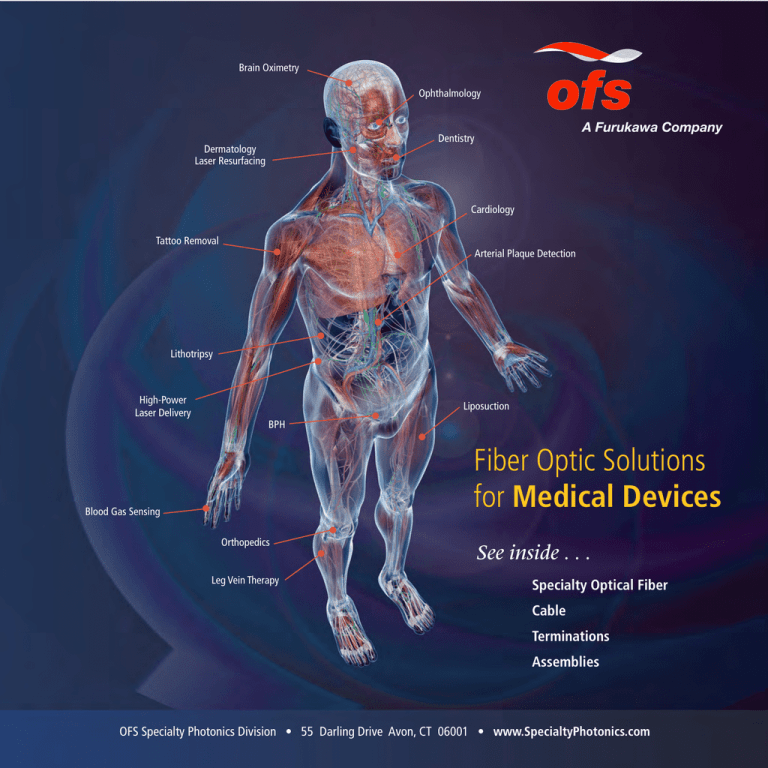

Brain Oximetry

Ophthalmology

Dentistry

Dermatology

Laser Resurfacing

Cardiology

Tattoo Removal

Arterial Plaque Detection

Lithotripsy

High-Power

Laser Delivery

Liposuction

BPH

Fiber Optic Solutions

for Medical Devices

Blood Gas Sensing

Orthopedics

Leg Vein Therapy

See inside . . .

Specialty Optical Fiber

Cable

Terminations

Assemblies

OFS Specialty Photonics Division • 55 Darling Drive Avon, CT 06001 • www.SpecialtyPhotonics.com

With over 20 years’ experience designing and

manufacturing specialty optical fibers, we have

the production history, process control, and

insight that make our medical-grade fibers the

❘❙❚ a b o u t t h e c o m p a n y

Optical Fiber Solutions from OFS

best in the world. Our comprehensive medical

assemblies and cabled fibers are complete, custom

product lines, all based on the broadest range of

optical fibers manufactured in-house, many from

our own preforms.

OFS: One source

for the optical fiber you need

Optical fiber can be customized in many ways to

yield exactly the features needed in different

medical applications. Whether you need fibers for

lasers, imaging, sensing, or data transmission, OFS

has the right fiber for you. Single-mode, multimode, and polarization maintaining fibers can all be

customized and manufactured to meet your needs.

Our signature HCS® optical fibers or all-silica

configurations together with a variety of coating and

other options allow you to design explicitly for your

application environment.

vertically integrated

Preform / Fiber / Cable /

Termination / Packaged Assemblies

totally focused

Providing Optical Fiber Solutions 1

Our medical manufacturing location is in Avon,

Connecticut, the headquarters for our Specialty

Photonics Division. This facility offers 110,000 square

feet of manufacturing and office space and includes

extensive facilities for the design, fabrication,

customization, and packaging of our medical and

other product lines:

• fiber draw towers of various heights, equipped with stations

for coating, cladding, prooftesting, measurement.

assembly

• on-site testing labs to ensure fibers are made to specification.

• cable extrusion lines.

• Monitored and controlled low-bioburden assembly rooms.

Simplified Supply Chain

fiber

OFS is the only optical fiber company in the world

to provide fiber, cable, and packaged assemblies supported by a deep pool of engineering know-how—all

from one location. In-house cabling, for example,

saves customers the tedious after-market step of

threading optical fiber through sections of tubing.

We’ll work with your team to develop the right design

for your application, stay on time, and provide support

at all stages of development. Then, when you’re

ready, we have the capacity to rapidly scale to meet

your production needs, up to thousands of finished

assemblies per week.

The Science Behind the Products:

OFS Laboratories

cable

OFS Laboratories provides academic research and

a patent-generating powerhouse that keeps us at the

forefront of our industry. The Labs are where we turn

science into real-world solutions. Dedicated engineers

for each manufacturing area and cross-functional

teams work together. We’re happy to bring all of this

to the table to meet the fiber optic requirements of

your medical applications. When our scientists are

able to partner early in the design process, customers

get the best results—innovations developed with the

key features they need.

