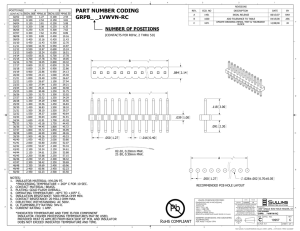

technical specification for

advertisement