Addendum #3 - Butte County Association of Governments

advertisement

BUTTE REGIONAL TRANSIT

OPERATIONS CENTER

Tenant Improvement

Butte County Association of

Governments

ADDENDUM NO. 3

PROJECT ADDRESS

326 Huss Lane

Chico, CA 95928

OWNER

Butte County Association of Governments

2580 Sierra Sunrise Terrace, Suite 100

Chico, CA 95928

Date

1/18/2016

Note: The following changes, modifications and additions to the Project Manual and Drawings described

within this Addendum are subject to all of the requirements as if originally specified.

2750 Gateway Oaks Drive, Suite 300

Sacramento, CA 95833

ADDENDUM NO. 3

BUTTE REGIONAL TRANSIT OPERATIONS CENTER

Tenant Improvement

Butte County Association of Governments

2850 Sierra Sunrise Terrace, Suite 100

Chico, CA 95928

Stamps & Signatures

Kitchell CEM

ADDENDUM NO. 3

ADDENDUM NO. 3

To the Plans and Specifications for:

BUTTE REGIONAL TRANSIT OPERATIONS CENTER

Tenant Improvement

Butte County Association of Governments

2850 Sierra Sunrise Terrace, Suite 100

Chico, CA 95928

Date: 1‐15‐2016

GENERAL INFORMATION FOR BIDDERS

See sheets A100, AD201, E100 & P201 for illustrations of bid alternates. General Contractor to

separate and itemize the price of these items as shown for selection by BCAG as to what to

execute within the project scope.

Additional revisions to the drawings have been made per Addendum #1 dated 01‐04‐2016 and

in response to City of Chico building department comments, which are clouded with a delta 2.

REVISION TO SPECIFICATIONS

1.1 REVISION TO SECTION 22 30 00 PLUMBING EQUIPMENT – DELETED IN ITS ENTIRETY

1.2 REVISION TO SECTION 22 33 00 ELECTRIC DOMESTIC WATER HEATERS – ADDED NEW SECTION

1.3 REVISION TO SECTION 22 33 13 INSTANTANEOUS ELECTRIC DOMESTIC WATER HEATERS –

ADDED NEW SECTION

REVISIONS TO DRAWINGS

1.1

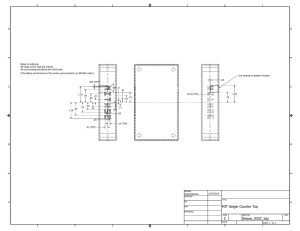

REVISION TO DRAWING G001 – COVER SHEET

a. Bid Alternate reference added

1.2

REVISION TO DRAWING A100 – ARCHITECTURAL SITE PLAN

a. Bid Alternate ‐ Information added to direct contractor to provide pricing for trenching a

gas line as shown and the installation of (2) bollards.

1.3

REVISION TO DRAWING AD201 – DEMO FLOOR PLAN

a. Bid Alternate added to remove the existing gas meter on the south elevation per keynote

34.

Kitchell CEM

ADDENDUM NO. 3

1.4

REVISION TO DRAWING A601 – SIGNAGE PLAN & ROOM FINISH SCHEDULE

a. ROOM FINISH SCHEDULE – The floor finish in room 133 has been revised

1.5

REVISION TO DRAWING A702 – DOOR SCHEDULES & DETAILS

a. Detail 3 has been revised to clarify the location and quantity of gate hinges

b. Detail 4 has been revised to clarify the construction of the gate hinge

1.6

REVISION TO DRAWING S200 – FOUNDATION PLAN & DETAILS

a. Plan 1 ‐ added reference callout to new interior spread footings on gridline B.1 and added

gate post size and drilled pier information at utility yard. Detail 4 ‐ added description to

clarify location of concrete drilled pier footing. Added detail 6 for concrete drilled pier

footing at utility yard.

1.7

REVISION TO DRAWING S210 – ENLARGED PLATFORM/RAMP FRAMING PLAN & DETAILS

a. Plan 1 ‐ added reference callout to new posts at the new ramp. Detail 2 ‐ revised nailing

requirements for new ledger, located adjacent to the existing CMU wall and new 4x10.

Detail 3 – added note for ledger at new 4x10.

1.8

REVISION TO DRAWING S220 – PARTIAL CEILING FRAMING PLAN & DETAILS

a. Plan 1 – Add note for attachment of plywood to Z purlins. Detail 3 – Extended plywood

over and attaching to HSS beam.

1.9

REVISION TO DRAWING S230 – ROOF FRAMING PLAN & DETAILS

a. Plan 1 – Added additional Z purlins to double up existing/new Z purlins supporting

mechanical unit located between grids 2&3 and A&B.1 and added note to reference detail

for existing metal deck opening. Detail 6 – Revised weld of new bent plate to existing rigid

frame beam and revised dimension of vertical slotted holes in bent plate. Added detail 7

to double up existing/new Z purlins supporting mechanical units.

1.10 REVISION TO DRAWING M701– MECHANICAL DETAILS

a. Detail 2 has been revised to include MC unit mounting.

1.11 REVISION TO DRAWING M702 – MECHANICAL DETAILS

a. Detail 2 has been revised to clarify exhaust/relief hood mounting detail.

b. Detail 3 has been revised to clarify fan coil mounting at wood joist.

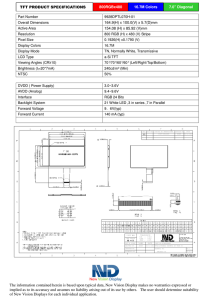

1.12 REVISION TO DRAWING M802 – MECHANICAL SCHEDULES

a. Notes for mounting detail have been added to VRF Indoor Unit Schedule.

b. Notes for mounting detail have been added to Dedicated Outdoor Air Split System Indoor

Fan Coil Unit Schedule.

c. Notes for mounting detail have been added to VRF Mode Change Unit Schedule.

d. Notes for mounting detail have been added to Roof Exhaust/Relief Hood Schedule.

e. Notes for mounting detail have been added to Ceiling Exhaust Fan Schedule.

1.13 REVISION TO DRAWING M901 – MECHANICAL TITLE 24

a.

Updated Title 24 Calculations

Kitchell CEM

ADDENDUM NO. 3

1.14 REVISION TO DRAWING M902 – MECHANICAL TITLE 24

a.

Updated Title 24 Calculations

1.15 REVISION TO DRAWING M903 – MECHANICAL TITLE 24

a. Updated Title 24 Calculations

1.16 REVISION TO DRAWING E201 – ELECTRICAL POWER PLAN

a. Added General Note 2 clarifying that all branch circuits are included. Added Keynote 5 to

A/V room for additional conduits to IDF Room.

b. Added disconnect for the electric water heater. See Mechanical Schedule.

c. Added junction box for instant water heater.

1.17 REVISION TO DRAWING E805 – ELECTRICAL PANEL SCHEDULES

a. Revised all panels per new panel schedule template.

b. Revised circuits for outlets at cable tray from 2 pole to 1 pole. Added circuits for

receptacles at A/V room.

c. Added a 1 pole circuit for instant water heater and a 2 pole circuit for the electric water

heater to panel “LB.”

1.18 REVISION TO DRAWING P001 – PLUMBING ABBREVIATIONS, SYMBOLS & NOTES

a. Deleted Gas Water Heater Schedule.

b. Deleted gas plumbing line symbol.

c. Added Electric Water Heater Schedule.

d. Added Instantaneous Water Heater Schedule.

e. Added Water Calculations.

1.19 REVISION TO DRAWING P201 – PLUMBING FLOOR PLAN WITH PLUMBING FIXTURES

LOCATED

a.

b.

c.

d.

e.

Deleted Gas Water Heater Detail.

Added Electric Water Heater Detail.

Added Instantaneous Water Heater Detail.

Revised plan to locate electric water heater.

Revised plan to locate instantaneous water heater.

1.20 REVISION TO DRAWING P901 – ISOMETRIC PLUMBING VIEWS

a. Isometric plumbing plans added for clarity.

1.21 REVISION TO DRAWING E201 – ELECTRICAL POWER PLAN

a. Added General Note 2 clarifying that all branch circuits are included. Added Keynote 5 to

A/V room for additional conduits to IDF Room.

b. Added disconnect for the electric water heater. See Mechanical Schedule.

c. Added junction box for instant water heater.

Kitchell CEM

ADDENDUM NO. 3

SHEET INDEX

BID SET

X

X

X

X

1/15/2016

X

2750 GATEWAY OAKS DRIVE, SUITE 300

SACRAMENTO, CA 95833

PROJECT SCOPE

THIS PROJECT IS FOR THE RENOVATION OF THE EXISTING BUS MAINTENANCE AND TRANSIT

OPERATIONS CENTER FOR THE BUTTE COUNTY ASSOCIATIONS OF GOVERNMENTS. THE

SCOPE INCLUDES THE REMOVAL OF ALL EQUIPMENT AND NON-STRUCTURAL WALLS AT THE

BUILDING INTERIOR AND THE REMOVAL OF ALL ROOF MOUNTED EQUIPMENT. NEW

CONSTRUCTION INCLUDES NEW WALLS AND EQUIPMENT AS INDICATED ON THE PLANS. SITE

WORK IS LIMITED TO WHAT IS DEPICTED ON THE PLANS, MOST SITE IMPROVEMENTS ARE TO

OCCUR UNDER A SEPARATE PERMIT PRIOR TO THE RENOVATION OF THIS BUILDING.

PROJECT LOCATION

2

LIC

JA E

S

ELECTRICAL

E001

ELECTRICAL ABBREVIATIONS, SYMBOLS, & NOTES

E100

ELECTRICAL SITE PLAN

E201

ELECTRICAL POWER PLAN

E202

ELECTRICAL LIGHTING PLAN

E203

ELECTRICAL DATA PLAN

E204

FIRE ALARM PLAN

E205

SECURITY & A/V PLANS

E501

ENLARGED POWER PLANS

E701

ELECTRICAL DETAILS

E801

ELECTRICAL SINGLE LINE DIAGRAM

E802

LOW VOLTAGE SINGLE LINE DIAGRAMS

E803

LIGHTING FIXTURES SCHEUDLE & SWITCHING DIAGRAM

E804

FIRE ALARM DIAGRAM, SCHEDULE & DETAILS

E805

ELECTRICAL PANEL SCHEDULES

E806

ELECTRICAL SCHEDULES

E901

ELECTRICAL TITLE 24

E902

ELECTRICAL TITLE 24

JAY MONNIN

KITCHELL CEM

IA

BUTTE REGIONAL TRANSIT OPERATIONS

CENTER

MECHANICAL

M001

MECHANICAL ABBREVIATIONS, SYMBOLS, & NOTES

M201

MECHANICAL PLAN

M202

MECHANICAL REFRIGERANT & CONDENSATE PLAN

M701

MECHANICAL DETAILS

M702

MECHANICAL DETAILS

M801

MECHANICAL SCHEDULES

M802

VRF SYSTEM PIPING DIAGRAM & SEQUENCE OF OPERATIONS

M803

VRF SYSTEM WIRING DIAGRAM

M901

MECHANICAL TITLE 24

M902

MECHANICAL TITLE 24

M903

MECHANICAL TITLE 24

X

X

A

T

AT R C H I T E C N

R

EO

F CA L I F O

PLUMBING

P001

PLUMBING ABBREVIATIONS, SYMBOLS & NOTES

P201

PLUMBING FLOOR PLAN WITH PLUMBING FIXTURES LOCATED

P901

ISOMETRIC PLUMBING VIEWS

PROJECT STATUS:

SPECIAL INSPECTIONS

THIS ENTIRE BUILDING AND FACILITY SHALL BE IN COMPLIANCE WITH 2013 CBC CH11B

ACCESSIBILITY TO PUBLIC BUILDINGS.

