ECE 501 Introduction to VLSI Design

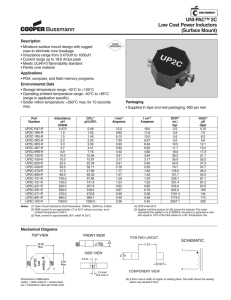

advertisement

ECE 715 System on Chip Design and Test Lecture 8: SoC Physical Design Issues: Wire Inductance Wire Inductance Wide wires in clock distribution & upper level metal layers These wires have low resistance Exhibit significant inductive effects New materials with low-resistance interconnect Inductance Complete interconnect model should include inductance + R i V L - C V=Ldi dt With increasing frequency and a decrease in resistance due to wide wires and the use of copper, inductance will begin to influence clocks/busses: Z = R + jL Inductance, by definition, is for a loop not a wire inductance of a wire in an IC requires knowledge of return path(s) inductance extraction for a whole chip is virtually impossible... Evolution of Interconnect Model Transmission Line Model Follow Board Notes Inductance Effects Lumped RLC line VO Vin R VO = Zo L C Treat RC problem as a resistive divider: 1 sC Zo = Zt 1 + (R + sL) sC 1 = s2LC Poles are P1,2 = n [- z +- sqrt(z 2-1)] Zt n = 1/sqrt(LC) z=RC/2sqrt(LC) = damping factor = + sRC + 1 Vin n2 s2 + s2zn + n2 z > 1 we have two real poles (RC effects) z < 1 we have two complex poles (RLC effects) Inductance Effects Follow board notes Other Inductance Effects For most gates Ron is in the order of K so typically R >> jL response is dominant by RC delay for most signals Only the large drivers have a small enough Ron to allow the inductance to control the dynamic response clocks busses For clocks, self-inductance term can dominate the response (especially if shielding is used) For busses, mutual inductance term dominates and creates noise events that could cause malfunction For power supplies, inductance can also be a problem due to the Ldi/dt drop (in addition to the IR drop) as supplies scale down Capacitive and Inductive Noise R L For most wires, jL < (Rwire+Rdrive) for the frequency and R of interest. So, for delay, L is not a big issue currently. C But L can be 20 - 30% of R so noise may be seen on adjacent line (mutual coupling) Dangerous scenario is a combination of localized capacitive coupling noise and long range mutual inductive coupling noise + - R L R R L R C L R C + L C Return path current C L C Double noise events Gate Driving an RLC Transmission Line Propagation Delay If the ratio of the total resistance of the line to the lossless characteristic impedance increases, inductive effects can be neglected If the ratio of the driver resistance to the lossless characteristic impedance increases, inductive effects can be neglected If the ratio between the time required to charge the load capacitance through the gate and wire resistance to the time of fight increase then inductive effects can be neglected Effect of inductance on Signal Delay Repeater Insertion revisited •Lower repeater size and less number of repeaters •The amount of inductance effects present in an RLC line depends on the ratio between the RC and the LC time constants of the line •As Inductance effect increases the LC time constant dominates the RC time constant and the delay of the line changes from a quadratic to a linear dependence on the line length. •Optimum number of repeaters for the minimum propagation delay decreases Inductance & Power Dissipation The dynamic power is given as Increasing inductance effects results in fewer number of repeaters as well as smaller repeater size Significantly reduces total capacitance Faster rise time results in lower short-circuit power Pdyn CVDD f 2 Inductance Extraction Inductance can only be defined for a closed current loop The inductance of the loop is proportional to the area of the loop At low frequency resistive impedance dominates Current uses as many returns as possible to have parallel resistances Situation is different at higher frequencies Mutual Inductance Causes extra noise and delay effects di1 di2 v1 L1 M dt dt di1 di2 v2 M L2 dt dt Inductive Noise in a bus Physically, a wide bus with all the lines switching in the same direction behaves as one wide line Hence, the effective inductance of a line that is part of a bus is far larger than the self-inductance of that line LC time constant of the line becomes much larger L di/dt effects on the Power Supply Antenna Effects As each metal layer is placed on the chip during fabrication, charge builds up on the metal layers due to CMP1, etc. If too much charge accumulates on gate of MOS transistor, it could damage the oxide and short the gate to the bulk terminal +++++++++++ Metal 1 Poly +++++++++++++++++++++++++++ This transistor could be damaged Metal 2 Antenna = Areawire Areagate Ratio Higher levels of metal accumulate more charge so they are more troublesome (i.e., metal 5 is worse than metal 1) Need to discharge metal lines during processing sequence to avoid transistor damage (becomes a design/layout issue) 1. CMP is chemical mechanical polishing which is used to planarize each layer before the next layer is placed on the wafer. Preventing Antenna Effects A number of different approaches for antenna repairs: Diode Insertion - Make sure all metal lines are connected to diffusion somewhere to discharge the metal lines during fabrication +++++++++++++++++++++++++++ n+ p Antenna diode -diodes costs area - need to optimize number and location - causes problems for design verification tool Preventing Antenna Effects Note that there are always diodes connecting to source/drain regions of all transistors and charge on each layer is drained before next layer is added…so why are we worried? Should put antenna diode here. Keep area of upper layer metals small near next transistor Gate input of next device may not be connected to a diode until it’s too late…charge accumulation on metal exceeds threshold Preventing Antenna Effects Second approach is to add buffers to interconnect to break up long wire routes and provide more gate area for antenna ratio Third approach is to use metal jumpers to from one layer of metal to another Metal 1/polish + + + + + + + + + + + + + + + + + + + + + + + + + + + + ++++++++ vias (charge removed) ++++ Metal2/polish ++++++++