instrumentation-and-tray

advertisement

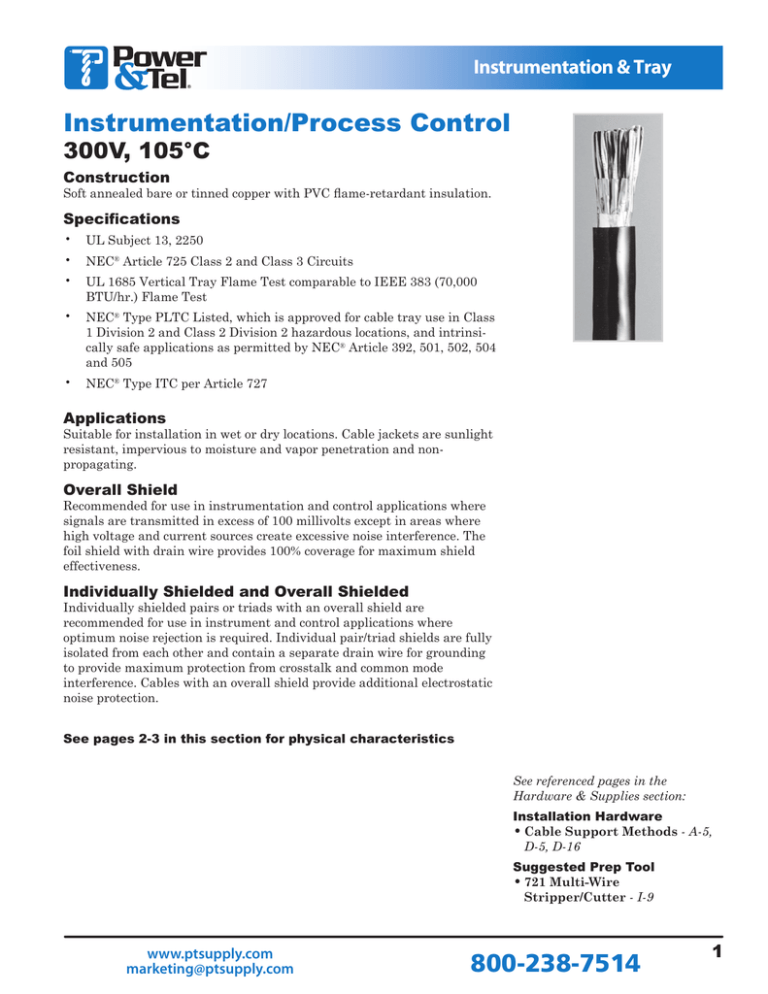

Instrumentation & Tray Instrumentation/Process Control 300V, 105°C Construction Soft annealed bare or tinned copper with PVC flame-retardant insulation. Specifications • UL Subject 13, 2250 • NEC® Article 725 Class 2 and Class 3 Circuits • UL 1685 Vertical Tray Flame Test comparable to IEEE 383 (70,000 BTU/hr.) Flame Test • NEC® Type PLTC Listed, which is approved for cable tray use in Class 1 Division 2 and Class 2 Division 2 hazardous locations, and intrinsically safe applications as permitted by NEC® Article 392, 501, 502, 504 and 505 • NEC® Type ITC per Article 727 Applications Suitable for installation in wet or dry locations. Cable jackets are sunlight resistant, impervious to moisture and vapor penetration and nonpropagating. Overall Shield Recommended for use in instrumentation and control applications where signals are transmitted in excess of 100 millivolts except in areas where high voltage and current sources create excessive noise interference. The foil shield with drain wire provides 100% coverage for maximum shield effectiveness. Individually Shielded and Overall Shielded Individually shielded pairs or triads with an overall shield are recommended for use in instrument and control applications where optimum noise rejection is required. Individual pair/triad shields are fully isolated from each other and contain a separate drain wire for grounding to provide maximum protection from crosstalk and common mode interference. Cables with an overall shield provide additional electrostatic noise protection. See pages 2-3 in this section for physical characteristics See referenced pages in the Hardware & Supplies section: Installation Hardware • Cable Support Methods - A-5, D-5, D-16 Suggested Prep Tool • 721 Multi-Wire Stripper/Cutter - I-9 www.ptsupply.com marketing@ptsupply.com 800-238-7514 1 Instrumentation & Tray Physical Characteristics: Instrumentation/Process Control 300V, 105°C Cond. Type No. of Strands Jacket Thick. (in) Nominal O.D. (in) Shielding Weight (lbs/M-ft) .038 .200 None 17 7 TC No. of Strands Jacket Thick. (in) Nominal O.D. (in) Shielding Weight (lbs/M-ft) .038 .214 None 20 Pairs 20 AWG Pairs 22 AWG 1 Pair Cond. Type 1 Pair 10 TC 1 Pair 7 TC .038 .202 Overall 23 1 Pair 10 TC .038 .216 Overall 23 2 Pairs 7 TC .043 .315 IS Prs 41 2 Pairs 7 BC .055 .378 IS Prs/OS 68 3 Pairs 7 TC .043 .331 IS Prs 53 4 Pairs 7 BC .055 .432 IS Prs/OS 101 4 Pairs 7 TC .043 .360 IS Prs 65 8 Pairs 7 BC .055 .540 IS Prs/OS 166 6 Pairs 7 TC .053 .437 IS Prs 100 12 Pairs 7 BC .055 .670 IS Prs/OS 243 9 Pairs 7 TC .053 .500 IS Prs 140 16 Pairs 7 BC .066 .740 IS Prs/OS 305 11 Pairs 7 TC .053 .551 IS Prs 160 20 Pairs 7 BC .066 .818 IS Prs/OS 369 19 Pairs 7 TC .063 .686 IS Prs 264 24 Pairs 7 BC .078 .886 IS Prs/OS 446 51 Pairs 7 TC .075 1.050 IS Prs 516 36 Pairs 7 BC .078 1.058 IS Prs/OS 630 2 Pairs 7 TC .043 .310 Overall 37 50 Pairs 7 BC .078 1.267 IS Prs/OS 850 3 Pairs 7 TC .043 .326 Overall 47 1 Pair 7 BC .037 .213 Overall 24 4 Pairs 7 TC .043 .353 Overall 57 4 Pairs 7 BC .055 .412 Overall 86 6 Pairs 7 TC .053 .425 Overall 84 8 Pairs 7 BC .055 .491 Overall 135 9 Pairs 7 TC .053 .488 Overall 112 12 Pairs 7 BC .055 .586 Overall 186 11 Pairs 7 TC .053 .536 Overall 131 16 Pairs 7 BC .066 .653 Overall 244 15 Pairs 7 TC .053 .594 Overall 163 24 Pairs 7 BC .066 .820 Overall 346 19 Pairs 7 TC .063 .631 Overall 207 36 Pairs 7 BC .078 .999 Overall 509 27 Pairs 7 TC .063 .741 Overall 