BUTTE COUNTY ASSOCIATION OF

GOVERNMENTS

X

X

No.: C32299

Exp.: 01/31/17

326 HUSS LANE, CHICO CA

X

X

X

D ARC

SE P. M HIT

N N

ON

O

STRUCTURAL

S001

STRUCTURAL ABBREVATIONS, SYMBOLS, & NOTES

S002

GENERAL NOTES AND TYPICAL DETAILS

S003

STRUCTURAL TYPICAL DETAILS

S004

STRUCTURAL TYPICAL DETAILS

S200

FOUNDATION PLAN & DETAILS

S210

ENLARGED PLATFORM / RAMP FRAMING PLAN & DETAILS

S220

PARTIAL CEILING FRAMING PLAN & DETAILS

S230

ROOF FRAMING PLAN & DETAILS

X

X

X

Capital Expenditure Managers

2750 Gateway Oaks Drive

Suite 300

Sacramento, CA. 95833

(916) 648-9700

ST

ARCHITECTURE

A001

ARCHITECTURAL ABBREVIATIONS, SYMBOLS & NOTES

A002

CODE ANALYSIS - EGRESS DIAGRAM

A003

DETAIL SCHEDULE

A100

ARCHITECTURAL SITE PLAN

A101

ENLARGED SITE PLAN

AD201

DEMO FLOOR PLAN

AD230

DEMO ROOF PLAN

A201

FLOOR PLAN

A202

FLOOR PLAN - DIMENSIONS

A211

ENLARGED FLOOR PLANS

A221

REFLECTED CEILING PLAN

A222

ENLARGED CEILING PLAN

A223

CEILING CONNECTION DETAILS

A230

ROOF PLAN

A301

EXTERIOR ELEVATIONS

A401

BUILDING SECTIONS

A501

WALL SECTIONS & DETAILS

A601

SIGNAGE PLAN & ROOM FINISH SCHEDULE

A602

INTERIOR ELEVATIONS

A603

INTERIOR ELEVATIONS

A604

INTERIOR ELEVATIONS

A605

ARCHITECTURAL DETAILS

A610

RESTROOM ENLARGED PLANS & ELEVATIONS

A611

RESTROOM DETAILS

A701

WINDOW SCHEDULES & DETAILS

A702

DOOR SCHEDULES & DETAILS

A703

SIGNAGE DETAILS

326 HUSS LANE

CHICO, CA

Butte County

COVER SHEET

T

EC N

NI

BUTTE COUNTY ASSOCIATION OF GOVERNMENTS

BUTTE REGIONAL TRANSIT OPERATIONS CENTER

TENANT IMPROVEMENT

GENERAL

G001

BID SET

FOR SPECIAL INSPECTIONS REQUIREMENTS, SEE SHEET S001.

2

PROJECT LOCATION

BUILDINGS:

CONSULTANT

OWNER

KITCHELL CEM

BUTTE COUNTY ASSOCIATION OF GOVERNMENTS

2750 GATEWAY OAKS DR SUITE 300

SACRAMENTO, CA 95833

PH. 916.648.9700

FAX 916.648.6534

1/18/2016 11:19:41 AM

LAST REVISION:

2580 SIERRA SUNRISE TERRACE, SUITE #100

CHICO, CA 95928

CONSTRUCTION MANAGER: RON DUEK

CONTACT: ANDY NEWSUM - DEPUTY DIRECTOR

3

PH. 530.879.2468

PROJECT ARCHITECT: JAY MONNIN, R.A.

STRUCTURAL ENGINEER: DANNY VANG, S.E.

MECHANICAL / PLUMBING ENGINEER: HENRY SAYARATH, P.E.

N

N

VICINITY MAP

LOCATION MAP

NTS

NTS

ELECTRICAL ENGINEER: MILUTIN BACKOVICH, P.E.

BID ALTERNATE

SHEET TITLE:

COVER SHEET

0

1/2

SCALE:

1

BAR IS ONE INCH ON ORIGINAL

DRAWING. IF NOT ONE INCH ON THIS

SHEET, ADJUST SCALES ACCORDINGLY

REVISIONS

NO.

DESCRIPTION

2 PERMIT RESPONSE

3 ADDENDUM 3

DATE

1/15/16

1/18/16

SEE SHEETS A100, AD201, E100 & P201 FOR ILLUSTRATIONS OF BID

ALTERNATES

JOB NO.

5006A3

DATE

12/3/15

SHEET

G001

C:\BIM\BCAG TI_asalija.rvt

1/18/2016 11:17:56 AM

LAST REVISION:

BASEMENT

BEAM

BEARING

BELOW

BENT PLATE

BETWEEN

BEVELED

BITUMINOUS

BLOCK

BLOCKING

BOARD

BOTH SIDES

BOTHWAYS/BARBED WIRE

BOTTOM

BRIDGING

BRONZE

BUILT-UP ROOF

BUMPER GUARD

CEM

CAB

CPT

CSMT

CIP

CI

CLKG

CTR

CL

CC

CMT

CT

CLF

CH BD

CH

CP

CIR

CIRC

CO

COTG

CLR

CLO

CLS

CRS

CR

CW

COL

COMB

COMM

CONC

CMU

CONF

CONN

CJ

COREBD

CG

CORR

CNTR

C FLASH

CTSK

CRG

CU

CUST

CYL

BACKER BOARD

CABINET

CARPET

CASEMENT

CAST IN PLACE

CAST IRON

CAULKING

CENTER

CENTER LINE/CHAIN LINK

CENTER TO CENTER

CERAMIC MOSAIC TILE

CERAMIC TILE

CHAIN LINK FENCE

CHALKBOARD

CHANNEL

CHECKERED PLATE

CIRCLE

CIRCUMFERENCE

CLEANOUT

CLEANOUT TO GRADE

CLEAR

CLOSET

CLOSURE

COARSE

COLD ROLLED

COLD WATER

COLUMN

COMBINATION/COMBINE

COMMUNICATIONS

CONCRETE

CONCRETE MASONRY UNIT

CONFERENCE

CONNECT/CONNECTION

CONSTRUCTION JOINT

COREBOARD

CORNER GUARD

CORRUGATED

COUNTER

COUNTER FLASHING

COUNTERSINK

CROSS GRAIN

COPPER

CUSTODIAN

CYLINDER

HT

HP

HPT

HC

HM

HK

HORIZ

HB

HR

HW

EW

EP

ELEC

EPNL

EWC

EWH

ELEV

ELV

EMER

ENCL

EQUIP

EQ

ENT

ESC

EXC

EF

(E)

EXP

EB

EJ

ES

EXP

EXT

EIFS

FAB

FoB

FoC

FoM

FoP

FoS

FoW

FAS

FEN

FBD

FGL

FIN

FO

FF

FF&E

EACH WAY

EDGE OF PAVEMENT

ELECTRICAL

ELECTRICAL PANELBOARD

ELECTRICAL WATER

COOLER

ELECTRICAL WATER

HEATER

ELEVATION

ELEVATOR

EMERGENCY

ENCLOSURE

EQUIPMENT

EQUAL

ENTRANCE

ESCAPE

EXCAVATE

EXHAUST FAN

EXISTING

EXPANSION

EXPANSION BOLT

EXPANSION JOINT

EXPANSION SHIELD

EXPOSED

EXTERIOR

EXTERIOR INSULATION &

FINISH SYSTEM

FHWS

FL CO

FD

FS

FLR

FLUOR

FTG

FND

FRG

FURN

FABRICATE

FACE OF BRICK

FACE OF CONCRETE

FACE OF MASONRY

FACE OF PANEL

FACE OF STUD

FACE OF WALL

FASTEN

FENCE

FIBERBOARD

FIBERGLASS

FINISH

FINISH OPENING

FINISHED FLOOR

FURNITURE, FIXTURES AND

EQUIPMENT

FINISHED FLOOR

ELEVATION

FINISHED GRADE

FIRE ALARM

FIRE EXTINGUISHER

FIRE EXTINGUISHER

CABINET

FIRE HOSE CABINET

FIBER GLASS REINFORCED

PANELING

FIRE RETARDANT

FIREPROOFING

FIXTURE

FLASHING

FLAT BAR

FLAT-HEAD MACHINE

SCREW

FLAT-HEAD WOOD SCREW

FLOOR CLEAN-OUT

FLOOR DRAIN

FLOOR SINK

FLOOR/FLOORING

FLUORESCENT

FOOTING

FOUNDATION

FURRING

FURNITURE

GALV

GI

GSM

GA

GEN

GL

GB

GR

GSF

GND

GT

G

GWB

GALVANIZED

GALVANIZED IRON

GALVANIZED SHEET METAL

GAUGE

GENERAL

GLASS

GRAB BAR

GRADE

GROSS SQUARE FEET

GROUND

GROUT

GUTTER

GYPSUM WALL BOARD

FFE

FG

FA

FE

FEC

FHC

FRP

FRT

FP

FIXT

FLSHG

FB

FHMS

ID

INSUL

INT

ISA

INV

IE

HARDBOARD

HARDWARE

HARDWOOD

HEAD/HEAVY DUTY

HEADER

HEATING

HEATING VENTILATING AIR

CONDITIONING

HEIGHT

HORSE POWER

HIGH POINT

HOLLOW CORE/HANDICAP

HOLLOW METAL

HOOK

HORIZONTAL

HOSE BIBB

HOSE

RACK/HOUR/HANDRAIL

HOT WATER

INSIDE DIAMETER

INSULATION

INTERIOR

INTERNATIONAL SYMBOL OF

ACCESSIBILITY

INVERT

INVERT ELEVATION

JAN

JT

JST

JANITOR

JOINT

JOIST

KP

KIT

KE

KO

KICK PLATE

KITCHEN

KITCHEN EQUIPMENT

KNOCKOUT

LBL

LAD

LB

LAM

LAV

LH

LT

LSD

LKR

LONG

LVR

LPT

MACH

MB

MS

MAINT

MH

MSG

MK

MU

MO

ML

MC

MEM

MTL

MCB

MFD

MF

MRD

MT

MEZZ

MSBG

MWK

MIR

MR

MLDG

MTD

MTG

MOV

MULL

MULTI

MUNI

(N)

NR

NRC

NC

NSG

OC

OPNG

OWJ

OPP

OP H

OP S

OD

OA

OF

OH

OFOI

LABEL

LADDER

LAG BOLT/POUND

LAMINATE

LAVATORY

LEFT HAND

LIGHT

LIQUID SOAP DISPENSER

LOCKER

LONGITUDINAL

LOUVER

LOW POINT

MACHINE

MACHINE BOLT

MACHINE SCREW

MAINTENANCE

MANHOLE

MANUFACTURER'S

STANDARD GRADE

MARK

MASONRY UNIT

MASONRY OPENING

MATCHLINE

MEDICINE CABINET

MEMBRANE

METAL

METAL CASING BEAD

METAL FLOOR DECKING

METAL FLOORING

METAL ROOF DECK

METAL THRESHOLD

MEZZANINE

MILD STEEL BARRIER

GRILLE

MILLWORK

MIRROR

MOISTURE RESISTANT

MOULDING

MOUNTED

MEETING

MOVABLE

MULLION

MULTIPLE

MUNICIPAL

NEW

NOISE REDUCTION

NOISE REDUCTION

COEFFICIENT

NON-COMBUSTIBLE

NON-SECURITY GLASS

ON CENTER

OPENING

OPEN-WEB JOIST

OPPOSITE

OPPOSITE HAND

OPPOSITE SURFACE

OUTSIDE DIAMETER

OVERALL

OVERFLOW

OVERHEAD

OWNER FURNISHED,

OWNER INSTALLED

SYMBOL

PNT

PR

PNL

PB

PTD

PBD

PTN

PVMT

PV

d

PERIM

PERP

PLAS

PLAM

PL

PG

PLBG

PLYWD

PCKT(S)

PT

POL

PVC

PCP

DESCRIPTION

PCF

PSF

PSI

PCC

PFN

PRF

PREP

PSC

PL, P/L

PROT

PAINT

PAIR

PANEL

PANIC BAR

PAPER TOWEL DISPENSER

PARTICLE BOARD

PARTITION

PAVEMENT

PHOTO VOLTAIC

PENNY (NAIL SIZE)

