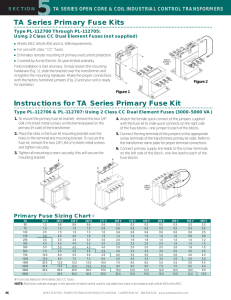

INDUSTRIAL CONTROL TRANSFORMERS

advertisement