Environmentally Controlled Rooms

❘❙❚ c a p a b i l i t i e s

—monitored for bioburden

See the

Reference Section

for additional

details

Biocompatibility

Many of our medical products meet ISO 10993 and

USP Class VI standards for nontoxicity and biocompatibility. Many are also already certified as biocompatible by NAMSA, and we work with our customers

to qualify other fibers to these standards where

needed. For the assembly stage, we maintain, test,

monitor, and control a low-bioburden room for medical assembly and packaging.

Specialized Recordkeeping

Upon customer request, OFS is equipped to provide

Device Master Records, maintain Device History

Records, and adhere to other components of FDA

Current Good Manufacturing Practices.

Sterilization

OFS optical fibers for medical use are sterilizable.

The ETO (Ethylene Tri-Oxide) method is preferred.

Autoclave is also recommended. We do not recommend gamma radiation sterilization, as this method

can damage the fiber.

We also offer sterilizable fibers for disposable use.

OFS is equipped to follow managed sterilization protocols for prepackaged devices.

Please note that, although OFS provides sterilization service as

an option and many of our fibers are certified as biocompatible,

it is the customer’s responsibility to test all finished medical assemblies for biocompatibility and to recommend the sterilization

procedure for their devices.

Providing Optical Fiber Solutions 3

OFS Medical Fibers

❘❙❚ p r o d u c t l i n e

HCS Optical Fibers

All OFS medical fibers are biocompatible and

sterilizable. These can also be cabled, tubed,

terminated, and assembled into higher-end

components right in our Avon, Connecticut, facility.

Designing a Fiber for Your Application:

While we have many standard designs already

available to order, we also offer the flexibility that

comes with in-house preform design and fiber

draw. Within broad manufacturing limits, you

can choose the fiber composition and select the

NA to precisely match the characteristics of your

laser input source. Coatings applied

during the draw or cabling process

provide physical protection for the

fiber in high-temperature environments (PYROCOAT™ polyimide),

additional strength (HCS fiber

coating), or chemical or abrasion

resistance (ETFE). Nylon and silicone

coatings are also available.

Our fibers are extremely well suited

for the rigors of use in medical environments.

4 www.SpecialtyPhotonics.com

OFS' proprietary HCS fiber

cladding enables an optical

fiber to be used safely and

efficiently in many specialized

applications.

HCS optical fibers offer high

tensile strength, are fatigue

and moisture resistant, tolerate

wide fluctuations in temperature, and can be easily

terminated using another OFS

innovation: Crimp and Cleave

Termination.

Typical Constructions for Medical Fibers

Customization is Always Available

Silica Core

Suggested fiber constructions,

HCS Clad

coatings, and cabling vary by the

specific medical application in

which the fiber will be used. Refer

ETFE Buffer

to individual application sections

”’

STAT

in this brochure for an overview of

the standard products available for

those uses.

BAR

Some of the Many Options

in Multimode Optical Fibers

from OFS

Standard HCS

Silica Core

Silica Core

HCS fibers

in NAs: 0.37 0.39 0.43

Silica Clad

Silica Clad

HCS Coating

Standard and custom

core sizes: 100 - 1500 µm

PYROCOAT

Coating

ETFE Buffer

All silica fibers

in NAs: 0.12 0.22 0.29

in a variety of Core/Clad ratios

Buffer choices:

Color, thickness, diameter

Class VI coatings:

ETFE, Polyimide, Nylon,

Silicone

All Silica

High Temperature

Sterilizable:

Autoclave, ETO

Providing Optical Fiber Solutions 5

OFS Optical Fibers for

Medical Lasers

❘❙❚ p r o d u c t s b y a p p l i c a t i o n

Over the past 15 years, OFS has seen an evolution

in the requirements for medical laser fibers.

Customers have used our fibers in wavelengths from

532 nm for KTP lasers to 2.1 µm for holmium lasers.

We have offered reusable fibers for aesthetic laser

treatments and disposable fibers for urology. Now,

power levels are increasing. Fiber diameters are

getting smaller, and fibers are increasingly pushed to

their limits for bend radius. OFS has anticipated and

responded to these changes with the development of

a new family of lasers fibers: HCXtreme™ optical

fibers, designed to improve damage thresholds at

high power and under tight bends.

Our flagship HCS optical fibers offer a crimpand-cleavable polymer cladding that makes using our

fibers in medical applications exceedingly easy and

cost effective. These are available in a choice of core

sizes or numerical apertures. General selection

parameters are illustrated on the following page, and

additional product selection criteria, including

standard catalog part numbers, can be found in the

Selection Guide beginning on page 18. Custom

solutions, from fiber design through cabling and

connectorization, can also help address individual

requirements in your unique application.

6 www.SpecialtyPhotonics.com

Managing High Power Under Tight Bends

With the high laser powers used in many medical procedures

today, one of the biggest issues that contributes to fiber

failure is excessive bending of the fiber under high energy.

OFS’s latest product line, HCXtreme, addresses and solves

that potential problem. In testing down to a 5 mm bend,

HCXtreme continued to transmit power without breakage.

For additional details and testing methodology, request our

white paper, entitled “Study of Optical Fiber Damage Under

Tight Bend with High Optical Power at 2140 nm.”