PERIMETER

PERPENDICULAR

PLASTER

PLASTIC LAMINATE

PLATE

PLATE GLASS

PLUMBING

PLYWOOD

POCKET(S)

POINT

POLISHED

POLYVINYL CHLORIDE

PORTLAND CEMENT

PLASTER

POST-TENSIONED

CONCRETE

POUNDS PER CUBIC FOOT

POUNDS PER SQUARE FOOT

POUNDS PER SQUARE INCH

PRECAST CONCRETE

PREFINISHED

PREFORMED

PREPARATION

PRESTRESSED CONCRETE

PROPERTY LINE

PROTECTED/PROTECTION

QT

QUARRY TILE

PTC

R

RWL

RECEP

REC

RWD

RE

REFL

REF

RCP

REINF

REM

RESIL

RA

RAG

REV

RH

ROW

RD

RH

RM

RO

RND

RHWS

RB

SP

SAN

SND

SNV

SS

SCR

SCUP

SECT

SEC

SGL

SHM

STH

SSD

SEG

SDS

SEP

SVC

SSK

SHTG

SHT

SM

SMS

SH(S)

SHWR

SK

SLP

SD

SC

STAG

SST

STIFF

STOR

SA

S4S

S2S

SUSP

RADIUS/RISER

RAIN WATER LEADER

RECEPTACLE

RECESSED

REDWOOD

REFERENCE

REFLECTED

REFRIGERATOR

REINFORCED CONCRETE

PIPE

REINFORCED/REINFORCING

REMOVE

RESILIENT

RETURN AIR

RETURN AIR GRILLE

REVERSE/REVISION

RIGHT HAND

RIGHT OF WAY

ROOF DRAIN

ROOF HATCH

ROOM

ROUGH OPENING/ROUGH

ROUND

ROUND HEAD WOOD

SCREWS

RUBBER BASE

SALLY PORT

SANITARY

SANITARY NAPKIN

DISPOSAL

SANITARY NAPKIN VENDOR

SANITARY SEWER

SCREEN

SCUPPER

SECTION

SECURITY

SECURITY GLASS/SINGLE

SECURITY HOLLOW METAL

SECURITY TOILET PAPER

HOLDER

SEE STRUCTURAL

DRAWINGS

SEGREGATION

SELF DRILLING SCREW

SEPARATION

SERVICE

SERVICE SINK

SHEATHING

SHEET

SHEET METAL

SHEET METAL SCREW

SHELF/SHELVES

SHOWER

SINK

SLOPE

STORM DRAIN

SOLID CORE/SCALE

STAGGERED

STAINLESS STEEL

STIFFENER

STORAGE

SUPPLY AIR

SURFACED FOUR SIDES

SURFACED TWO SIDES

SUSPENDED

SYMBOL

TK BD

TV

TEMP

TECH

TB

TER

THERM

THR

TPH

TSCD

T&G

TRBG

TJ

T&B

TOC

TOP

TOS

TOW

TR

TRANSV

TRD

TS

UC

UL

TACKBOARD

TELEVISION

TEMPERED

TECHNICAL

TERMINATION BAR

TERRAZZO

THERMAL

THRESHOLD

TOILET PAPER HOLDER

TOILET SEAT COVER

DISPENSER

TONGUE AND GROOVE

TOOL RESISTANT BARRIER

GRILLE

TOOLED JOINT

TOP AND BOTTOM

TOP OF CONCRETE/CURB

TOP OF PAVING

TOP OF STEEL

TOP OF WALL

TRANSOM

TRANSVERSE

TREAD

TUBE STEEL

UNIF

UON

UR

UTIL

UNDERCUT

UNDERWRITER'S

LABORATORY

UNIFORM

UNLESS OTHERWISE NOTED

URINAL

UTILITY

VA

VNR

VTR

VENT

VIF

VEST

VB

VCT

VF

VJ

VOL

VACUUM ADHERED

VENEER

VENT THROUGH ROOF

VENTILATOR/VENTILATION

VERIFY IN FIELD

VESTIBULE

VINYL BASE

VINYL COMPOSITION TILE

VINYL FABRIC

V-JOINT

VOLUME

WSCT

WTW

WC

WH

WR

WI

WAINSCOT

WALL TO WALL

WATER CLOSET

WATER HEATER

WATER RESISTANT/WASTE

RECEPTACLE

WATERSTOPS

WELDED WIRE FABRIC

WELDED WIRE MESH

WHEEL BUMPER

WINDOW

WIRE FLANGE BEAM

WIREGLASS

WOOD

WOOD BASE

WORKING

POINT/WATERPROOF

WROUGHT IRON

XE

XENON

WS

WWF

WWM

WB

WDW

WF

WG

WD

WD B

WP

SYMBOL

DESCRIPTION

DESCRIPTION

DESCRIPTION

SYMBOL

DESCRIPTION

N

EARTH

SYMBOL

INTERNATIONAL

SYMBOL OF

ACCESSIBILITY

NORTH ARROW

Capital Expenditure Managers

2750 Gateway Oaks Drive

Suite 300

Sacramento, CA. 95833

(916) 648-9700

ROCK FILL

SAND / MORTAR / PLASTER /

GROUT

CAST IN PLACE, PRECAST OR

INFILL CONCRETE

1 / A101A

MATCH LINE

1 / A101B

VIEW NUMBER /

SHEET NUMBER

SHADED PORTION IS SIDE

CONSIDERED

XX

KEYNOTE TAG

D ARC

SE P. M HIT

N N

ON

O

XX

No.: C32299

DOOR TAG

101

Exp.: 01/31/17

2

A

T

AT R C H I T E C N

R

EO

F CA L I F O

IA

HBD

HDWR

HDWD

HD

HDR

HTG

HVAC

DESCRIPTION

CMU WALL

DATUM HEIGHT

WINDOW TAG

0.0

STEEL

WALL TAG

A

GRID LINES

0.0

WOOD FINISH

WOOD FRAMING THRU MEMBER

BUILDING

SECTION

EQUIPMENT TAG

C1045802

SECTION IDENTIFIER

X

XXXX

LIMIT OF WORK

SHEET NUMBER

WOOD FRAMING INTERRUPTED

MEMBER

WALL

SECTION

PLYWOOD

ACOUSTIC TILE OR BOARD

SECTION IDENTIFIER

X

XXXX

SHEET NUMBER

SECTION IDENTIFIER

1

XXXX

DETAIL

SECTION

GYPSUM BOARD OMIT DOUBLE

LINES AT SMALL SCALE

CHAIN LINK

FENCE

SHEET NUMBER

LOUVER

TAG

10

BUTTE COUNTY ASSOCIATION OF

GOVERNMENTS

BSMT

BM

BRG

BEL

BP

BET

BEV

BITUM

BLK

BLKG

BD

BS

BW

BOT

BRDG

BRNZ

BUR

BG

DAMPROOFING

DEEP/DEPTH

DEMOLISH/DEMOLITION

DEMOUNTABLE

DEPRESSED/DEPRESSION

DRINKING FOUNTAIN

DISABLED ACCESS

DISPENSER

DIVISION

DOOR

DOOR LOUVER

DOOR OPENING

DOUBLE

DOUBLE HUNG

DOWNSPOUT

DRAWER

DRAWING

DUMBWAITER

SYMBOL

1

VIEW NUMBER(S)

BUILDING

ELEVATION

4

XXXX

2

INSTALLATION SIDE

FOR GLAZING STOPS

SHEET NUMBER

BATT INSULATION

3

1

RIGID INSULATION

INTERIOR

ELEVATION

VIEW NUMBER(S)

4

XXXX

2

SHEET NUMBER

FIRE

DEPARTMENT

CONNECTION

3

CERAMIC TILE

CEMENTITIOUS BACKER BOARD

GLASS (OMIT LINES AT SMALL

SCALE)

1

INTERIOR

EQUIPMENT

ELEVATION

ROOM TAG

VIEW NUMBER(S)

4

XXXX

2

SURFACE BRACKET

SHEET NUMBER

3

ROOM

NAME

101

ROOM NAME

FIRE

EXTINGUISHER

SURFACE CABINET

ROOM NUMBER

SEMI-RECESSED

GLASS / PLASTIC (ELEVATION)

VIEW REFERENCE

1

XXXX

VIEW NUMBER

SHEET NUMBER

RECESSED

GENERAL NOTES:

1.

DIMENSIONS ARE TO FACE OF CONCRETE OR FACE OF STUD, UNLESS OTHERWISE NOTED.

2.

IN THE EVENT THAT CERTAIN DETAILS OF THE CONSTRUCTION ARE NOT FULLY SHOWN OR NOTED IN THESE DRAWINGS OR CALLED FOR IN THE SPECIFICATIONS, THEIR CONSTRUCTION SHALL BE OF

THE SAME CHARACTER AND SIZE AS SIMILAR TO EXISTING CONDITIONS.

3.

CONTRACTOR TO CHECK AND VERIFY ALL DIMENSIONS AND CONDITIONS AT JOB SITE AND NOTIFY ARCHITECT OF ANY DISCREPANCIES BETWEEN DRAWINGS AND FIELD CONDITIONS BEFORE

COMMENCING WITH ANY WORK.

4.

ARCHITECTS DOCUMENTS ARE TO CONVEY CONSTRUCTABILITY, SCOPE AND DESIGN INTENT. CONTRACTOR ACCEPTS FULL RESPONSIBILITY FOR ACCURACY AND IMPLEMENTATION ACCORDING

TO STANDARDS OF ABILITY.

5.

CONTRACTOR SHALL BE RESPONSIBLE FOR UNDERSTANDING ARCHITECTS DOCUMENTS.

6.

ALL OSHA, STATE COUNTY AND LOCAL REGULATIONS ARE TO BE STRICTLY ENFORCED.

7.

CONTRACTOR SHALL COORDINATE ALL UTILITY DISCONNECTS WITH EACH UTILITY PROVIDER AND OWNER’S REPRESENTATIVE.

8.

THE CONTRACTOR SHALL PROVIDE AN ALTERNATE ACCESSIBLE ROUTE FOR PERSONS WITH DISABILITIES AROUND CONSTRUCTION AREAS, INCLUDING DIRECTIONAL SIGNAGE.

326 HUSS LANE, CHICO CA

ADDENDUM/ADDENDA

ADHESIVE

ADJACENT

ADJUSTABLE

ADMINISTRATION

ADMINISTRATIVE

SEGREGATION

AGGREGATE

AIR CONDITIONING

AIR HANDLING UNIT

ANCHOR BOLT

ANGLE, LENGTH

ANGLE/LENGTH

AT

ANODIZED

AREA DRAIN

ASBESTOS

ASPHALT

ASPHALTIC CONCRETE

ASPHALTIC TILE

AUDIO/VISUAL

AUTOMATIC FIRE

SPRINKLER

DPF

DP

DEMO

DMT

DEP

DF

DA

DISP

DIV

DR

DL

DO

DBL

DH

DS

DWR

DWG

DW

DESCRIPTION

T

EC N

NI

AGG

A/C

AHU

AB

LL

L

@

ANOD

AD

ASB

ASPH

AC

AT

A/V

AFS

ABOVE

ABOVE CEILING

ABOVE FINISHED FLOOR

ACCESS DOOR

ACCESS FLOOR

ACCESS PANEL

ACCESS

ACCESSORIES

ACOUSTICAL

ACOUSTICAL INSULATION

SYMBOL

ST

ABV

ABC

AFF

ACC DR

ACC FL

ACC PL

ACC

ACCES

ACOUST

ACOUST

INSUL

ADD

ADH

ADJ

ADJST

ADMIN

AD SEG

DESCRIPTION

ARCHITECTURAL SYMBOLS

LIC

JA E

S

SYMBOL

ARCHITECTURAL MATERIALS

BUTTE REGIONAL TRANSIT OPERATIONS

CENTER

ARCHITECTURAL ABBREVIATIONS

PROJECT STATUS:

BID SET

BUILDINGS:

SHEET TITLE:

ARCHITECTURAL

ABBREVIATIONS,

SYMBOLS & NOTES

0

1/2

SCALE:

1

BAR IS ONE INCH ON ORIGINAL

DRAWING. IF NOT ONE INCH ON THIS

SHEET, ADJUST SCALES ACCORDINGLY

REVISIONS

NO.

