cover sheet - Port of Moses Lake

advertisement

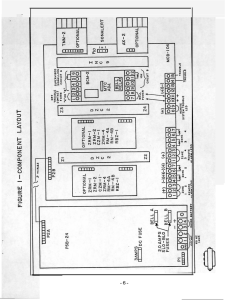

DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: REVISIONS: DATE APPD. PROJECT NUMBER: SHEET NO. OF A FP-1 DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: REVISIONS: DATE APPD. PROJECT NUMBER: SHEET NO. OF DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: REVISIONS: DATE APPD. PROJECT NUMBER: SHEET NO. OF DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: REVISIONS: DATE APPD. PROJECT NUMBER: SHEET NO. OF DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: REVISIONS: DATE APPD. PROJECT NUMBER: SHEET NO. OF DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: REVISIONS: DATE APPD. PROJECT NUMBER: SHEET NO. OF DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: REVISIONS: DATE APPD. PROJECT NUMBER: SHEET NO. OF C FP-2A B FP-2 C FP-2A J C FP-2A J A FP-2 A FP-2 J D FP-2 DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: REVISIONS: DATE APPD. PROJECT NUMBER: SHEET NO. OF NAC 1 F TB12 TB11 TB2 TB7 TB6 TB13 WIRING BY OTHERS H M W/Z C L EO 1-008 AI X T C L EO 1-009 AI X L 1-010 AI X FL C L EO 1-011 AI X T C L EO W TB14 S L EO 1-012 AI X FL 1-014 AI X FL 1-013 AI X T OVERHEAD PRE-ACTION RISER #1 TO PROTECTOWIRE PANEL TB2 OUTPUT #2 = ZONE #1 OVERHEAD PRE-ACTION RISER #2 TO PROTECTOWIRE PANEL TB2 OUTPUT #3 = ZONE #2 S C RISER #2 TB5 COMBO 2 E COMBO 1 NAC 2 L EO 1-007 AI X FL TB4 PROTECTOWIRE PANEL ALARM OUTPUT TB3 TB14 L C C L EO LEGEND / PARTS LIST SYMBOL QUAN. L EO PART # DESCRIPTION MANUFACTURER 1 EXISTING FENWALNET 6000 FIRE ALARM / RELEASE PANEL FENWAL 2 EXISTING 24.0 AH BATTERY DISCOVER BATTERY CABINET 1 EXISTING BATTERY CABINET FENWAL BELOW CONTROL PANEL 2 33Ahr 33.0 AH BATTERY WHEELOCK BATTERY CABINET AI 43 70-407008-001 MONITOR MODULE (N/O) FENWAL 4S BOX OR 2 GANG AO 2 70-408004-001 CONTROL MODULE FENWAL 4S BOX OR 2 GANG NAC 2 PS-24-8MC POWERPATH NAC POWER SUPPLY, 8 AMP WHEELOCK 2 BATC-R BATTERY CABINET WHEELOCK BELOW NAC PANELS 4 24Ahr 24.0 AH BATTERY WHEELOCK BATTERY CABINET 6 MDL3W 12/24 V SYNC MODULE - WHITE SYSTEM SENSOR 15 P2WHK 15 LENS-B WALL MOUNT LENS - BLUE SYSTEM SENSOR HORN/STROBE 1 SSM24-6 6" BELL SYSTEM SENSOR 4S BOX OR 2 GANG DEEP IR 10 40/40I IR3 FLAME DETECTOR SPECTREX F 2 30-330002-001 FOAM HOSE REEL ACTIVATION STATION FENWAL 4S BOX OR 2 GANG DEEP SIGN 2 CUSTOM FOAM HOSE LINE ACTIVACTION CUSTOM AT EACH PULL STATION SIGN 15 CUSTOM FOAM SYSTEM ACTIVATION CUSTOM AT EACH HORN/STROBE SIGN 1 CUSTOM FOAM DELUGE ACTIVATION CUSTOM AT BELL IN RISER ROOM