Attenuation (dB/km)

NOTE: Spectral attenuations

at Excimer and Ho:YAG laser

wavelengths are beyond the

scope of this chart and are

available upon request.

❘❙❚ p r o d u c t s b y a p p l i c a t i o n

Typical Attenuation for Various Types of Specialty Fiber

Wavelength (nm) ⇒

Attenuation and Fiber Design

Fiber loss at a particular wavelength depends largely

on the fiber’s properties. These include high or low

water content, cladding material, core diameter, NA,

and coating. The graph above shows a snapshot of the

major categories of optical fibers we offer and generally

whether they are suitable for a particular laser wavelength.

The following is an introduction to various considerations in choosing a fiber for your application. When

you are ready to begin making your selections, please

call us for a consultation.

NA you choose will depend on your launch conditions and your

desired distal end output. A higher NA also allows a fiber to

better contain energy and may be better suited for applications

requiring tight bends.

Core Size Select a core size that accommodates your input

spot size and allows for tolerances. If the core size is too small,

some laser energy may launch into the cladding, which may

result in fiber failure.

Cladding Material HCS fiber cladding creates a higher NA

than silica cladding alone and enables the use of a crimp-andcleave connector.

OH Content

High OH is typically preferred for

700 nm and shorter wavelengths. Low OH is suggested for

longer wavelengths.

Coating/Buffer Material* PYROCOAT, our proprietary

polyimide, is a thin, high-temperature coating, good for use

when small diameters must be achieved. ETFE is a fluoropolymer buffer typically applied over HCS fiber cladding. A nylon

buffer is an excellent choice for tight buffer constructions.

Numerical Aperture (NA) The numerical aperture of the

fiber influences how much light from your source is captured at

the proximal end and carried through to the distal end. Which

*Not all coatings and buffers are compatible with each other.

Please contact us for the best combination to meet your needs.

Providing Optical Fiber Solutions 7

OFS Components for Fiber Lasers

❘❙❚ p r o d u c t s b y a p p l i c a t i o n

In components for fiber lasers and other highpower laser systems, OFS uses technologies and

designs developed by OFS Laboratories. Our

products include tapered fiber bundles (power

combiners), doped fibers with double or triple

cladding, fiber bragg gratings and various

combinations of these components.

• Yb or Er/Yb and other dopants

• Connectorization

• Double and triple cladding

• Ferrule types: hermetic or

strain relief

Customer-specifiable options are extensive, and

we provide strong technical support for testing

under high-power generation.

• High reflectivity

• Multimode launch fiber matching

• Stability for either pulsed or

CW lasers

• Large Mode Areas

• Air cladding

• Splicing parameters

• Fiber end preparation

Cladding Pumped Fiber Amplifier (CPLA)

Cladding Pumped Fiber Laser (CPFL)

CLADDING

PUMPED FIBERS

Also Available Separately

ErYb 130 µm

Yb 130 µm

PM Yb 125 µm

PM ErYb 125 µm

Yb 200 µm

PM Yb 200

Custom available:

Yb and ErYb Large Mode Area

Output Wavelength:

1064 nm, 1083 nm, 1100 nm, 1117 nm

POWER COMBINERS

for CPFLasers

Multimode Input

CPF Output

(105/125 µm)

(0.45 NA)

7 fibers 0.15 NA

7 fibers 0.22 NA

19 fibers 0.15 NA

1 - undoped 125 µm

1 - undoped 200 µm

1 - undoped 200 µm

8 www.SpecialtyPhotonics.com

CLADDING

PUMPED FIBERS

Also Available

Separately

Yb 130 µm

Yb 200 µm

CLADDING PUMPED FIBER

GAIN MODULE

CONFIGURATIONS

Includes Power Combiner and

Cladding Pumped Fiber

Yb Gain Module

ErYb Gain Module

PM Yb Gain Module

PM ErYb Gain Module

POWER COMBINERS

for CPFAmplifiers

Input

CPF Output (0.45 NA)

6 MM 105/125 µm

+ 1 SM signal fiber

1 - undoped 125 µm

18 MM 105/125 µm

+ 1 SM signal fiber

1 - undoped 200 µm

6 MM 105/125 µm

+ 1 PM signal fiber

1 - undoped PM 125 µm

18 MM 105/125 µm

+ 1 PM signal fiber

1 - undoped PM 200 µm

Large Mode

Area fibers

available

separately

by special

arrangement.

OFS Optical Fibers for

❘❙❚ p r o d u c t s b y a p p l i c a t i o n

Imaging and Sensing

Medical optical fibers are designed for the rigors of

imaging and sensing in applications such as:

OCT (plaque imaging and detection)

Blood gas monitoring in real time

Blood pressure monitoring

Temperature monitoring

Radiation dose sensing

Pressure sensing in robotic arms

Tight bend radius is particularly critical in

intrabody applications where the fiber must wind

through veins or arteries, around organs, and bones

on their way to an application area—all without breakage or loss of transmission capacity. OFS offers a full

suite of single-mode and multimode fibers with either

high or low water content that may be bent as small as

9 mm with no increase in attenuation.

