A systems model for commercialising emerging technology: wave

advertisement

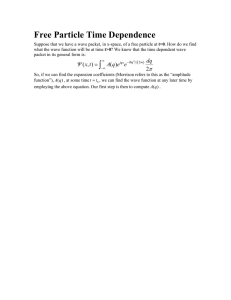

Int. J. Industrial and Systems Engineering, Vol. 14, No. 4, 2013 A systems model for commercialising emerging technology: wave energy farm system (WEFS) case study Oscar Bonilla*, Donald N. Merino, Michael Raftery, Tamara Wainer and Rashmi Jain School of Systems and Enterprises, Stevens Institute of Technology, Castle Point on Hudson, Hoboken, NJ 07030, USA E-mail: oscarbonilla100@gmail.com E-mail: dmerino@stevens.edu E-mail: michaelwraftery@hotmail.com E-mail: tamarawainer@hotmail.com E-mail: rashmijain@verizon.net *Corresponding author Abstract: This paper proposes a systems life cycle model that could be used to analyse the commercial feasibility of emerging technologies development. The model is based on a comprehensive review of the literature on the key factors impacting the success or failure in commercialising technology. The proposed systems model includes a technical, economic and operational domain and covers a project’s planning, project implementation and feedback, analysis and control phases. This model was applied to a case study, a wave energy technology, with a concentration on the economic domain. The economic domain includes an after tax analysis model, which a typical company uses to assess economic feasibility and a sensitivity analysis that identifies the most important attributes. The internal rate of return (IRR) and other figures of merit (FoMs) were used to show whether the project meets standard business criteria. This case shows how financial leverage significantly improves a project’s economic attractiveness. Keywords: technology commercialisation; systems model; commercialising emerging technology; renewable energy; wave/ocean energy farm; systems engineering; after tax analysis; ATA; engineering economics; internal rate of return; IRR; net present value; NPV; life cycle costs; LCC/EUAC. Reference to this paper should be made as follows: Bonilla, O., Merino, D.N., Raftery, M., Wainer, T. and Jain, R. (2013) ‘A systems model for commercialising emerging technology: wave energy farm system (WEFS) case study’, Int. J. Industrial and Systems Engineering, Vol. 14, No. 4, pp.441–462. Biographical notes: Oscar Bonilla is a PhD student of engineering management at Stevens Institute of Technology. He obtained his Bachelor in Automation Engineering from La Salle University, Colombia, Masters in Industrial Processes’ Automation from Los Andes University, Colombia, and Masters in Business Administration from Stevens Institute of Technology, Hoboken – New Jersey. He has over ten years of professional experience in industry areas like six sigma, project management, maintenance management, Copyright © 2013 Inderscience Enterprises Ltd. 441 442 O. Bonilla et al. lean manufacturing, continuous processes’ improvement, and project financial analysis. Currently, he serves as financial analyst for the information technology industry. Donald N. Merino is a Tenured Full Professor and the Alexander Crombie Humphreys Chaired Professor of Economics of Engineering at Stevens Institute of Technology. He is the Founder Emeritus of the undergraduate Bachelor of Engineering in Engineering Management and the Executive Master in Technology Management programme at Stevens. He won the Morton Distinguished Teaching Award for Full Professors at Stevens, was awarded the ASEM and ASEE Bernard Sarchet Award, and received two centennial certificates from the ASEE in Engineering Economics and Engineering Management. John Wiley published his book, The Selection Process for Capital Projects and he has published over 50 refereed journal articles and conference papers and over 30 research reports. Michael Raftery is Founder and CEO of Seahorse Power and Research Engineer at the Center for Maritime Systems at Stevens Institute of Technology. He is an active member of the Technical Advisory Group for the National Renewable Energy Lab and advises on standards for the wave energy industry. He is a member of the Society of Naval Architects and Marine Engineers and holds a Masters of Ocean Engineering from Stevens Institute of Technology and Bachelors in Oceanography from Humbolt State University. He is a former US Navy Deep Sea Diver and Underwater Construction Technician. Tamara Wainer is a Director in Global Risk Management at a Big 4 public accounting firm and has held several positions in tax consulting in the USA and Amsterdam. She is a graduate of the Executive Master in Technology Management (EMTM) programme at Stevens Institute of Technology with an MBA and Bachelor in Economics and Politics from Brandeis University. Rashmi Jain is an Associate Professor of Systems Engineering at Stevens Institute of Technology. She has over 15 years of experience in information technology (IT) systems. Prior to joining Stevens, she was with Accenture (formerly known as Andersen Consulting). Over the course of her career, she has been involved in leading the implementation of large and complex systems engineering and integration projects. She has done lectures internationally at Keio University, overseas Chinese Institute of Technology (OCIT), and Indian Institute of Technology, Delhi. She is a Visiting Professor for System Architecture and Integration at Keio University. Her teaching and research interests include systems integration, systems architecture and design, business process reengineering and rapid systems engineering. She has authored several papers on these topics. She holds a PhD and an MS in Technology Management from Stevens Institute of Technology. 1 Systems model introduction Emerging technologies face several barriers to commercialisation. For instance, in the quest to achieve energy independency and to reduce greenhouse gases (GHG) emissions many technologies have been developed that are more efficient than others but most of them have not been commercialised despite their technical feasibility or demonstrated A systems model for commercialising emerging technology 443 potential. It is clear that a broader approach is needed to successfully commercialise these types of emerging technology. A systems life cycle model to commercialise emerging technologies is proposed based on a review of the literature for the last 20 years (see sub-Section 2.1). Three major domains are explored, technical, operational, and economic. The focus of this paper is on the economic domain. An economic after tax analysis (ATA) model was developed to explore the economics of a patented wave energy conversion device. The financial results demonstrate that the technology meets standard business criteria. The sensitivity analysis (SA) indicates that electricity revenue, cost of capital, and the total capital costs are the dominant factors. The financial leverage analysis indicates that as loan amounts increase, the economics significantly improve. Since capital intensive projects like this would be financed this would add to the project’s economic attractiveness but would also add to the project’s financial risk. 2 Review of literature 2.1 Key factors for commercialising