JOB NO.

5006A3

DATE

12/3/15

DESCRIPTION

DATE

SHEET

A001

C:\BIM\BCAG TI_asalija.rvt

A-3

FE

2 OCC.

BREAKOUT/CLOSED

SESSION ROOM

482 SF / 15

OL=33

BUILDING

OCCUPANCY

CLASSIFICATION

AND USE (CBC

CHAPTER 3):

BOARD ROOM

1739 SF / 15

OL=142

1 OCC.

.

T.

CC DIS

1 O EL

20

V

RA

'T

55

OVERFLOW

478 SF / 5

OL=96

CBC 304

CBC 303.4

2

MIXED OCCUPANCY BUILDING WITH INCIDENTAL USES

REQUIRED

SEPARATIONS

(CBC TABLE 508.4)

A / B, NON-SPRINKLERED - 2HR

MAXIMUM ALLOWABLE AREA: B OCCUPANCY / TYPE VB = 9,000 SF

ACTUAL AREA = 8,000 SF

2

TYPE OF CONSTRUCTION

(CBC CHAPTER 6):

TABLE 601

TYPE OF CONSTRUCTION:

TYPE VB

MEN'S

119 SF / 100

OL=2

OFFICE

96 SF / 100

OL=1

STORAGE

79 SF / 300

OL=1

DIRECTOR OFFICE

126 SF / 100

OL=2

1 OCC.

IDF ROOM

84 SF / 100

OL=1

4 OCC.

8 OCC.

WOMEN'S

122 SF / 100

OL=2

OFFICE

99 SF / 100

OL=1

1 OCC.

OFFICE

130 SF / 100

OL=2

OFFICE

87 SF / 100

OL=1

COPY/WORK ROOM

180 SF / 100

OL=2

EXIT

0.2" x 19 OCCUPANTS

3.8" MIN REQUIRED

36" PROVIDED

OFFICE

87 SF / 100

OL=1

OFFICE

136 SF / 100

OL=2

OFFICE

136 SF / 100

OL=2

4 OCC.

FE

13 OCC.

LOBBY

404 SF / 100

OL=5

MGMT OFFICE

171 SF / 100

OL=2

NON-BEARING WALLS AND PARTITIONS, EXTERIOR:

(TABLE 602, FIRE SEPARATION = 10 ≤ x < 30)

0

NON-BEARING WALLS AND PARTITIONS, INTERIOR:

0

FLOOR CONSTRUCTION AND SECONDARY MEMBERS

(CBC SEC 202):

0

ROOF CONSTRUCTION AND SECONDARY MEMBERS

(CBC SEC 202):

0

OPENING FIRE

PROTECTION

(TABLE 716.5)

2HR WALL - MINIMUM FIRE DOOR RATING - 1.5 HR

GLAZING MARKING - >100 SQ IN = D-H-W-90

FIRE

PROTECTION

SYSTEMS

(CHAPTER 9):

FIRE ALARM SYSTEM: SHALL BE PROVIDED IN ACCORDANCE WITH SECTION 907.1

AUTOMATIC FIRE SPRINKLER SYSTEM: NOT REQUIRED PER SECTION 903.2.1.3

CBC 906.3(1)

PORTABLE FIRE EXTINGUISHERS (LOW HAZARD) :

CBC 1005.3.2

OTHER EGRESS COMPONENTS:

MINIMUM NUMBER REQUIRED: 3

MAX DISTANCE TO EXTINGUISHER :75FT

THE CAPACITY, IN INCHES, OF MEANS OF EGRESS COMPONENTS OTHER THAN

STAIRWAYS SHALL BE CALCULATED BY MULTIPLYING THE OCCUPANT LOAD SERVED

BY SUCH COMPONENT BY A MEANS OF EGRESS CAPACITY FACTOR OF 0.2 INCH PER

OCCUPANT.

CBC 1014.3

TABLE 1014.3

EXIT ACCESS AND COMMON PATH OF EGRESS TRAVEL:

1. B OCCUPANCY:

100 FEET

CBC 1015

TABLE 1015.1

TWO EXITS OR EXIT ACCESS DOORWAYS FROM ANY SPACE

SHALL BE PROVIDED WHERE OCCUPANT LOAD EXCEEDS:

B OCCUPANCY:

49 OCCUPANTS

1.

A-3 OCCUPANCY:

49 OCCUPANTS

2.

CBC 1016

TABLE 1016.2

EXIT ACCESS TRAVEL DISTANCE SHALL NOT EXCEED THE VALUES

SHOWN IN TABLE 1016.2:

BID SET

BUILDINGS:

FE

OPEN

CONF/WORKROOM

134 SF / 15

OL=9

2

1.

2.

B OCCUPANCY:

A-3 OCCUPANCY:

SHEET TITLE:

MEANS OF EGRESS IDENTIFICATION AND ILLUMINATION SHALL BE IN ACCORDANCE WITH CBC 1011 AND

CBC1006 - SEE SHEET E202 FOR ILLUMINATED EXIT SIGNS LOCATIONS.

CBC 11B-219.3 - ASSISTED LISTENING RECEIVERS

BOARD ROOM - 68 SEATS

x 0.4

2.72 REQUIRED - 4 PROVIDED

EXIT

0.2" x 29 OCCUPANTS

5.8" MIN REQUIRED

36" PROVIDED

CODE ANALYSIS EGRESS DIAGRAM

200 FEET

200 FEET

0

1/2

SCALE:

1

BAR IS ONE INCH ON ORIGINAL

DRAWING. IF NOT ONE INCH ON THIS

SHEET, ADJUST SCALES ACCORDINGLY

(2) ALS RECEIVERS TO BE HEARING AID COMPATIBLE

CONTRACTOR TO CONTACT CHICO FIRE FOR APPROVAL PRIOR TO OCCUPANCY.

EXIT

0.2" x 13 OCCUPANTS

2.6" MIN REQUIRED

72" PROVIDED

PROJECT STATUS:

EXIT AND EXIT ACCESS DOORWAYS:

MGMT OFFICE

171 SF / 100

OL=2

29 OCC.

RECEPTION

103 SF / 100

OL=2

N/A

KITCHEN

172 SF / 15

OL=12

16 OCC.

OFFICE

136 SF / 100

OL=2

55

' T 19 O

RA

C

VE C.

LD

IST

.

56' TRAVEL DIST.

JANITOR

54 SF / 100

OL=1

INTERIOR:

2 HR SEPARATION

OPEN

CONF/WORKROOM

149 SF / 15

OL=10

OFFICE

99 SF / 100

OL=1

N/A

A-3

B

BUTTE COUNTY ASSOCIATION OF

GOVERNMENTS

16 OCC.

DN

EXTERIOR:

326 HUSS LANE, CHICO CA

BEARING WALLS:

BUTTE REGIONAL TRANSIT OPERATIONS

CENTER

0

PRIMARY STRUCTURAL FRAME:

CONF. ROOM

164 SF / 15

OL=11

REVISIONS

NO.

DESCRIPTION

2 PERMIT RESPONSE

JOB NO.

5006A3

N

3/16" = 1'-0"

2013 EDITION

2013 EDITION

BUILDING ELEMENT

11 OCC.

1/18/2016 11:17:58 AM

B: OFFICE

A-3: BOARD ROOM / ASSEMBLY

GENERAL BUILDING

HEIGHTS AND

AREAS

(CBC CHAPTER 5):

DN

EGRESS PLAN

A

T

AT R C H I T E C N

R

EO

F CA L I F O

ASSEMBLY PERMIT TO BE OBTAINED FROM CHICO FIRE PRIOR TO OCCUPANCY

CHAIR STORAGE

124 SF / 300

OL=1

1

No.: C32299

Exp.: 01/31/17

B / A-3

89 OCC.

LAST REVISION:

BUILDING STANDARDS ADMINISTRATIVE CODE

CALIFORNIA BUILDING CODE VOLS. 1 & 2 (2012 IBC AS AMENDED BY CA)

CALIFORNIA ELECTRICAL CODE (2008 NEC AS AMENDED BY CA)

CALIFORNIA MECHANICAL CODE (2009 UMC AS AMENDED BY CA)

CALIFORNIA PLUMBING CODE (2009 UPC AS AMENDED BY CA)

CALIFORNIA FIRE CODE (2009 IFC AS AMENDED BY CA)

CALIFORNIA GREEN BUILDING STANDARDS CODE (CALGreen)

CALIFORNIA REFERENCED STANDARDS

PARTIAL LIST OF APPLICABLE STANDARDS

NFPA 72

NATIONAL FIRE ALARM CODE (CA AMENDED)

NFPA 80

FIRE DOOR AND OTHER OPENING PROTECTIVES

33 OCC.

EXIT

0.2" x 201 OCCUPANTS

40.2" MIN REQUIRED

92" PROVIDED

2013

2013

2013

2013

2013

2013

2013

2013

ST

PART 1

PART 2

PART 3

PART 4

PART S

PART 9

PART 11

PART 12

D ARC

SE P. M HIT

N N

ON

O

T

EC N

NI

A/V ROOM

131 SF / 100

OL=2

GOVERNING CODES CALIFORNIA BUILDING CODE (CBC)

AND REGULATIONS: CALIFORNIA CODE OF REGULATIONS TITLE 19

PUBLIC SAFETY, STATE FIRE MARSHAL REGULATIONS

CALIFORNIA CODE OF REGULATIONS TITLE 24

ELECTRICAL

58 SF /

89

65

O

'T

RA CC.

VE

LD

IST

.

Capital Expenditure Managers

2750 Gateway Oaks Drive

Suite 300

Sacramento, CA. 95833

(916) 648-9700

IA

PROJECT DESCRIPTION: RENOVATION OF THE EXISTING BUS MAINTENANCE AND TRANSIT OPERATIONS CENTER FOR THE

BUTTE COUNTY ASSOCIATIONS OF GOVERNMENTS. THE SCOPE INCLUDES THE REMOVAL OF ALL

EQUIPMENT AND NON-STRUCTURAL WALLS AT THE BUILDING INTERIOR AND THE REMOVAL OF ALL

ROOF MOUNTED EQUIPMENT. NEW CONSTRUCTION INCLUDES NEW WALLS AND EQUIPMENT AS

INDICATED ON THE PLANS. SITE WORK IS LIMITED TO WHAT IS DEPICTED ON THE PLANS, MOST SITE

IMPROVEMENTS ARE TO OCCUR UNDER A SEPARATE PERMIT PRIOR TO THE RENOVATION OF THIS

BUILDING.

LIC

JA E

S

2 HR SEPARATION

B

CODE ANALYSIS

EXIT

0.2"x89 OCCUPANTS

17.8" MINIMUM REQ.

72" PROVIDED

DATE

12/3/15

DATE

1/15/16

SHEET

A002

C:\BIM\BCAG TI_asalija.rvt

VISUAL WARNING

STRIPS SHALL BE 2" MIN.

WIDTH & INSTALLED 1"

MAX. FROM EDGE OF

THE TOP AND BOTTOM

TREADS OF INTERIOR

STAIRS, AND ON ALL

TREADS OF EXTERIOR

STAIRS.

