InGaP Makes HBT Reliability a Non

advertisement

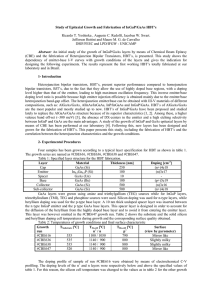

Copyright © 2001, GaAs MANTECH, Inc. InGaP Makes HBT Reliability a Non-Issue Aditya Gupta, Alex Young and Burhan Bayraktaroglu ANADIGICS, Inc, 35 Technology Drive, Warren, NJ 07059 Tel: (908)668-5000 agupta@anadigics.com ABSTRACT Among the many benefits InGaP brought to the GaAs-based heterojunction bipolar transistor (HBT) over the last few years, nothing is more profound than the drastic improvement it provided in the long-term reliability. Today, it is relatively common to obtain activation energies higher than 1.5eV with InGaP HBTs operating under bias and temperature conditions suitable for modern telecommunication applications. This significant improvement in reliability coupled with excellent fabrication control afforded by selective etching has made InGaP HBT the prime choice for large volume fabrication of cellular phone power amplifiers. All new HBT fabrication facilities around the world today either have or plan to have 6-inch InGaP HBT wafers as their only choice for power amplifiers. INTRODUCTION There are a number of fundamental differences in the construction of heterojuctions made from InGaP compared to older approaches using AlGaAs. First, InGaP emitter layers do not have the type of defects associated with Al-containing layers such as AlGaAs. Second, the energy band gap alignment in InGaP/GaAs heterointerface favors the use of abrupt junctions compared to graded junctions commonly employed with AlGaAs. Low interface defects combined with better confinement of holes at the interface, are some of the reasons for achieving consistent predicted lifetimes in excess of 109 hours with InGaP HBTs. Previous investigations have consistently shown that InGaP emitter Heterojunction Bipolar Transistors (HBTs) have reliability superior to AlGaAs emitter HBTs [1-6]. Using MOCVD growth techniques, the excellent reliability advantages of InGaP HBTs have been extended to 6-inch wafers. It has been shown recently that the mean-time-to-failure (MTTF) of the devices in 6-inch manufacturing fabrication process is in excess of 2x109 hours with an activation energy of EA = 1.8 ± 0.2 eV. A lifetime of 3250 hours has been measured at a junction temperature, Tj, of 275°C and current density, J C= 25 kA/cm2 [7]. As GaAs HBT technology matured over the last decade, a significant and steady progress has been made in reliability improvements. Most of these improvements can be attributed to superior material quality available nowadays with MOCVD. However, device fabrication is also a major factor in achieving a reliable final device. As the technology matured, the assessment of reliability was often confused between the factors introduced by details of the fabrication method and the materials growth. This is particularly the case with AlGaAs HBTs, whose emitter-base heterojunction must be graded for proper device operation. The preparation of this junction is an art that is practiced in a unique way by each material supplier. To make the matters worse, each device manufacturer practices the fabrication of AlGaAs HBTs with significant variations. In sum, the constituents of reliability limiting factors are not clearly assessed. This situation is much less ambiguous with InGaP HBTs. Because of minimal conduction band offset between InGaP emitter and GaAs base regions, an abrupt junction is used. Such a junction is better able to confine holes at the heterojunction and therefore offer reduced gain sensitivity to temperature. Further, an abrupt junction when coupled with excellent etch selectivity, provides the manufacturability control needed for high volume applications. It is this repeatability and reproducibility of manufacturing process that allows us to investigate the effects of epitaxial material on the reliability of the HBT devices, independent of the fabrication process. The material contributions are significant as epitaxial material suppliers continue to develop their 150mm growth capabilities. We will examine the impact of epitaxial material on the reliability of InGaP HBTs fabricated in a high volume 150mm wafer facility. We will discuss our results obtained with traditional and other rapid assessment techniques. DEVICE FABRICTION The