new/emerging technology Commercial development of renewable energy technology began since the early 1990s, but yet the amount of modern renewable energy only accounts for 1% of the world’s energy demand (Pinkze and van den Busee, 2012). It is a clear indicator that commercialising new and emerging renewable energy technologies is still a problem that needs to be addressed. A major obstacle to commercialising new technologies like renewable energy is the length of time to scale the technology from pilot plants to commercial production. There is a need to quickly commercialise beneficial technologies to abate GHG and alleviate the increasing demand for energy (Johnson, 2009). The demand for renewable energy is driving several alternative energy solutions, not all of which are carbon-free. Therefore, it is critical to be able to develop and commercialise technologies quickly. To do this a concurrent engineering approach must be appropriately designed and implemented; there is evidence that its successful implementation reduces the technology cycle time and time-to-market (Sharma, 2004). One of the most dominant factors for technology commercialisation failure is the unfavourable economic performance (Kimura, 2010; Patterson, 1992; Pinkze and van den Busee, 2012). Moreover, the factors resulting in the failure of commercialisation and diffusion are classified into five patterns: 1 unfavourable performance of the technology, such as low efficiency and lack of reliability 2 unfavourable economic performance, i.e., high cost and long payback period 3 organisational changes, such as restructuring and shifts of business strategy 4 market changes, which refer to unexpected changes in market demand 5 regulatory changes, such as the tightening of environmental regulations (Kimura, 2010). Major impediments to achieving commercial viability of new technology were found in the mid ‘80s during the adoption of compressed natural gas as an alternate transportation 444 O. Bonilla et al. fuel in Canada (Flynn, 2002). The lack of supporting infrastructure and poor design of promotional programmes, known as the marketing strategy, limited the acceptability and adaptability of the emerging technology in the market. On the other hand, commercialisation and diffusion in the market can be expedited and successful if all of the key factors are considered and dealt with in a concurrent rather than a sequential manner. Examining successful cases published in the literature, reveals that most of the key factors can be identified as well as those driving the technology to fail in the market. Table 1 summarises the key factors for success/failure in the commercialisation/diffusion of new and emerging technologies for relevant studies published over the last two decades. Such factors such as public R&D, long-term R&D support by the government, a marketing and diffusion strategies to respond to and influence market demand, investment subsidy, and combination of R&D and deployment policy were the key factors to accelerate the commercialisation of energy-efficient technologies in Japan during the ‘80s and ‘90s (Kimura, 2010). Energy efficiency policy is a fundamental factor for successful commercialisation of new technologies in the energy area and must be considered. Both developers and government have to work together to allow technologies to be diffused and to allow markets to accept them. Government plays a crucial role in renewable energy commercialisation, while it is essential for government to promote deployment of technologies that are already on the market by regulations and financial incentives such as subsidies, it is also important to stimulate research and development (R&D) to supply new, innovative energy efficient technologies by publicly funded R&D (Geller et al., 2006). Subsidies not only reduced the relative cost disadvantage of new technology against conventional technology, but also increased market volumes and thus stimulated technology learning (Kimura, 2010). Another key factor for successful commercialisation of new technology that has been broadly discussed in the literature is market segmentation and strategy (Balachandra et al., 2010). Commercialisation is the process whereby the technology comes to play a useful role in society, ‘commercialisation’ is thus a quintessential ‘market’ concept, if the price is too high, people will not buy the technology; if the price is too low, the manufacturers will gain no benefit from selling it, and will stop (Patterson, 1992). Therefore, knowing the market and defining a niche is a fundamental factor to address. In new technology commercialisation there are a few users who put high value on innovativeness or environmental friendliness of the technologies which at first are much more expensive than conventional technologies. These are innovators or early adopters in the diffusion process of the technology (Rogers, 2003), and form the initial market on which the developers can expand their marketing activities. Market development based on the feedback from market experience proved to be indispensable (Pinkze and van den Busee, 2012). It is possible to identify success/failure factors for some of the renewable energy technologies that have made their way through commercialisation such as solar, both thermal and photovoltaic (PV) and wind. The Luz International Limited (LUZ) is one of the world’s most successful company in commercialising solar power plants for the utility sector with 95% of the world’s solar generated electricity (Lotker, 1991). In a study conducted on solar energy, the analysis suggests that it is uncertain whether all oil and gas firms will abandon the commercialisation of solar PV technology completely, as this depends to what extent they are able to generate profits (Pinkze and van den Busee, 2012). This study highlights the importance of economic feasibility in the process of A systems model for commercialising emerging technology 445 commercialising an emerging technology. Investments in solar PV increased extensively after 2000 due to increased cell efficiency (technology improvement), reduced capital costs (economic feasibility), and favourable policy, leading to annual growth in grid-connected solar capacity of 60% from 2002 onwards (REN21, 2008) whereas wind had an average annual growth rate of 25% from 2002 to 2006 (REN21, 2008). Understanding the success factors is an opportunity for technologies such as wave energy which indirectly depend on wind currents to generate energy. Though, solar technology has proven to be efficient there is still a lot of uncertainty regarding its economic benefits. There are many solar plants out there but yet only few are making money. It is a major treat for the environment because the oil industry is leaving solar and positioning towards a ‘re-carbonisation’ of business activities. Hydrogen or fuel cells (FC) technology on the other hand, has proved to be economically feasible on certain applications such as bus public transportation (Bonilla and Merino, 2010). Although, it is currently in a pre-commercial phase of development with a lack of cost and performance