design requirements - 3.6 electrical engineering

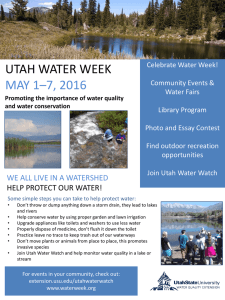

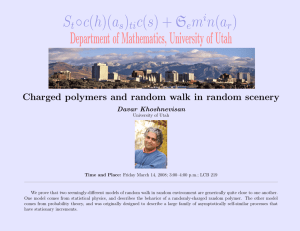

advertisement