CP C EXISTING SINGLE LINE DIAGRAM HANGER MULTI-cd W N G 6" H 120VAC INPUT POWER S MONITOR RISER #1 NACA AC POWER H H S MONITOR RISER #2 N S 6" MONITOR RISER #3 AUX OUT NACA - 1 NACA - 2 NACA - 3 NACA - 4 WIRING BY OTHERS AA A1 A2 A3 A4 M S C HOSE LINE RISER #4 AI K F C L EO AI K F C L EO AO X NACA C C AI X AC POWER LOSS C AI X NACA TROUBLE AO X NACB C C AI X AC POWER LOSS AI X C AI X C AI X NACB TAMPER TROUBLE 8" BUTTERFLY VALVE C AI X AI X CBA AI X CBA AI X CBA AI X CBA AI X CBA AI X CBA AI X CBA AI X CBA AI X CBA AI X CBA AI X CBA AI X CBA AI X TAMPER 8" BUTTERFLY VALVE TAMPER 4" BUTTERFLY VALVE CBA C AI X C C AI X AI X C AI X C NACB AC POWER C AI X C AI X C AI X TAMPER 2.5" BUTTERFLY VALVE TAMPER 4" BUTTERFLY VALVE IR IR IR IR IR IR IR IR IR IR IR IR PS-10 PS-10 PS-10 PS-10 DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR ALARM ALARM ALARM ALARM TROUBLE ALARM TROUBLE ALARM TROUBLE ALARM TROUBLE ALARM TROUBLE ALARM TROUBLE ALARM PRESSURE PRESSURE PRESSURE PRESSURE SWITCH SWITCH SWITCH SWITCH 120VAC INPUT POWER AI X TAMPER 8" BUTTERFLY VALVE TAMPER 4" BUTTERFLY VALVE C AI X AI X C TAMPER 4" BUTTERFLY VALVE CAA AI X CAA AI X CAA AI X CAA AI X CAA IR IR IR IR IR IR IR IR DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR DETECTOR ALARM TROUBLE ALARM TROUBLE ALARM TROUBLE ALARM TROUBLE 6' AFF AI X C AI X C AI X HORN/STROBE - MULTI CANDELA WEATHER PROOF SYSTEM SENSOR PWBBW DEEP 1. THESE DRAWINGS ARE CONCEPTUAL AND INTENDED TO SHOW GENERAL INFORMATION FOR EQUIPMENT PLACEMENT AND ROUTING. THE CONTRACTOR IS RESPONSIBLE FOR PROVIDING ALL SHOP DRAWINGS, CALCULATIONS, EQUIPMENT, CONDUIT AND FITTINGS NECESSARY FOR A COMPLETE SYSTEM, AS APPROVED BY THE AUTHORITY HAVING JURISDICTION. 2.VERIFY ALL SITE CONDITIONS, ALL EXISTING EQUIPMENT AND CONNECTIONS TO THE EXISTING FENWALNET 6000 RELEASE PANEL. 3. ALL MATERIAL AND EQUIPMENT SHALL BE NEW AND LISTED WITH THE EXISTING RELEASE PANEL. C PS-40 PS-40 PS-40 HIGH/LOW HIGH/LOW HIGH/LOW PRESSURE PRESSURE PRESSURE SWITCH SWITCH SWITCH ELECTRICAL SYSTEM NOTES : 1. THE DETECTION AND CONTROLS SYSTEM FOR THE NEW FOAM SYSTEM SHALL BE INSTALLED IN ACCORDANCE WITH NFPA 70, 72, MANUFACTURES GUIDELINES AND STATE AND LOCAL CODES WHERE APPLICABLE. 2. ALL WIRING FOR THE FOAM RELEASE SYSTEM SHALL BE INSTALLED IN MINIMUM OF 3/4" ELECTRICAL METALLIC TUBING (EMT) OR CONDUIT. 3. INITIATING AND RELEASING CIRCUITS SHALL BE INSTALLED IN RACEWAYS. 4. AC AND DC CURRENT SHALL BE RUN IN SEPARATE CONDUIT AND BOXES. 5. PAINT ALL J-BOXES AND COVERS RED TO IDENTIFY FIRE ALARM SYSTEM. 