competitiveness, current high costs and the predicted gradual cost reduction are likely to imply slow market acceptance (Hellman and van den Hoed, 2007). Table 1 summaries the literature review for the key factors impacting the success or failure of technology commercialisation or diffusion. Table 1 Key factors for success/failure in commercialisation/diffusion of new and emerging technologies Author(s) Year Lotker 1991 Patterson Flynn 1992 2002 Rogers Sharma Geller et al. Hellman and van den Hoed Balachandra et al. 2003 2004 2006 2007 Kimura Pinkze and van den Busee Key factors for success/failure in commercialisation/diffusion Government tax policy, avoided cost energy pricing, lack of incentives to utility owners, lack of recognition to environmental benefits Timing, cost Lack of supporting infrastructure, marketing strategy, subsidies Market segmentation, cost Concurrent engineering approach Energy efficiency policy Lack of cost and performance competitiveness 2010 Market strategy, market-based approaches, private sector driven business model, innovative regulatory, financing 2010 Public R&D, long-term R&D support by the government, marketing and diffusion strategies, investment subsidy, R&D and deployment policy, technology performance, economic performance, business strategy, market changes, regulatory changes/policy 2012 Profit, economic feasibility Domain Economic, policy Technical, economic Operational, economic, policy Operational, economic Policy Economic, technical Operational, economic Technical, economic, operational, policy Economic 2.2 Systems perspective on commercialising new technology A systems perspective provides the life-cycle approach to design, development, implementation, maintenance, support and retirement of systems. A system life-cycle 446 O. Bonilla et al. begins from its conception and ends in its retirement or disposal (Lang and Merino, 2002). Circulating fluidised-bed combustion (CFBC) for instance, is a textbook example of how to commercialise a new energy technology and an example of a systems life cycle approach, where every aspect of the technology was investigated, from fuel handling to waste disposal (Patterson, 1992). Therefore, understanding the systems perspective to commercialising a new technology is the first step (Blanchard, 2004; Parnaby, 1955). Systems engineering has been defined in several different ways – each having its own flavour. NASA views it as a robust approach to the design, creation, and operation of systems. It is the management of technology that controls a total system life-cycle process, which involves the definition, development, and deployment of a system that is high quality, trustworthy, and cost-effective in meeting user needs (Sage and Armstrong, 2000). The Mil-Std defines it as the application of scientific and engineering efforts to: 1 transform an operational need into a description of system performance parameters and a system configuration through the use of an iterative process of definition, synthesis, analysis, design, test, and evaluation 2 integrate related technical parameters and ensure compatibility of all related, functional, and programme interfaces in a manner that optimises the total system definition and design 3 integrate reliability, maintainability, safety, survivability, human, and other such factors into the total technical engineering effort to meet cost, schedule, and technical performance objectives. From an industry life cycle perspective, two main phases in industry evolution can be identified: a formative period and a market expansion period. The formative period is characterised by uncertainty in technologies, markets, and regulations, whereby a range of competing technology designs exist. Market formation on the other hand is characterised by growth in multiple niche markets for which the technology is superior (Jacobsson and Bergek, 2004). From the systems engineering perspective, some approaches and frameworks have been proposed to minimise technology uncertainty and the product/technology development time to allow market expansion. Reverse engineering (RE) is one of them (Dereli et al., 2008), though renewable energy technology is emerging there are so many of the shelf components involved for which RE and systems cost integration can be leveraged. The rapid systems engineering framework (Jain et al., 2011) and the systems integration framework (SIF) are systems life cycle-based frameworks to reduce development time and to increase technology operational effectiveness. SIF is an end-to-end approach based on the premise that integration occurs in the life cycle of a system, it is not a one-time activity (Jain et al., 2010). An important step in technology commercialisation is to know when it is fully developed and when the system is ready. Knowing this can minimise the time to market and to accelerate its diffusion. This can be accomplished through the use of the technology readiness level (TRL) scale and the systems readiness level (SRL) index. TRL is a measure of maturity of an individual technology, with a view towards operational use in a system context. SRL is a method for determining readiness of a system in the systems engineering life cycle (Saucer et al., 2008). A systems model for commercialising emerging technology 447 Through the use of a system life cycle approach all the domains/phases of a system are integrated concurrently minimising time to market and enhancing technology maturity. The main aim of this paper is therefore to provide a system-based model for the commercialisation of new/emerging technology. 3 System model to commercialise new technology 3.1 Proposed systems model The literature review and examples from the renewable energy area indicate that a broader systems approach is needed to successfully commercialise emerging technologies. Figure 1 illustrates a systems decision model which could be used to examine the development of new technologies. Figure 1 A system model to commercialise new technology 448 O. Bonilla et al. Based on the literature review it is clear that a company or investor needs to analyse all the elements of the model to ensure success. This is not an easy task and will require robust sub models for all the domains and project phases. This paper will concentrate on the economic domain in the planning phase. A brief overview of the various domains will be discussed. However, each domain is complex and needs to be explored more fully. A more comprehensive explanation of the other domains and phases will be explored in subsequent papers. 