279 50 Pairs 7 BC .078 1.136 Overall 671 51 Pairs 7 TC .075 .950 Overall 377 Triads 20 AWG Triads 22 AWG 1 Triad 10 TC .038 .225 None 26 30 1 Triad 7 TC .038 .210 None 25 1 Triad 10 TC .038 .227 Overall 1 Triad 7 TC .038 .212 Overall 25 1 Triad 7 BC .037 .224 OS 31 4 Triads 7 BC .055 .484 IS Tr/OS 131 2 www.ptsupply.com marketing@ptsupply.com 8 Triads 7 BC .055 .620 IS Tr/OS 217 12 Triads 7 BC .066 .770 IS Tr/OS 232 16 Triads 7 BC .066 .853 IS Tr/OS 407 24 Triads 7 BC .078 1.075 IS Tr/OS 607 800-238-7514 Instrumentation & Tray Physical Characteristics: Instrumentation/Process Control 300V, 105°C Cond. Type No. of Strands Jacket Thick. (in) Nominal O.D. (in) Shielding Weight (lbs/M-ft) Cond. Type No. of Strands Jacket Thick. (in) Nominal O.D. (in) Shielding Weight (lbs/M-ft) .043 .324 None 34 Pairs 16 AWG Pairs 18 AWG 1 Pair 26 TC 26 1 Pair 26 TC .043 .326 Overall 36 1 Pair 7 BC .037 .258 None 36 1 Pair 19 TC .038 .230 None 26 1 Pair 19 TC .038 .236 Overall 2 Pairs 19 TC .043 .381 IS Prs 69 3 Pairs 19 TC .053 .421 IS Prs 100 2 Pairs 7 BC .055 .454 IS Prs/OS 110 4 Pairs 19 TC .053 .486 IS Prs 124 4 Pairs 7 BC .055 .516 IS Prs/OS 172 6 Pairs 19 TC .053 .546 IS Prs 179 8 Pairs 7 BC .066 .675 IS Prs/OS 313 9 Pairs 19 TC .063 .666 IS Prs 266 12 Pairs 7 BC .066 .826 IS Prs/OS 441 11 Pairs 19 TC .063 .686 IS Prs 309 24 Pairs 7 BC .077 1.155 IS Prs/OS 832 15 Pairs 19 TC .063 .766 IS Prs 401 36 Pairs 7 BC .088 1.342 IS Prs/OS 1213 1 Pair 7 BC .037 .261 Overall 45 2 Pairs 7 BC .055 .412 IS Prs/OS 86 4 Pairs 7 BC .055 .472 IS Prs/OS 133 3 Pairs 7 BC .055 .473 Overall 126 4 Pairs 7 BC .055 .499 Overall 145 8 Pairs 7 BC .055 .594 IS Prs/OS 222 12 Pairs 7 BC .066 .737 IS Prs/OS 328 8 Pairs 7 BC .055 .601 Overall 242 12 Pairs 7 BC .066 .745 Overall 355 24 Pairs 7 BC .077 1.025 IS Prs/OS 615 36 Pairs 7 BC .077 1.169 IS Prs/OS 938 24 Pairs 7 BC .077 1.038 Overall 666 2 Pairs 19 TC .043 .361 Overall 65 36 Pairs 7 BC .077 1.184 Overall 945 3 Pairs 19 TC .053 .400 Overall 91 4 Pairs 19 TC .053 .451 Overall 111 Triads 16 AWG 6 Pairs 19 TC .053 .481 Overall 149 1 Triad 7 BC .037 .272 None 49 9 Pairs 19 TC .053 .556 Overall 205 1 Triad 26 TC .043 .342 None 46 11 Pairs 19 TC .063 .676 Overall 258 1 Triad 7 BC .037 .285 Overall 61 15 Pairs 19 TC .063 .750 Overall 331 1 Triad 26 TC .043 .345 Overall 53 1 Pair 7 BC .037 .233 Overall 35 3 Pairs 7 BC .055 .419 Overall 90 Pairs 14 AWG 4 Pairs 7 BC .055 .456 Overall 107 1 Pair 42 TC .043 .324 None 52 8 Pairs 7 BC .055 .546 Overall 177 1 Pair 42 TC .043 .326 Overall 63 12 Pairs 7 BC .066 .677 Overall 260 24 Pairs 7 BC .077 .938 Overall 480 36 Pairs 7 BC .077 1.068 Overall 671 Triads 14 AWG 1 Triad 42 TC .043 .342 None 72 1 Triad 42 TC .043 .345 Overall 83 Triads 18 AWG 1 Triad 19 TC .038 .246 None 35 1 Triad 19 TC .038 .248 Overall 39 1 Triad 7 BC .037 .245 Overall 42 Pairs 12 AWG 1 Pair 65 TC .052 .424 None 86 1 Pair 65 TC .053 .426 Overall 103 Color Code Pairs Black and White Triads Black, White and Red Tinned Copper Conductors Pairs Black and Red Triads Black, White and Red Bare copper conductors use Table K-5 per ICEA method 1. Multiple pair or triad cables have each pair/triad numbered for ease of identification. www.ptsupply.com marketing@ptsupply.com 800-238-7514 3 Instrumentation & Tray Multi-Pair Instrumentation 600V, 90°C Construction Soft annealed bare or tinned copper conductors, PVC insulated with a nylon overcoat, 90°C rated TFN, TFFN or THHN. Specifications • UL Subject 1277 • UL 1685 Vertical Tray Flame Test comparable