 3289 AWM 3289/04T133 4 133/25 60 .385 170.9 3289 AWM Description: Application: • Soft annealed stranded tinned copper conductor. • Irradiated cross-linked polyolefin insulation. • VW-1 Compound • Stripes or prints may be added to base colors for Recommended for internal wiring of appliances, computers, transformers, and other electronic and electrical equipment. For wiring lighting devices, ballasts and transformers. additional coding. 18 Irradiated Cross-Linked Polyethylene (XLP) 125°C, 600V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 3271/22T07 22 7/30 30 .093 5 3271 CL1251 3271/20T07 20 7/28 30 .101 7 3271 CL1251 3271/18T07 18 7/26 30 .111 9.5 3271 CL1251 3271/18T16 18 16/30 30 .109 13.6 3271 CL1251 3271/18T19 18 19/30 30 .113 11 3271 CL1251 3271/16T19 16 19/.0117 30 .120 12 3271 CL1251 3271/16T26 16 26/30 30 .123 13 3271 CL1251 3271/14T19 14 19/.0147 30 .134 18 3271 CL1251 3271/14T41 14 41/30 30 .133 18 3271 CL1251 3271/12T19 12 19/.0185 30 .154 26 3271 CL1251 3271/12T65 12 65/30 30 .156 27 3271 CL1251 3271/10T65 10 65/28 30 .172 40 3271 CL1251 3271/10T105 10 105/30 30 .182 41 3271 CL1251 3271/08T84 8 84/27 45 .238 73 3271 CL1251 3271/06T133 6 133/.0141 60 .341 113 3271 CL1251 Description: Application: • Soft annealed stranded tinned copper conductor. • Irradiated cross-linked polyethylene VW-1 insulation. • Colors available in many sizes. • Meets MIL-W-16878/16 except for 10-4 awg. Suitable for appliance wiring material, transformer leads, lighting ballasts, motors, electrical heating, gas heating, cooking equipment and hairdressing equipment. Economical replacement for silicone insulated wire. In applications where exposed to gasoline vapors up to +75°C or immersed in gasoline up to 30°C. Withstands pulse up to 30,000 volts. 19 Chemically Cross-Linked Polyethylene (XLP) 125°C, 600V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 3173/22T07 22 7/30 30 .093 6 3173 CL1251 3173/20T10 20 10/30 30 .103 7 3173 CL1251 3173/18T16 18 16/30 30 .109 10 3173 CL1251 3173/16T26 16 26/30 30 .124 13 3173 CL1251 3173/14T41 14 41/30 30 .140 19 3173 CL1251 3173/12T65 12 65/30 30 .162 27 3173 CL1251 3173/10T105 10 105/30 30 .190 42 3173 CL1251 3195/08T133 8 133/29 45 .262 75 3195 CL1251 3196/06T133 6 133/27 60 .338 110 3196 CL1251 3196/04T133 4 133/25 60 .390 178 3196 CL1251 RoHS compliant material available upon request. Description: Application: • Soft annealed stranded tinned copper conductor. • Chemically cross-linked polyethylene insulation. • Colors available in most sizes. • IEEE 130°C motor lead, class B. • Varnish bake cycle: 300°F 24 hr. Appliance wiring material suitable for internal wiring of appliances, coil leads, switchboard panels, and power operated dispensing units where exposed to gasoline vapors, also as class B motor lead wire. 325°F 12 hr. 350°F 8 hr. 20 Chemically Cross-Linked Polyolefin (XLP) 150°C, 600V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 3321/22T07 22 7/30 30 .093 5 3321 CL1503 3321/20T10 20 10/30 30 .100 7 3321 CL1503 3321/18T16 18 16/30 30 .109 10 3321 CL1503 3321/16T26 16 26/30 30 .125 13 3321 CL1503 3321/14T41 14 41/30 30 .140 19 3321 CL1503 3321/12T65 12 65/30 30 .160 28 3321 CL1503 3321/10T105 10 105/30 30 .190 43 3321 CL1503 3321/08T133 8 133/29 45 .260 75 3321 AWM 3321/06T133 6 133/27 45 .292 104 3321 AWM 3321/04T133 4 133/25 45 .365 178 3321 AWM RoHS compliant material available upon request. Description: Application: • Soft annealed stranded tinned copper conductor. • Chemically cross-linked polyolefin insulation. • Colors available in many sizes. • Upon Request, 18, 16 and 14 AWG meets NEC Suitable for appliance wiring material, transformer leads, lighting ballasts, motors, electrical heating, gas heating, cooking equipment and hairdressing equipment. Type XFF. Economical replacement for silicone insulated wire. • Type XF, 7 strand material available on special request. • CL1503, 600 volts, 150°C. In applications where exposed to gasoline vapors up to +75°C or immersed in gasoline up to 30°C Withstands pulse up to 30,000 volts. CSA TEMPERATURE AND VOLTAGE REFERENCE CSA Type CL1052 CL1053 CL1251 CL1254 CL1503 Voltage 300 600 600 600 600 21 Temperature 105°C 105°C 125°C 125°C 150°C Hypalon* (Chlorosulfonated Polyethylene) Appliance, Transformer and Motor Lead Wire 105°C, 300, 600 or1000V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. 