TW = TREAD WIDTH

1'-0" MIN

PULL SIDE

* FOR TYPICAL RESTROOM MOUNTING HEIGHTS SEE A611

2

1 1/4" TO 2"

1 1/2" MIN CLR

ANY AMOUNT

4" MAX

HANDRAILS

HANDRAIL

No.: C32299

ADA HANDRAIL / GUARDRAIL

3/32" = 1'-0"

FIG. (A)

X

30" MIN

C

MAXIMUM FORWARD REACH OVER AN OBSTRUCTION

CLEAR FLOOR SPACE

PARALLEL APPROACH

2

HIGH AND LOW

D SIDE REACH LIMITS

MAXIMUM SIDE

REACH OVER AN

E OBSTRUCTION

ADA REACH REQUIREMENTS

27"

CANE RANGE

FIG. (A)

4

FIN. FLOOR

LEVEL

THRESHOLD

FIG. (B)

ADA PROTRUDING OBJECTS

1/8" = 1'-0"

A

WHERE ADJACENT

OBSTRUCTION OR

WALL OCCURS

2

1

12" MINIMUM IF DOOR

HAS BOTH A CLOSER

AND A LATCH

1. LETTERS AND NUMBERS ON SIGNS SHALL BE RAISED 1/32" MINIMUM AND SHALL BE SANS-SERIF UPPERCASE

CHARACTERS ACCOMPANIED BY GRADE 2 BRAILLE.

36" MINIMUM

B

THRESHOLD

C

LEVEL CHANGES

2. RAISED CHARACTERS OR SYMBOLS SHALL BE A MINIMUM OF 5/8" HIGH.

48" MINIMUM

60" MINIMUM

INTERNATIONAL ACCESSIBILITY SYMBOL

4. LETTERS AND NUMBERS ON SIGNS SHALL HAVE A WIDTH-TO-HEIGHT RATIO OF BETWEEN 3:5 AND 1:1 AND A STROKE

WIDTH-TO-HEIGHT RATIO BETWEEN 1:5 AND 1:10.

REQUIRED

CLEAR SPACE

DOOR WIDTH PLUS

24" MIN. EXTERIOR

18" MIN. INTERIOR

B

1. 1/2" MAXIMUM TOTAL HEIGHT WITH 1/4" MAXIMUM

VERTICAL CHANGE AT EDGE.

6. CHARACTERS AND NUMBERS ON SIGNS SHALL BE SIZED ACCORDING TO THE VIEWING DISTANCE FROM WHICH THEY

ARE TO BE READ. THE MINIMUM HEIGHT IS MEASURED USING AN UPPER CASE X. LOWER CASE CHARACTERS ARE

PERMITTED. FOR SIGNS SUSPENDED OR PROJECTED ABOVE THE FINISH FLOOR IN COMPLIANCE WITH SECTION 1121B,

THE MINIMUM CHARACTER HEIGHT SHALL BE 3".

2. 1 : 2 SLOPED BEVEL REQUIRED IF LEVEL CHANGE IS

OVER 1/4" VERTICAL LEVEL CHANGE.

3. 1/4" MAXIMUM VERTICAL LEVEL CHANGE.

7. CONTRACTED GRADE 2 BRAILLE SHALL BE USED WHEREVER BRAILLE SYMBOLS ARE SPECIFICALLY REQUIRED IN

OTHER PORTIONS OF THESE REGULATIONS. DOTS SHALL BE 1/10" ON CENTERS IN EACH CELL WITH 2/10" SPACE

BETWEEN CELLS. DOTS SHALL BE RAISED A MINIMUM OF 1/40" ABOVE THE BACKGROUND.

RAISED

A PLAN

NOTES:

5. CHARACTERS AND SYMBOLS SHALL CONTRAST WITH THEIR BACKGROUND, EITHER LIGHT CHARACTERS ON A DARK

BACKGROUND OR DARK CHARACTERS ON A LIGHT BACKGROUND.

5/8"

24" MIN. EXTERIOR

18" MIN INTERIOR

3. PICTORIAL SYMBOL SIGNS (PICTOGRAMS) SHALL BE ACCOMPANIED BY THE EQUIVALENT VERBAL DESCRIPTION

PLACED DIRECTLY BELOW THE PICTOGRAM. THE BORDER DIMENSION OF THE PICTOGRAM SHALL BE A MINIMUM OF 6"

IN HEIGHT.

CORRIDOR PLAN

SIGN LOCATIONS:

24" MIN. EXTERIOR & 18" MINIMUM

INTERIOR BEYOND STRIKE EDGE

OF A GATE OR DOOR ON THE SIDE

TOWARD WHICH IT SWINGS.

2

2

6" MIN

INTERNATIONAL SYMBOL OF ACCESSIBILITY:

48" MINIMUM

WOMEN

RESTROOMS

2. WHITE FIGURE ON BLUE BACKGROUND, COLOR # 15090 ON FEDERAL STANDARD # 595A.

EAR

32" CL

INGLE

FOR S

18"-1

9"

1. WITHIN ALCOVES MINIMUM 63" WIDE, MINIMUM 18" DEEP WHEN DOUBLE

DRINKING FOUNTAINS ARE REQUIRED AND 32" MIN. CLR. WHEN A SINGLE

FOUNTAIN IS PERMITTED.

1. USE CONTRASTED GRADE 2 BRAILLE. DOTS TO BE 0.1 INCH ON CENTER IN EACH CELL.

18" MIN INTERIOR

24" MIN EXTERIOR

D

27" MIN.

36" MAX.

4. SEE 4/T-4 FOR MORE INFO.

MEN

6" MAX

1. WARNING FOR THE VISION IMPAIRED AT A PROJECTED DRINKING FOUNTAIN

CAN BE PROVIDED BY EITHER OF THE FOLLOWING MEANS:

17"-1

9"

VESTIBULE PLAN

1/18/2016 11:18:01 AM

LAST REVISION:

NOTES:

2. WHERE DOORS OPEN ONTO, BUT NOT INTO A CORRIDOR, THE

REQUIRED LEVEL AREA BEYOND THE DOORS MAY BE A MINIMUM

OF 48". FOR ADDITIONAL INFORMATION, SEE APPLICABLE NOTES

ON TYPICAL ACCESSIBILITY NOTES SHEET.

ADA DOOR CLEARANCES

1/8" = 1'-0"

5

1/8" = 1'-0"

NOTE:

ILLUSTRATIONS SHOWN HERE ARE FOR DIMENSIONAL ACCESSIBILITY

PURPOSES ONLY. A SECOND DRINKING FOUNTAIN SHOULD BE PROVIDED

AT A MOUNTING HEIGHT SUITABLE TO PERSONS WITH LIMITED PHYSICAL

BENDING ABILITY, ADJACENT TO THE ACCESSIBLE FOUNTAIN,

MAINTAINING MINIMUM CLEARANCES NOTED AND AS REQUIRED. PROVIDE

TEXTURED AREA OF CONTRASTING COLOR TO IDENTIFY WATER FOUNTAIN

LOCATION AS NOTED. WHEN FOUNTAIN IS AT AN INTERIOR LOCATION, THE

TEXTURED AREA SHALL ALSO BE OF DIFFERENT RESILIENCY THAN THAT

OF THE ADJACENT FLOOR SURFACE FINISH. SEE TYPICAL ACCESSIBILITY

NOTES SHEET FOR ADDITIONAL REQUIREMENTS.

INTERNATIONAL SYMBOL

OF ACCESS FOR

HEARING IMPAIRED

ADA SIGNS / PICTOGRAMS

3

ADA FOUNTAIN CLEARANCE

1/8" = 1'-0"

BUILDINGS:

SHEET TITLE:

DETAIL SCHEDULE

RECESSED FOUNTAINS

DOORWAY PLAN

8

A. THE SURFACE OF THE FLOOR OR GROUND AT THE DRINKING FOUNTAIN

CAN BE OF CONTRASTING COLOR WITH A TEXTURE THAT CONTRASTS IN

RESILIENCY WITH THE ADJACENT FINISHED FLOOR MATERIAL, SO THAT

IT CAN BE SENSED BY A CANE, WITH THE FRONT EDGE OF THE DRINKING

FOUNTAIN AND ONE FOOT BEYOND EACH SIDE OF THE FOUNTAIN, OR

B. INSTALL WING WALLS ON EACH SIDE OF THE DRINKING FOUNTAIN TO

PROJECT OUT FROM THE MAIN WALL AT LEAST AS FAR AS THE DRINKING

FOUNTAIN AND TO WITHIN 6" OF THE PATH OF TRAVEL FLOOR FINISH.

THERE MUST BE 32" CLEAR BETWEEN THE WING WALLS, OR

INTERNATIONAL

TDD SYMBOL

BID SET

PROJECTED FOUNTAINS:

3. DOTS RAISED MINIMUM 0.025 INCH ABOVE BACKGROUND.

1. CLEAR SPACES MUST BE LEVEL TO PREVENT WHEELCHAIRS

FROM ROLLING WHEN THE OCCUPANT RELEASES THE WHEEL

GRIPS TO REACH FOR THE DOOR. 1/4" PER FOOT IS ALLOWED

FOR DRAINAGE.

PROJECT STATUS:

2. SEE TYPICAL ACCESSIBILITY NOTES SHEET SECTIONS "R" & "U".

2. 0.2 INCH SPACE BETWEEN CELLS.

A

RAMP LANDING AT

RECESSED FOUNTAINS:

A. CONTRACTOR SHALL COORDINATE WITH SIZE OF WATER FOUNTAIN TO

BE USED AND SIZE ALCOVE ACCORDINGLY COMPLYING WITH

REQUIREMENTS AND RECOMMENDATIONS AND COORDINATING WITH THE

ARCHITECT

PROPORTIONS

INTERNATIONAL SIGN

OF ACCESSIBILITY

C

2

BRAILLE:

48" MINIMUM

DOOR WIDTH + 42" MIN

3. WHEN ENFORCING AGENCY DETERMINES, IF APPROPRIATE, SPECIAL DESIGNS AND COLORS MAY BE APPROVED.

32" CLEAR

ADA THRESHOLD / LEVELING

1/8" = 1'-0"

1. SEE A601 FOR ALL SIGN LOCATIONS AND A610 / A703 FOR MOUNTING INSTRUCTIONS.

1. STANDARD USED TO IDENTIFY ACCESSIBLE FACILITIES.

DOOR WIDTH + 42" MIN

1/4" MAX

LETTERS AND NUMBERS:

1/4" MAX

48" MINIMUM

REQUIRED

CLEAR SPACE

326 HUSS LANE, CHICO CA

48" MINIMUM

BUTTE REGIONAL TRANSIT OPERATIONS

CENTER

54" PREFERRED

TRANSITION BETWEEN FLOOR FINISHES

BUTTE COUNTY ASSOCIATION OF

GOVERNMENTS

1/8" = 1'-0"

CANE RANGE

12' MAX

COMPRESSED CARPET 1/4"

MAX. BELOW THRESHOLD

1/2" MAX

7

MAX

27"

46" MAX

MIN

WHEN X IS 20 TO 25

INCHES, THEN Y SHALL BE

44 INCHES MAXIMUM.

ADA DOOR CLEARANCE

1/2" = 1'-0"

48" MAX

3.

2

1/2" MAX PILE

HEIGHT

B

HIGH FORWARD REACH LIMIT

WHEN X < 20 INCHES,

THEN Y SHALL BE 48

INCHES MAXIMUM.

48" MIN

1

15"

48" MIN

PUSH SIDE

X SHALL BE < 25 INCHES; Z

SHALL BE > X.

2.

Z

Z

48" MIN

1.

FIG. (B)

CANE HITS POST OR PYLON

BEFORE PERSON HITS OBJECT

30"

A

T

AT R C H I T E C N

R

EO

F CA L I F O

PROVIDE THIS ADDITIONAL SPACE

IF DOOR IS EQUIPPED WITH BOLT

LATCH & A CLOSER

MIN

2

48" MIN

Y

30" MIN

MIN

2

15"

48" MAX

X

30" MIN

NOTES:

2

A

24"

34" MIN

48" MIN

12".