Small outer diameter. For system requirements

where fiber diameters must be as small as possible

without sacrificing optical quality or exceeding

mechanical limits, OFS can modify core and cladding

parameters in the fiber’s original design. OFS’s

PYROCOAT polyimide is the thinnest coating available

and can be applied to achieve these smaller diameters

along with high-temperature performance.

Low-cost designs are important for the disposable

fiber optic assemblies and catheters used in imaging

and sensing applications. But, managing cost does not

mean you need to sacrifice the features you need.

Our engineers can help design a solution that meets

both goals.

Fiber Bragg Gratings (FBGs). Gratings, an

emerging technology for medical devices, are well understood at OFS. With over 60 patents in this field,

we can offer custom-designed gratings, written into

OFS fibers, that provide a means for measuring and

monitoring pressure, temperature, and strain.

Providing Optical Fiber Solutions 9

OFS Optical Fibers for

Data Transmission

❘❙❚ p r o d u c t s b y a p p l i c a t i o n

In operating rooms and other hospital

environments where radio frequency and electromagnetic interference are pervasive, glass optical fibers

from OFS are ideal. Immune to EMI/RFI, they also

provide high bandwidth capacity for transmitting

complex data from medical equipment to output

devices or computer monitors in MRI suites. Some

degree of ruggedness is also expected in these

applications when, for example, cables are strung

across unprotected areas between a piece of diagnostic

equipment and its computer monitor located behind a

protective shield.

10 www.SpecialtyPhotonics.com

For data transmission in these environments,

we offer several standard cable options. The environment is considered by our engineers before

recommending certain protective buffers and jacket

materials.

OFS Optical Fibers for

❘❙❚ p r o d u c t s b y a p p l i c a t i o n

Illumination

Specialty optical fibers are commonly used to

illuminate the eye—either externally or from within the

eye itself—during complex ophthalmic procedures and

surgeries. Wide-angle, 0.43 NA optical fibers are best for

these applications since the high NA allows maximum

light to be coupled into the fiber. We also offer 0.37 NA

fibers for some illumination applications.

As these fibers may be used either inside or outside the

body, they are also manufactured to be biocompatible.

Because they are subject to handling, the fibers must also

be cabled before use.

OFS fiber makes an excellent light guide

across the visible spectrum.

Providing Optical Fiber Solutions 11

Cabling Options

❘❙❚ p r o d u c t o p t i o n s

Cable and Tubing Options

OFS’s vertically integrated capabilities do not stop

at designing preforms and drawing fibers.

Our in-house, fully automated, cabling operation

provides more options. Our customers can save the

tedious and potentially damaging assembly step of

threading optical fiber through sections of tubing by

choosing to have OFS cable the fiber. You can then

focus instead on cutting the cable to your desired

lengths and connectorizing.

12 www.SpecialtyPhotonics.com

The cable structure—either tight buffer or loose

tube—protects the optical fiber from mechanical and

environmental stresses and eases handling for smaller

fibers. Our Cable Engineers are available to work with

medical device manufacturers to deliver a cable or

terminated cable assembly that will integrate well into

the final system.

❘❙❚ p r o d u c t o p t i o n s

Cabling Options

Tight Buffer—an option that involves extruding

protective coatings in direct contact with the fibers.

Loose Tube—an outer cable jacket is applied with

spacing between the jacket and inner fiber.

Aramid Yarn—these strength members (applied

parallel, spiral, or braided) are available with either

tight-buffer or loose-tube constructions.

Color and Print Options

To match your established protocols and prints, OFS

can produce cables with custom jacket printing and

any color you choose (including those specified in the

Pantone Matching System). Both options are available

at no additional cost.

Required Feature:

Optimal

Construction:

Small Diameter . . . . . . . . . . . . . . . . . . Tight Buffer

Lighter Weight. . . . . . . . . . . . . . . . . . . Tight Buffer

Smaller Bend Radius . . . . . . . . . . . . . . Tight Buffer

Better Protection

During Repeated Flexing . . . . . . . . . . . Tight Buffer

Isolate fiber from

tensile load in a bend. . . . . . . . . . . . . . Loose Tube

Isolate fiber from compressive loads . . Loose Tube

OFS optical fiber cables

can be optimized for

many features. Select

the parameter/s necessary for your particular

application, and use

this chart to determine

whether a tight- buffer

or loose-tube cable will

generally be better for

your intended use.

Better isolation from buffer thermal

expansion and contraction. . . . . . . . . . Loose Tube

Easier buffer stripping . . . . . . . . . . . . . Loose Tube

Providing Optical Fiber Solutions 13

Cabling Material Selection

❘❙❚ p r o d u c t o p t i o n s

Material Selection

In addition to choosing tight-buffer or loosetube construction, our Cable Engineers will

consider your cable’s potential exposure to high

or low temperatures, abrasion, UV light, chemicals, moisture, and dynamic flexing. Other considerations for medical applications include the

technique for sterilization, biocompatibility, USP

Class VI certification, and the softness of the material if the cable will be in contact with skin.

Opacity of the outer jacket material may also be

important in your application. Each of these criteria will help to indicate which are the best materials for your medical cable.