to IEEE 383 (70,000 BTU/hr.) Flame Test • For use in cable trays, raceways, conduit or for aerial applications where installed with a messenger. For use within Class 1 Division 2 and Class 2 Division 2 hazardous locations, and intrinsically safe locations permitted by NEC® Article 392, 501, 502, 504 and 505 Applications These cables are suitable for installation in wet or dry locations. Cable jackets are sunlight resistant, impervious to moisture and vapor penetration, and non-propagating. The cables can be used in raceways, aerial supported by messenger wire, outdoor applications and direct burial applications. Overall Shield Recommended for use in instrumentation and control applications where signals are transmitted in excess of 100 millivolts except in areas where high voltage and current sources create excessive noise interference. The foil shield with drain wire provides 100% coverage for maximum shield effectiveness. Individually Shielded and Overall Shielded Individually shielded pairs or triads with an overall shield are recommended for use in instrument and control applications where optimum noise rejection is required. Individual pair/triad shields are fully isolated from each other and contain a separate drain wire for grounding to provide maximum protection from crosstalk and common mode interference. Cables with an overall shield provide additional electrostatic noise protection. See referenced pages in the Hardware & Supplies section: Installation Hardware • Cable Support Methods - A-5, D-5, D-16 • Pole Line Hardware Suggested Prep Tool • 721 Multi-Wire Stripper/Cutter - I-9 4 www.ptsupply.com marketing@ptsupply.com 800-238-7514 Instrumentation & Tray Physical Characteristics: Multi-Pair Instrumentation 600V, 90°C Cond. Type No. of Strands Jacket Thick. (in) Nominal O.D. (in) Shielding Weight (lbs/M-ft) .048 .271 None 39 No. of Strands Jacket Thick. (in) Nominal O.D. (in) Shielding Weight (lbs/M-ft) .048 .293 None 45 Pairs 16 AWG Pairs 18 AWG 1 Pair Cond. Type 19 TC 1 Pair 19 TC 1 Pair* 7 BC .045 .266 Overall 35 1 Pair* 7 BC .045 .290 OS 45 2 Pairs 7 BC .050 .385 IS Prs/OS 77 2 Pairs 7 BC .050 .420 IS Prs/OS 101 4 Pairs 7 BC .050 .492 IS Prs/OS 126 3 Pairs 7 BC .050 .480 IS Prs/OS 136 8 Pairs 7 BC .066 .658 IS Prs/OS 236 4 Pairs 7 BC .066 .578 IS Prs/OS 187 12 Pairs 7 BC .066 .789 IS Prs/OS 330 6 Pairs 7 BC .066 .674 IS Prs/OS 257 16 Pairs 7 BC .089 .908 IS Prs/OS 455 8 Pairs 7 BC .066 .729 IS Prs/OS 321 24 Pairs 7 BC .089 1.125 IS Prs/OS 646 12 Pairs 7 BC .089 .878 IS Prs/OS 454 36 Pairs 7 BC .089 1.309 IS Prs/OS 914 16 Pairs 7 BC .089 1.023 IS Prs/OS 623 50 Pairs 7 BC .089 1.537 IS Prs/OS 1226 20 Pairs 7 BC .089 1.131 IS Prs/OS 743 1 Pair 19 TC .048 .273 Overall 43 24 Pairs 7 BC .089 1.259 IS Prs/OS 891 2 Pairs 7 BC .050 .404 Overall 72 36 Pairs 7 BC .089 1.433 IS Prs/OS 1265 4 Pairs 7 BC .050 .474 Overall 108 50 Pairs 7 BC .089 1.723 IS Prs/OS 1721 8 Pairs 7 BC .066 .603 Overall 197 1 Pair 19 TC .048 .295 Overall 52 12 Pairs 7 BC .066 .721 Overall 273 2 Pairs 7 BC .050 .455 Overall 92 16 Pairs 7 BC .066 .797 Overall 339 3 Pairs 7 BC .050 .480 Overall 119 24 Pairs 7 BC .089 1.027 Overall 523 4 Pairs 7 BC .066 .558 Overall 160 36 Pairs 7 BC .089 1.167 Overall 730 8 Pairs 7 BC .066 .670 Overall 265 50 Pairs 7 BC .089 1.456 Overall 986 12 Pairs 7 BC .066 .804 Overall 372 16 Pairs 7 BC .089 .938 Overall 509 24 Pairs 7 BC .089 1.147 Overall 724 Triads 18 AWG 1 Triad** 7 BC .045 .279 Overall 45 36 Pairs 7 BC .089 1.307 Overall 1,022 4 