MAX

6

Exp.: 01/31/17

ST

27"

B

IA

HANDRAIL

48" MIN

GRAB BAR

80" MIN

GRAB BAR

HANDRAIL

STAIR SECTION

T

EC N

NI

BOTTOM LANDING

A

D ARC

SE P. M HIT

N N

ON

O

LOBBY

MAX

TW + 1'-0"

36" CLR

LIC

JA E

S

34" TYP

1 1/2"

1 1/4" TO

2" (OD)

2

24" MIN CLR @ EXTERIOR DOORS

18" MIN @ INTERIOR DOORS

60" MIN

2

27"

1'-0" MIN

34" MIN

TW

TOP LANDING

1 1/2" MIN CLR

1 1/4" TO 2"

CLEAR

1 1/2" CLR

2

1 1/2" MIN CLR

1 1/4" TO 2"

2

18" MIN

1 1/2" MIN CLR

1 1/4" TO 2"

Capital Expenditure Managers

2750 Gateway Oaks Drive

Suite 300

Sacramento, CA. 95833

(916) 648-9700

0

1/2

SCALE:

1

BAR IS ONE INCH ON ORIGINAL

DRAWING. IF NOT ONE INCH ON THIS

SHEET, ADJUST SCALES ACCORDINGLY

REVISIONS

NO.

DESCRIPTION

2 PERMIT RESPONSE

JOB NO.

5006A3

DATE

12/3/15

DATE

1/15/16

SHEET

A003

C:\BIM\BCAG TI_asalija.rvt

NOTE:

SITE SHOWN AS EXISTING IS BEING

COMPLETED WITHIN A PROJECT ON

CAMPUS AHEAD OF THIS PROJECT.

Capital Expenditure Managers

2750 Gateway Oaks Drive

Suite 300

Sacramento, CA. 95833

(916) 648-9700

LEGEND:

D ARC

SE P. M HIT

N N

ON

O

T

EC N

NI

LIC

JA E

S

ACCESSIBLE PATH OF TRAVEL

No.: C32299

Exp.: 01/31/17

NO

PARKING

ST

IA

A

T

AT R C H I T E C N

R

EO

F CA L I F O

APPROXIMATE

POINT OF

CONNECTION

BID ALTERNATE

3

GAS STUB UP TO 12" AND

TRENCH TO APPROXIMATE

POINT OF CONNECTION AS

SHOWN FOR FUTURE USE.

INSTALL (2) BOLLARDS FOR

PROTECTION AS SHOWN.

2

SEE

A100

3

EXISTING BUILDING

BID ALTERNATE

1

A101

28' - 0"

3' - 0"

NO

PARKING

VAN

BUTTE REGIONAL TRANSIT OPERATIONS

CENTER

3' - 0"

NO

PARKING

EXISTING BUILDING

TO BE RENOVATED

3

(N) CONC

WORK

9"

CONC CROWN

1/2" HIGH MIN

4'-0 "

6" DIA GALV STD

STEEL PIPE - PAINT

YELLOW & FILL W/

CONC MAX 5'-0" OC

TYP

3' - 6"

CONC FTG

3"

CLR

NOTE:

OMIT GALV PROCESS

WHERE PIPE

CONTACTS CONC.

326 HUSS LANE, CHICO CA

2' - 0"

BUTTE COUNTY ASSOCIATION OF

GOVERNMENTS

NEW UTILITY YARD

(E) PARKING LOT

VAN

NO

PARKING

1' - 6" DIA

PROJECT STATUS:

EXISTING TREES TO REMAIN TYP

2

TYPICAL BOLLARD SECTION

1/2" = 1'-0"

(E) PARKING LOT

BID SET

BID ALTERNATE

BUILDINGS:

SHEET TITLE:

ARCHITECTURAL SITE

PLAN

0

1/2

LAST REVISION:

1

BAR IS ONE INCH ON ORIGINAL

DRAWING. IF NOT ONE INCH ON THIS

SHEET, ADJUST SCALES ACCORDINGLY

HUSS LANE

REVISIONS

NO.

DESCRIPTION

3 ADDENDUM 3

1

SITE PLAN

DATE

1/18/16

N

1/18/2016 11:18:05 AM

SCALE:

1" = 20'-0"

JOB NO.

5006A3

DATE

12/3/15

SHEET

A100

C:\BIM\BCAG TI_asalija.rvt

KEYNOTES

2

3

4

5

6

7

PEDESTRIAN CONCRETE PAVING: PER CITY OF CHICO REQUIREMENTS. MATCH EXISTING CONCRETE

PAVING THICKNESS ADJACENT TO BUILDING (MIN. 4” PCC ON 2” SAND) AND REINFORCING (MIN. #4 @ 16” OC

EW). SUBGRADE: SCARIFY AND RECOMPACT 6” OF NATIVE SOIL TO 95% RELATIVE COMPACTION.

ASPHALT CONCRETE: PER CITY OF CHICO REQUIREMENTS. MATCH EXISTING STRUCTURAL SECTION

THICKNESS. SUBGRADE: SCARIFY AND RECOMPACT 6” OF NATIVE SOIL TO 95% RELATIVE COMPACTION.

INSTALL NEW ORNAMENTAL FENCING PER DETAILS THIS SHEET.

INSTALL NEW VEGETATION TRELLIS (“GREENSCREEN”) PER DETAILS THIS SHEET.

CONNECT (N) TO (E) CONCRETE PER DETAIL 5 THIS SHEET.

UTILITY PAD CONCRETE: SEE STRUCTURAL FOR DETAILS. EXTEND PAST CMU WALL AS SHOWN.

PROVIDE SAWCUT JOINTS AT 5’-0” MIN. SPACING PER DETAIL 6 THIS SHEET.

6' - 0"

PAVING

(N) CONCRETE SIDEWALK

ISOLATION JOINT - SEE

EXPANSION JOINT

DETAIL FOR FILL

(N) ORNAMENTAL

FENCING

CMU WALL PER

STRUCTURAL

(E) WALKWAY; FIELD

VERIFY THICKNESS

(E) BUILDING

#4 @ 16" OC EW

3/4" SMOOTH 12" DOWEL @

18" OC W/ 3/4"x13" PVC

CAPPED SLEEVE THIS END

MATCH (E)

ELEVATION

STRIPING PER

PREVIOUS PROJECT

DRILL & EPOXY 3/4" DIA

x12" DOWEL THIS END

D ARC

SE P. M HIT

N N

ON

O

(N) CONCRETE WALK

2% MAX

T

EC N

NI

(E) SEWER

LINE

A

1'-0"

(N) AC

(E) DI

Capital Expenditure Managers

2750 Gateway Oaks Drive

Suite 300

Sacramento, CA. 95833

(916) 648-9700

LIC

JA E

S

1

EQ

#

No.: C32299

Exp.: 01/31/17

EQ

S

ST

IA

A

T

AT R C H I T E C N

R

EO

F CA L I F O

(E) POSSIBLE GREASE

TRAP, FIELD VERIFY

(N) FENCE

FOUNDATION AS

PER DETAILS ON

THIS SHEET

6

3

(E) BUILDING

FOUNDATION; FIELD

VERIFY LOCATIONS

AND DIMENSIONS

CONC SIDEWALK AND PAVING SECTION

2

1/2" = 1'-0"

(N) TO (E) CONC DOWEL CONNECTION

1/2" = 1'-0"

24' - 9 1/4"

SAWCUT PERPENDICULAR TO CJ'S

WITHIN 4 HOURS OF SLAB

PLACEMENT. USE THE "SOFF-CUT"

PROCEDURE. FILL W/ EPOXY FILLER.

(SEE SPECIFICATIONS FOR

ADDITIONAL INFO)

CONTROL JOINTS SHALL BE

LOCATED PARALLEL TO AND

CENTERED BETWEEN

CONSTRUCTION JOINTS.

1 1/2"

2' - 8"

TYP

NOTE:

REINFORCING SHALL

BE CONT THROUGH

CONTROL JOINTS

3

BEGIN

BUTTE COUNTY ASSOCIATION OF

GOVERNMENTS

S

5

18' - 10"

4

SAWCUT JOINT

AMERISTAR MONTAGE PLUS

CLASSIC 3R EXT 7'T 8' PANEL

8' MAX

1

7

TYP

4X MTL POST

CAST ALUMINUM

LETTER SIGNAGE

7' - 0"

4

6

NOTE:

BUILDING SIGNAGE

LOCATION PER FIRE

AUTHORITY DIRECTIVE

7

48" CLR

A101

10"

A101

MIN

2

TYP

3

A101

6

ORNAMENTAL FENCE DETAIL

5

1/4" = 1'-0"

BUILDING ID SIGN

1/16" = 1'-0"

326 HUSS LANE, CHICO CA

BUTTE REGIONAL TRANSIT OPERATIONS

CENTER

12" = 1'-0"

12' - 0"

CONTRACTOR IS CAUTIONED THAT

AN EXISTING JOINT TRENCH IS

LOCATED ALONG THE BUILDING

SOUTH SIDE OF THE EXISTING

CONDENSING UNITS.

CONTRACTOR SHALL POTHOLE

AND IDENTIFY TRENCH ALIGNMENT

PRIOR TO DEMO / CONSTRUCTION

ACTIVITIES.

EQ

EQ

PROJECT STATUS:

2' - 9"

EQ

BID SET

2' - 9"

GREENSCREEN FREESTANDING

VERTICAL VEGETATION

TRELLIS

GREENSCREEN.COM

4'-0" MIN CLR

(N) CONC

(2) LAYERS OF

BARK AT PLANTER

SOIL FOR

VEGETATIONIRRIGATED

2' - 10"

FENCE

SHEET TITLE:

ENLARGED SITE PLAN

0

1/2

SCALE:

1

BAR IS ONE INCH ON ORIGINAL

DRAWING. IF NOT ONE INCH ON THIS

SHEET, ADJUST SCALES ACCORDINGLY

REVISIONS

PLANT "VIRGINIA

CREEPER" - (3)

CONTAINERS

NO.

DESCRIPTION

DATE

FOOTING, SEE

STRUCTURAL

SECTION

ELEVATION

JOB NO.

1

ENLARGED SITE PLAN

1/8" = 1'-0"

N

LAST REVISION:

1/18/2016 11:18:08 AM

3

END

FENCE

14' - 0"

5

2' - 10"

2' - 10"

BUILDINGS:

7

VEGETATION TRELLIS DETAIL

5006A3

1/4" = 1'-0"

DATE

12/3/15

SHEET

A101

C:\BIM\BCAG TI_asalija.rvt

LEGEND:

EXISTING WALL TO BE REMOVED

EXISTING BOLLARD TO BE REMOVED

EXISTING WALL TO REMAIN

EXISTING BOLLARD TO REMAIN

(E) AC PAVING

Capital Expenditure Managers

2750 Gateway Oaks Drive

Suite 300

Sacramento, CA. 95833

(916) 648-9700

PAVEMENT SAWCUT LINE

EXISTING DOOR TO BE REMOVED

(E) DI

D ARC

SE P. M HIT

N N

ON

O

Exp.: 01/31/17

19

IA

G

S

A

T

AT R C H I T E C N

R

EO

F CA L I F O

1. CONTRACTOR TO CHECK AND FIELD VERIFY ALL DIMENSION AND CONDITIONS AT JOB SITE INCLUDING

LOCATIONS AND DEPTHS OF (E) UTILITIES AND NOTIFY ARCHITECT OF ANY DISCREPANCIES BETWEEN

DRAWINGS AND FIELD CONDITIONS BEFORE COMMENCING ANY WORK.

ST

B.1

A

No.: C32299

GENERAL NOTES:

S

T

EC N

NI

LIC

JA E

S

EXISTING CURBS / PAVING TO BE REMOVED

(E) SEWER

LINE

2. CONTRACTOR TO NOTIFY ARCHITECT AND OWNER OF ANY DRY ROT THAT MAY BE DISCOVERED DURING

DEMO.

(E) POSSIBLE GREASE

TRAP, FIELD VERIFY

29

3. CONTRACTOR TO REPAIR IN-KIND ANY AREAS DAMAGED DURING REMOVAL AND DEMO OF (E) ROOFING

ASSEMBLY.