14 www.SpecialtyPhotonics.com

Buffer/Jacket Type

Material*

Temperature Range

Hytrel (elastomer)

-40 to +135°C

PVC

-35 to +90°C

Polyurethane

-50 to +80°C

TPE

-20 to +105°C

FEP

-100 to +200°C

PVDF

-50 to +150°C

ETFE

-125 to +150°C

PFA

-200 to +260°C

Nylon

-65 to +105°C

PEEK

-55 to +240°C

*Material temperatures are for illustration purposes only. The

temperature range of the final cabled product will depend on

factors not illustrated in this chart, such as the extreme limits of

the fiber itself. Please consult us for further details.

+

❘❙❚ p r o d u c t o p t i o n s

Assembly Manufacturing Options

facilities

certifications

experienced design team

Your Assembly Needs MET

Medical Assemblies

Terminating Your Optical Fiber

Beyond preforms. Beyond fiber. Beyond cable.

Our services also include assemblies packaged and

sterilized in environmentally controlled rooms.

Our customers specify their requirements, and we create

a custom assembly to meet them. No two projects are

alike. Final configurations take into account fiber type,

cabling options, proximal or distal end preparations,

connectorization, anti-reflective coatings, or metalization.

Quality end-face preparation is essential to good optical

fiber performance. Faulty termination can result in poor

transmission or fiber breakage and, in critical high-power

applications, contaminants left from the termination

process can result in end-face burning. Allowing OFS to

terminate your assemblies can help. We can also help with

critical epoxy selection or provide complete termination

kits for do-it-yourself, high-quality connectorization at

your facility to the fiber/cable lengths you require.

Types of Assemblies:

Crimp & Cleave Termination

• Single-use disposables

(faster termination with no surface contaminants.)

• Multiple-use sterilizable units

Crimp & Cleave is an OFS innovation, and only we can

provide the full system, including HCS fibers, compatible

connectors, termination tools, and testing kits.

• Sub-assemblies

• Final assemblies

Providing Optical Fiber Solutions 15

Assembly Manufacturing Options

❘❙❚ p r o d u c t o p t i o n s

Fiber Metalization and Soldering

Another form of end preparation involves

metalizing the bare fiber end (or midspan) such

that the resulting subassembly can be hermetically soldered into a package. Our proprietary

electroless metalization process is considered by

many to be superior to other methods and provides another option for our medical customers’

novel requirements, such as for radio-opacity.

Additional Facilities, Options for Assemblies

Epoxy-Polish Connectorization

Epoxy-polish terminations require proper equipment

and trained operators. OFS has both. We install our

own connectors or obtain specified connectors on our

customer’s behalf from third-party vendors. We can also

design custom ferrules to meet your needs.

Bare Fiber End Preparations

Fibers with a bare distal (or output) end, are common

in some applications, such as leg vein therapy. Options

for the bare end include cleaves at various angles or

polishes. For medical lasers, bare end terminations must

have a high-polish optical finish to prevent excessive

losses, end-face burning, and damage to the laser. With

100% optical inspection at high magnifiction, we are

well-equipped to meet and exceed the stringent quality

requirements for those protocols.

16 www.SpecialtyPhotonics.com

Environmentally Controlled Rooms (ECRs) are

dedicated to medical assembly production and

employ protocols and monitoring to ensure

conformance to stated bioburden levels. An

outside service firm validates our controls and

processes. (For additional information on our

monitoring and certification, see the Reference

section on page 24.)

Test and Measurement

A full team of highly experienced technicians

and engineers is equipped with an array of inhouse test and measurement equipment.

Evaluations and quality-control checks are

performed right here. Some customers ask that

we perform a final quality test on finished

assemblies using their own equipment. We are

happy to facilitate such requests.

❘❙❚ s e r v i c e f e a t u r e s

We Speak Your Language

Cross-Functional

Engineering Support Team

Continuous support throughout the design

and manufacturing process helps you get the

exact specialty optical fiber product you need

for your application. To accomplish this, we

assign a cross-functional team to meet with

you from the very first contact. We’ll select a

fiber engineer, cable engineer, assembly

engineer, customer service representative, and

technical sales engineer to help make a smooth

transition between what you imagine and

what we design and deliver. This team approach helps us look at all the angles throughout the process so you get a product that works

optimally in your application. We understand

the unique language of the medical industry.

Quality Systems

Medical applications have unique quality

requirements, which are fully supported by

OFS. OFS is an ISO 9001:2000 registered

facility. Changes are documented, controlled,

and managed according to procedures set in

place in accordance with our ISO certification.

We monitor raw materials through incoming

quality inspections and finished goods in a

separate conformance check. Where applicable, we can maintain Device History Records

(DHRs). Lot traceability, documentation, and

certification are also available.

History • Stability • Experience

OFS has been active in the fiber optic industry for over

20 years. We are part of Furukawa Electric Company of Japan,

a multi-billion dollar company operating since 1884.

Our Western heritage from the world-renowned Bell Labs

combines with our Eastern heritage to create a formidable,

reliable company with the agility you need to get your projects

going.

