Infrared Windows and NFPA 70

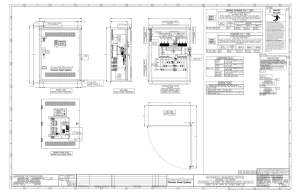

advertisement

Infrared Windows and NFPA 70 Martin Robinson CEO IRISS, Inc. 1 2 1 3 4 2 5 6 3 7 8 4 9 10 5 11 12 6 13 14 7 NFPA 70E Tasks & Hazard/Risk taken from Table 130.7(C)(9) 15 NFPA 70E Table 130.7(C)(11)2 16 8 17 NFPA 70E 18 9 19 20 10 IR Window Program Cost Analyses 21 Electrical Panel Removal Man-hours • 3 Man Live Electrical Thermography Team consists of: – 2 x Electrical Engineers: – 2 x Electricians for panel removal – 1 x Infrared Themographer (Contracted) Time For Live Inspection 1 hour 6 minutes (excludes PPE Suit‐up Time) 22 11 Cost Analysis of Energized IR Survey Removing Panels Operation Man Hours Total Man Hours Rate ($/hr) Thermographer PPE Suit-up 0.5 0.5 $150 $75.00 Electrician PPE Suit-up 0.5 1.0 $125 $125.00 Manpower Costs Per PPE Suit-up As Per NFPA 70E = Operation Total $200.00 Man Hours Total Man Hours Rate ($/hr) Cover Removal 0.5 1.0 $125 Total $125.00 Infrared Inspection 0.1 0.1 $150 $15.00 Cover Replacement 0.5 1.0 $125 $125.00 Thermographer Waiting Time 1.0 1.0 $150 $150.00 Electrician Waiting Time 0.1 .2 $125 $25.00 Manpower Costs Per Inspection of 1 Electrical Panel = $450.00 Total Manpower Costs Per Inspection of 1 Electrical Panel = $650.00 23 Cost Analysis of Energized IR Survey Using IR Windows Operation Man Hours Total Man Hours Rate ($/hr) Thermographer PPE Suit-up 0 0 $150 Electrician PPE Suit-up 0 0 $125 Manpower Costs Per PPE Suit-up As Per NFPA 70E = Operation Total $0 $0 $00.0 Man Hours Total Man Hours Rate ($/hr) 0 0 $125 $0 Infrared Inspection 0.15 0.5 $150 $22.50 Cover Replacement 0 0 $125 $0 Thermographer Waiting Time 0 0 $150 $0 Electrician Waiting Time 0 0 $125 Cover Removal Manpower Costs Per Inspection of 1 Electrical Panel = Cost of IRISS VPFR 75 (3 inch diameter) Infrared Inspection Window Year 1 Manpower Costs Per Inspection of 1 Electrical Panel = Total $0 $22.50 190.00 $212.50 24 12 5 Year Cost Benefit Analysis $ Savings Per Inspection Total % Saving $212.50 $437.50 67% $235.00 $1,065.00 82% $1,950.00 $257.50 $1,692.50 87% $2,600.00 $280.00 $2,320.00 89% $3,250.00 $302.50 $2,947.50 91% Cumulative Cost Without IR Windows Cumulative Cost Using IR Windows Year 1 $650.00 Year 2 $1,300.00 Year 3 Year 4 Year 5 Period • Example shows a saving of nearly $3,000.00 over a 5 year period (91%) for 1 cable compartment in a Medium Voltage Electrical Panel 25 Cost Analysis For Paper Mill Scenario: Paper Mill “X” currently have 150 pieces of primary switchgear that they inspect annually (due to intrusive nature of the inspection). These inspections are currently completed “ENERGISED” in line with the requirements of NFPA70E & 70B. (full PPE and Strict guidelines on how inspections are completed) Inspection is completed by 2 Plant Electricians ( required for panel removal) and 1 Contract Thermographer. Inspections currently take approximately 150 hrs (3 weeks) 26 13 Cost Analysis of Energized IR Survey Removing Panels Operation Man Hours Total Man Hours Rate ($/hr) Thermographer PPE Suit-up 0.5 0.5 $150 Total $75.00 Electrician PPE Suit-up 0.5 1.0 $125 $125.00 Manpower Costs Per PPE Suit-up As Per NFPA 70E = $200.00 21 Days, 2 suit-ups per day (42 total dress-outs = 63.0 hrs) $8,400.00 Operation Man Hours Total Man Hours Rate ($/hr) Cover Removal 0.5 150.0 $125 $18,750.00 Total Infrared Inspection 0.1 15.0 $150 $2,250.00 Cover Replacement 0.5 150.0 $125 $18,750.00 Thermographer Waiting Time 1.0 150.0 $150 $22,500.00 Electrician Waiting Time 0.1 30.0 $125 $3,750.00 Manpower Costs of 150 Electrical Panels = $66,000.00 Total Manpower Costs Per Inspection of 1 Electrical Panel = $74,400.00 27 Cost Analysis of Energized IR Survey Using IR Windows Operation Man Hours Total Man Hours Rate ($/hr) Thermographer PPE Suit-up 0 0 $150 Total $0 Electrician PPE Suit-up 0 0 $125 $0 Manpower Costs Per PPE Suit-up As Per NFPA 70E = Operation Man Hours Cover Removal Total Man Hours Rate ($/hr) $0 Total 0 0 $125 $0 Infrared Inspection 15.0 15.0 $150 $2,250.00 Cover Replacement 0 0 $125 $0 Thermographer Waiting Time 0 0 $150 $0 Electrician Waiting Time 0 0 $125 $0 Manpower Costs Per Inspection of 