8

29

4. CONTRACTOR SHALL COORDINATE ALL UTILITY DISCONNECTS/INTERRUPTIONS WITH OWNER MINIMUM 2

WEEKS PRIOR TO START OF WORK.

1

29

14

14

2

5. 20 CY DEBRIS BOX FOR OWNER TRASH TO BE RENTED BY CONTRACTOR FOLLOWING MOVE OUT. INCLUDE

IN BASE BID AMOUNT.

14

6. GENERAL CONTRACTOR TO DEMO ALL EQUIPMENT NOT REMOVED BY OWNER.

7. GENERAL CONTRACTOR TO CLEAN ALL WALLS AND SLABS AS REQUIRED TO OBTAIN OPTIMAL

CONDITIONS TO RECEIVE NEW FINISHES AND ELIMINATE ODOR.

1

8. PROVIDE APPROVED REFRIGERENT RECOVERY DOCUMENTATION ACCEPTABLE TO THE AHJ.

1

9. REMOVE ALL CONDUCTORS FROM ALL DEMOLISHED CONTROL, SIGNAL & POWER CIRCUITS TO THE

SERVICE TERMINATION POINT.

31

#

2

1

25

1

7

5 26 27

25

1

28

14

KEYNOTES

1

2

3

4

5

6

7

8

9

10

14

33

11

3

12

(E) AC PAVING

13

22

14

32

1

21

INTERIOR

WALLS TO

REMAIN

(E) AC PAVING

2

16

2

4

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

3

33

BID ALTERNATE 34

13

2

4

25

32

5

25

30

17

20

5

5

5

5

5

12

5

3

34

11

5

16

5

5

3

18

9

5

CONTRACTOR IS CAUTIONED THAT

AN EXISTING JOINT TRENCH IS

LOCATED ALONG THE BUILDING

SOUTH SIDE OF THE EXISTING

CONDENSING UNITS. CONTRACTOR

SHALL POTHOLE AND IDENTIFY

TRENCH ALIGNMENT PRIOR TO

DEMO / CONSTRUCTION ACTIVITIES.

5

25

5

9

5

12

5

(E) ROLL UP DOOR TO BE REMOVED IN ITS ENTIRETY AND TURNED OVER TO THE COUNTY.

(E) DOOR AND FRAME TO BE REMOVED.

(E) INTERIOR WALLS TO BE REMOVED IN THEIR ENTIRETY UNLESS NOTED.

(E) WASH STATION TO BE REMOVED.

ALL CEILING & ASSOCIATED LIGHTS, DIFFUSERS, ETC TO BE REMOVED.

(E) WALL TO BE REMOVED.

DEMOLISH (E) SLAB AS SHOWN.

DEMOLISH (E) CMU WALL AS REQUIRED FOR (N) DOOR.

DEMOLISH (E) FURNACE UNIT, DUCTWORK, AND ALL ASSOCIATED REFRIGERANT PIPING, GAS PIPING, AND

CONTROLS.

DEMOLISH (E) CONDENSING UNIT AND ALL ASSOCIATED REFREGERANT PIPING AND CONTROLS. REMOVE

CAP W/ PROPER FITTINGS INTENDED FOR PIPE, CONDUIT OR DUCT TERMINATION AND ABANDONMENT.

DEMOLISH (E) PLUMBING FIXTURES. REMOVE ALL ASSOCIATED PIPING. REMOVE CAP W/ PROPER FITTINGS

INTENDED FOR PIPE, CONDUIT OR DUCT TERMINATION AND ABANDONMENT.

DEMOLISH (E) CEILING EXHAUST JAMS. REMOVE ALL ASSOCIATED DUCTWORK AND CONTROLS. REMOVE

CAP W/ PROPER FITTINGS INTENDED FOR PIPE, CONDUIT OR DUCT TERMINATION AND ABANDONMENT.

DEMOLISH (E) ELECTRIC WATER HEATER. REMOVE ALL ASSOCIATED PIPING AND CONTROLS. REMOVE CAP

W/ PROPER FITTINGS INTENDED FOR PIPE, CONDUIT OR DUCT TERMINATION AND ABANDONMENT.

DEMOLISH (E) GAS UNIT HEATERS (TYP. OF 6) AND REMOVE ALL ASSOCIATED GAS PIPING AND CONTROLS.

REMOVE CAP W/ PROPER FITTINGS INTENDED FOR PIPE, CONDUIT OR DUCT TERMINATION AND

ABANDONMENT.

(E) MAIN SERVICE SWITCHBOARD TO BE DEMOLISHED.

(E) PANELS TO BE DEMOLISHED.

(E) WINDOW / STOREFRONT TO BE REMOVED. PATCH / REPAIR OPENING TO RECEIVE (N) WINDOW.

(E) PLATFORM ABOVE CEILING TO REMAIN.

DEMOLISH (E) ASPHALT & CONCRETE AS REQUIRED FOR UTILITY YARD.

DEMO SLAB AS REQUIRED FOR JANITOR SINK AND PLUMBING LINES.

DEMO SLAB AS REQUIRED FOR RESTROOMS AND PLUMBING LINES.

SAWCUT, DEMO & REMOVE (E) PAVING WITHIN LIMITS AS SHOWN.

SAWCUT, DEMO AND REMOVE (E) CURB WITHIN LIMITS AS SHOWN.

REMOVE (E) CHAIN LINK FENCE AND GATE; REMOVE FOUNDATION TO 12 INCHES BELOW GRADE.

REMOVE (E) BOLLARDS AND FOUNDATION TO 12 INCHES BELOW GRADE ALONG SOUTH SIDE OF BUILDING.

DEMO ALL (E) UNISTRUT ALONG INSIDE OF CMU.

ALL (E) ROOF INSULATION TO BE REMOVED AND REPLACED.

DEMO SLAB AS REQUIRED FOR RAMP. SEE STRUCTURAL DRAWINGS.

COORDINATE THE REMOVAL OF (E) ANTENNA W/ OWNER.

DEMO SLAB AS REQUIRED FOR LINES TO KITCHEN SINK.

DEMO SLAB AS REQUIRED FOR FLOOR BOX AND CONDUIT PATH.

(E) EXTERIOR LIGHTS TO BE DEMOLISHED.

DEMO SLAB AS REQUIRED FOR COLUMN FOOTING. SEE STRUCTURAL DRAWINGS.

CONTRACTOR TO PROVIDE A PRICE TO REMOVE (E) GAS METER, CAP/ABANDON PIPING AS NECESSARY

AND REPAIR BUILDING EXTERIOR FINISH AS APPROPRIATE. GC TO COORDINATE W/ LOCAL UTILITY.

BUTTE COUNTY ASSOCIATION OF

GOVERNMENTS

14

326 HUSS LANE, CHICO CA

33

BUTTE REGIONAL TRANSIT OPERATIONS

CENTER

14

PROJECT STATUS:

BID SET

17

2

24

5

6

6

BUILDINGS:

5

5

5

2

5

SHEET TITLE:

DEMO FLOOR PLAN

32

WALL TO REMAIN

32

23

0

LAST REVISION:

D

E

1

BAR IS ONE INCH ON ORIGINAL

DRAWING. IF NOT ONE INCH ON THIS

SHEET, ADJUST SCALES ACCORDINGLY

REVISIONS

NO.

DESCRIPTION

1 ADDENDUM 1

3 ADDENDUM 3

1

BUILDING & SITE DEMO PLAN

1/8" = 1'-0"

DATE

1/4/16

1/18/16

N

1/18/2016 11:19:03 AM

B

1/2

SCALE:

JOB NO.

5006A3

DATE

12/3/15

SHEET

AD201

C:\BIM\BCAG TI_asalija.rvt

1. ALL ITEMS SHOWN ON PLAN TO BE REMOVED ARE DIAGRAMMATIC & LOCATIONS

ARE APPROXIMATE.

2. GC TO FIELD VERIFY QUANTITY OF ITEMS TO BE REMOVED FROM ROOM AND TO

COORDINATE WITH OWNER WHAT IS TO BE SALVAGED FOR FUTURE USE.

#

KEYNOTES

G

1

DEMOLISH ALL HVAC & EXHAUST EQUIPMENT FROM ROOF IN THEIR ENTIRETY. ALL ITEMS REMOVED THAT

LEAVE AN OPENING IN THE ROOF TO BE FILLED TO MATCH (E) ROOF SECTION. METAL ROOF PANEL ON TOP

TO BE REPLACED W/ A (N) PANEL TO MATCH.

(E) GUTTERS & DOWNSPOUTS TO BE REMOVED.

REMOVE (E) VENTILATION PIPE & CAP. REUSE PENETRATION FOR (N) RELIEF VENT HOOD.

T

EC N

NI

2

3

D ARC

SE P. M HIT

N N

ON

O

LIC

JA E

S

A

Capital Expenditure Managers

2750 Gateway Oaks Drive

Suite 300

Sacramento, CA. 95833

(916) 648-9700

No.: C32299

Exp.: 01/31/17

1

A

T

AT R C H I T E C N

R

EO

F CA L I F O

ST

IA

GENERAL NOTES:

1

BUTTE COUNTY ASSOCIATION OF

GOVERNMENTS

2

BUTTE REGIONAL TRANSIT OPERATIONS

CENTER

1

(E)

(E)

3

4

2

2

(E)

(E)

3

326 HUSS LANE, CHICO CA

2

1

1

1

1

5

PROJECT STATUS:

(E)

BID SET

BUILDINGS:

SHEET TITLE:

6

DEMO ROOF PLAN

2

1

0

1/2

1

LAST REVISION:

BAR IS ONE INCH ON ORIGINAL

DRAWING. IF NOT ONE INCH ON THIS

SHEET, ADJUST SCALES ACCORDINGLY

REVISIONS

B

1

DEMO ROOF PLAN

1/8" = 1'-0"

D

NO.

DESCRIPTION

1 ADDENDUM 1

E

DATE

1/4/16

N

1/18/2016 11:19:05 AM

SCALE:

JOB NO.

5006A3

DATE

12/3/15

SHEET

AD230

C:\BIM\BCAG TI_asalija.rvt

KEYNOTES

GENERAL NOTES:

1

(E) LOAD BEARING WALL TO REMAIN. GENERAL CONTRACTOR TO PROTECT DURING CONSTRUCTION AND

TO REPAIR AS NECESSARY BASED ON SCOPE OF (N) CONSTRUCTION. INSTALL (N) FINISH MATERIALS

(GYPSUM BOARD, WALL BASE, PAINT, STC.) AS REQUIRED TO MATCH (N) DESIGN.

(N) DOWNSPOUTS & GUTTERS. REMOVE (E) DOWNSPOUT & GUTTERS AND REPLACE. GENERAL

CONTRACTOR TO COORDINATE WITH ARCHITECT ON POSITION OF DOWNSPOUTS.

SEE STRUCTURAL DRAWINGS FOR WALL CONSTRUCTION. FINISHES PER INTERIOR ELEVATIONS.

1. SEE A221 FOR WALLS THAT EXTEND TO ROOF DECK.

2

2. ALL INTERIOR DOORS SET A MINIMUM OF 3" FROM ADJACENT WALLS.

D ARC

SE P. M HIT

N N

ON

O

6"

6"

WALL BRACING PER

STRUCTURAL DWGS

T

EC N

NI

6"

3

Capital Expenditure Managers

2750 Gateway Oaks Drive

Suite 300

Sacramento, CA. 95833

(916) 648-9700

LIC

JA E

S

#

No.: C32299

Exp.: 01/31/17

(E) CMU WALL

G

4

3 5/8" MTL STUDS @ 16" OC

9' - 0"

8' - 8"

9' - 0"

6' - 2"

J

137

FE

H

7

H

3

6"

1

A501

132

H

129

J

3

A501

BOARD

ROOM

130

E

131

CEMENT BD

SAB INSULATION

H

E

DF

CHAIR

STORAGE

131

K

WALL TYPE 'D'

E

2

A301

MEN'S

126

CONF.