Providing Optical Fiber Solutions 17

❘❙❚ s e l e c t i o n g u i d e

Optical Fiber and Cable Selection Guide

The following are summary specification sheets

designed to introduce a medical customer to the many

standard options available through OFS. Please

remember that complete customization is available to

meet virtually any set of specifications. For ease of

selection, only the most critical fiber parameters are

listed.

For a complete listing of all standard OFS fibers

with complete specifications, please request a copy

of our product catalog or visit our website at

www.SpecialtyPhotonics.com.

Biocompatible, sterilizable,

Class VI, non-toxic

Providing Optical Fiber Solutions 19

Optical Fiber and Cable Selection Guide: Medical Lasers

❘❙❚ s e l e c t i o n g u i d e

Most optical fibers optimized for medical lasers are

Multimode Step-Index designs, (though singlemode fibers, typically operating at the 1310 nm

wavelength can be used for certain specialized

applications).

or low water content for transmission wavelengths

under or over 700 nm, respectively. Core size can be

selected to ensure that the laser output will be fully

contained within the fiber’s core. All-silica fibers can

be selected for lower NAs of 0.29 and under. HCS

fibers are available with NAs of 0.37 and over.

Within the Multimode Step-Index category,

further refinements can be made by choosing high

For Medical Lasers

0.37 NA Multimode Step-Index HCS Fibers

Fiber Name

Core/Clad/Buffer

Diameter

Operating

Temperature

Short/Long-Term

Bend Radius

Part Number

For 700 nm and higher (Suggested Wavelengths):

HCS 37 Low OH 125

125/140/250 µm

-65 to +125 °C

≥9/15 mm

CF01493-09

HCS 37 Low OH 200

200/230/500 µm

-65 to +125 °C

≥10/16 mm

CF01493-10

HCS 37 Low OH 300

300/330/650 µm

-65 to +125 °C

≥15/24 mm

CF01493-11

HCS 37 Low OH 400

400/430/730 µm

-65 to +125 °C

≥29/47 mm

CF01493-12

HCS 37 Low OH 600

600/630/1040 µm

-65 to +125 °C

≥58/94 mm

CF01493-14

HCS 37 Low OH 800

800/830/1040 µm

-65 to +125 °C

≥73/118 mm

CF01493-65

HCS 37 Low OH 1000

1000/1035/1400 µm

-65 to +125 °C

≥73/118 mm

CF01493-15

HCS 37 Low OH 1500

1500/1535/2000 µm

-65 to +125 °C

≥182/295 mm

CF01493-62

For under 700 nm (Suggested Wavelengths):

HCS 37 High OH 200

200/230/500 µm

-65 to +125 °C

≥10/16 mm

CF01493-18

HCS 37 High OH 300

300/330/650 µm

-65 to +125 °C

≥15/24 mm

CF01493-19

HCS 37 High OH 400

400/430/730 µm

-65 to +125 °C

≥29/47 mm

CF01493-20

HCS 37 High OH 600

600/630/1040 µm

-65 to +125 °C

≥58/94 mm

CF01493-22

HCS 37 High OH 800

800/830/1040 µm

-65 to +125 °C

≥73/118 mm

CF01493-60

20 www.SpecialtyPhotonics.com

For Medical Lasers

(continued)

Fiber Name

Core/Clad/Buffer

Diameter

Operating

Temperature

Short/Long-Term

Bend Radius

Part Number

For 700 nm and higher (Suggested Wavelengths):

UltraSil 272 Blue

272/326/356/420 µm

-65 to +125°C

≥16/26 mm

BF05246

UltraSil 330

330/400/430/730 µm

-65 to +125 °C

≥30/49 mm

BF04746-02

UltraSil 200 Pyrocoat

200/240/270 µm

-65 to +300 °C

≥18/30 mm

BF04830-01

UltraSil 320 Pyrocoat

320/385/415 µm

-65 to +300 °C

≥30/49 mm

BF04830-02

365/400/430/730 µm

-65 to +135 °C

≥29/47 mm

CF01493-52

All Silica Low OH 550

550/600/630/750 µm

-65 to +135 °C

≥58/94 mm

CF01493-53

All Silica Low OH 940

940/1000/1035/1400 µm

-65 to +135 °C

≥73/118 mm

CF01493-54

All Silica Low OH 200 Pyrocoat

200/220/250 µm

-65 to +135 °C

≥17/28 mm

CF04406-13

All Silica Low OH 320 Pyrocoat

320/385/415 µm

-65 to +300 °C

≥29/49 mm

CF04406-15

All Silica Low OH 600 Pyrocoat

600/660/690 µm

-65 to +300 °C

≥99/167 mm

CF04406-17

❘❙❚ s e l e c t i o n g u i d e

0.29 NA Multimode Step-Index All Silica Fibers

0.22 NA Multimode Step-Index All Silica Fibers

For 700 nm and higher (Suggested Wavelengths):

All Silica Low OH 365

For under 700 nm (Suggested Wavelengths):

