Load Regulation Using PIC Controller in Power Utilization System

advertisement

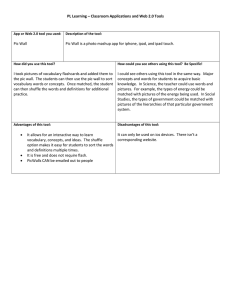

International Journal of Electronics, Electrical and Computational System IJEECS ISSN 2348-117X Volume 3, Issue 2 April 2014 Load Regulation Using PIC Controller in Power Utilization System Jigar D. Patel Ashish D. Prajapati Student of Instrumentation and control Government Engineering College Gandhinagar jigarpatel4774@gmail.com Student of Instrumentation and control Government Engineering College Gandhinagar ashishprajapati.ic@gmail.com Mayank S. Hingol Student of Instrumentation and control Government Engineering College Gandhinagar mayank.hingol@gmail.com Abstract This paper reviews load regulation using transmission system to measure a active PIC controller in power utilization system power of industry. After measuring of the and their application in any type of industry. active power, which can be compare to the Power station provides the main power to main power limit. If active power value goes industry and decides the power limits. to above the main power limit, so at that Sometime industry using a main power time to turn off the unwanted machineries above the decided limits so at that time automatically. In addition, to maintain the industry have to pay some penalty. Now a main power limits so industry does not pay day’s industry using a load regulation any types of penalty. Therefore, industry system and which is depended on the PLC. gets the profits. So the cost of the circuit is become a higher and provide a high maintenance cost. Therefore, our project aim is to reduce the cost of circuit and maintenance using a PIC controller in load regulation power utilization system. The working of load regulation using PIC controller in power 15 Jigar, Ashish, Mayank Keywords: AT PIC CONTROLLER, LCD DISPLAY, DAC0808, EXTERNAL LOAD International Journal of Electronics, Electrical and Computational System IJEECS ISSN 2348-117X Volume 3, Issue 2 April 2014 1. INTRODUCTION The main purpose of Manufacturing of load In industries power station provides a main regulation system in power utilization power and provides a main power limit. So system:- industries a) To measure the active power and increases above the limits so at that time compare with the main power limit industries have to pay some penalty. So to maintain the active power. sometime main power of industries use a load regulation system in b) To maintain the main power, so power utilization system that is depended on industry does not pay the penalty and PLC. So the cost of the system is become a get the profit. higher and provide a high maintenance cost. c) To control the external load and turn off the unwanted machineries. Therefore, our project works aim to develop load regulation system using a PIC 2. LITRETURE controller in power utilization system to reduce a cost of the system and maintenance. Therefore, the system to maintain the main power limit and industries do not pay the penalty and industries get a profit. CONCEPT OF LOAD REGULATION SYSTEM Load regulation using PIC controller in power utilization system, the basic concept of this system is to measure the active power and compare with the main power limits. If active power is greater than the main power so at that time we can regulate the load and to stop the unwanted machinery and to maintain the main power limits. BASIC REQUIREMENTS LOAD Figure 1.1 Overview of External Device Interfacing REGULATION SYSTEM In many industries number of machine connected 16 Jigar, Ashish, Mayank to means power. If the International Journal of Electronics, Electrical and Computational System IJEECS ISSN 2348-117X Volume 3, Issue 2 April 2014 machineries start simultaneously, so at that digital to analog converter used to convert time main power cross to main power limits. the analog value in to digital value. So use of the Maximum demand of the main power customer has to pay penalty to energy The software demands of this project are: distributor, so we can require the load Software is also divided into two regulation system in power utilization segments: system and to maintain the main power limit and do not pay penalty. 1. Proteus: - For making simulation model of project. 2. MP Lab: - For programming of 3. COMPONENT OF LOAD project. REGULATION SYSTEM 4. BLOCK DIAGRAM AND The Entire load regulation system divided PECIFICATIONS into two segments: 1. Hardware 4.1 BLOCK DIAGRAM: - 2. Software The hardware of this project divided into two parts: 1. The LCD (liquid crystal display) interfacing with PIC controller (16F877A): The LCD is connected to PIC controller and to display the main power and active power value. 2. Digital to analog converter interfacing with PIC controller: Here the 17 Jigar, Ashish, Mayank International Journal of Electronics, Electrical and Computational System IJEECS ISSN 2348-117X Volume 3, Issue 2 April 2014 a. BLOCK SPECIFICATIONS ABSOLUTE MAXIMUM RATING (DAC0808) : 1. MAINS POWER: The main power limits applied to the PIC controller and to display the main power limits on the LCD display. 2. PIC CONTROLLER: We can use a 40pin PIC controller and the main power To the PIC controller and to compare connected to PIC controller to display The block of active power and main power. We use the 16x2 character LCD to display the value. The LCD interfacing circuit denoted as below. D TO A CONVERTER: We use a digital to analog converter to convert the digital value in analog value. In this project to use a dac0808 to convert the digital value in analog value. The DAC (digital to analog converter) interfacing circuit denoted as below. Digital Input Voltage,( V5–V12) :−10 VDC to +18 VDC Applied Output Voltage, (VO):−11 VDC to +18 VDC Reference Current, I14 Reference Amplifier Inputs, Power Dissipation 1000 mW Storage Temperature Range −65°C to +150°C the LCD display to use a display of the 5. VEE −18 VDC V14,V15 respectively VCC, VEE the power value. LCD INTERFACING: o 5 mA with the main power limit. LCD 4. VCC +18 VDC o and to applied. 3. o o and reference voltage applied to the controller. Measure the active power Power Supply Voltage:- Lead Temp. (Soldering, 10 seconds):o Dual-In-Line Package (Plastic) 260°C o Dual-In-Line Package (Ceramic) 300° o 6. EXTERNAL LOAD: To use external load like a bulb, heater coil, fan etc…As an external load we can use analog and digital input type load. Some external load provides analog input and some external load provides digital input. So 18 Jigar, Ashish, Mayank International Journal of Electronics, Electrical and Computational System IJEECS ISSN 2348-117X Volume 3, Issue 2 April 2014 analog input type load provide input to PIC is again take signals of current and the DAC (digital to analog converter) voltage and multiply. This value is again output and digital input type load display and compare with power limit and provide input to the controller output, again external load is ON or OFF. which can be provided by ADC (analog to digital converter). 6. CONCLUSION In this paper, the load regulation system 5. WORKING using PIC controller in power utilization system use to maintain the main power limit. Here, Output is connected with PIC Controller via relays. External supply is applied to the output load. According to the output of PIC controller, relay can be open or closed. So at that time take signals of This projects use to reduce the maintenance and cost of the load regulation system. With the help of this projects it is possible to get the profit of the industries and do not pay the penalty. current and voltage of external supply and convert it into 0-5 V. This 0-5 V is applies to ADC of the PIC controller. Here, PIC take samples of current and voltage signals 7. REFERENCES: [1] Muhammad Ali Mazidi, Rolin at instant time. These signals are multiply D.Mckinlay, Danny Causey ‘PIC and get the value of power of external output Microcontroller and embedded system’ load. These powers of external load, [2] http://www.national.com/pdfs/dac0808 condition of external load (ON/OFF), power datasheet.pdf. limit are display in LCD. Now power of [3] http://www.microchip.com external load is compare with power limit [4] Dr. Amer Iqbal ‘Teach yourself PIC which is previously set by the user. If power of external load is greater than power limit, according to priority external load is ON or OFF using relay. Again measure the power of external load and sent it to PIC controller. 19 Jigar, Ashish, Mayank microcontrollers’, [5] http://www.theengineeringprojects.com