300 VOLTS UL & CSA HYPL18T16 18 16/32 HYPL16T26 16 26/30 600 VOLTS UL, 300 VOLTS CSA HYP20T10 20 10/30 HYP18T16 18 16/30 HYP16T26 16 26/30 HYP14T41 14 41/30 HYP12T65 12 65/30 HYP10T104 10 104/30 HYP08T84 8 84/27 HYP06T84 6 84/25 HYP04T133 4 133/25 HYP02T259 2 259/26 HYP01T259 1 259/25 HYP1/0T259 1/0 259/24 HYP2/0T259 2/0 259/23 HYP3/0T259 3/0 259/22 HYP4/0T266 4/0 266/21 1000 VOLTS UL, 600 VOLTS CSA HYP06T84/1KV 6 84/25 HYP04T133/1KV 4 133/25 HYP02T259/1KV 2 259/25 HYP01T259/1KV 1 259/25 HYP1/0T259/1KV 1/0 259/24 HYP2/0T259/1KV 2/0 259/23 HYP3/0T259/1KV 3/0 259/.0198 HYP4/0T266/1KV 4/0 266/.0223 HYP250T259/1KV 250 259/.0311 HYP350T259/1KV 350 259/.0368 HYP500T259/1KV 500 259/.0439 DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 30 30 .110 .124 11 15 3190 3190 CL1052 CL1052 45 45 45 45 45 45 60 60 60 60 80 80 80 80 80 .135 .150 .165 .167 .200 .213 .298 .340 .395 .457 .550 .595 .634 .700 .770 9 14 19 25 34 50 88 126 184 274 358 436 541 666 826 3191 3191 3191 3191 3191 3192 3192 3192 3192 3193 3193 3193 3193 3193 CL1053 CL1053 CL1053 CL1053 CL1052 CL1052 CL1052 CL1052 CL1052 CL1052 CL1052 CL1052 CL1052 CL1052 80 80 80 95 95 95 95 95 110 110 110 .385 .440 .515 .566 .635 .710 .745 .810 .890 1.010 1.165 140 200 267 400 439 533 688 850 954 1335 1845 3591 3591 3591 3591 3591 3591 3591 3591 3309/3591 3309/3591 3309/3591 CL1053 CL1053 CL1053 CL1053 CL1053 CL1053 CL1053 CL1053 CL1053 CL1053 CL1053 RoHS compliant material available upon request. * Hypalon is a DuPont Tradename. Description: Application: • Soft annealed stranded tinned copper conductor. • Hypalon insulated, VW-1 compound, standard color black. • IEEE 130°C motor lead, class B • Varnish bake cycle: 300°F 24 hr. Appliance wiring material suitable for internal wiring of appliances where exposed to temperatures not exceeding 105°C, or where exposed to oil at a temperature not to exceed 80°C, 600V. Also as hook-up wire, lead wire, transformer coil leads and class B motor lead wires. 325°F 12 hr. 350°F 4 hr. • CL1052, 300 volts, 105°C. • CL1053, 600 volts, 105°C. 22 Ethylene Propylene Rubber (EPR) Appliance and Motor Lead Wire 125°C, 600V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 3284/08T133 8 133/29 80 .330 81 3284 CL1254 3284/06T133 6 133/27 80 .380 115 3284 CL1254 3284/04T133 4 133/25 80 .446 172 3284 CL1254 3284/02T266 2 266/26 80 .496 279 3284 CL1254 3284/01T817 1 817/30 80 .564 360 3284 CL1254 3284/1/0T1045 1/0 1045/30 95 .610 447 3284 CL1254 3284/2/0T1330 2/0 1330/30 95 .677 535 3284 CL1254 3284/3/0T1672 3/0 1672/30 95 .714 643 3284 CL1254 3284/4/0T2109 4/0 2109/30 95 .790 811 3284 CL1254 RoHS compliant material available upon request. Description: Application: • Soft annealed stranded extra flexible tinned copper As wires exposed to temperatures not exceeding 125°C. As lead wires for coils, transformers, motors, ballasts or solenoids where high temperature operation or baking cycles are involved. Also recommended under IEEE standards for class 130°C as motor leads. conductor. • Ethylene Propylene-Rubber insulation, standard color: black. • IEEE 130°C motor lead, class B. CSA TEMPERATURE AND VOLTAGE REFERENCE CSA Type CL1052 CL1053 CL1251 CL1254 CL1503 Voltage 300 600 600 600 600 23 Temperature 105°C 105°C 125°C 125°C 150°C Ethylene Propylene Rubber (EPR) Appliance and Motor Lead Wire 125°C/150°C, 600V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 3340/18T16 18 16/30 45 .142 14 3340/3374 CL1254 3340/16T26 16 26/30 45 .154 17 3340/3374 CL1254 3340/14T41 14 41/30 45 .169 23 3340/3374 CL1254 3340/12T65 12 65/30 45 .190 33 3340/3374 CL1254 3340/10T104 10 104/30 60 .240 53 3340/3374 CL1254 3340/08T84 8 84/27 80 .327 94 3340/3374 CL1254 3340/06T84 6 84/25 80 .380 133 3340/3374 CL1254 3340/04T133 4 133/25 80 .432 189 3340/3374 CL1254 3340/02T259 2 259/26 80 .494 281 3340/3374 CL1254 3340/01T259 1 259/25 95 .583 359 3340/3374 CL1254 3340/1/0T259 1/0 259/24 95 .633 441 3340/3374 CL1254 3340/2/0T259 2/0 259/23 95 .698 541 3340/3374 CL1254 3340/3/0T259 3/0 259/22 95 .758 665 3340/3374 CL1254 3340/4/0T266 4/0 266/21 95 .849 826 3340/3374 CL1254 