3.2 General system requirements for model At least three major domains are indicated in the planning phase in Figure 1. They are technical, economic and operational constraints. A key to all of these is the interaction among tasks. Timing and processor/successor relationships need to be carefully considered to develop a robust project plan. Every business venture has three phases, namely, planning, implementing and feedback/analysis together with feedback loops that ensure continuous process improvement and learning. The learning model is essential for efficient operation and for effective future development. Once the technical, economic and operational constraints are considered feasible a business plan is developed, funding is obtained and the project proceeds to the implementation phase. Feasibility criteria should be established at the beginning of the project and used a phase gates. In each case the feasibility is a function of acceptable risk. The implementation phase consists of manufacturing/assembling the system and installing it. Lastly, lessons learned from this enterprise need to be used to formulate future developments. Among the domains, unfavourable economics and unexpected market change seem to be the major factors on the factors for limited diffusion, economics and market factors are almost domain. 3.3 Technical domain The venture starts with conceptual ideas and invention(s). Intellectual property (IP) is usually sought to provide a barrier to entry from other competitors. Developing the IP may require multiple patents and licensing from others. Engineering design is normally aided by computer models (simulations, discrete programmes, etc.). Design and testing are interrelated. As the design progress, models and/or prototypes are used to provide feedback to the models and alter the design. A concurrent engineering process has been shown to both reduce the manpower required as well as the elapsed time to complete the design (Blanchard, 2004; Parnaby, 1955). Another major constraint is the cost of the devise. As the engineering design progresses from the models/calculations to prototypes the accuracies of cost should increase. At each stage of technical development both the cost and risk needs to be developed. Lastly, when the risk is deemed acceptable the technical feasibility is achieved. Risk criteria should be established at the beginning of the project and reviewed at various stages of development. Go or no go decisions should be based on predetermined criteria (Blanchard, 2004). A systems model for commercialising emerging technology 449 At this point in the planning phase of the project the technical capabilities are assessed in order to determine the technology’s feasibility. Once the technical domain has successfully passed through all the steps a decision can be made with respect to the technical domain. Successful outcomes from the economic and operational constraints domains are necessary to proceed with implementation/deployment. 3.4 Economic domain –ATA The major emphasis of this model is on determining the economic feasibility of a new technology, as previously found in several studies, the economic feasibility was determined to be the major factor for technology commercialisation success. Figure 2 illustrates a typical after tax process used in industry to determine economic feasibility (Lang and Merino, 2002). Figure 2 General decision model to determine economic feasibility Economic Feasibility Model – Business Cases 450 O. Bonilla et al. 3.5 Operational domain This domain includes a number of important operational constraints that new technologies need to satisfy in their operational environment. These constraints are extremely critical to their successful deployment and sustainability. Issues such as global warming, security, reliability, maintainability and aesthetics provide constraints for power generation projects. Risk determination of the technical, economic and operational constraints requires detailed analysis. 4 Business case study for a wave energy harnessing device system: economic feasibility 4.1 Introduction for business cases World energy demand has steadily increased over the last 50 years. The slope of the demand curve has increased due to rapid industrialisation in a number of countries such as Brazil, Russia, India and China (BRIC countries) (Energy Information Administration, 2009). Exaggerated fossil fuel use has increased the amount of green house gases (GHG) in the atmosphere resulting in global warming. Global warming has been discussed for almost a decade with scientific and political opinions varying widely, particularly in the USA. The United Nations Intergovernmental Panel on Climate Change report that states “global warming is a serious issue and alternative to fossil fuels are required to reduce GHG emissions” (Bernstein et al., 2007). There have been a wide variety of solutions ranging from limiting demand (conservation) to producing energy with little or no carbon footprint. Wave energy is one of the emerging technologies that could lead to electricity production without using fossil fuels. 4.2 Use of after tax model – Figure 2 for business cases Though every factor is important towards commercialisation, the economic domain is one of most important and is usually explored first or in parallel with the technical domain. See Appendix A for a more detailed description of the technology. This paper concentrates on determining the economic feasibility of the wave energy harnessing device (WEHD) using business case economics. There are many methods to determine the economics of electricity produced from renewable and non-renewable sources (Kammen and Pacca, 2004). The ATA method is widely used by utilities and industrial companies (Lang and Merino, 2002) – see Figure 2. An economic decision model was used to determine the economics. It required an ATA framework with capital and cost estimated for the WEHD. This was not a static model but was run numerous times to help refine the estimates and evaluation. In addition, cost sub-models were developed that automatically updated the main model. For example, as more refined cost estimates became available they were entered into the cost sub model which updated the main model. Another major advantage of the ATA approach with sub-models is that it helps optimise engineering design as it is being developed. For instance, should additional hardware capital be spent to increase the equipment life from seven years to ten years, the ATA will produce the NPV or internal rate of return (IRR) or EUAC incremental A systems model for commercialising emerging technology 451 difference. If the difference meets the economic criteria it should be pursued. This incremental analysis can also be used to provide ‘targets’ or ‘goals’ which would guide engineering design. These approaches are examples of a Concurrent Engineering approach outlined in Figure 1. Figure 2 is a description of a typical ATA decision process. ATA is necessary because the government is a de facto ‘partner’ in capital decisions since depreciation rates, tax rates, investment tax credits and capital gains taxes greatly influence the attractiveness of capital expenditures. In addition, future investors need to determine the rate of return [or other figure of merit (FoM)] of their investment before committing to the project. This is true for private as well as public companies. 4.3 Scenarios and alternatives trade-offs The first step in determining the business case and economic feasibility is to develop possible alternatives that are mutually exclusive. In this case, two alternatives were explored including wave farms of 500 megawatts (MW) and 1,000 (MW) plate capacity. Trade-off analysis is conducted of the different alternatives by analysing their ability to support the required operational scenarios. 