1 Electrical Panel = $2,250.00 Cost of 150 IRISS VPFR 75 (3 inch diameter) Infrared Inspection Window = $28,500.00 Year 1 Manpower Costs Per Inspection of 1 Electrical Panel = $30,750.00 28 14 5 Year Labor Savings: Cost Analysis Period Cumulative Cost Without IR Windows Cumulative Cost Using IR Windows $ Savings Per Inspection Total % Saving Year 1 $74,400.00 $30,750.00 $43,650.00 59% Year 2 $148,800.00 $33,000.00 $115,800.00 78% Year 3 $223,200.00 $35,250.00 $187,950.00 84% Year 4 $297,600.00 $37,500.00 $260,100.00 87% Year 5 $372,000.00 $39,750.00 $332,350.00 89% • Example shows a saving of $332,350.00 over a 5 year period (89%) for 150 cable compartments in a Medium Voltage Electrical Panels 29 Increased Inspection Frequency: 5 Year Cost Analysis: Inspection Frequency Cumulative Cost Using IR Windows $ Cumulative Savings Total % Saving Annual $39,750.00 $332,350.00 89% 6 Monthly $51,000.00 $321,100.00 86% 4 Monthly $62,250.00 $309,850.00 83% 3 Monthly $73,500.00 $298,600.00 80% • Example shows that using IR windows you can increase your inspection frequency by a factor of 4 and the 5 year program cost is less than the original Annual “Energized” inspection 30 method 15 Infrared Inspection Case Study 31 Case Study 1: 8.3 kV Load Interrupter Switch Feyen‐Zylstra, LLC Electrical contractors, a TEGG services contractor secured an Electrical Preventative Maintenance contract (EPM) with the Bradford White Corporation. The maintenance agreement included a value added product and service comprising of the installation of 40 4inch IRISS infrared windows during a scheduled maintenance shutdown. A crew of 11 technicians completed the installation of the IR windows on the 1st July as well as performing cleaning and housekeeping tasks on the High Voltage equipment. A sample of the newly installed IR window is shown: During the second week of service (11th July) the Feyen‐ Zylstra technicians identified a fault using the newly installed IR windows on the B Phase of 14.4 KV 200 Amp fuse. At this time the fuse displayed max temp of 65 °C. 32 16 Case Study 1: 8.3 kV Load Interrupter Switch Due to the nature of the fault it was decided to monitor the component closely. Another IR inspection was completed on the 31st July, the results were results were alarming as the problem temperature had risen to 508 °C, an increase indicating a significant and accelerated deterioration of the assembly Image taken through the Plexiglas window shows at this stage the fault was in fact luminescent 33 Case Study 1: 8.3 kV Load Interrupter Switch Once the Fault had been identified an immediate shutdown was planned. This entailed putting in place a temporary generator system to allow for production to continue whilst the repair was completed As soon as the temporary generator system was in operation the switchgear was made safe and the repairs were allowed to be completed with minimal disruption to plant operations and 34 production 17 Case Study 1: 8.3 kV Load Interrupter Switch As soon as the switchgear was opened it became apparent that the original suspicions and analysis was right on the mark. The fuse itself was visually discoloured from the heat damage The fuse clamp assembly was burnt and the plastic tightening knob was melted off its mount and was found lying in the bottom of the enclosure. 35 Case Study 1: 8.3 kV Load Interrupter Switch Before the Repair the temperature was in excess of 500 °C After the Repair the temperature is approximately 50 °C 36 18 Case Study 1: 8.3 kV Load Interrupter Switch Cost Savings The decision to include IR Windows in the maintenance agreement proved to be priceless. Had they not been installed this fault would have probably gone undetected, especially as the maintenance had just been completed on the switchgear!!! Identifying the fault allowed the maintenance teams to plan the maintenance shutdown, order parts, manpower etc… with no loss in production time. The cost to the plant in loss of production revenue would have run into several million dollars! 37 38 19 Questions???? Visit www.iriss.com and download your free copy of: “10 Things you Need to Know About Infrared Windows” 39 20