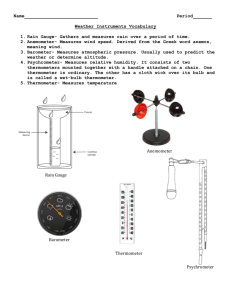

Handheld Infrared Thermometer

advertisement