4.4 Cost estimation – capital-related – see Table 2 For new technologies estimating the capital required is the most difficult task. By definition they do not have an established set of capital and operating costs. As indicated in the technical domain, cost estimation is an evolutionary process. As the design matures, the cost estimates become substantiated. Table 2 WEHD capital cost estimates Cost description WEHD system Cost estimate (k$) 500 MW 1,000 MW 1,528,649 2,780,416 Anchoring system hardware 12,320 22,400 Electrical distribution system 232,198 284,222 Installation cost and oil fill 41,500 80,000 1,814,668 3,167,038 Total capital cost Note: The estimates are for 2009 in USD$. For this case study estimates were based on discussions with vendors and industry subject matter experts (SMEs). These estimates tend to be plus or minus 30%. To further refine the estimates requires the following: 1 Detailed parts list for equipment including size of parts, number required and material specification 2 Technology identification as commercial, emerging or new. Commercial suppliers should be identified together with catalogued costs and features. 452 O. Bonilla et al. 3 Determination of size impacts on part costs. Sizing techniques such as using the Boston Consulting Group (BCG) curves and/or the Lang factor (Lang and Merino, 2002) could be used to estimate the cost of a larger part. 4 Determination of economies of scale through the learning curve can be applied to pricing multiple units. Rules of thumb are used for engineering design, environmental studies and other capital related costs. Installation plans and associated budgets provide the basis for these estimates. For this particular case, most of the capital expenditure is for commercial off-the-shelf (COTS) parts already in use in a marine environment. Assembling these items will require some engineering design. Overall, the range of cost estimates should be relatively low. 4.5 Cost estimation – operating costs – see Table 3 Development of the facilities, installation plans and associated budgets are required to estimate fixed and variable operating costs. Some rules of thumb for items such as insurance and taxes are also used. Table 3 WEHD operating cost Cost description Cost estimate (k$/yr) 500 MW 1,000 MW Fixed costs 2,002 2,002 Maintenance costs 14,185 24,696 Other yearly fixed costs 33,192 55,386 Total operating yearly costs 49,380 82,084 Notes: The estimates are for 2009 in USD$. Variable costs were estimated to be zero (or economically insignificant) because the case is a 24/7 engineering operation. 4.6 Revenue estimates – see Table 4 The key revenue estimate is the sales price of electricity. The actual electricity revenue will depend upon the location, the utility involved and other factors. This business case includes all the transmission lines and control equipment to deliver the energy to the system so the sales price would be closer to retail than wholesale. With national distribution of electricity it is difficult to estimate the location. The wave farm in this case would probably be located off the Pacific or Atlantic coasts of the USA. Electricity costs in the Northeast and California coastal areas are higher than in the middle of the USA. Thus, the 10 cents per kWh is a conservative estimate. A systems model for commercialising emerging technology Table 4 453 Electricity costs in USA Electricity cost New England – all sectors – retail Date Amount (c$/kWh) April 2009 12.24 USA – all sectors – retail April 2009 9.30 Base case 500/1,000 MW 2011–2012 10.00 Note: Estimates are in cents USD$. Source: Average retail price of electricity to ultimate customers by end – use sector, by state, April 2009 and 2008. From the DOE/EIA Energy Report (Energy Information Administration, 2009, Table 5.6.A) 4.7 ATA – economic criteria – see Table 5 The first step is to determine the minimum attractive rate of return (MARR) an electric utility company would use to evaluate this case. The MARR reflects the opportunity cost for the investor’s capital. Risk plays a role because wave energy investments will involve more risk than others until the technologies have an operational track record. Since this study focuses on the ATA an applicable tax rate needs to be estimated for the chosen time horizon. A time horizon needs to be determined that reflects the project life. The ATA starts with a base case where the owner uses 100% of their own capital (e.g., full equity). Next financial leverage is explored at various levels of loans and equity. What level of loans and equity capital is chosen depends upon the availability of financing, risk of defaulting and other facts. Other criteria are the figures of merit (FoMs). Given that the ATA model is an Excel spreadsheet it is relatively easy to report on more than one FoM. FoMs include the net present value (NPV) and the equivalent uniform annual cost (EUAC). EUAC is also known as the life cycle cost. Table 5 summarises the figures used in the case study. Table 5 WEHD economic model assumptions Assumptions Units 500 MW 1,000 MW MARR/hurdle rate/cost of capital %/yr 12 12 Income tax rate %/yr 35 35 Capital gains tax rate % 20 20 Investment tax credit % 0 0 Loan interest rate %/yr 7 7 Growth rate-revenue %/yr 3 3 Operating-inflation %/yr 2 2 Project life Years 20 20 The most significant assumption is the MARR, which greatly varies by investor and capital projects. 454 O. Bonilla et al. 4.8 Evaluation of non-economic factors This is a major task which involves environmental studies, siting analysis, and risk analyses (technical, economic and operational constraints). While the scope of this paper is limited to the economic feasibility, all these areas must be assessed before commercialisation can occur. There are a number of multi-attribute tools which can be used. Analytical hierarchy process (AHP) and utility analysis are two common techniques (Lang and Merino, 2002). 4.9 Decision process – trade-offs based on sensitivity analysis – see Table 6 Trade-off analysis of the alternative technologies will be based on sensitivity analysis. Such analysis will help determine the most sensitive attributes impacting the decision. This helps in separating the ‘vital few’ from the ‘trivial many’. This is an aid in decision making because it focuses the effort on the most important variables. Table 6 WEHD sensitivity analysis results Attribute used in the ATA model Spread 500 MW a 1,000 MW Sen. ratio Rank 1 6.46 1 30.68 2 5.88 2 +/– 20% 30.01 3 4.97 3 + 20% 22.97 4 4.41 4 Total replacement capital cost 7 and 14 yr +/– 20% 7.44 5 1.29 5 Operating costs +/– 20% 4.7 6 0.74 6 Electricity costs MARR – cost of capital Total capital cost MARR – cost of capital Sen. ratio Rank +/– 20% 34.04 – 20% b a Notes: The ratio provided by the change in parameter with respect to its initial value (base case). b Rank is given by considering the most sensitive variable as number 1 and the less sensitive as number 6. Electricity costs, the cost of capital (MARR) and total capital