All Silica High OH 200

200/240/260/375 µm

-65 to +300°C

≥9/14 mm

CF01493-41

All Silica High OH 365

365/400/430/730 µm

-65 to +135 °C

≥29/47 mm

CF01493-42

All Silica High OH 550

550/600/630/750 µm

-65 to +135 °C

≥58/94 mm

CF01493-43

All Silica High OH 940

940/1000/1035/1400 µm

-65 to +135 °C

≥73/118 mm

CF01493-44

All Silica High OH 100 Pyrocoat

100/110/140 µm

-65 to +135 °C

≥9/14 mm

CF04406-01

All Silica High OH 200/220 Pyrocoat

200/220/250 µm

-65 to +300 °C

≥17/28 mm

CF04406-03

All Silica High OH 200/240 Pyrocoat

200/240/270 µm

-65 to +300 °C

≥18/31 mm

CF04406-04

All Silica High OH 400 Pyrocoat

400/440/470 µm

-65 to +300 °C

≥66/112 mm

CF04406-05

Single-mode Fibers

For 700 nm and higher (Suggested Wavelengths):

Fiber Name

Operating

MFD

at Operating

Wavelength

Numerical

Wavelength

Clad/Coating

Aperture

Coating Type

Diameter

Part Number

Polyimide Coated

1310/1550 nm

9.3/10.5

0.11

125/155 µm

Polyimide

BFF05717

Providing Optical Fiber Solutions 21

Optical Fiber and Cable Selection Guide: Other Medical

❘❙❚ s e l e c t i o n g u i d e

For Sensing and Imaging

Multimode Step-Index Low OH Launch Fibers

Fiber Name

Core/Clad/Buffer

Diameter

Attenuation

@ 850/1300

Operating

Temperature

NA

Short/Long-Term

Bend Radius

Part Number

40/125 Launch

40/125/250 µm

≤10.0 dB/km

-40 + 85 °C

0.22

10/17 mm

BF06269

50/125 Launch

50/125/250 µm

≤5.0 dB/km

-40 + 85 °C

0.22

10/17 mm

BF06864

60/125 Launch

60/125/250 µm

≤6.0 dB/km

-40 + 85 °C

0.22

10/17 mm

F8950

105/125 Launch

105/125/250 µm

≤12.0 dB/km

-40 + 85 °C

0.22

10/17 mm

BF05859

105/125 Low NA

Launch

105/125/250 µm

≤20.0 dB/km

-40 + 85 °C

0.15

10/17 mm

F10017

Single-mode Fibers

Fiber Name

Core/Clad/Buffer

Diameter

Attenuation

Operating

Temperature

NA

Short/Long-Term

Bend Radius

Part Number

CL 1550 12

CL 1550 17

9.3/125/245 µm

≥0.6 dB/km @ 1550 nm

≥0.6 dB/km @ 1550 nm

-40 + 85 °C

-40 + 85 °C

0.12

0.17

10/17 mm

10/17 mm

F10819-01

BF06158

Geo 1310 11

8.4/125/155 µm

≥0.7 dB/km @ 1310 nm

≥0.6 dB/km @ 1550 nm

-65 + 300 °C

0.11

4/4 mm

BF05717

CL Carbon/Poly 1310 111

8.4/125/155 µm

≥0.70 dB/km @ 1310 nm

≥0.60 dB/km @ 1550 nm

-65 + 300 °C

0.11

8/10 mm

BF04447

CL Poly 1310 11

8.4/125/155 µm

≥0.70 dB/km @ 1310 nm

≥0.60 dB/km @ 1550 nm

-65 + 300 °C

0.11

10/17 mm

BF04446

22 www.SpecialtyPhotonics.com

For Data Transmission

Sub-unit

Diameter

Outer

Diameter

Cable

Rating

Short/Long-Term

Bend Radius

Part Number

0 to +75°C

not applicable

2.23 mm

NFPA-262 Plenum

15/10 mm

BC03597-10-BL

2.2 Riser Simplex

-20 to +80°C

not applicable

2.2 mm

UL-1666 Riser

15/10 mm

BC04265-10

2.2 Simplex

-20 to +105°C

not applicable

2.2 mm

Rated to 105°C

25/10 mm

AC02737-10

2.5 Simplex

-20 to +80°C

not applicable

2.5 mm

General Purpose

38/25 mm

AC01281-10

3.0 Simplex

-40 to +80°C

not applicable

3.0 mm

General Purpose

60/45 mm

AC01287-10

2.2 Plenum Zipcord

0 to +75°C

2.2 mm

2.2 x 4.6 mm

NFPA-262 Plenum

15/10 mm

BC04340

2.2 Riser Zipcord

-20 to +80°C

2.2 mm

2.2 x 4.6 mm

UL-1666 Riser

15/10 mm

BC04307

2.2 Zipcord

-20 to +105°C

2.2 mm

2.2 x 4.6 mm

Rated to 105°C

25/10 mmm

AC02581-10

2.5 Zipcord

-20 to +80°C

2.5 mm

2.5 x 5.2 mm

General Purpose

38/25 mm

AC01282-10

2.5 Duplex

-20 to +80°C

2.5 mm

3.5 x 6.0 mm

General Purpose

53/35 mm

AC03720-10

2.2 Riser 2-Fiber Breakout

-20 to +80°C

2.2 mm

7.5 mm

UL-1666 Riser

113/75 mm

BC04791-10

2.2 Riser 4-Fiber Breakout

-20 to +80°C

2.2 mm

7.5 mm

UL-1666 Riser

113/75 mm

BC04791-12

2.2 2-Fiber Breakout

-20 to +105°C

2.2 mm

8.4 mm

Rated to 105°C

50/75 mm

AC02739-10

Fiber Name

2.2 Plenum Simplex

Operating

Temperature

❘❙❚ s e l e c t i o n g u i d e

0.37 NA HCS 200 µm Step-Index Indoor Cables

For Illumination

0.37 NA Multimode Step-Index Fibers

Core/Clad/Buffer

Diameter

Operating

Temperature

Short/Long-Term

Bend Radius

Part Number

HCS 37 Low OH 200

200/230/500 µm

-65 to +125 °C

≥10/16 mm

CF01493-10

HCS 37 Low OH 300

300/330/650 µm

-65 to +125 °C