6. IDENTIFY EACH COVER WITH POWER LIMITED FIRE ALARM CKT. 7. MAINTAIN 1" SEPARATION BETWEEN ALL POWER LIMITED AND NON POWER LIMITED CIRCUITS. 8. FIRE ALARM SYSTEM SHALL BE INSTALLED AND TESTED IN ACCORDANCE WITH NFPA 72 , AS WELL AS ALL APPLICABLE LOCAL CODES. 9. RIGID CONDUIT BELOW 7'-0" AFF FOR MECHANICAL PROTECTION REQUIRED. 10. ALL DEVICES LOCATED BELOW 7'-0" AFF SHALL CARRY NEMA 4X RATING. AI X ADDITIONS TO SINGLE LINE DIAGRAM HANGER SEE FLOOR PLAN FOR DEVICE LAYOUTS EXCLUSIONS : RED 3/8" THICK PANEL APPLICABLE CODES : NFPA 13 CURRENT EDITION NFPA 70 CURRENT EDITION NFPA 72 CURRENT EDITION NFPA 409 CURRENT EDITION SCOPE OF WORK : EXPAND EXISTING FENWALNET 6000 RELEASING PANEL TO PROVIDE IR3 FLAME DETECTION AND FOAM SYSTEM MONITORING AND RELEASE. PROVIDE OPEN AREA HANGAR AUDIBILITY WITH REQUIRED ADDITIONAL POWER SUPPLIES AND NAC PANELS AS REQUIRED. DEVICES SHOWN FADED ABOVE REPRESENT THE EXISTING EQUIPMENT ON THE FENWALNET 6000. ( SHALL BE FIELD VERIFIED) 3" 21" RED 3/8" THICK PANEL 4" 4" CUT THIS OUT. YELLOW ACRYLIC/PLASTIC 3/8" THICK PANELS WITH RED LETTERING AND A 4" X 5.5"( 1/8") CUT OUT AT DESIGNATED POSITION. AREA MAP PROJECT DATA : FOAM DELUGE ACTIVATION SIGN DETAIL FOAM HOSE LINE ACTIVATION SIGN DETAIL OWNER: PORT OF MOSES LAKE BUILDING 3401 MOSES LAKE, WASHINGTON 98837 6" 5" RED 2" TEXT HEIGHT .66 WIDTH FACTOR (TO SKEW TO FIT PANEL) FOAM DELUGE ACTIVATION RED ACRYLIC/PLASTIC 3/8" THICK PANELS WITH WHITE LETTERING ALL LETTERING TO BE 3/4" 12" HANGAR BLDG 3401 **WORK LISTED BELOW SHALL BE PROVIDED BY OTHERS OR UNDER OTHER SECTIONS OF THE PROJECT.** 1. 120 VAC POWER SUPPLY TO THE NAC POWER SUPPLY PANELS. 2. TELEPHONE LINES FOR REMOTE MONITORING. 3. INTERLOCK WIRING AND CONDUIT FOR SHUTDOWN OF HVAC , DAMPERS AND/OR ELECTRIC POWER SUPPLIES , RELAYS , SHUNT TRIP BREAKERS OR OTHER DEVICES. 6" YELLOW 3/8" THICK PANEL .5 NACB - 4 B4 AI X 1 3/8" NACB - 3 B3 CAA 2 1/2" NACB - 2 B2 AI X 5.5" NACB - 1 B1 CBA 1.5" AUX OUT BA AI X NOTES NOTES: TAMPER 4" BUTTERFLY VALVE C TAMPER 4" BUTTERFLY VALVE C WIRING BY OTHERS CBA ENCLOSURE L EO RISER #1 E W TB5 EO 1-006 AI X L RISER #2 TB4 PROTECTOWIRE PANEL TROUBLE OUTPUT C RISER #1 TB10 1-005 AI X T C RISER #3 FENWALNET 6000 CONTROL PANEL TB9 L 1-004 AI V C RISER #3 EO 1-003 AI V RISER #3 C RISER #4 1-002 AI K F RISER #4 F TB8 AUX 1 & 2 AC POWER J3 RELEASE 2 120VAC INPUT POWER P RS-232 J8 1-001 C P TB4 WIRING BY OTHERS BATTERY C J5 RISER #4 TB15 NETWORK INTERFACE RELEASE 1 RELAY 1 RELAY 2 RELAY 3 RELAY 4 USB SLC TB1 RELAY #1 RELAY #2 RELAY #3 TROUBLE P RS-232 J RS-485 C FLASHING LIGHT MEANS FOAM SYSTEM ACTIVATION AHJ: GRANT COUNTY BUILDING / FIRE 4571 1ST AVENUE NW EPHRATA, WA 98823 PHONE: 509-754-2011 RED ACRYLIC/PLASTIC 3/8" THICK PANELS WITH WHITE LETTERING ALL LETTERING TO BE 3/4" FOAM SYSTEM ACTIVATION SIGN DETAIL DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: DATE APPD. PROJECT NUMBER: SHEET NO. OF FENWALNET 6000 SPECIFICATIONS: To Next Device To Next Device AO Relay Module TB2 24 VDC PSU Release STATUS TB3 ABAB + TB1 4 RRM Remote Release Module ASM Signal Module PC LINE OUT IN BLU RED WHT ORN N/O 7 To Next Device 6 CO M PC (- ) 2 1 3 PC (- ) PC ( +) PC (+) N/C AAM AlarmLine Module 5 POWER SUPPLY: **5 AMP MAXIMUM ALL EXTERNAL DEVICES** NOTE: EXTERNAL DEVICES INCLUDE ALL NOTIFICATION APPLIANCES, RELEASING SOLENOIDS, SLC INITIATING AND CONTROL DEVICES AND ALL DEVICES POWERED FROM THE PANEL POWER SUPPLY. TB #13 - AC/DC POWER SUPPLY UNIT 5.4 A @ 24VDC 120 OR 240 VAC 50/60 Hz LINE VOLTAGE NON-POWER LIMITED TB #3 - BATTERY CONNECTION SUPERVISED 24 VDC NOMINAL MAX. BATTERY SIZE 70 A/H NON-POWER LIMITED - DEDICATED CIRCUIT 8 7 6 5 4 Polarized Notification Appliance (Typical) 2 3 GND RXTX OUT RXTX IN Optional Isolator Module (Single-Gang Mount) Detector Base FENWALNET ADDRESS APPROVED Detector Base RS 485 SLC OUT 7 4 IN 7 RET 24 V RET 24 V 3 2 1 4 3 USB B 2 J3 RS 232B - - + + RS 232 A TB15 C J P P P Polarized Notification Appliance (Typical) J8 S2 Branch 3 3 4 SLC-Style Switch (S2) 2 E TB3 - TB4 1 BUZZER 3 4 + + BATT OUT 1 2 F TB2 Auxillary Outputs Regulated 24 VDC, Current: 1.0 (max) each output PSU J12 AC IN N L A/B G H 240 120 G 2 3 RELEASE 1 4 FROM BATTERIES TB6 TB2 TB11 1 TO NACB H TB7 TB12 TB13 SIGNALING LINE CIRCUIT (SLC): TB #1 SIGNALING LINE CIRCUIT WIRING REQUIREMENTS POWER LIMITED AND SUPERVISED UP TO 255 ADDRESSABLE DEVICES CLASS "B" STYLE 4 (CLASS "A" CONDUIT SEPERATION SHALL BE MAINTAINED AT A MINIMUM OF 1 FOOT VERTICALLY AND 4 FEET HORIZONTALLY. NFPA 72 CHAPTER 6 CLASS "A" STYLE 6 CLASS "A" STYLE 7 USING ISOLATOR DEVICES 350MA MAX / 28VDC MAX / 40 OHMS MAX / 20Pf PER FOOT TWISTED, UNSHIELDED, LOW-CAPACITANCE, ADDRESSABLE-FIRE ALARM WIRE White Black Green TB5 AC Supply Select Switch (S4) 120 VAC, 50/60 Hz, 3.2 A or 240 VAC, 50/60 Hz, 1.6 A NAC2 Notes: 1. Move SLC-Style Switch S2 to the left into the Style-4 position. 