devices studied in this work consist of MOCVD grown InGaP HBTs supplied by commercial epitaxial material vendors on 150mm GaAs substrates. The device structure includes a 500Å InGaP emitter and a 1000Å thick base layer, carbon doped at NA = 4 x 1019 cm-3. Reliability test devices, shown in Figure 1, were fabricated with a four finger 3x20µm2 emitter area HBT using the ANADIGICS, Inc. production fabrication process. The reliability test structure includes a 5Ω ballast resistor on each emitter finger. The process also includes a 1.0 µm ledge structure made from the depleted InGaP layer. Wafers are thinned to 100 µm and via contacts are used to ground the emitter. Devices are then assembled into packages using a AuSn solder die attach process to reduce the thermal resistance. methods. In the more conventional temperature accelerated tests, devices were stressed at 25kA/cm2 current density and Vce=3.3V at three elevated temperatures (275°C, 300°C, and 325°C). DC current gain was continuously monitored in-situ and the failure criteria for this test was defined as a 20% degradation in gain. The data was captured using an automated measurement system that logs the collector current once per hour for each device. The current acceleration technique relies on selecting a suitable high current density and junction temperature to rapidly assess the propensity of the device to degrade. This test only yields a pass-fail type assessment and no clear activation energy is determined. 0.10 C ol le ct or C ur re nt (A 0.08 Ib = 500 µA Ib = 400 µA 0.06 I = 300 µA 0.04 b I = 200 µA b 0.02 I = 100 µA b 0 0 1 2 3 4 5 Vce (V) Figure 2: Common emitter I-V characteristics of an InGaP emitter HBT. Figure 1: Reliability test device. The DC characteristics of this device is shown in Figure 2. Typical DC current gain of this device is 100 with small signal microwave performance of ft = 28 GHz and fmax = 40 GHz. RELIABILITY TEST RESULTS Device reliability assessment was conducted using both temperature and the current acceleration A typical plot of the normalized DC Beta over the lifetest at Tj = 300°C is shown in Fig. 3. Similar to previous reports, we observe two degradation mechanisms in this material [2]. The first mechanism results in a small gradual decrease in the collector current that is not catastrophic. This accounts for approximately a 10% reduction in the DC current gain. Device failure occurs when the current drops rapidly as a result of a second degradation mechanism. A failed device exhibits an increased base current. Figure 4 shows the Gummel measurement taken both before the device was stressed and after a 1058 hour stress at Tj = 300°C. Both measurements were made at an ambient room temperature of TA=25°C. As shown in this figure, the degradation in current gain is due to increased base current similar to previous observations [2]. The magnitude of change in base current, however, is strongly dependent on Vbe value. At Vbe less than 1.2V, the current gain rapidly approaches unity. 1.2 Using the time at which 50% of the devices reached failure, t50, the failure time at each temperature is plotted in Fig. 6. A straight line fit to these data yields a MTTF = 3 x 109 hours at Tj = 125 °C with an activation energy of EA = 1.8 eV for our production process. These values of MTTF and EA are consistent with other reported results of InGaP HBTs. This fact demonstrates that the InGaP emitter HBT is a robust device on 150mm substrates as well as other substrates. T = 300 C j Normalized DC Beta 1.0 0.8 0.6 0.4 0.2 0 1 10 100 1000 10 4 Time (hr) MTTF = 3 x 109 hr @ T = 125 C 109 Fig. 3: Normalized DC Beta in-situ measurements during 300 ºC lifetest. j Current (A) 10 -1 MTTF (hr) 7 Before Stress After Stress 105 103 IC 10 -3 10 E = 1.8 eV A 10 -5 1 10 1.25 IB 1.5 1.75 2 2.25 2.5 1000/Tj (1/K) 10 -7 10 -9 0.6 0.8 1 1.2 1.4 1.6 Fig. 6: Median-time-to-failure (MTTF) as a function of inverse junction temperature, Tj , at JC= 25 kA/cm2 with VCE = 3.3 V. Vbe (V) Fig. 4: Gummel plot measured before (solid lines) and after (dashed lines) 1058 hour stress at Tj = 300 °C. 1.0 Tj = 325 C 0.8 109 0.6 275 C 0.4 0.2 0 10 Vendor A 300 C MTTF (hr) % Cumulative failures (x100) The cumulative failures are plotted over the lifetest for each temperature. At Tj = 325°C, there