Description: Application: • Soft annealed stranded tinned copper conductor. • Ethylene Propylene-Rubber insulation, standard As appliance wires exposed to temperatures not exceeding 150°C non-flexing/125°C flexing applications in air. As lead wires for coils, transformers, motors, ballasts or solenoids where high temperature operation or baking cycles are involved. Also recommended under IEEE standards for class 155°C as motor leads. color black. • IEEE 155°C motor lead class F. • CL1254, 600 volts, 125°C. • Varnish bake cycle: 350°F 24 hr. 375°F 4 hr. 24 Ethylene Propylene Diene (EPDM) 7500V AC - 150°C UL Recognized INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATIONS THICKNESS MILS. - NOM. DIAMETER INCHES NOM. UL STYLE HV08T84/7.5 8 84 125 0.423 3499 HV06T84/7.5 6 84 125 0.470 3499 HV04T105/7.5 4 105 125 0.526 3499 HV02T163/7.5 2 163 125 0.581 3499 HV01T210/7.5 1 210 125 0.638 3499 HV1/0T262/7.5 1/0 262 125 0.688 3499 HV2/0T504/7.5 2/0 504 125 0.753 3499 HV3/0T630/7.5 3/0 630 125 0.813 3499 HV4/0T805/7.5 4/0 805 125 0.909 3499 Description: Application: • The insulation Belden uses for this High Voltage wire is EPDM is used in numerous high voltage applications. Recommended maximum baking cycles: 350°F/177°C 24 hrs. 375°F/190°C 4 hrs. a chemically cross-linked ethylene-propylene diene elastomer with a separator for improved stripability. EPDM is naturally corona resistant and more heat resistant than many other rubber compounds and is able to take the longer bake cycles frequently needed for the big jobs. EPDM has superior weather resistance and low temperature pliability. 25 Braidless Silicone Appliance and Motor Lead Wire 150°C, 600V, UL Recognized INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT UL STYLE C.S.A. TYPE 3212/22T07 22 7/30 45 .124 10 3212 AWM 3212/20T10 20 10/30 45 .130 12 3212 AWM 3212/18T16 18 16/30 45 .135 14 3212 AWM 3212/16T26 16 26/30 45 .148 17 3212 AWM 3212/14T41 14 41/30 45 .162 23 3212 AWM 3212/12T65 12 65/30 45 .180 34 3212 AWM 3212/10T105 10 105/30 45 .205 49 3212 AWM 3213/08T133 8 133/29 60 .285 81 3213 AWM 3213/06T133 6 133/27 60 .326 118 3213 AWM 3213/04T133 4 133/25 60 .390 173 3213 AWM 3213/02T259 2 259/25 60 .467 256 3213 AWM 3214/01T259 1 259/25 80 .540 327 3214 AWM 3214/1/0T259 1/0 259/24 80 .586 404 3214 AWM 3214/2/0T259 2/0 259/23 80 .639 512 3214 AWM 3214/3/0T259 3/0 259/22 80 .707 633 3214 AWM 3214/4/0T259 4/0 259/21 80 .774 775 3214 AWM RoHS compliant material available upon request. Description: Application: • Soft annealed stranded tinned copper conductor. • Silicone insulated, standard colors black or white. • IEEE 180°C motor lead class H, For use in motor leads, appliances, lighting fixtures, high temperature electronic applications. Most every high temperature application where flexibility is required. MIL-W-16878D/33 Type FF upon request. • Varnish bake cycle: 300°F 24 hr. 325°F 12 hr. 350°F 4 hr. 26 Glass Braided Silicone Fixture, Apparatus and Motor Lead Wire 150°C, 600V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. GLASS BRAID MILS. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. UL STYLE C.S.A. TYPE SRML18T16/3070 18 16/30 30 .007 .124 11 3070 SEWF-2 SRML16T26/3070 16 26/30 30 .007 .138 19 3070 SEWF-2 SRML14T41/3070 14 41/30 30 .007 .154 26 3070 SEWF-2 SRML12T65/3070 12 65/30 30 .007 .171 38 3070 SEWF-2 SRML10T105/3101 10 105/30 45 .008 .221 62 3101 SEWF-2 SRML08T133/3127 8 133/29 60 .015 .299 88 3127 SEWF-2 SRML06T133/3127 6 133/27 60 .013 .369 140 3127 SEWF-2 RoHS compliant material available upon request. Description: Application: • Soft annealed stranded tinned copper conductor. • Silicone insulated, varnish impregnated glass For use in motors or high temperature lead wire. Appliance and electronic leads. braid. • 18, 16, 14 AWG meets NEC SFF-2. • Varnish bake cycle: 300°F 24 hr. 325°F 12 hr. 350°F 4 hr. 27 Glass Braided Silicone Fixture, Apparatus and Motor Lead Wire 200°C, 600V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. GLASS BRAID MILS. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. UL STYLE C.S.A. TYPE SRML18T07/3071 18 7/26 30 .007 .124 13 3071 SEW-2 SRML16T07/3071 16 7/24 30 .007 .136 17 3071 SEW-2 SRML14T07/3071 14 7/.0242 30 .007 .152 23 3071 SEW-2 SRML12T19/3074 12 19/25 30 .007 .171 33 3074 SEW-2 SRML10T19/3075 10 19/23 45 .008 .221 55 3075 SEW-2 SRML08T54/3125 8 54/25 62 .012 .299 90 3125 SEW-2 SRML06T84/3125 6 84/25 60 .013 .362 131 3125 SEW-2 SRML04T133/3231 4 133/25 60 .014 .423 188 3231 SEW-2 SRML02T133/3231 2 133/23 60 .015 .483 272 3231 SEW-2 SRML01T259/3231 1 259/25 80 .015 .570 362 3231 SEW-2 SRML1/0T259/3231 1/0 259/24 80 .015 .616 435 3231 SEW-2 SRML2/0T259/3231 2/0 259/23 80 .015 .669 533 3231 SEW-2 SRML3/0T259/3231 3/0 259/22 80 .015 .728 647 3231 SEW-2 SRML4/0T259/3231 4/0 259/21 80 .015 .793 890 3231 SEW-2 SRML250T427/3410 250 427/.0242 95 .040 .939 997 3410 - SRML350T427/3410 350 427/.0286 95 .040 1.059 1347 3410 - SRML500T427/3410 500 427/.0342 95 .040 1.213 1549 3410 - RoHS compliant material available upon request. Description: Application: • Soft annealed stranded tinned copper conductor. • Silicone insulated, varnish impregnated glass braid. • 250-500 MCM K-Fiber Braid. • 18, 16, 14 AWG meets NEC SF-2. • Varnish bake cycle: 300°F 24 hr. For use in motors or high temperature lead wire. Appliance and electronic leads. 325°F 12 hr. 350°F 4 hr. 28 Mercury Switch Lead Wire Braidless Silicone Rubber 150°C, 600V, UL Recognized INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. UL STYLE C.S.A. TYPE 3123/17T210 17 210/40 30 .119 13 3123 AWM 3123/20T105 20 105/40 32 .103 7 3123 AWM 3135/18T07* 18 7/.0152 30 .108 11 3135 AWM RoHS compliant material available upon request. * UL 3135, 200C, 600V. Description: Application: • Extra-flexible stranded tinned copper conductor. • Silicone insulated, standard color grey. For mercury switches when protected against mechanical abuse. This product has a durable silicone insulation that will withstand temperatures from +150°C to -55°C, while allowing very low moisture absorption. 29 Silicone Gas Ignition Lead Silicone Rubber High Voltage, UL Recognized INDUSTRIAL ELECTRIC PART # SIZE AWG NO.OF STRANDS INSULATION THICKNESS MILS.-NOM. DIAMETER INCHES NOM. APPROX. NET WT #/1000 FT. UL STYLE TEMPERATURE AND VOLTAGE 3257/20N7 20 7/0121 81 .198 20.5 3257 250°C 10 KVAC/25 KVDC 3257/18N19 18 19/0092 81 .206 23.5 3257 250°C 10 KVAC/25 KVDC 3257/16N26 16 26/0100 81 .218 28.0 3257 250°C 10 KVAC/25 KVDC 3257/14N41 14 41/0100 81 .233 35.0 3257 250°C 10 KVAC/25 KVDC 3257/20N7 20 7/0121 113 .262 33.5 3257 250°C 10 KVAC/25 KVDC 3257/16N26 16 26/0100 113 .282 42.5 3257 250°C 10 KVAC/25 KVDC STANDARD WALL HEAVY WALL Description: Application: • Nickel plated stranded copper conductor. • Silicone insulated, braid reinforced, silicone jacket, For wiring oil burner ignition circuits, gas appliance ignitors, gas fired infra-red heaters and furnaces where protected from repeated flexing, abrasion and physical damage. standard color red. 30 Silicone High Voltage Appliance Wire 150°C, UL Style 3239 10 KVDC to 30 KVDC INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. D.C. VOLTAGE APPROX. NET WT. #/1000 FT. 3239/22T07/10KV 3239/22T07/15KV 3239/22T07/20KV 3239/22T07/25KV 3239/22T07/30KV 3239/20T10/10KV 3239/20T10/15KV 3239/20T10/20KV 3239/20T10/25KV 3239/20T10/30KV 3239/18T16/10KV 3239/18T16/15KV 3239/18T16/20KV 3239/18T16/25KV 3239/18T16/30KV 3239/16T26/10KV 3239/16T26/15KV 3239/16T26/20KV 3239/16T26/25KV 3239/16T26/30KV 3239/14T41/10KV 3239/14T41/15KV 3239/14T41/20KV 3239/14T41/25KV 3239/14T41/30KV 3239/12T65/10KV 3239/12T65/15KV 3239/12T65/20KV 3239/12T65/25KV 3239/12T65/30KV 3239/10T105/10KV 3239/10T105/15KV 3239/10T105/20KV 3239/10T105/25KV 3239/10T105/30KV 22 22 22 22 22 20 20 20 20 20 18 18 18 18 18 16 16 16 16 16 14 14 14 14 14 12 12 12 12 12 10 10 10 10 10 7/30 7/30 7/30 7/30 7/30 10/30 10/30 10/30 10/30 10/30 16/30 16/30 16/30 16/30 16/30 26/30 26/30 26/30 26/30 26/30 41/30 41/30 41/30 41/30 41/30 65/30 65/30 65/30 65/30 65/30 105/30 105/30 105/30 105/30 105/30 40 45 50 62 78 40 45 50 62 78 40 45 50 62 78 40 45 50 62 78 40 45 50 62 78 40 45 50 62 78 40 45 50 62 78 .111 .121 .131 .154 .186 .120 .130 .140 .164 .197 .132 .140 .152 .174 .208 .146 .152 .166 .190 .222 .163 .170 .183 .207 .239 .169 .179 .189 .213 .245 .194 .204 .214 .238 .270 10KV 15KV 20KV 25KV 30KV 10KV 15KV 20KV 25KV 30KV 10KV 15KV 20KV 25KV 30KV 10KV 15KV 20KV 25KV 30KV 10KV 15KV 20KV 25KV 30KV 10KV 15KV 20KV 25KV 30KV 10KV 15KV 20KV 25KV 30KV 10 11 12 13 14 11 12 13 14 15 17 18 19 20 21 19 20 21 22 23 24 27 30 34 38 30 34 38 42 46 42 49 56 62 67 Description: Application: • Soft annealed stranded tinned copper conductor. • Silicone insulated, standard colors white or charcoal. • UL Style 3239, voltage as specified. Internal wiring of T.V. receivers or where the acceptability has been determined by Underwriters Laboratories. 