2. Each isolator module creates a 0.12-V voltage drop. NACA NAC1 Branch 1 1 2 3 4 TB10 STYLE 4 0 ON 9 1 2 3 4 8 ON 7 J10 1 2 3 4 6 ON 5 1 2 3 4 4 ON 3 1 2 3 4 2 TB9 1 ON TB8 TROUBLE TROUBLE RELAY NO NC C Branch 2 TB4 RELAY 3 Optional Isolator Module (Single-Gang Mount) NO NC C RET 24 V RET 24 V RELAY 2 Optional Isolator Module (Single-Gang Mount) PROGRAMMABLE RELAYS IN NO NC C RET 24 V RET 24 V OUT RELAY 1 IN NO NC C OUT AI MODULE AC POWER LOSS J4 J6 3 Caution: DO NOT USE LOOPED WIRE UNDER TERMINALS of detector bases. Break SLC wire run to provide supervision of connections. . End-of-Line Resistor 10 k +/- 10%, 0.5 W J5 JTAG 1 TB1 3 AUXILIARY POWER: TB #2 - RESETABLE 24VDC POWER OUTPUT POWER LIMITED AND SUPERVISED 1 AMP MAXIMUM EACH CIRCUIT **5 AMP MAXIMUM ALL EXTERNAL DEVICES** NOTE: EXTERNAL DEVICES INCLUDE ALL NOTIFICATION APPLIANCES, RELEASING SOLENOIDS, SLC INITIATING AND CONTROL DEVICES AND ALL DEVICES POWERED FROM THE 24 Vdc POWER SUPPLY. 120VAC 50-60Hz NON-POWER LIMITED (PS-6, PS-8) BLACK GREEN WHITE R FM RELAYS (POWER OR NON-POWER LIMITED BUT NOT BOTH): TB #4, TB #8, TB #9 - PROGRAMMABLE RELAY SPDT FORM C CONTACT RATED FOR 1.0 AMPS @ 30 VDC (RESTRICTIVE) RATED FOR 0.5 AMPS @ 30 VDC (INDUCTIVE) RATED FOR 0.5 AMPS @ 120 VDC (INDUCTIVE) TB #10 - TROUBLERELAY SPDT FORM C CONTACT RATED FOR 1.0 AMPS @ 30 VDC (RESTRICTIVE) RATED FOR 0.5 AMPS @ 30 VDC (INDUCTIVE) RATED FOR 0.5 AMPS @ 120 VDC (INDUCTIVE) End-of-Line Resistor 10 k +/- 10%, 0.5 W AIM Monitor Module 1 PC PC PC PC SW SW LED LED (+) (-) (+) (-) A B (+) (-) AI Monitor Module + 1 2 3 4 1 RELEASE 2 2 3 4 AUX 24VDC 1 2 3 4 COMBO 1 1 2 3 4 COMBO 2 To PSU Earth Ground Solenoid Blk Red Solenoid AO MODULE ACTIVATION Red Blk Solenoid 10K In-Line Releasing Device (Locate as close as possible to solenoid) Blk 0.480A 0.480A 0.480A 0.480A 0.480A Red AI MODULE POWER SUPPLY TROUBLE 5K In-Line Releasing Device (Typ 2) Locate as close as possible to solenoid 2.2 K EOL 0.480A 2.2 K EOL 0.480A 2.2 K EOL WEST IR3 FLAME DETECTORS NOTIFICATION APPLIANCE CIRCUITS (NAC) AND RELEASING CIRCUITS: TB #5 AND TB #14 NAC CIRCUITS POWER LIMITED AND SUPERVISED NOT "T" TAPPABLE REGULATED 24VDC, 1.5 AMPS MAX PER CIRCUIT CLASS "B", STYLE "Y" / CLASS "A", STYLE "Z" MAXIMUM # SYNCHRONIZED DEVICES PER CIRCUIT IS 25 TB # 11 AND TB #12 RELEASING CIRCUITS SERIES WIRED INITIATOR ASSEMBLIES SINGLE CONTROL HEAD OR SOLENOID VALVE TWO SERIES-SUPERVISED, PARALLEL-ACTUATED CONTROL HEADS OR SOLENOID VALVES MAX RELEASE CURRENT 2.4 AMPS PER CIRCUIT TB #6 AND TB #7 COMBINATION CIRCUITS PROGRAMMED AS NAC CIRCUITS FUNCTION THE SAME AS ABOVE PROGRAMMED AS RELEASE CIRCUITS CAN SUPPORT ONE CONTROL HEAD OR ONE PREACTION SOLENOID FENWALNET 6000 TYPICAL WIRING DIAGRAM 