Triads 7 BC .066 .587 IS Tr/OS 180 50 Pairs 7 BC .089 1.598 Overall 1,384 8 Triads 7 BC .066 .755 IS Tr/OS 324 12 Triads 7 BC .089 .972 IS Tr/OS 482 Triads 16 AWG 24 Triads 7 BC .089 1.301 IS Tr/OS 866 1 Triad** 7 BC .045 .305 OS 60 4 Triads 7 BC .066 .650 IS Tr/OS 244 Color Code 8 Triads 7 BC .089 .887 IS Tr/OS 466 12 Triads 7 BC .089 1.065 IS Tr/OS 618 24 Triads 7 BC .089 1.457 IS Tr/OS 1,202 Pairs Black and White Triads Black, White and Red *Pairs Black and Red 1 Pair 42 TC .048 .359 None 69 Black, Red and Blue 1 Pair 42 TC .048 .361 Overall 80 **Triads Bare copper conductors use Table K-5 per ICEA method 1. Multiple pair or triad cables have each pair/triad numbered for ease of identification. www.ptsupply.com marketing@ptsupply.com Pairs 14 AWG Pairs 12 AWG 1 Pair 37 TC .048 .380 None 88 1 Pair 37 TC .048 .384 Overall 106 800-238-7514 5 Instrumentation & Tray Tray Cable 600V, UL VNTC, 90°C, Unshielded and Shielded Construction Class B stranded, bare copper, PVC/nylon insulation, PVC jacket. Unshielded has optional bare ground wire, separator tape. Specifications • UL 1277 • UL 83 for Type THHN • UL 70,000 BTU/hr. Vertical Tray Flame Test • Color Code per ICEA Table K.2, Method 1 Applications NEC® specifies Type TC for installation in cable trays, ducts, conduit and for direct earth burial. They are extensively used in manufacturing facilities, especially the process industries - petrochemical, steel, pulp and paper, cement and mining - and are found in a variety of control and instrumentation circuits. These cables are acceptable for use in Class 1 Division 2 hazardous locations. Overall Shield Recommended for use in instrumentation and control applications where signals are transmitted in excess of 100 millivolts except in areas where high voltage and current sources create excessive noise interference. The foil shield with drain wire provides 100% coverage for maximum shield effectiveness. Design Advantages • Cost savings can be substantial over traditional wiring methods • Less space is required for the same number of cables • Cable is more flexible than traditional wiring methods • Oil- and gasoline-resistant single conductors • Jacket listed as sunlight-resistant • UL listed for direct burial • Ground wire is included in unshielded 8 AWG and larger See referenced pages in the Hardware & Supplies section: Installation Hardware • Cable Support Methods - A-5, D-5, D-16 • Pole Line Hardware Suggested Prep Tool • 721 Multi-Wire Stripper/Cutter - I-9 6 www.ptsupply.com marketing@ptsupply.com 800-238-7514 Instrumentation & Tray Physical Characteristics: Tray Cable 600V, 90°C Unshielded Unshielded Jacket Thick. (in) Nominal O.D. (in) Weight (lbs/M-ft) 2 Fl. .045 .184 x .275 41 2 Rd. .045 .275 3 .045 4 Shielded Jacket Thick. (in) Nominal O.D. (in) Weight (lbs/M-ft) 2 Fl. .045 .184 x .275 50 2 Rd. .045 .275 56 3 .045 .288 60 175 4 .045 .312 70 .500 210 5 .045 .338 81 .045 .500 235 6 .045 .366 95 8 .060 .575 280 7 .045 .366 100 Jacket Thick. (in) Nominal O.D. (in) Weight (lbs/M-ft) 2 .045 .250 x .370 90 46 3 .045 .390 120 .288 50 4 .045 .420 150 .045 .312 60 5 .045 .460 5 .045 .338 71 6 .045 6 .045 .366 85 7 7 .045 .366 89 No. Cond. 18 AWG No. Cond. 12 AWG No. Cond. 18 AWG 9 .045 .421 112 9 .060 .615 320 8 .045 .394 110 10 .045 .438 121 10 .060 .665 350 9 .045 .421 125 12 .045 .461 156 12 .060 .685 410 10 .045 .438 135 15 .045 .507 169 14 .060 .720 465 12 .045 .461 165 19 .060 .578 220 15 .060 .760 500 20 .060 .594 228 16 .060 .760 525 24 .060 .643 268 