costs are the most sensitive economic factors in this case. These are not surprising since the WEHD is similar to a hydroelectric plant from an economic perspective. It has high capital costs, low operating costs and no fuel costs. As with hydroelectric projects, siting is important for wave energy projects taking into consideration stakeholder preferences, government regulations, seafloor composition and wave activity. Figure 3 – spider plot, graphically illustrates the sensitivity analysis. Electricity, cost of capital (MARR) and total capital costs have the steepest slopes although in opposite directions. That is, for a given change of the parameter (electricity or capital) there is a relatively large change in the FoM (NPV or IRR or EUAC). Similar changes in the parameters (operating or replacement costs) do not have a relatively large change in the FoMs. The implication of this is that the economic feasibility of this technology is a function of the power purchase agreement, whether the capital cost of the wave farm can be built as estimated and the owner’s cost of capital or MARR. A systems model for commercialising emerging technology Figure 3 455 Spider plots for sensitivity analysis results (see online version for colours) 4.10 Multiple attribute analysis decision process Next, a decision needs to be made whether an economic or non-economic analysis is to be employed. If all the attributes can be monetised and converted into dollars, then the standard ATA with a FoMs such as NPV or EUAC can be used to either maximise benefits or minimise costs. If all the attributes cannot be monetised then some form of non-economic analysis must be employed such as multiple attribute analysis (MAA). MAA was not in the scope of this paper. 4.11 Final decision – FoMs – see Table 7 Lastly, a decision needs to be made to determine whether the analysis yields a mutually exclusive alternative that meets the economic and/or non-economic criteria. If it does, then a decision is made. If it does not, the process needs to be repeated starting with step 1 (Figure 2). This process must continue until a mutually exclusive feasible solution is found. The following results in Table 7 are based on the ATA model developed for this case. The methodology used in this model is similar to that used by major industrial companies and utilities in the USA. Table 7 WEHD economic model (ATA) results FoM Units 500 MW 1,000 MW IRR NPV EUAC %/yr. k$ k$ 12.47 60,459 8,094 14.77 637,230 85,312 The results from this case indicate an acceptable IRR, given the industry MARR used. It should be noted, however, that this analysis is based on 100% equity from the investor. For a project this size, it is almost certain that the owner(s) would borrow a substantial portion of the capital cost. Typically, this could be 40% to 70% or more. The percent of 456 O. Bonilla et al. loan utilised are decided by the utility or joint venture and/or by government agencies. Thus, it must be examined how borrowing a portion of the capital impacts the economics. 4.12 Financial leverage – see Table 8 and Figure 4 The following table provides the FoMs for the two scenarios. As indicated in Table 8, the FoMs increase significantly as the amount of loans increase. Since financial leverage (using loans instead of equity) is commonly used to finance large energy projects this has the effect of improving the project’s rate of return. This is caused by using relatively cheaper after tax loan dollars for relatively more expensive equity dollars in the case where the after tax loan interest rate is less than the after tax IRR. Table 8 WEHD financial leverage Loan (%) Equity (%) Base case 0% 60% 70% 80% 90% 100% 40% 30% 20% 10% NPV (k$) 500 MW IRR (%/yr) EUAC (k$) NPV (k$) 60,459 523,496 600,668 677,841 755,014 12.47 21.62 26.72 37.45 72.06 8,094 70,085 80,417 90,749 101,080 637,230 1,445,053 1,579,690 1,714,327 1,848,964 1,000 MW IRR (%/yr) 14.77 27.04 34.00 48.50 93.01 EUAC (k$) 85,312 193,462 211,487 229,512 247,537 However, increasing the percentage of loans increases the financial risk of default. If the project is not successful (technology does not work, demand for electricity declines, etc.), the financial losses could be substantial and the probability of default increases. There are a number of strategies to offset this risk including purchasing insurance to guarantee the loan. While this would be expensive, the additional economic return from the investment is more than adequate to cover insurance expenses. The following graph illustrates how increasing the loan percentage increases the project’s IRR. Figure 4 Financial leverage results (see online version for colours) A systems model for commercialising emerging technology 457 4.13 Comparison with other technologies – benchmarking Although both scenarios met the economic criteria, there is still the question of how this technology compares with other renewable resources like wind and with the prevailing technology-coal. There is an enormous amount of literature comparing alternative technologies to produce electricity (Kammen and Pacca, 2004). It is beyond the scope of this paper to fully explore all the potential alternative technologies. However, as an example, a comparison with a clean coal project by Duke Energy in North Carolina indicates a $2.45 billion to-date expenditure for a planned 825 MW plant (Downey, 2009). Since 2005, the price of this plant has increased by $400 M with the output reduced by half resulting in costs that are four times the original estimate per watt of output capacity (Duke Energy, 2005). The National Energy Technology Laboratory (NETL, 2007) projections for US coal plant production nationwide are consistent with Duke Energy’s original estimates of $2 billion for 1,600 MW output capacity. It is anticipated that the economic and political drivers for the cost overruns will be pervasive in similar projects. This WEHD project cost of $3.1 billion for a 1,000 MW and $ 1.8 Billion for a 500 MW plant to be built in 2011–2013 is in the same ballpark. Given that most of the hardware for this project is COTS will help mitigate cost overruns. Thus, the capital cost for this WEHD wave farm is in the ‘ball park’ of similar coal plants. With the trend towards coal sequestration the capital costs for coal plants will rise significantly. 4.14 Risk analysis Another factor impacting the project is risk. Note that the case study was based on deterministic estimates. While the sensitivity analysis helped us decide the importance of the various attributes it does not provide us with the probabilities of various risks. There are many risks that need to be analysed before a final decision is made. There are technical, economic and operating constraint risks. There are project risk in implementation and control. Lastly there is a weather risk in this case due to high seas. For each of this risk there is a risk mitigation strategy that needs to be developed. For instance the technical risk can be migrated by scaled up and tested in actual environments. Scaling up via prototype reduces the risk that the devise will fail in operation (Blanchard, 2004). Developing a comprehensive set of risk models is beyond the scope of this paper. 