120VAC 50-60Hz NON-POWER LIMITED (PS-6, PS-8) BLACK GREEN WHITE AI MODULE AC POWER LOSS 1 2 3 4 ON 1 2 3 4 ON 1 2 3 4 ON 1 2 3 4 ON 1 2 3 4 ON NACB FROM NACA FROM BATTERIES AO MODULE ACTIVATION 0.480A 0.480A 0.480A 0.480A 0.480A 0.480A 0.480A SLC FROM PREVIOUS DEVICE OR FACP SLC TO NEXT DEVICE OR FACP 1 SLC FROM PREVIOUS DEVICE OR FACP SLC TO NEXT DEVICE OR FACP 2 3 4 RELEASE 1 10K In-Line Releasing Device (Locate as close as possible to solenoid) SLC TO NEXT DEVICE OR FACP 8 7 6 E.O.L. SLC FROM PREVIOUS DEVICE OR FACP AUX. IN +- +- TROUBLE CKT. OUTPUT CKT. 24 VDC + - +- +- +- +- 70-407008-001 MONITOR MODULE 1 2 3 RELEASE 2 RELEASE Blk Solenoid Red AUX. TO NEXT DEVICE 70-200200-001 SIGNAL OUTPUT MODULE 70-600000-01 REMOTE RELEASE MODULE EAST IR3 FLAME DETECTORS Solenoid TO RELEASE DEVICE AUX. FROM PREVIOUS DEVICE OR FACP Compensating Resistor 5K In-Line Releasing Device (Locate as close as possible to solenoid) + - +Red AUX. TO NEXT DEVICE 4 2.2 K EOL 4 TB11 TO NAC PANEL TO NOTIFICATION APP. 70-408004-001 CONTROL MODULE PSU 3 2.2 K EOL 0.480A Initiator RRM Remote Release Module SLC TO NEXT DEVICE OR FACP AUX. FROM PREVIOUS DEVICE OR FACP Blk A BA B PC LINE ASM Signal Module 2 RELEASE 1 TB12 Red A BA B PC LINE 5 4 3 2 3 2 1 SLC FROM PREVIOUS DEVICE OR FACP AI Monitor Module 1 PC (+) PROGRAMABLE RELAY CONTACT PC PC PC PC SW SW LED LED (+) (-) (+) (-) A B (+) (-) 7 6 5 NC 4 C PC (- ) PC (-) NO PC ( +) AO Relay Module N/C COM N/O TB12 1 AI MODULE POWER SUPPLY TROUBLE 2.2 K EOL 5K In-Line Releasing Device (Locate as close as possible to solenoid) Blk Solenoid SOLENOID AND INITIATOR WIRING IR3 WIRING DETAIL DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: DATE APPD. PROJECT NUMBER: SHEET NO. OF -60d -50d 147mm -45d 76.23mm -40d -35d -30d -20d 238mm 76.2mm 100mm -10d IR3 FLAME DETECTOR PLUS TILT MOUNT DETAIL 100% 90% 80% 70% 60% 50% NTS 10d 150' 20d 30d 35d 100' 40d 45d 50d 60d IR 10' 185cd W F 48" 7' 150' CONE OF VISION VERTICAL FIELD OF VIEW NTS GENERAL ELEVATION NTS 20d H -30d -35d 30d 35d 80% -40d -45d E BL 40d 45d 70% 50d RM OU A AL TR N IN I R R TO TO C E TEC T E DE D E E M AM A FL FL 3 3 IR IR T -50d 60d R EA OUTPUTS AND CONTROLS LI N 50% -60d 150' H EA 60% H C IT SW SW RE R U PE SS M E TA PR EM TEM T S S SY SY AM AM O F FO R R FO FO E E G G U LU L DE DE DE AC TE TI C TI SY VA O N ST TIO BA EM N TT T OF G ER RO M RO Y U A B IN O UN FAU LE TE PE D N L AN LO N C FA T C U SS IR L E T C BY M O U IS F IT PA SI P F SS N RI AU G M L DE AR T VI Y C PO E PR W EER PR AC E TI PU -AC ON LL TIO