19 .060 .800 610 2 Fl. .045 .195 x .297 60 30 .060 .705 325 20 .080 .885 690 2 Rd. .045 .297 65 37 .060 .760 390 24 .080 .985 805 3 .045 .312 75 25 .080 .985 835 4 .045 .338 90 30 .080 1.030 980 5 .045 .368 105 6 .045 .399 120 7 .045 .399 130 16 AWG 2 Fl. .045 .195 x .297 49 2 Rd. .045 .297 54 3 .045 .312 66 4 .045 .338 79 5 .045 .368 94 6 .045 .399 109 7 .045 .399 118 8 .045 .430 133 9 .045 .461 147 10 .045 .480 162 12 .045 .506 202 14 .060 .572 230 15 .060 .587 243 16 .060 .602 258 19 .060 .633 296 20 .060 .651 24 .060 26 10 AWG 16 AWG 2 .045 .260 x .425 135 8 .045 .430 145 3 .045 .450 175 9 .045 .461 160 4 .045 .500 225 10 .045 .480 170 5 .060 .580 285 12 .045 .506 215 6 .060 .625 340 7 .060 .625 375 14 AWG 8 .060 .680 425 2 .045 .235 x .330 80 9 .060 .730 480 3 .045 .350 100 10 .060 .790 525 4 .045 .375 125 11 .060 .790 570 5 .045 .410 140 12 .080 .860 65 6 .045 .445 165 7 .045 .445 180 8 .045 .480 200 8 AWG 2 .060 .555 220 9 .045 .515 225 310 3 .060 .590 290 10 .060 .595 265 .706 367 4 .060 .640 365 11 .060 .595 280 .060 .726 391 12 .060 .610 300 30 .060 .775 456 37 .080 .877 580 14 AWG 6 AWG 2 .060 .630 315 12 AWG 3 .060 .665 415 2 .045 .250 x .370 110 4 .060 .735 540 3 .045 .390 140 4 .045 .420 170 5 .045 .460 195 2 .045 .235 x .330 65 3 .045 .350 85 4 .045 .375 110 2 .060 .765 490 6 .045 .500 230 5 .045 .410 125 3 .080 .860 675 7 .045 .500 255 6 .045 .445 150 4 .080 .940 891 8 .060 .575 300 7 .045 .445 165 9 .060 .615 340 8 .045 .480 185 10 .060 .653 370 9 .045 .515 210 2 .080 .920 770 11 .060 .665 395 10 .060 .595 250 3 .080 .980 1,000 12 .060 .685 430 12 .060 .610 285 4 .080 1.100 1,305 14 .060 .640 325 15 .060 .675 355 16 .060 .675 370 19 .060 .710 425 20 .060 .745 455 24 .060 .825 530 25 .060 .825 550 26 .060 .825 565 30 .080 .925 685 www.ptsupply.com marketing@ptsupply.com 4 AWG 2 AWG 800-238-7514 7 Instrumentation & Tray Conductor Color-Code Chart Per ICEA Table K.2, Method 1 Conductor No. Insulation Color Stripe Color Conductor No. Insulation Color Stripe Color 1 Black — 22 Black Orange 2 Red — 23 Red Orange 3 Blue — 24 Blue Orange 4 Orange — 25 Yellow Orange 5 Yellow — 26 Brown Orange 6 Brown — 27 Black Yellow 7 Red Black 28 Red Yellow 8 Blue Black 29 Blue Yellow 8 9 Orange Black 30 Orange Yellow 10 Yellow Black 31 Brown Yellow 11 Brown Black 32 Black Brown 12 Black Red 33 Red Brown 13 Blue Red 34 Blue Brown 14 Orange Red 35 Orange Brown 15 Yellow Red 36 Yellow Brown 16 Brown Red 37 Black — 17 Black Blue 38 Red — 18 Red Blue 39 Blue — 19 Orange Blue 40 Orange — 20 Yellow Blue 41 Yellow — 21 Brown Blue 42 Brown — www.ptsupply.com marketing@ptsupply.com Note The color-code repeats after 36 conductors. The lowest conductor numbers are located in the center core of the cable assembly. 800-238-7514 Instrumentation & Tray Custom Tray Cable 600V, 90°C, Unshielded and Shielded See the Quik-Pull® section for more information on custom wire and cable assemblies. Construction Class B stranded bare copper, PVC/nylon insulation THHN, TFFN or XHHW-VW1. PVC insulated 90°C, Shore "A" Hardness based on ASTM D-2240. Conforms to UL 1277. Applications NEC® specifies Type TC for installation in cable trays, ducts, conduit and for direct earth burial. They are extensively used in manufacturing facilities, especially the process industries - petrochemical, steel, pulp and paper, cement and mining - and are found in a variety of control and instrumentation circuits. Advantages & Benefits • Less expensive than wire-in-pipe • Less space is required for the same