≥15/24 mm

CF01493-11

HCS 37 Low OH 400

400/430/730 µm

-65 to +125 °C

≥29/47 mm

CF01493-12

HCS 37 Low OH 600

600/630/1040 µm

-65 to +125 °C

≥58/94 mm

CF01493-14

Fiber Name

HCS 37 Low OH 800

800/830/1040 µm

-65 to +125 °C

≥73/118 mm

CF01493-65

HCS 37 Low OH 1000

1000/1035/1400 µm

-65 to +125 °C

≥73/118 mm

CF01493-15

HCS 37 Low OH 1500

1500/1535/2000 µm

-65 to +125 °C

≥182/295 mm

CF01493-62

0.43 NA Multimode Step-Index Fibers

HCS High NA 200

200/230/500 µm

-65 to +125 °C

≥10/16 mm

CF05578-01

HCS High NA 400

400/430/730 µm

-65 to +125 °C

≥29/47 mm

CF05578-03

Providing Optical Fiber Solutions 23

Reference

Biocompatibility of OFS Optical Fibers and Cables:

Additional Technical Detail

Biocompatibility testing of fibers and cables from OFS, Specialty

Photonics Division, has been certified by NAMSA (North American Science

Associates, Inc.). Our fibers and cables have passed USP Class VI and ISO

10993 biocompatibility testing. USP Class VI tests include Systemic Toxicity,

Intracutaneous Toxicity, and Muscle Implantation. ISO 10993 tests include

Hemolysis, Cytotoxicity, Irritation and Sensitization, Systemic Toxicity and

Pyrogenicity. Several different fiber structures were selected to represent

the majority of fibers offered and used in medical applications. The fibers

tested included multimode step-index fibers with NAs ranging from 0.22 to

0.39 and comprised of pure silica core, Ge doped silica core, F doped clad,

HCS fiber cladding, and ETFE, Nylon, and Polyimide buffers. In addition,

we tested our medical grade PVC cable. Certificates of Compliance for the

fibers tested are available upon request.

Low Bioburden Assembly Area

OFS’s dedicated medical-assembly manufacturing space is specially

designed, operated, and monitored to assure a low level of bioburden

contaminants and particulates during the production of medical assemblies.

Bioburden refers to naturally occurring biological materials, such as dust,

pollen, mold spores, and other organisms. Other particulates are identified

down to .5 µm particle size. The facility has been qualified to less than 100

CFUs (Colony Forming Units) and is governed by very strict protocols,

including monthly sanitizing and quarterly bioburden sampling, modeled

after ISO procedures for Clean Rooms. Our controlled rooms are

monitored and tested for alert and action levels on a regular basis to assure

compliance. We maintain class 100,000 alert and action levels in our

manufacturing area with these procedures and positive pressure. With the

addition of laminar flow, Class 100 alert and action levels for particle counts

are maintained in our final packaging area. This means the customer is

assured of low levels of bioburden when they begin their own processes,

allowing our products to be introduced directly into their clean rooms.

24 www.SpecialtyPhotonics.com

This worksheet illustrates

the many options you have

from OFS in designing your

medical assembly. You may

download this worksheet from

www.SpecialtyPhotonics.com

as a handy reference or to serve

as a guide when you call us.

Providing Optical Fiber Solutions 25

This document is for informational

purposes only and is not intended to

modify or supplement any OFS warranties or specifications relating to

any of its products and services.

Drawings are not to scale. OFS reserves the right to make changes at

any time, without notice, to the products and specifications described in

this document.

OFS products described herein may be

subject to the U.S. Export Administration Regulations and may require

approval from the U.S. Department of

Commerce, Bureau of Industry & Security, prior to export.

Copyright © 2010 OFS Fitel, LLC.

All Rights Reserved.

HCXtreme and PYROCOAT are trademarks of OFS Fitel, LLC.

HCS is a registered trademark in the

USA of OFS Fitel, LLC.

For additional information please

contact your sales representative.

1010 SPD

55 Darling Drive

Avon, CT 06001 USA

Phone: 1 860 678 0371

Email:

Info@SpecialtyPhotonics.com

Web:

www.SpecialtyPhotonics.com