GE Marine L250 and V250 Series Diesel Engines

advertisement

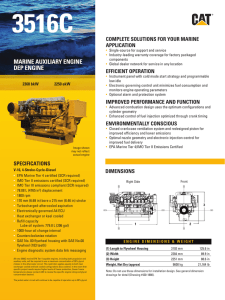

GE Transportation Simply clean GE Marine L250 and V250 Series Diesel Engines EPA Tier 4 / IMO III No aftertreatment. No kidding. A World Leader in Manufacturing Diesel Engines For over 40 years, GE Marine has built dependable, longlasting, and fuel-efficient medium-speed diesel engines. Our engines are found in some of the world’s most challenging industrial environments including tugboats in Turkey, fishing vessels in Peru, and ferries and offshore oil and gas support vessels in Norway. In total, more than 15,000 GE diesel engines are in service worldwide. Today’s Environment The marine industry is facing an ever-increasing demand for efficiency, reliability, and emissions compliance. 2015 marked the transition of new vessel construction to comply with the U.S. Environmental Protection Agency’s (EPA) Tier 4 emission standards. Starting January 1, 2016, the IMO Tier III emission standard will become effective in the NOx Emission Control Areas (NECA). Engineered to Exceed The GE Marine L250 and V250 Series Diesel Engine meets the EPA’s stringent Tier 4 and IMO’s Tier III emission standards without the use of selective catalytic reduction (SCR) equipment and urea-based aftertreatment. Our diesel engine integrates an upgraded control system, high-pressure common rail fuel injection, two-stage turbocharging, and advanced exhaust gas recirculation (EGR) to meet the EPA’s Tier 4 and IMO Tier III emissions. No Aftertreatment. No Kidding, Carrying, injecting, and cleaning SCR systems that use urea is time-consuming and costly. Vessels with SCR systems installed must carry six to eight percent more tank capacity in urea. Our non-SCR/non-urea based in-engine emission design leaves you with more cargo and accommodation space while reducing the time spent maintaining hardware saving you money over the life of your vessel. If you’re looking to repower your existing fleet, our EPA Tier 4/IMO Tier III L250 and V250 Series Diesel Engine helps make upgrading your vessels easy. Adding SCR reactors, urea tanks, and dosing equipment to repower a vessel that was not designed to have an SCR system installed, is cumbersome. Seamlessly update your fleet, meet emission standards, and get back to doing business faster with the help of our non-urea based engine. Size Matters Our EPA Tier 4/IMO Tier III L250 and V250 Series Diesel Engine is a compact solution for customers. Though the V250 engines have grown only about five percent, the L250 design remains virtually the same between the EPA Tier 3/IMO Tier II models. In addition, our engines do not require aftertreatment equipment saving customers up to 75 percent space overall. Maintenance Less equipment means less time spent maintaining hardware and servicing technology when there is a problem. When compared to maintaining an SCR system and its related equipment – dosing system, monitoring systems, urea injection, and urea tanks –the maintenance time and cost for our EGR based emission solution is minimal and, depending on duty cycle, the time between overhaul is still an industry leading 40,000 hours. With an SCR equipped vessel, owners have a higher operating expense that entails injecting urea and exchanging catalytic reactors. The Marine Industry With the L250 and V250 Series Diesel Engine, GE Marine delivers industry-leading in-engine technology for emission compliance to the offshore oil and gas industry. Powering platform supply vessels (PSVs), offshore support vessels (OSVs), offshore construction vessels (OCVs), and inspection maintenance and repair (IMR) vessels allows customers to see that day-to-day operations are completed cleanly and efficiently. Our L250 and V250 Series Diesel Engine powers global marine markets. Due to NOx taxation, other countries already drive cleaner engines. Many offshore oil and gas support vessels built in Norway today are fitted with SCR systems or are otherwise operating cleaner than IMO Tier II emissions. With our technology key emissions are reduced by more than 70 percent and enable in-engine compliance with EPA Tier 4 and IMO Tier III emissions standards making it the environmental choice for global customers. Aftertreatment Solution SCR Technology Dosing & Monitoring Equipment Urea GE Tier 4/IMO III Marine Engine GE L250 and V250 Series Diesel Engine L250/V250 Series Diesel Engine specifications 6L250MDC Rated speed MCR 8L250MDC 12V250MDC 16V250MDC rpm 900 1,000 900 1,000 900 1,000 900 1,000 bkW 1,700 1,900 2,250 2,500 3,150 3,500 4,200 4,700 bhp 2,280 2,548 3,017 3,353 4,224 4,694 5,632 6,303 Engine data 6L250 8L250 12V250 16V250 Number of cylinders 6 8 12 16 Stroke cycle 4 4 4 4 inline inline V V Bore 250 mm (9.8 in) 250 mm (9.8 in) 250 mm (9.8 in) 250 mm (9.8 in) Stroke 320 mm (12.6 in) 320 mm (12.6 in) 320 mm (12.6 in) 320 mm (12.6 in) 15.0:1 15.0:1 15.0:1 15.0:1 12V250 16V250 Cylinder arrangement Compression ratio Engine dimensions mm (in) 6L250 8L250 2,809 (110.6) 2,809 (110.6) 3,636 (143) 3,721 (147) N/A N/A 3,520 (138.6) 3,540 (139.4) A Height w/ deep sump B Height w/ shallow sump C Length 4,691 (184.7) 5,580 (219.7) 5,284 (208) 6,285 (247) D Width 2,006 (79) 2,006 (79) 2,693 (106.3) 2,693 (106.3) E Crank center line marine sump 940 (37) 940 (37) 1,077 (42.4) 1,161 (45.8) F Crank center line to mounting feet 308 (12.13) 308 (12.13) 536 (21.1) 536 (21.1) G Exhaust diameter 260 (10.2) 260 (10.2) 610 (24) 610 (24) 19,944 (43,876) 23,356 (51,491) 27,080 (59,700) 35,788 (78,900) Dry weight kg (lb) D G C www.getransportation.com ge.marine@ge.com A B E F GE Marine 2901 East Lake Road Erie, PA 16531 USA GE Marine is an operating component of General Electric Company. The GE brand, and GE monogram are trademarks of General Electric Company. © 2015 GE Transportation. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions. 20275-A