are some infant failures as demonstrated in Fig. 5. The dependence on the material quality has been demonstrated in our evaluation of InGaP emitter HBT epitaxial material from three different suppliers. Each vendor has grown InGaP HBT structures with identical characteristics of Beta, Rb, BVceo and Vbe. Given the mature process technology and the stability of our production fabrication process, we believe the process does not contribute to any differences in the reliability results from different vendors. Vendor B 107 Vendor C 105 103 100 1000 10 4 Time (hr) Fig. 5: Cumulative failures plotted for Tj = 275, 300, and 325 °C. 101 1.25 1.5 1.75 2 2.25 2.5 1000/Tj (1/K) Fig. 7: Comparison of MTTF for three epi material vendors. The results of life tests (see Figure 7) on each set of material indicates that the activation energy varies from 1.5 eV to greater than 2.0 eV for the different vendors. The MTTF at Tj = 125 °C is >10 8 hours even at the lowest activation energy 150kA, 1.5V Stress 1.E+00 1.E-01 1.E-02 CURRENT ACCELERATED TESTS 150kA, 1.5V Stress 1.E-01 1.E-02 Current 1.E-03 1.E-04 20hr 3hr 1.E-05 1.E-07 1.E-04 1.E-05 1.E-06 1.E-07 20hr 3hr 1hr 5min 1.E-08 1.E-09 0.75 1 1.25 1.5 Vbe (V) Figure 9: High current stress has negligible base current increase on reliable devices. the resulting statistics are used to assess the overall reliability of the wafer. MTTF and activation energy are not determined by this screening method. SUMMARY We have demonstrated the reliability of our production InGaP emitter HBT fabrication process using 150 mm GaAs substrates. The MTTF was determined to be 3 x 109 hours at Tj = 125 °C with an activation energy of EA = 1.8 eV at a collector current density of J C= 25 kA/cm2 with VCE = 3.3 V. We have also demonstrated the influence of epitaxial material growth on the reliability of 150 mm InGaP emitter HBTs. We have obtained lifetimes that range from 1 to 3 x 109 hours at Tj = 125 °C with activation energies that range from 1.5 to greater than 2.0 eV. ACKNOWLEDGEMENTS The authors would like to thank the ANADIGICS, Inc. wafer fabrication personnel that do a great job processing wafers. 1.E+00 1.E-06 Current 1.E-03 The assessment of HBT reliability by temperature accelerated life tests is a well known and proven technique. A major drawback of this method, however, is the significant effort required in packaging the devices and the long time taken to complete the tests and obtain the desired data. At ANADIGICS, HBT reliability is also assessed by a technique that does not require any packaging and yields results in a few hours. In this method, typically performed at the wafer level, the reliability test device (Figure-1) is stressed for a brief period (e.g. one hour) at extremely high current densities (150kA/cm2 in our test) and the Gummel plot is monitored before and after the test. The HBT is stressed both due to the high current density as described in [8] and due to the high Tj as a result of self heating. In our tests, Tj is estimate to be 300ºC under VCE=1.5V and JC=150kA/cm2. Our experience shows that HBTs with a propensity to degrade will do during this “hammer” test and that 1 hour is adequate to show this tendency (Figure-8). Degraded HBTs show increased base current and base ideality factor as in conventional life tests. Thus, we believe , the same failure mechanism is activated by this method. Reliable devices (Figure-9) will not show any significant degradation in β after this stress. This test is performed on a sample of HBTs on the wafer and 1hr 5min 1.E-08 1.E-09 0.75 1 1.25 1.5 Vbe (V) Figure 8: Current accelerated degradation showing increase in base current similar to temperature accelerated degradation. REFERENCES [1] Low, T.S., et al., 1998 GaAs IC Symposium Technical Digest, pp. 153-6. [2] Yeats, B., et al., 2000 GaAs MANTECH Digest, pp. 131-5. [3] Ueda, O., Microelectronics Reliability, 1999, vol. 39, pp. 1839-55. [4] Pan, N., et al., IEEE Electron Device Letters, April 1998, vol. 19, no.4, pp 115-7. [5] Oka, T., et al., 2000 GaAs MANTECH Digest, pp. 137-40. [6] Alderstein, M., et al., IEEE Trans. Electron Devices, Feb. 2000,vol. 47, no. 2, pp. 434-9. [7] Cheskis, D., et al, 2000 GaAs Reliability Workshop, Seattle, WA [8] Sugahara, H., et al, GaAs ’93 Technical Digest, pp. 115-18.