ECI Facility Integration Technology

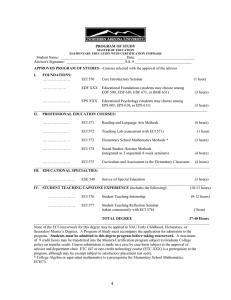

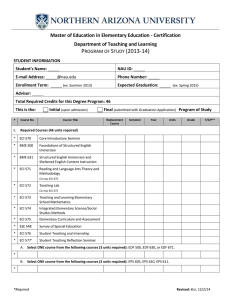

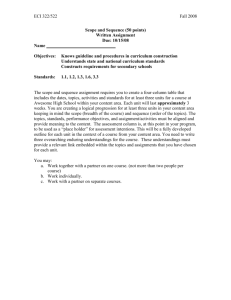

advertisement