40-45-50 KVDC MATERIAL AVAILABLE BUT NOT UL LISTED. 31 TGGT Apparatus and Motor Lead Wire 250°C, 600V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS DIAMETER INCHES MILS. - NOM. APPROX. NET WT. #/1000 FT. UL STYLE C.S.A. TYPE TGGT18N19-5256 18 19/.0092 .094 9 5256 AWM TGGT16N26-5256 16 26/30 .103 14 5256 AWM TGGT14N41-5256 14 41/30 .118 19 5256 AWM TGGT12N65-5256 12 65/30 .136 27 5256 AWM TGGT10N105-5256 10 105/30 .174 43 5256 AWM TGGT08N133-5256 8 133/30 .205 65 5256 AWM TGGT06N133-5256 6 133/27 .256 102 5256 AWM TGGT04N133-5256 4 133/25 .319 156 5256 AWM Description: Application: • Conductor of nickel plated copper. • Composite insulation: TFE tape insulation, double For internal wiring of domestic, commercial and industrial heating and cooking equipment in both damp and dry application. For continuous operations up to 250°C. fiberglass serve, fiberglass braid, teflon finish. • Natural (tan) color. Stripes may be added for color coding. • CSA Type AWM 1 A/B FT-1. 32 MGT Apparatus and Motor Lead Wire 450°C, 600V, UL Recognized & CSA Certified INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. MGT20N10-5335 20 10/30 38 0.109 10 5335/5107 MGT18N16-5335 18 16/30 38 0.123 13 5335/5107 MGT16N26-5335 16 26/30 38 0.133 16 5335/5107 MGT14N41-5335 14 41/30 38 0.147 22 5335/5107 MGT12N65-5335 12 65/30 38 0.173 31 5335/5107 MGT10N105-5335 10 105/30 45 0.204 53 5335/5107 MGT08N133-5107 8 133/30 45 0.256 80 5335/5107 UL STYLE Description: Application: • Conductor of 27% minimum nickel coated copper. • Composite insulation of reinforced mica tapes and For internal wiring of domestic and commercial apparatus, and motor lead wire for continuous operation up to 450°C. overall teflon impregnated glass braid. • Treated flame retardant and heat resistant glass braid. • CSA Type AWM Class I Group A/B FT-1. • Also available in MGS, which is manufactured with a silicone impregnated glass braid. MGS is not CSA certified. MGT Style 5107 available upon request. 33 Polytetrafluroethylene (PTFE) UL Style 1371 UL, AWM, 1371, 105°C, No Voltage Specified CSA, AWM, Class I, Group A, See CSA Rating Below INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. MIN. AVG. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. UL STYLE 1371/30S07 30 7/38 5.5 .025 .719 1371 1371/28S07 28 7/36 5.5 .028 .989 1371 1371/26S07 26 7/34 5.5 .033 1.43 1371 1371/24S07 24 7/32 5.5 .038 2.11 1371 1371/24S19 24 19/36 5.5 .038 2.11 1371 1371/22S07 22 7/30 5.5 .044 3.05 1371 1371/22S19 22 19/34 5.5 .044 3.09 1371 1371/20S07 20 7/28 5.5 .052 4.57 1371 1371/20S19 20 19/32 5.5 .052 4.67 1371 1371/18S19 18 19/30 8 .067 7.48 1371 1371/16S19 16 19/29 8 .076 9.75 1371 1371/14S19 14 19/27 13 .102 16.4 1371 1371/12S19 12 19/25 13 .120 24.8 1371 1371/10S37 10 37/26 13 .141 35.1 1371 Description: Application: • Soft annealed, solid or stranded, silver plate In back panel areas of electronic equipment, such as electronic computers and business machines, where not subjected to movement or mechanical damage. Suitable for immersion in gasoline, gasoline vapor and 60°C or 80°C in oil. copper conductor. • TFE extruded teflon insulation. • CSA Ratings: 18 -16 AWG 150°C, 150V 14 -10 AWG 200°C, 300V • Imprint required for UL/CSA .051 O.D. and larger. 34 Polytetrafluroethylene (PTFE) UL Style 1213 UL, AWM, 1213, 105°C, No Voltage Specified CSA, AWM, Class I, Group A, See CSA Rating Below INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. MIN. AVG. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. UL STYLE 1213/32S07 1213/32S19 1213/30S01 1213/30S07 1213/30S19 1213/28S01 1213/28S07 1213/28S19 1213/26S01 1213/26S07 1213/26S19 1213/24S01 1213/24S07 1213/24S19 1213/22S01 1213/22S07 1213/22S19 1213/20S01 1213/20S07 1213/20S19 1213/18S07 1213/18S19 1213/16S19 32 32 30 30 30 28 28 28 26 26 26 24 24 24 22 22 22 20 20 20 18 18 16 7/40 19/44 SOLID 7/38 19/42 SOLID 7/36 19/40 SOLID 7/34 19/38 SOLID 7/32 19/36 SOLID 7/30 19/34 SOLID 7/28 19/32 7/26 19/30 19/29 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 .027 .029 .030 .032 .032 .033 .035 .035 .036 .039 .039 .040 .044 .043 .045 .050 .050 .052 .058 .058 .068 .068 .077 .692 .801 .90 1.00 1.03 1.12 1.22 1.30 1.55 1.73 1.77 2.12 2.35 2.45 2.92 3.33 3.42 4.18 4.97 5.10 7.50 7.50 9.05 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 1213 Description: Application: • Soft annealed, solid or stranded, silver plated Internal wiring of electronic equipment where not exposed to undue mechanical abuse. Back panel areas of electronic equipment such as computers and business machines. copper conductor. • TFE extruded teflon insulation. • CSA material rated 150°C, 150 volts. • Imprint required for UL/CSA .051 O.D. and larger. 35 Polytetrafluroethylene (PTFE) UL Style 1180 UL, AWM, 1180, 200°C, 300V CSA, AWM, Class I, Group A, See CSA Rating Below INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. MIN. AVG. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. UL STYLE 1180/30S01 1180/30S07 1180/30S19 1180/28S19 1180/26S07 1180/26S19 1180/24S07 1180/24S19 1180/22S07 1180/22S19 1180/20S07 1180/20S19 1180/18S19 1180/16S19 1180/14S19 1180/12S19 1180/10S37 30 30 30 28 26 26 24 24 22 22 20 20 18 16 14 12 10 SOLID 7/38 19/42 19/40 7/34 19/38 7/32 19/36 7/30 19/34 7/28 19/32 19/30 19/29 19/27 19/25 37/26 13 13 13 13 13 13 13 13 13 13 13 13 13 13 13 13 13 .040 .041 .042 .041 .045 .045 .050 .049 .056 .056 .064 .064 .073 .082 .195 .114 .140 2.16 1.52 1.60 1.95 2.48 2.48 3.69 3.69 4.32 4.32 6.10 6.10 8.52 11.1 16.4 24.8 36.7 1180 1180 1180 1180 1180 1180 1180 1180 1180 1180 1180 1180 1180 1180 1180 1180 1180 Description: Application: • Soft annealed, solid or stranded, silver plated Internal wiring of electronic equipment. Back panel areas of electronic equipment, computers, business machines, etc. copper conductor. • TFE extruded teflon insulation. • CSA material rated 200°C, 300V, 28-10 AWG. • Imprint required for UL/CSA .051 O.D. and larger. 36 Polytetrafluroethylene (PTFE) UL Style 1199 UL, AWM, 1199 200°C, 600V CSA, AWM, Class I, Group A, See CSA Rating Below INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. MIN. AVG. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. UL STYLE 1199/26S01 26 SOLID 20 .056 3.2 1199 1199/26S07 26 7/34 20 .059 3.4 1199 1199/26S19 26 19/38 20 .063 3.6 1199 1199/24S01 24 SOLID 20 .060 3.8 1199 1199/24S07 24 7/32 20 .064 4.2 1199 1199/22S01 22 SOLID 20 .065 4.8 1199 1199/22S07 22 7/30 20 .070 5.4 1199 1199/22S19 22 19/34 20 .070 5.4 1199 1199/20S01 20 SOLID 20 .072 6.5 1199 1199/20S07 20 7/28 20 .078 7.3 1199 1199/20S19 20 19/32 20 .078 7.3 1199 1199/18S07 18 7/26 20 .088 9.6 1199 1199/18S19 18 19/30 20 .087 9.6 1199 1199/16S19 16 19/.0117 20 .096 11.9 1199 1199/14S19 14 19/.0147 20 .109 18.9 1199 1199/12S19 12 19/.0185 20 .128 24.8 1199 Description: Application: • Soft annealed, solid or stranded, silver plate copper Internal wiring of appliances and electronic equipment. Suitable for immersion in gasoline, gasoline vapor and 80°C in oil. conductor. • TFE extruded teflon insulation. • CSA material rated 200°C, 600V. • Imprint required for UL/CSA .051 O.D. and larger. 37 MIL-W-16878/4 Type E 600V/200°C, Rev. E INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. M16878/4-BAB M16878/4-BBA M16878/4-BBB M16878/4-BCA M16878/4-BCB M16878/4-BDA M16878/4-BDB M16878/4-BDE M16878/4-BEA M16878/4-BEB M16878/4-BEE M16878/4-BFA M16878/4-BFB M16878/4-BFE M16878/4-BGA M16878/4-BGB M16878/4-BGE M16878/4-BHA M16878/4-BHB M16878/4-BHE M16878/4-BJE M16878/4-BKE M16878/4-BLE M16878/4-BMG 32 30 30 28 28 26 26 26 24 24 24 22 22 22 20 20 20 18 18 18 16 14 12 10 7/40 SOLID 7/38 SOLID 7/36 SOLID 7/34 19/38 SOLID 7/32 19/36 SOLID 7/30 19/34 SOLID 7/28 19/32 SOLID 7/26 19/30 19/29 19/27 19/25 37/26 8 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 13 13 13 13 .029 .030 .032 .033 .035 .036 .039 .040 .040 .044 .045 .045 .050 .051 .052 .058 .058 .061 .069 .069 .080 .088 .107 .127 .784 .90 1.00 1.12 1.22 1.55 1.73 1.73 2.12 2.35 2.35 2.92 3.33 3.33 4.18 