Swaroop Ghosh and Kaushik Roy

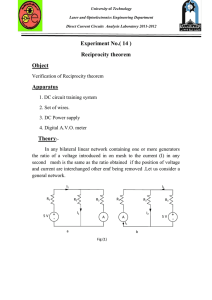

advertisement