A Contractor`s Guide to Installing Segmental

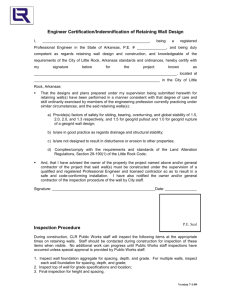

advertisement