number of cables • Cable is more flexible than traditional wiring methods • Oil- and gasoline-resistant single conductors • Jacket listed as sunlight resistant • UL listed for direct burial • Easily identifiable; can be your numbers and letters Quik-Pull® Benefits • Shipped in one week • 100' minimum order • Different gauge sizes in the same tray cable • Conductors and jackets available in any color • Custom striping and printing on conductors • Custom printing on outer jacket • No-charge non-returnable wooden reels Custom Cable Jacketing & Shielding • Sturdy indoor and outdoor jackets for custom wire bundles • Outdoor jackets for indoor cables • PVC, PE and tray rated compounds offered in several colors • Jackets available for sunlight resistance, harsh environments, direct burial and in cable tray CALL with your custom specifications! www.ptsupply.com marketing@ptsupply.com See referenced pages in the Hardware & Supplies section: Installation Hardware • Cable Support Methods - A-5, D-5, D-16 • Pole Line Hardware Suggested Prep Tools • MK01A Outer Jacket Cable Stripper - I-11 • 721 Multi-Wire Stripper/Cutter - I-9 800-238-7514 9 Instrumentation & Tray Belden® Blue Hose® Meets many installation requirements Belden Blue Hose cable is a robust physical media for the transmission of PLC/DCS signals across the factory floor. The needs of real-time, highthroughput industrial applications such as automotive transfer lines, paint shops, assembly lines, sectional conveyors, water/wastewater processing, food processing and pharmaceutical production can be routinely met by the control network and the use of Blue Hose cable. Typically utilized in the Control Layer, handling a wide range of automation and control data on the same cable. Examples: • • • • • PLC Processor Interlocking Peer-to-Peer Messaging Remote Programming A wide variety of constructions are available, allowing for installation flexibility. Troubleshooting I/O Updates Blue Hose Standard Cable One pair, 20 AWG stranded, tinned copper, PE insulation, 55% tinned copper braid. Designed for light industrial environments 600V Blue Hose Cable – UL Type TC One pair, 18 AWG stranded, tinned copper, flameretardant polyolefin insulation. Designed for cable tray use in industrial applications; can occupy same tray or conduit as 600V power cables. High-Flexibility Blue Hose Cable One pair, 20 AWG stranded, tinned copper, PE insulation, 85% tinned copper braid. Highly flexible version of the standard Blue Hose cable. Heavier braid coverage for better noise immunity. Gel-Filled Direct Burial Cable One pair, 20 AWG stranded, tinned copper, PE insulation. Gel-filled, featuring a low-density PE jacket. Suited for high-moisture environments and burial applications. Aluminum Interlocked Armor Blue Hose Cable One pair, 20 AWG stranded, tinned copper, PE insulation, 55% tinned copper braid. An ideal alternative to conduit installation. Provides both mechanical protection and electrical shielding. Up to 25 Data Highway cables can be bundled under one sheath. Steel Interlocked Armor Blue Hose Cable One pair, 20 AWG stranded, tinned copper, PE insulation, 55% tinned copper braid. Provides mechanical protection and electrical shielding. Prevents against low-frequency 60 Hz magnetic noise from power lines. Up to 25 cables can be bundled under one sheath. Continuously Corrugated Aluminum Armor Blue Hose Cable One pair, 20 AWG stranded, tinned copper, PE insulation, 55% tinned copper braid. Provides mechanical protection, electrical shielding and is impervious to moisture. Plenum Cable One pair, 20 AWG, stranded, tinned copper, FEP insulation, 76% tinned copper braid. A plenum, 200°Cgrade cable suitable for installations where high and low temperatures are encountered and in corrosive environments. 