4.97 4.97 6.70 7.50 7.60 9.80 14.7 22.6 34.9 * The X in this column shall be replaced by color code in accordance with MIL-STD-104, System I. **Not listed in 16878/4E. Description: Application: • Soft annealed, solid or stranded, silver plated As stated in MIL-W-16878/4. copper conductor. • TFE extruded teflon insulation. • No imprint required for Military M16878/E. MILITARY COLOR CODE 0 1 2 3 4 38 BLACK BROWN RED ORANGE YELLOW 5 6 7 8 9 GREEN BLUE VIOLET GRAY WHITE MILITARY SPEC NO. * M16878/4-BAB-X M16878/4-BBA-X M16878/4-BBB-X M16878/4-BCA-X M16878/4-BCB-X** M16878/4-BDA-X M16878/4-BDB-X M16878/4-BDE-X** M16878/4-BEA-X M16878/4-BEB-X M16878/4-BEE-X** M16878/4-BFA-X M16878/4-BFB-X M16878/4-BFE-X** M16878/4-BGA-X M16878/4-BGB-X M16878/4-BGE-X** M16878/4-BHA-X M16878/4-BHB-X M16878/4-BHE-X** M16878/4-BJE-X** M16878/4-BKE-X** M16878/4-BLE-X** M16878/4-BMG-X** MIL-W-16878/5 TYPE EE 1000V/200°C, Rev. E INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. M16878/5-BBA M16878/5-BBB M16878/5-BCA M16878/5-BCB M16878/5-BDA M16878/5-BDB M16878/5-BEA M16878/5-BEB M16878/5-BEE M16878/5-BFA M16878/5-BFB M16878/5-BFE M16878/5-BGA M16878/5-BGB M16878/5-BGE M16878/5-BHA M16878/5-BHB M16878/5-BHE 30 30 28 28 26 26 24 24 24 22 22 22 20 20 20 18 18 18 SOLID 7/38 SOLID 7/36 SOLID 7/34 SOLID 7/32 19/36 SOLID 7/30 19/34 SOLID 7/28 19/32 SOLID 7/26 19/30 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 .040 .042 .043 .045 .046 .049 .050 .054 .055 .055 .060 .061 .062 .068 .069 .071 .079 .079 2.16 1.55 1.74 1.89 2.16 2.40 2.80 3.24 3.24 3.74 4.18 4.18 5.16 5.84 5.84 7.33 8.33 8.33 * The X in this column shall be replaced by color code in accordance with MIL-STD-104, System I. **Not listed in 16878/5E. Description: Application: • Soft annealed, solid or stranded, silver plated As stated in MIL-W-16878/5. copper conductor. • TFE extruded teflon insulation. • No imprint required for military M16878/E. MILITARY COLOR CODE 0 1 2 3 4 39 BLACK BROWN RED ORANGE YELLOW 5 6 7 8 9 GREEN BLUE VIOLET GRAY WHITE MILITARY SPEC NO. * M16878/5-BBA-X M16878/5-BBB-X M16878/5-BCA-X M16878/5-BCB-X** M16878/5-BDA-X M16878/5-BDB-X M16878/5-BEA-X M16878/5-BEB-X M16878/5-BEE-X** M16878/5-BFA-X M16878/5-BFB-X M16878/5-BFE-X** M16878/5-BGA-X M16878/5-BGB-X M16878/5-BGE-X** M16878/5-BHA-X M16878/5-BHB-X M16878/5-BHE-X** MIL-W-22759/9 1000V/200°C, Rev. E INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS. - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. MILITARY SPEC NO. * M22759/9-28 M22759/9-26 M22759/9-24 M22759/9-22 M22759/9-20 M22759/9-18 M22759/9-16 M22759/9-14 M22759/9-12 M22759/9-10 28 26 24 22 20 18 16 14 12 10 7/36 19/38 19/36 19/34 19/32 19/30 19/29 19/27 19/25 37/26 14 15 15 15 15 15 15 16 17 16 .043 .048 .053 .060 .068 .078 .085 .100 .120 .141 1.90 2.60 3.30 4.60 6.40 9.10 11.00 16.00 25.00 38.00 M22759/9-28-X M22759/9-26-X M22759/9-24-X M22759/9-22-X M22759/9-20-X M22759/9-18-X M22759/9-16-X M22759/9-14-X M22759/9-12-X M22759/9-10-X MIL-W-22759/11 600V/200°C, Rev. D INDUSTRIAL ELECTRIC PART # SIZE AWG NO. OF STRANDS INSULATION THICKNESS MILS - NOM. DIAMETER INCHES NOM. APPROX. NET WT. #/1000 FT. MILITARY SPEC NO. * M22759/11-28 M22759/11-26 M22759/11-24 M22759/11-22 M22759/11-20 M22759/11-18 M22759/11-16 M22759/11-14 M22759/11-12 M22759/11-10 28 26 24 22 20 18 16 14 12 10 7/36 19/38 19/36 19/34 19/32 19/30 19/29 19/27 19/25 37/26 9 10 10 9 10 10 12 11 15 15 .033 .038 .043 .049 .058 .068 .075 .090 .111 .139 1.40 1.90 2.60 3.70 5.40 8.10 10.00 15.00 24.00 38.00 M22759/11-28-X M22759/11-26-X M22759/11-24-X M22759/11-22-X M22759/11-20-X M22759/11-18-X M22759/11-16-X M22759/11-14-X M22759/11-12-X M22759/11-10-X * The X in this column shall be replaced by color code in accordance with MIL-STD-104, System I. Description: Application: • Soft annealed, solid or stranded, silver plated As stated in MIL-M22759/9 and 11. copper conductor. • TFE extruded teflon insulation. • No imprint required for military. • Printing is required for Rev. D. 40 Properties of Common Thermoplastic Compounds RESISTANT TO PVC LDPE HDPE POLYPROPYLENE POLYURETHANE NYLON TEFLON ABRASION ACID ALCOHOL ALKALI BENZOL,TOLUOL DEGREASER SOLVENT ELECTRICAL FLAME GASOLINE, KEROSENE HEAT LOW TEMP FLEXIBILITY NUCLEAR