5 Conclusions The ATA model with a series of sub models were an example of how a concurrent engineering approach could be used to shorten the commercialisation time cycle. Two scenarios were considered: 500 MW and 1,000 MW wave energy farms. The capital cost estimates are relatively conservative because most of the equipment is COTS. The IRR and other FoMs showed that the WEHD case met standard business criteria for both the scenario considered. Sensitivity analysis indicated that electricity revenues, total capital costs and the owner’s cost of capital (MARR) dominated the economics for both cases. 458 O. Bonilla et al. The financial leverage analysis indicated that the project economics significantly improves as the amount of loans increase. This is a positive result this type of capital intensive project that would financed. However, as the percentage of loans increase so does the financial risk. Insurance could offset this risk. The ‘bottom line’ is that this project meets the normal financial criteria used in evaluating business cases and meets the Figure 1 (Part B – item 5) economic feasibility. The other two major domains (technical and operational constraints) in Figure 1 need to be satisfied. The ‘technical feasibility’ involves a series of prototypes while the ‘operational constraints’ involves risk analysis for environmental, financial, etc. Lastly, the ATA model can be used to help design the wave farm by providing guidance on cost/benefit trade-offs. 6 Future research Future research will include a risk analysis which evaluates the financial and other risks such as weather related events. This research will include MAA. The engineering systems aspect of this project will also be explored. Included here would be the impact of redundancy and other improvements to achieve a higher level of reliability, supportability and maintainability. Additional economic analysis will include the impact of carbon credits and/or cap and trade for this project. A major feature of using ATA models is the ability to test various engineering scenarios. For instance should extra hardware capital be spent to provide a ten-year life instead of the seven-year life in the model? Since the economic feasibility is greatly impacted by the amount of financial leverage these alternatives should be explored. There already exist many different financial schemes to finance major infrastructure projects like power plants. The financial impact of those schemes on their impact on the project risk needs to be explored. This also has implications for proposals to establish a ‘Green Bank’ to spur renewable energy projects. References Balachandra, P. et al. (2010) ‘Commercialization of sustainable energy technologies’, Renewable Energy, Vol. 35, No. 8, pp.1842–1851. Bernstein, L. et al. (2007) ‘Climate change 2007: synthesis report’, available at http://www.ipcc.ch/ pdf/assessment-report/ar4/syr/ar4_syr_spm.pdf (accessed on 2 June 2009). Blanchard, B. (2004) Systems Engineering Management, 3rd ed., John Wiley and Sons, Hoboken, NJ. Bonilla, O. and Merino, D. (2010) ‘Economics of a hydrogen bus transportation system: case study using an after tax analysis model’, Engineering Management Journal, Vol. 22, No. 3, pp.34–44. Department of Business, Economic Development, and Tourism (2002) ‘Feasibility of developing wave power as a renewable energy resource for Hawaii’, available at http://hawaii.gov/dbedt/ info/energy/publications/wavereport02.pdf (accessed on 26 June 2009). Dereli, T. et al. (2008) ‘An affordable reverse engineering framework for innovative rapid product development’, International Journal of Industrial and Systems Engineering, Vol. 3, No. 1, pp.31–37. A systems model for commercialising emerging technology 459 Downey, J. (2009) ‘Coal debate highlights Duke meeting’, Triangle Business Journal, 8 May. available at http://www.bizjournals.com/triangle/stories/2009/05/04/daily67.html (accessed on 24 July 2009). Duke Energy (2005) ‘Duke power lays groundwork for upgraded power portfolio to meet growing customer demand’, available at http://www.dukeenergy.com/news/releases/2005/ May/2005051101.asp (accessed on 24 July 2009). Energy Information Administration (2009) ‘Annual energy outlook 2009’, available at http://www.eia.doe.gov/oiaf/aeo/ (accessed on 10 May 2009). Flynn, P.C. (2002) ‘Commercializing an alternate vehicle fuel: lessons learned from natural gas for vehicles’, Energy Policy, Vol. 30, No. 7, pp.613–619. Geller, H. et al. (2006) ‘Polices for increasing energy efficiency: thirty years of experience in OECD countries’, Energy Policy, Vol. 34, No. 5, pp.556–573. Hellman, H.L. and van den Hoed, R. (2007) ‘Characterising fuel cell technology: challenges of the commercialisation process’, International Journal of Hydrogen Energy, Vol. 32, No. 3, pp.305–315. Jacobsson, S. and Bergek, A. (2004) ‘Transforming the energy sector: the evolution of technological systems in renewable energy technology’, Industrial and Corporate Change, Vol. 13, No. 5, pp.815–849. Jain, R. et al. (2010) ‘A framework for end-to-end approach to systems integration’, International Journal of Industrial and Systems Engineering, Vol. 5, No. 1, pp.79–109. Jain, R. et al. (2011) ‘Feasibility of a rapid systems engineering framework: an exploratory study’, International Journal of Industrial and Systems Engineering, Vol. 7, No. 1, pp.45–65. Johnson, K. (2009) ‘Making waves: why getting power from the ocean is so tough’, The Wall Street Journal, 9 June, available at http://blogs.wsj.com/environmentalcapital/2009/06/09/ making-waves-why-getting-power-from-the-ocean-is-so-tough/tab/article/ (accessed on 10 June 2009). Kammen, D. and Pacca, S. (2004) ‘Assessing the costs of electricity’, Annual Review of Environment and Resources, Vol. 29, pp.301–344. Kimura, O. (2010) ‘Public R&D and commercialization of energy-efficient technology: a case study of Japanese projects’, Energy Policy, Vol. 38, No. 11, pp.7358–7369. Lang, H. and Merino, D. (2002) The Selection Process for Capital Projects, John Wiley, New York, NY. Lotker, M. (1991) ‘Barriers to commercialization of large-scale solar electricity: lessons learned from the LUZ experience’, available at http://www.nrel.gov/csp/troughnet/pdfs/sand91_ 7014.pdf (accessed on 10 September 2011). National Energy Technology Laboratory (NETL) (2007) Tracking new coal-fired power plants’, available at http://cmnow.org/NETL%20New%20Coal%205.2007.pdf (accessed on 24 July 2009). Ocean Energy Council (2009) ‘News and information about ocean renewable energy’, available at http://www.oceanenergycouncil.com/index.php/Wave-Energy/Wave-Energy.html (accessed on 26 June 2009). Parnaby, J. (1955) ‘Systems engineering for better engineering’, Engineering Management Journal, Vol. 5, No. 6, pp.256–266. Patterson, W.C. (1992) ‘The commercialization of new technologies’, Energy Policy, Vol. 20, No. 3, pp.186–189. Pinkze, J. and van den Busee, D. (2012) ‘The development and commercialization of solar PV technology in the oil industry’, Energy Policy, available at http://www.sciencedirect.com/ science/article/pii/S0301421510007159 (accessed on 5 October 2011). REN21 (2008) ‘Renewables 2007 global status report’, REN21 Secretariat, Paris and Worldwatch Institute, Washington, DC. Rogers, E. (2003) Diffusion of Innovations, 5th ed., Free Press, New York. 460 O. Bonilla et al. Sage, A.P. and Armstrong, J.E. (2000) Introduction to Systems Engineering, Wiley, New York. Saucer, B. et al. (2008) ‘A system maturity index for the systems engineering life cycle’, International Journal of Industrial and Systems Engineering, Vol. 3, No. 6, pp.673–691. Sharma, K.J. (2004) ‘Concurrent engineering in practice: a brief review’, International Journal of Manufacturing Technology and Management, Vol. 6, Nos. 3/4, pp.334–344. Appendix A Seahorse Power’s WEHD description A.1 WEHD system The patent-pending WEHD is a system as illustrated in Figure 5, converts the energy from surface ocean waves into electricity by using a buoy-driven electrical generation subsystem. The electricity will be delivered to shore via existing sea floor cable technologies currently in use in the offshore wind industry in Europe. The heavy mechanical components of the electrical generation subsystem are contained in a submersible housing anchored to the ocean floor and do not reside on the surface. A cable reel and flotation device enables the system to harness a large range of waves on the sea surface. By using winches and anchors, the electrical generation subsystem can be lowered to a safe depth during storms or can be raised near the surface for a shoaling effect in calm seas. The minimum depth of the anchors will be determined by the historic wave climate in the region of operation. This configuration protects the components of the electrical generation subsystem from the effects of damaging surface waves, such as those generated by storms and hurricanes. Unlike existing wave energy conversion devices, the WEHD is designed to operate in a greater range of wave heights by using synthetic lines and winch reels. The WEHD is designed to be fully operational in waves over 30 meters in height, resulting in an increased electrical output capacity relative to other known existing systems. The limitations of existing wave energy conversion systems can be solved by the WEHD. This invention includes variable depth, shoaling, storm avoidance, continuous phase control, energy storage, and a ‘no shaft seal required’ between the sea water and the generator shaft features. The WEHD allows for rapid deployment and recovery of the electricity generating system which helps deployment crews avoid the dangers of high energy wave regions. The WEHD incorporates a shoaling feature that uses a buoyant platform to shoal incident waves. The shoaling capabilities concentrate wave energy and are a function of platform dimensions, buoyancy, lift capacity and wave conditions. Figure 5 WEHD (patent pending) system (see online version for colours) Design specs: • • • • • • • Stable platform based on ocean-going barges Variable depth platform Buoyant platform when fully flooded Hydraulic mooring and power take-off Continuous phase control Autonomous and remote controls Low mass/inertia point absorber A systems model for commercialising emerging technology 461 One economic advantage of the WEHD over other existing systems is its ability to shoal waves in calm and moderate seas. This feature enables the WEHD to change the shape of waves, making the waves steeper which enables the device to harness more energy from increased buoy acceleration. This effect increases output capacity of the WEHD. The advantages are two-fold. One, this device is not required to be located in extremely high-energy wave climates where the probability survival is lower and deployment and maintenance costs are higher. Two, this device is more economically efficient over existing systems because it has the capacity to continue to harness energy from waves during periods of low to moderate wave activity and store the harnessed energy at sea to provide electricity for up to an hour during periods of flat seas. A.2 WEHD concept of operation The WEHD is an electricity generating device energised by water motion. The general field is commonly referred to as hydrokinetics. The WEHD utilises a winch and buoy system to harness wave energy. Synthetic lines connect the surface buoy to the winch reels situated on a submerged platform. The energy is extracted with the buoy motion, similar to the motion of a yo-yo. The winch reels combined with a buoyant platform, provide a method for controlling platform depth. This variable depth feature enables two other features, the shoaling feature and active storm avoidance feature. In calm and moderate seas the platform can be raised near the surface to shoal waves. In storms or periods of extremely large waves, the platform can be lowered near the sea floor where water particle motion is reduced, thereby reducing the kinematic and dynamic loads on the platform and anchor lines. The variable depth feature is designed to be controlled by submersible winches with continuous response to changing anchor line or buoy tether tension, thereby providing a continuous phase control feature. A.3 Scope of WEHD The scope of this case study is a simulated wave farm based on the WEHD design that is equivalent to the size of one large coal plant or nuclear power plant. The objective of wave energy system development is to eventually replace carbon-based and nuclear power projects. The calculations are estimated costs for a full-scale deployment after an in-water pilot programme. Some of the WEHD system objectives are: • 1 MW minimum plate capacity • minimise anchor loading • provide buoyant integrity • provide wave tuning capabilities • decouple energy extraction and electricity generation • provide energy storage capabilities. 462 A.4 O. Bonilla et al. Risk analysis Another factor impacting the project is risk analysis. Deterministic, component-based safety factors, based on extreme storm analysis are required to increase the probability of a 20-year life cycle. High safety factors generally increase production costs while reducing the risk of catastrophic failure. A key financial risk is rate of return on investment due to the large amount of capital required to commission a facility. A.5 Wave farm comparisons and sizing Investors have multiple choices in the renewable energy sector including solar, wind, and wave energy. Key factors for economic viability include the magnitude, concentration, and availability of each resource as well as the cost of commissioning and operating systems. Ocean wave energy is approximately 1000 times more concentrated than wind energy and wind energy is a concentrated form of solar energy (Ocean Energy Council, 2009). Capacity factor, or the percentage of output per year based on plate capacity for wind energy ranges from 25% to 30% and wave energy ranges from 50% to 90% depending on location (Department of Business, Economic Development, and Tourism, 2002). The WEHD design facilitates plate capacity in excess of 1 megawatt (1 MW) using less than 500 square meters of sea surface area in moderate and high-energy wave climates.