ROOM

128

HALL

125

OFFICE

121

IDF

ROOM

123

A

126

2

4

JANITOR

105

C

A

G

122

OFFICE

124

F

F

105

4

A501

135

1

5/8" GYP BD

A301

E

4" MTL STUDS @ 16" OC

OPEN

CONF/WORKROOM

117

CEMENT BD

A

TILE

F

OFFICE

120

F

125

106

F

OFFICE

106

A

117.3

F

6" MTL STUDS @ 16" OC

4" MTL STUDS @ 16" OC

5/8" NOISE

REDUCING GYPSUM

SAB INSULATION

SAB INSULATION

5/8" NOISE

REDUCING GYPSUM

SAB INSULATION

WALL BASE AS SCHEDULED

1" GAP

WALL BASE AS SCHEDULED

B

OFFICE

107

A

B

1

B

OFFICE

114

OFFICE

115

B

OFFICE

116

A

WALL TYPE 'G'

A

A

115

A

1

107

A

114

A

RECEPTION

102

HALL

113

KITCHEN

112

(E) COL

FE

(E) COL

MGMT

OFFICE

109

A

6

LOBBY

101

2

A211

A

A

A

68

6

1

MGMT

OFFICE

110

1

1

5/8” GYP

BOARD

(2) 2x, POSITION AS NEEDED

OPEN

CONF/WORKROOM

111

69

110

5/8” GYP

BOARD

POST, SEE

STRUCTURAL

DRAWINGS

1

WALL BASE AS SCHEDULED

A301

SHEET TITLE:

FLOOR PLAN

3

B

BID SET

2x NAILER

BUILDINGS:

2

A501

A

WALL TYPE 'J'

5’-0” AFF

A

HALL

108

108

B

FE

A

109

A

WALL TYPE 'H'

PROJECT STATUS:

116

5

1/18/2016 11:18:11 AM

NOTE:

(N) CONSTRUCTION TO

UNDERSIDE OF ROOF

117.1

COPY/WORK

ROOM

104

5

HOLD DOWN, SEE

STRUCTURAL DRAWINGS

D

E

0

1/2

SCALE:

1

BAR IS ONE INCH ON ORIGINAL

DRAWING. IF NOT ONE INCH ON THIS

SHEET, ADJUST SCALES ACCORDINGLY

REVISIONS

NO.

DESCRIPTION

DATE

G

WALL TYPE 'K'

JOB NO.

1

FLOOR PLAN

1/8" = 1'-0"

N

LAST REVISION:

WALL TYPE 'F'

(E) CMU WALL

2

120

A

OFFICE

122

NOTE:

(N) CONSTRUCTION TO

UNDERSIDE OF ROOF

WALL BRACING PER

STRUCTURAL DWGS

117.2

HALL

118

124

2

STORAGE

135

HALL

134

119

51

WOMEN'S

127

G

121

A

A

E

A

123

127

A

H

DIRECTOR

OFFICE

119

6"

D

G

SIM

G

WALL TYPE 'E' - 2HR-UL U404

A

3

3

A501

WALL BASE AS

SCHEDULED

DN

DN

128

(E) CMU WALL

WALL BASE AS SCHEDULED

DAIS

141

A

1

A610

A

2 1/2" MTL STUDS @

16" OC TO 6" ABOVE

CEILING

3

8

OVERFLOW

129

5/8" GYP BD

WALL BASE AS SCHEDULED

PARTIAL HEIGHT WALLS

4

WALL TYPE 'C'

(2) LAYERS OF 5/8"

GYP BOARD EA.

SIDE - 3" MINERAL

TILE

H

WALL BASE AS

SCHEDULED

4" MTL STUDS (20ga)

@ 16" OC W/ SAB

INSULATION

133

73

SIM

NOTE:

(N) CONSTRUCTION TO

UNDERSIDE OF ROOF

8" MTL STUDS @ 16" OC

3

E

H

WALL TYPE 'B'

WALL BRACING PER

STRUCTURAL DWGS

A

2

3

A501

WALL BASE AS

SCHEDULED

WALL TYPE 'A'

ELECTRICAL

136

8

2

WALL BASE AS SCHEDULED

DN

BREAKOUT/CLOSED

SESSION

ROOM

133

1

A401

GYP BD

BUTTE COUNTY ASSOCIATION OF

GOVERNMENTS

136

E

8" MTL STUDS 16" OC

326 HUSS LANE, CHICO CA

1

2

(E) CMU WALL

CEMENT BD

SAB INSULATION

12' - 0"

UTILITY YARD

A/V

ROOM

132

TILE AS

SCHEDULED

74

1

A211

H

4" MTL STUDS @ 16" OC

5/8" GYP BD EACH SIDE

1" GAP, FILL W/ EXP

MATERIAL

CMU WALL,

SEE STRUCTURAL

A

T

AT R C H I T E C N

R

EO

F CA L I F O

ST

F

IA

C

A301

BUTTE REGIONAL TRANSIT OPERATIONS

CENTER

B.1

6"

A

2

ARCHITECTURAL WALL TYPES

3/4" = 1'-0"

5006A3

DATE

12/3/15

SHEET

A201

C:\BIM\BCAG TI_asalija.rvt

Capital Expenditure Managers

2750 Gateway Oaks Drive

Suite 300

Sacramento, CA. 95833

(916) 648-9700

B.1

C

F

G

T

EC N

NI

A

LIC

JA E

S

D ARC

SE P. M HIT

N N

ON

O

No.: C32299

11' - 9"

33' - 10"

11' - 3"

9' - 0"

6' - 2"

8' - 8"

A

T

AT R C H I T E C N

R

EO

F CA L I F O

MASONRY

ST

26' - 8"

INTERIOR WALLS

IA

22' - 6"

Exp.: 01/31/17

9' - 0"

1' - 4 1/4"

3' - 0"

12' - 0"

(N) OPENING

HALL

118

HALL

125

WOMEN'S

127

14' - 10"

5' - 5"

JANITOR

105

6' - 0 1/2"

11' - 4 1/2"

OFFICE

124

14' - 8 1/2"

OFFICE

122

4' - 0"

STORAGE

135

3' - 0"

8' - 9 1/4"

HALL

134

4' - 8 1/2"

1' - 2"

DIRECTOR

OFFICE

119

OFFICE

121

4' - 10"

OPEN

CONF/WORKROOM

117

6' - 3 1/2"

OFFICE

120

9' - 9"

CLR

4'-0 "

10' - 0"

CLR

MIN

11' - 2"

17' - 7 3/4"

MEN'S

126

IDF

ROOM

123

4' - 4 1/2"

4' - 2"

1' - 2"

4'-0"

CLR

CHAIR

STORAGE

131

8' - 0 1/2"

4' - 5 1/4"

22' - 8 1/2"

23' - 4"

16' - 9 1/2"

12' - 0"

326 HUSS LANE, CHICO CA

BOARD

ROOM

130

OVERFLOW

129

MIN

5' - 10"

R

BUTTE REGIONAL TRANSIT OPERATIONS

CENTER

6' - 8"

5' - 9"

1' - 6"

BUTTE COUNTY ASSOCIATION OF

GOVERNMENTS

8"

29' -

5' - 1"

5' - 1"

CONF.

ROOM

128

5' - 7"

9' - 4"

17' - 3"

22' - 5 1/2"

BREAKOUT/CLOSED

SESSION

ROOM

133

VARIES TO MATCH

SLOPE OF COL. TYP.

3

ELECTRICAL

136

5' - 9"

2

INTERIOR WALLS

A/V

ROOM

132

3' - 9"

1

4

COPY/WORK

ROOM

104

4' - 9 1/4"

OFFICE

106

10' - 5"

OFFICE

107

10' - 5"

OFFICE

114

10' - 5"

OFFICE

115

10' - 5"

OFFICE

116

10' - 5"

11' - 4 3/4"

13' - 6"

MGMT

OFFICE

110

18' - 4"

4' - 7"

4' - 11"

6' - 6"

7' - 4 1/2"

HALL

108

OPEN

CONF/WORKROOM

111

CLR

8' - 4 1/2"

5' - 0"

1' - 4"

LOBBY

101

BUILDINGS:

SHEET TITLE:

FLOOR PLAN DIMENSIONS

0

B

D

E

G

INTERIOR WALLS

A

FLOOR PLAN - DIMENSIONS

1/8" = 1'-0"

1

BAR IS ONE INCH ON ORIGINAL

DRAWING. IF NOT ONE INCH ON THIS

SHEET, ADJUST SCALES ACCORDINGLY

REVISIONS

NO.

JOB NO.

1

1/2

SCALE:

N

LAST REVISION:

1/18/2016 11:18:13 AM

6

BID SET

2' - 6"

5' - 0"

MGMT

OFFICE

13' - 4" 109

7' - 5 3/4"

RECEPTION

102

KITCHEN

112

5' - 5"

5

4' - 6"

HALL

113

CLR

CLR

2' - 8"

3'-10"

PROJECT STATUS:

5006A3

DATE

12/3/15

DESCRIPTION

DATE

SHEET

A202

C:\BIM\BCAG TI_asalija.rvt

1 3/4"

CLOSURE PANEL TO CEILING

WHERE OCCURS

2

A401

EDGE BAND

2x LEDGER

UNDERCABINET

TASK LIGHT

SEE 10

4"

1

A501

2"

2x BLOCKING

SEE INT ELEVS

4"

6

A211

1

A501

PROJECTOR

W/ SHELF ABOVE

5

7' - 5"

19' - 7 1/4"

A211

E4

FLOOR BOX, SEE

ELCTRICAL DRAWINGS

E2

A602

1

A401

0°

.0

0

9

P

TY

FULL HEIGHT CABINET SECTION

BOARD

ROOM

130

COUNTERSUNK

#12 x 2" FHWS

@ 16" OC

H

C1

C2

3/4" CABINET BASE

2x4 BLOCKING

A603

MOVABLE LECTERN BY OTHERS

C4

FIXED

CASEWORK

C3

4' - 1 3/4"

7' - 5"

PROJECTOR

W/ SHELF ABOVE

2x @ 24" OC

DAIS

141

BASE

CONCRETE FLOOR

BASE CABINET FLOOR ANCHOR

2

CHAIR

STORAGE

131

3" = 1'-0"

4' - 0"

UPPER CABINET - EXTEND

BOTTOM EDGE OF DOOR TO

ALIGN W/ VALANCE

19' - 1 3/4"

12" MIN

16d @ 16" OC

12' - 0"

+18"

DN

1:12 MAX

0"

12" MIN

5' - 1 1/2"

POWDER ACTIVATED

DRIVE PIN @ 16" OC

1/4" x 2-1/2"

HANDRAILS

STORAGE

135

DN

P.LAM VALANCE, COORDINATE W/

ELECTRICAL FOR DEPTH- MATCH

DOOR FACE

E1

E3

1" = 1'-0"

9

A

T

AT R C H I T E C N

R

EO

F CA L I F O

HANDRAILS

GROMMET, TYP

SINK, WHERE

OCCURS (SEE

PLUMBING)

2X @ 24" OC

9

A211

+18"

A3

EDGE BAND

NOTE: WHITE MELAMINE

TYPICAL ALL INTERIORS AND

SHELVES.

8

0"

A1

#10x3"SELF TAPPING

WOOD SCREW

3/4" DOORS AND

DRAWER FRONTS

3/4" ADJ

SHELF

3

A211

A604

2x LEDGER

1'-0"

2

LIGHT FIXTURE, SEE

ELECTRICAL DRAWINGS

1 1/2" = 1'-0"

ENLARGED DAIS CASEWORK PLAN

1

1/2" = 1'-0"

1/4" = 1'-0"

WD2 OVER 1/2" MDF

SSM2 OVER 3/4" PLYWOOD

1

1

2' - 0"

1

PROJECT STATUS:

6" METAL STUD PARTITION, DOUBLE

STUDS @ EA COUNTER SUPPORT TYP

PARTITION, SEE PLAN, DOUBLE STUDS

@ EA COUNTER SUPPORT TYP SED

2' - 1"

2"

2' - 1"