E lect romechanical Load Frame E nvi ronmental Chambers

advertisement

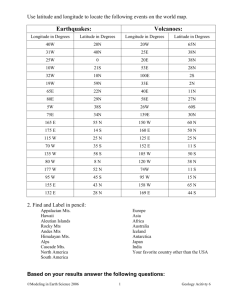

Electromechanical Load Frame Environmental Chambers Features © Temperature ranges from -129°C (-200°F) to 315°C (600°F). © Forced convection heating provides rapid heat transfer, overshoot pro t e c t i o n . © Large circulating fan helps ensure small specimen temperature gradients; fan baffle minimizes radiant heat on specimen. © Cooling ranges available fro m ambient to: -129°C (-200°F) when equipped for liquid nitrogen (standard ) . © Built-in high quality temperature controller, with digital communications. © Removable “U-plug” sections for top and bottom walls allow the chamber to be put in place for testing after mounting the specimen and all instru m e n t ation in the load frame. © Local protection against thermal runaway (additional pro t e c t i o n is provided by the temperature controller). © Internal light illuminates the test area. © Temperature sensor can be located anywhere in test are a . © 2.0 inch ports for instrument/extensometer cables. © CE certified. MTS Series Chambers enable the testing of materials and components within various ranges of high and low temperature s . Two electrical heating elements are used for high temperature testing. An electric motor-driven fan with a baffle provides diffused convection heat for uniform temperatures. The specimen is shielded f rom direct radiant heat by the fan baffle and fan blades. Use of liquid nitrogen (at 22 psi) allows temperature control between ambient and -129°C (-200°F). Chambers may be provided for carbon dioxide operation between ambient and -73°C (-100°F) as an option (specify either 300 psi or 900 psi carbon dioxide supply). The chambers will maintain a constant temperature within a few degrees (see specifications) of the desired setting with very little temperature gradient across the specimen. Temperature gradient acro s s the specimen, while heating or cooling, depends mainly on the geometry, mass, and material of the specimen. m Typical uses are elastomer material studies, body and engine mount tests, shock absorber tests, tire cord tests, plastics, composite material tests, laminate tests, and vibration isolator tests. These chambers a re used in re s e a rch, in reliability testing, quality control, and production testing. Chambers are of all-welded construction with Fiberglass® insulation between the outer liner and the stainless steel inner liner. The door opens to 180°, or it may be lifted from the chamber if that is more convenient. The window is multipane, tempered glass, sealed to keep moisture out and to prevent fogging and frosting. MTS can also supply special chambers designed for use with mechanical refrigeration, humidity control, or salt spray applications and in special sizes to suit your unique requirements. Contact your MTS sales engineer for more inform a t i o n about these options. Description Light Access Holes Mounting Accessories © Access Holes Fan Inst. P o rt Various chamber mounting accessories are available for use with MTS load frames. These accessories allow the chambers to be mounted to the base plate. Window Fan Baffle Fan Motor Coolant Exhaust Vent Latch Hinges Base Angle Chamber Interior Door Latch and Handle Rail Mount 2 Dimensions F D C A M H E B J N Dimensions of Environmental Chambers* Model