Objectives: WP1. Experimental studies and modelling of pressurised

advertisement

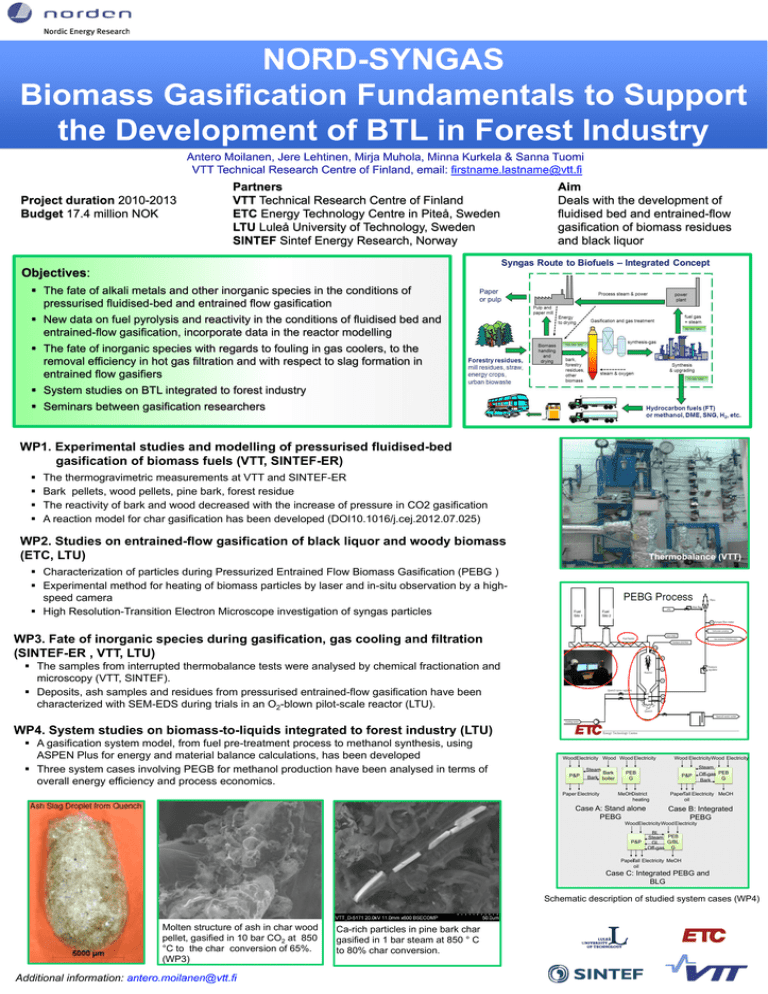

NORD-SYNGAS Biomass Gasification Fundamentals to Support the Development of BTL in Forest Industry Antero Moilanen, Jere Lehtinen, Mirja Muhola, Minna Kurkela & Sanna Tuomi VTT Technical Research Centre of Finland, email: firstname.lastname@vtt.fi Project duration 2010-2013 Budget 17.4 million NOK Partners VTT Technical Research Centre of Finland ETC Energy Technology Centre in Piteå, Sweden LTU Luleå University of Technology, Sweden SINTEF Sintef Energy Research, Norway Aim Deals with the development of fluidised bed and entrained-flow gasification of biomass residues and black liquor Objectives: The fate of alkali metals and other inorganic species in the conditions of pressurised fluidised-bed and entrained flow gasification New data on fuel pyrolysis and reactivity in the conditions of fluidised bed and entrained-flow gasification, incorporate data in the reactor modelling The fate of inorganic species with regards to fouling in gas coolers, to the removal efficiency in hot gas filtration and with respect to slag formation in entrained flow gasifiers System studies on BTL integrated to forest industry Seminars between gasification researchers WP1. Experimental studies and modelling of pressurised fluidised-bed gasification of biomass fuels (VTT, SINTEF-ER) The thermogravimetric measurements at VTT and SINTEF-ER Bark pellets, wood pellets, pine bark, forest residue The reactivity of bark and wood decreased with the increase of pressure in CO2 gasification A reaction model for char gasification has been developed (DOI10.1016/j.cej.2012.07.025) WP2. Studies on entrained-flow gasification of black liquor and woody biomass (ETC, LTU) Thermobalance (VTT) Characterization of particles during Pressurized Entrained Flow Biomass Gasification (PEBG ) Experimental method for heating of biomass particles by laser and in-situ observation by a highspeed camera High Resolution-Transition Electron Microscope investigation of syngas particles WP3. Fate of inorganic species during gasification, gas cooling and filtration (SINTEF-ER , VTT, LTU) The samples from interrupted thermobalance tests were analysed by chemical fractionation and microscopy (VTT, SINTEF). Deposits, ash samples and residues from pressurised entrained-flow gasification have been characterized with SEM-EDS during trials in an O2-blown pilot-scale reactor (LTU). WP4. System studies on biomass-to-liquids integrated to forest industry (LTU) A gasification system model, from fuel pre-treatment process to methanol synthesis, using ASPEN Plus for energy and material balance calculations, has been developed Three system cases involving PEGB for methanol production have been analysed in terms of overall energy efficiency and process economics. WoodElectricity Wood Wood Electricity Steam P&P Bark Bark boiler Paper Electricity Wood Electricity Wood Electricity PEB G P&P MeOHDistrict heating Case A: Stand alone PEBG Steam Off-gas Off-gas PEB G Bark PaperTall Electricity MeOH oil Case B: Integrated PEBG WoodElectricity Wood Electricity P&P BL Steam PEB G/BL GL Off-gas G PaperTall Electricity MeOH oil Case C: Integrated PEBG and BLG Schematic description of studied system cases (WP4) Molten structure of ash in char wood pellet, gasified in 10 bar CO2 at 850 °C to the char conversion of 65%. (WP3) Additional information: antero.moilanen@vtt.fi Ca-rich particles in pine bark char gasified in 1 bar steam at 850 ° C to 80% char conversion.