10 www.ptsupply.com marketing@ptsupply.com 800-238-7514 Instrumentation & Tray Belden® Variable-Frequency Drive (VFD) Cables 1,000V UL Flexible Motor Supply Cable Designed to overcome the problems and limitations of other cabling systems used for variable-frequency AC motor drives. VFD cables carry the power from AC drive systems to AC motors and must handle not only high power levels, but also extremely high voltage. Variable-frequency AC motor drive output cables are subject to a harsh operating environment characterized by high voltage spikes, high noise levels and adverse environmental conditions. VFD systems exist in both process and discrete industries such as general assembly, automotive, food and beverage, pulp and paper and petrochemical. Conventional VFD cabling systems experience failure due to corona discharge or adverse conditions and are difficult and expensive to install. Belden VFD cable uses a thicker and more stable electrical insulation, plus features a dual shield. The combination of these two features result in Belden VFD cable to be installed at a lower cost than the least expensive VFD cable alternative. One (1) Four-Conductor Stranded TC Circuit Conductors + (1) Full-sized Ground; Overall Beldfoil® + 85% TC Braid Shield; Full-sized TC Drain Wire. AWG: 2, 4, 6, 8, 10, 12, 14 and 16. Ethernet Cables Made for Tough Industrial Environments DataTuff™ twisted pair copper Industrial Ethernet cables Designed to withstand the rigors of industrial environmental factors such as exposure to oil and sunlight, temperature variation, abrasion and crushing or the presence of electro-magnetic interference (EMI) or radio frequency interference (RFI). The DataTuff series includes nine twisted pair designs, verified to meet Category 5E performance standards and featuring heavy duty sunlight- and oil-resistant jackets. Seven of the cables feature Installable Performance® with Belden’s patented Bonded-Pairs technology that delivers superior electrical performance even in harsh industrial installations. www.ptsupply.com marketing@ptsupply.com 800-238-7514 11 Instrumentation & Tray Teck 90 UL 1569, CSA Construction Class B stranded, bare copper conductors, cross-link PE insulation, bare copper ground wire, PVC inner jacket, aluminum or galvanized steel interlocking armor, PVC outer jacket. Thermoset insulation. 600V (14-10 AWG), 1,000V (8-2 AWG), -40°C to 90°C. Applications A general purpose cable used in the pulp and paper, mining, petroleum, and chemical industry as well as in commercial buildings. Teck 90 may be used under the following conditions: exposed or concealed wiring in dry or wet conditions, in ventilated, nonventilated or ladder type cable trays in dry or wet conditions, on walls or beams, directly buried and Class I and II Division 2 locations and all Class III locations. Design Advantages Insulation Properties • High tensile strength • • • • Part No. AWG No. of Cond. Ground Wire Insulation Thick. (in) Nominal O.D. (in) Ampacity* Weight (lbs/M-ft) Impact and crush resistant 2C14B7TEK90 14 2 14 .030 .650 15 215 Heat and moisture resistant 3C14B7TEK90 14 3 14 .030 .671 15 240 4C14B7TEK90 14 4 14 .030 .706 15 270 5C14B7TEK90 14 5 14 .030 .749 12 305 6C14B7TEK90 