PR FO S N ES AM TAT TA SU DE H IO MP RE LU OS N ER S G E SW WIT E L FO IN IT CH E C R H FO AC AM TIV A H TIO O SE N LI N E PR ES SU RE 90% C IT H -20d INPUTS AND ACTIONS 10d IT C 100% SW -10d ACTIVATE HORN/STROBE NOTIFICATION APPLIANCE FOAM SYSTEM ZONE ACTIVATE WATER FLOW NOTIFICATION APPLIANCE FOAM SYSTEM ACTIVATE WATER FLOW NOTIFICATION APPLIANCE PRE-ACTION SYSTEM LOCK-OUT RELEASE CIRCUITS FOAM SYSTEM ZONE ACTIVATE SOLENOIDS (TYP. 3) FOAM SYSTEM ZONE SEND FOAM SYSTEM WATER FLOW SIGNAL TO BUILDING FIRE ALARM CONTROL PANEL ACTIVATE SOLENOID PRE-ACTION SYSTEM ZONE SEND ALARM SIGNAL TO BUILDING FIRE ALARM CONTROL PANEL SEND TROUBLE SIGNAL TO BUILDING FIRE ALARM CONTROL PANEL SEND SUPERVISORY SIGNAL TO BUILDING FIRE ALARM CONTROL PANEL 150' ACTIVATE SOLENOID FOAM HOSE LINE ACTIVATION STATIONS CONE OF VISION HORIZONTAL FIELD OF VIEW NTS SEQUENCE OF OPERATIONS DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: DATE APPD. PROJECT NUMBER: SHEET NO. OF ??? N IR HANGAR BUILDING 3401 IR3 DETECTOR AREA OF COVERAGE PLAN 1/16" = 1'-0" DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: DATE APPD. PROJECT NUMBER: SHEET NO. OF IR 11 AI ALARM AI AI TROUBLE AI ALARM 12 IR TROUBLE 10 EOL 6 185cd EOL 185cd EOL 185cd EOL 185cd 6 8 7 AI ALARM AI TROUBLE IR IR ALARM AI TROUBLE AI ALARM IR AI 7 10 d 12 12 12 AI 5c 18 185cd F 16 AI TROUBLE 10 8 185cd 185cd 185cd 13 14 11 IR J 4 5 185cd EOL ALARM AI TROUBLE 12 12 J 4 185cd 7 AI F 16 AI ALARM AI TROUBLE IR IR 4 J 4 AI ALARM AI TROUBLE NACB AO AI AI J 8 185cd 1 185cd 9 2 1 15 CP 4X4 NACA AO AI 14 5 185cd 9 EOL 185cd 12 11 AI ALARM AI ALARM IR AI TROUBLE AI TROUBLE IR PROPOSED FOAM CONTROLS LAYOUT PLAN N NOTES: 1. RELOCATE THE EXISTING FENWAL NET 6000, PROTECTOWIRE PANEL AND PULL STATION LOCATED ON THE EAST WALL OF THE FOAM RISER ROOM. TO THE SOUTH WALL, ADJACENT THE TRANSFORMER. 2. ALL DEVICES SHOWN HERE ARE LOCATED IN THE FOAM RISER ROOM FOR ADDITIONAL MONITORING POINTS SEE THE SINGLE LINE DRAWING FP-1 3. ALL CONDUIT SHALL BE RUN AT 10'-0" AFF. 4. RISE APPROXIMATELY 90' TO HANGAR CEILING. 5. NAC A-1. 6. NAC A-2. 7. NAC A-3. 8. NAC B-1. 9. NAC B-2. 10. NAC B-3. 11. NACA - AUX 12. NACB - AUX 13. TO BE LOCATED IN CONDITIONED SPACE. PROVIDE ADEQUATE HEAT BY OTHERS. 14. PROVIDE 90 HOURS STANDBY WITH 5 MINUTES IN ALARM BATTERY BACK-UP. 15. REPLACE THE EXISTING BATTERIES WITH 33 Ahr AT FENWALNET 6000 CONTROL PANEL. 16. FOAM HOSE LINE ACTIVATION STATION. AI 1/16" =1'-0" DATE: DESIGN: DRAWN: CHECKED: REVISION NUMBER: SCALE: DATE APPD. PROJECT NUMBER: SHEET NO. OF