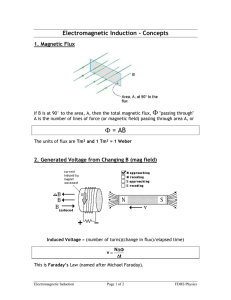

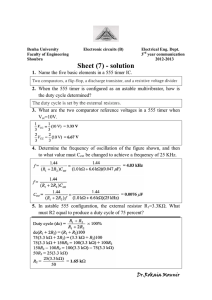

fulltext

advertisement