A B C D E F H J M N (WxDxH) 10x10x24 mm in 254 10 610 24 254 10 406 16 762 30 737 29 152 6 304 12 114 4.5 861 33.88 10x10x32 mm in 254 10 813 32 254 10 406 16 965 38 737 29 152 6 406 16 114 4.5 1064 41.88 14x17x24 mm in 356 14 610 24 432 17 533 21 762 30 914 36 152 6 304 12 114 4.5 858 33,75 14x17x32 mm in 356 14 813 32 432 17 533 21 965 38 914 36 152 6 406 16 114 4.5 1061 41.75 *Dimensions shown are appropriate. Dimensions shown in millimeters are rounded to closest millimeter. MTS reserves the right to change dimensions without notice. 3 m Specifications Width x Depth x Height 10x10x24 Performance Temperature Range 10x10x32 14x17x24 -200°F to 600°F (-129°C to 316°C) 14x17x32 -200°F to 600°F (-129°C to 316°C) Ambient to 600°F (316°C) Less than 45 minutes Less than 45 minutes Less than 45 minutes Less than 45 minutes Ambient to 400°F (204°C) Less than 20 minutes Less than 20 minutes Less than 25 minutes Less than 25 minutes Ambient to -200°F (-129°C) Less than 20 minutes Less than 20 minutes Less than 40 minutes Less than 40 minutes Temperature Gradient +/- 5°F (+/-3°C) +/- 5°F (+/-3°C) +/- 5°F (+/-3°C) +/- 5°F (+/-3°C) Temperature Stability +/-2% of set point or +/- 5°F (+/- 3°C) which ever is greater Specs Interior Dimensions (W x D x H) 10" x 10" x 24" 10" x 10" x 32" 14" x 17" x 24" 14" x 17" x 32" 254 x 254 x 610mm 254 x 254 x 813mm 356 x 432 x 610mm 356 x 432 x 813mm 16" x 29" x 30" 16" x 29" x 38" 21" x 36" x 30" 21" x 36" x 38" A p p rox. Ext. Dimensions (W x D x H) 406 x 737 x 762mm 406 x 737 x 965mm 533 x 914 x 462mm 533 x 914 x 965mm Top/Bottom U-Plug Port Diameters 4.5" O.D. 4.5" O.D. 4.5" O.D. 4.5" O.D. Top/Bottom Port Plug Insert Sizes 1.25" I.D. /2.0" I.D. /2.88" I.D. 1.25" I.D. /2.0" I.D. /2.88" I.D. 1.25" I.D. /2.0" I.D. /2.88" I.D. 1.25" I.D. /2.0" I.D. /2.88" I.D. Top Exhaust Port w/ Plug 1.5" O.D. 1.5" O.D. 1.5" O.D. 1.5" O.D. Side Instrumentation Port w/ Plug 2.0" O.D. 2.0" O.D. 2.0" O.D. 2.0" O.D. Window 6" x 12" 3 pane 6" x 16" 3 pane 6" x 12" 3 pane 6" x 16" 3 pane Chamber P/N (US Plug) 566372-01 Drawing 566372-05 Drawing 566373-01 Drawing 566373-05 Drawing Chamber P/N (WW Plug) 566372-02 Drawing 566372-06 Drawing 566373-02 Drawing 566373-06 Drawing CE Marked YES YES YES YES N RTL (i.e. UL listed) YES YES YES YES Ship Weight 300 lbs. 350 lbs. 350 lbs. 400 lbs. Color B rushed Stainless Steel Brushed Stainless Steel Brushed Stainless Steel B rushed Stainless Steel Main Contro l l e r E u ro t h e rm2404 Euro t h e rm2404 Euro t h e rm2404 E u ro t h e rm2404 High Limit Controller E u ro t h e rm2116FM Euro t h e rm2116FM Euro t h e rm2116FM E u ro t h e rm2116FM Volts 208/230V 208/230V 208/230V 208/230V Line Fre q u e n c y 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz Phase Single Single Single Single Full Load Amps 16.0-14.4 amps 16.0-14.4 amps 23.2-20.9 amps 23.2-20.9 amps C i rcuit Req. 30 amps 30 amps 30 amps 30 amps MTS Systems Corporation 14000 Tech n o logy Drive Eden Prair ie, Minnesota 55344 -2290 USA Toll Free: 800·9 44·1687 Phone: 952·937·45 5 5 Fax: 952·937·4515 E-mail: info@mts.com www.mts.com ISO 9001:2000 CE RT IFIED QMS Specifications subject to change without notice. MTS is a registered trademark, and Advantage is a trademark of MTS Systems Corporation. RTM No.211177. ©2007 MTS Systems Corporation 100-177-320a ElectromechanicalChamber Printed in U.S.A. 5/07 4