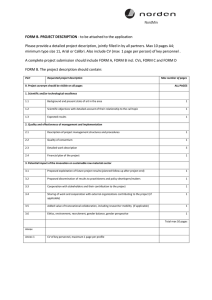

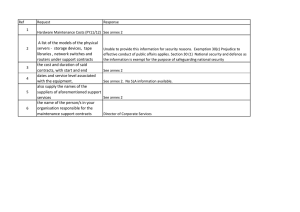

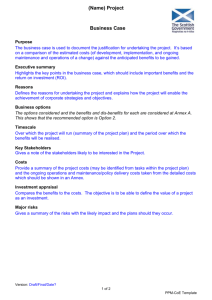

AGREEMENT

advertisement