power electronic systems design co-ordination for doubly

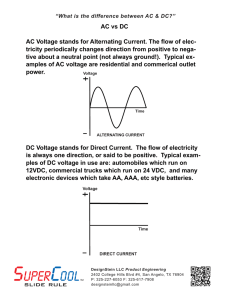

advertisement