RADIATION OIL OXIDATION OZONE WATER WEATHER, SUN F-G G-E P-F G-E P-F P-F F-G E P G-E P-G F F E E F-G G-E G G-E E G-E P G E P G-E G E G-E G-E E E E E E E E E P G E P G-E E E G-E G-E E E E E F-G E E E P-F P E P P-F E P F F E E E E O F P-G F P-G P-G P P P-G G G G E E E P-G G E P-F P E G G P P G E G F-G E E E P-F E E E E E E E E O E O O P-G O O E E O Properties of Common Thermoset Compounds RESISTANT TO SBR NEOPRENE HYPALON NBR EPOM SILICONE XLP ABRASION ACID ALCOHOL ALKALI BENZOL,TOLUOL DEGREASER SOLVENT ELECTRICAL FLAME GASOLINE, KEROSENE HEAT LOW TEMP FLEXIBILITY NUCLEAR RADIATION OIL OXIDATION OZONE WATER WEATHER, SUN G-E F-G F F-G P P E P P F-G F-G G P P P G-E F G-E G F G P-F P P G G G F-G F-G G G G E G G E G E F P-F G G F E F E G E E E E G-E G E F-G G P P P-F E G F-G F-G G-E F P G-E F-G G G-E P G-E F P E P P E G-E G P E E G-E E P F-G G F-G P P-G G F-G P-F O O E F-G E O G-E O G-E E E E G G E-O E G G G E G-E E E G-E G-E KEY: O = OUTSTANDING E = EXCELLENT G = GOOD Ratings based on average performance of general purpose compounds. 41 F = FAIR P = POOR Typical Temperature Range of Insulation & Jacket Materials Temperature Centigrade 600° 540° 500° 400° 300° 200° -60° -60° 200° 150° -40° -55° -75° -75° -200° 42 -70° -20° FEP 75° SBR Neoprene PolyPropylene 60° TFE 105° Tefzel -20° EPDM Hypalon -20° -100° XLPE 0 150° 80° Poly-ethylene 80° PVCStandard 90° 100° 200° Braided Silicone 135° Braidless Silicone 200° MICA 260° -30° -40° -70° -70° Flame Retardancy Flame Retardancy in cable usage is normally the ability of the material to cease burning once the source of heat is removed. Several tests have been formulated to measure this property. UL Tests Horizontal Flame Test (UL Standards 44 & 83) A moderate flame test conducted on a horizontal sample in a special enclosure. A Tirrill gas burner with a 1500°F flame is applied to the sample for a period of 30 seconds. The flame must not progress beyond a point 2 inches to the left or right of the point of application of the flame, or ignite the cotton batting on the floor of the test chamber (by means of burning particles dripping from the cable). All Wires Flame Test (UL Standard 83) A vertical flame test in an enclosure using a Tirrill gas burner with a 1500°F flame. A paper flag is positioned on the sample, 10 inches above the point where the flame source is applied to the wire. The flame is applied for a period of 15 seconds, removed for 15 seconds, and then reapplied for 15 seconds. The total number of flame applications is 5. The sample shall be considered unsatisfactory if more than 25% of the paper flag is burned away or the cotton batting at the base of the chamber ignites or if the sample continues to burn for longer than 60 seconds after the last flame application. Vertical Flame Test UL VW-1 (UL Standard 1581) The test is a small-scale test conducted on a single 24 inch length of wire that is fixed in a vertical position in a test booth, with a paper indicator flag attached 10 inches above the flame source with cotton batting laid below the wire. The flame source is a Tirrill burner with a heat output of approximately 3,000 BTUs per hour. The flame is applied for 15 seconds and is then reapplied 4 more times after the wire self-extinguishes. If the sample burns longer than 60 seconds after any application, or the indicator flag or cotton batting is ignited during the test, the wire fails the test. The CSA FT-1 Test is very similar. Vertical Tray Flame Test (UL Standard 1581) This test is conducted on cables lashed to a vertical metal ladder tray 8 feet in height. The combustion source is a ribbon burner with a flame temperature of approximately 1500°F and which supplies 70,000 BTUs of heat per hour. The flame application time is 20 minutes. This rating requires the cable to self-extinguish prior to reaching the top of the tray, a distance of 6 feet. A “Tray Rated” cable must meet this test. The IEEE 383 test is very similar. CSA Tests per CSA Standard C22.2 No. 210.2 FTI: Vertical Wire Flame Test (Similar to UL VW-1 except no cotton) FT2: Horizontal Flame Test (Similar to UL Horizontal Flame Test) FT4: Vertical Tray Flame Test (Similar to UL Vertical Tray Flame Test except 4.9' maximum char height) 43