14 6 14 .030 .789 12 340 Excellent elongation Good low-temperature properties 7C14B7TEK90 14 7 14 .030 .789 11 355 Electrical Properties • High insulation resistance 10C14B7TEK90 14 10 14 .030 1.029 11 550 12C14B7TEK90 14 12 14 .030 1.049 11 590 • Low dielectric loss • High dielectric strength 15C14B7TEK90 14 15 14 .030 1.124 11 685 20C14B7TEK90 14 20 14 .030 1.251 11 870 30C14B7TEK90 14 30 14 .030 1.400 9 1,125 2C12B7TEK90 12 2 14 .030 .688 20 245 3C12B7TEK90 12 3 14 .030 .712 20 280 4C12B7TEK90 12 4 14 .030 .752 20 325 2C10B7TEK90 10 2 12 .030 .736 30 300 3C10B7TEK90 10 3 12 .030 .764 30 350 4C10B7TEK90 10 4 12 .030 .840 30 435 3C8B7TEK90 8 3 10 .045 .897 45 475 4C8B7TEK90 8 4 10 .045 1.035 45 665 3C6B7TEK90 6 3 8 .060 1.117 65 770 4C6B7TEK90 6 4 8 .060 1.237 65 950 3C4B7TEK90 4 3 8 .060 1.263 85 1,035 4C4B7TEK90 4 4 8 .060 1.345 85 1,290 3C3B7TEK90 3 3 6 .060 1.313 105 1,210 3C2B7TEK90 2 3 6 .060 1.377 120 1,390 4C2B7TEK90 2 4 6 .060 1.478 120 1,820 Other Features • Corrosion resistant • Versatile and flexible • Provides cost saving as the need for conduit and ducts are not required See referenced pages in the Hardware & Supplies section: Suggested Prep Tools • MK01A Outer Jacket Cable Stripper - I-11 • 721 Multi-Wire Stripper/Cutter - I-9 12 * Ampacity is based on rule 12-2212 of the CEC Part 1 for installation at 30°C ambient or less and 90°C conductor temperature with at least one cable diameter spacing in ventilated and ladder type trays. Color Coding: For sizes 14, 12, 10 use ICEA Method 1, Table K.2 with printed numbers. For sizes 8 and larger use ICEA Appendix K, Method 4 with printed numbers. www.ptsupply.com marketing@ptsupply.com 800-238-7514 Instrumentation & Tray Type MC UL 1569 Construction Class B stranded bare copper conductors, cross-link PE insulation, bare copper ground wire, aluminum or galvanized steel interlocking armor, PVC outer jacket. Thermoset insulation. NEC conductor temperature 90°C dry and 90°C wet. 600V (14-2 AWG). Applications A general purpose cable used in the pulp and paper, mining, petroleum, and chemical industry as well as in commercial buildings. MC Cable may be used under the following conditions: exposed or concealed wiring in dry or wet conditions, in ventilated, non-ventilated or ladder type cable trays in dry or wet conditions, on walls or beams, directly buried, Class I and II Division 2, and Class III Division 1 and 2 hazardous locations. Design Advantages Insulation Properties • High tensile strength • • • • Part No. 2C14B7MC AWG No. of Cond. Ground Wire Insulation Thick. (in) Nominal O.D. (in) Weight (lbs/M-ft) 14 2 14 .030 .608 180 Impact and crush resistant 3C14B7MC 14 3 14 .030 .629 205 Heat and moisture resistant 4C14B7MC 14 4 14 .030 .665 235 Excellent elongation Good low temperature properties Electrical Properties • High insulation resistance • Low dielectric loss • High dielectric strength Other Features • Corrosion resistant • Versatile • Flexible • Provides cost-saving as the need for conduit and ducts are not required See referenced pages in the Hardware & Supplies section: Suggested Prep Tools • MK01A Outer Jacket Cable Stripper - I-11 • 721 Multi-Wire Stripper/Cutter - I-9 5C14B7MC 14 5 14 .030 .704 270 6C14B7MC 14 6 14 .030 .745 300 7C14B7MC 14 7 14 .030 .745 315 10C14B7MC 14 10 14 .030 .882 415 12C14B7MC 14 12 14 .030 .903 460 15C14B7MC 14 15 14 .030 .978 545 20C14B7MC 14 20 14 .030 1.131 735 30C14B7MC 14 30 14 .030 .1.282 985 2C12B7MC 12 2 12 .030 .646 220 3C12B7MC 12 3 12 .030 .660 250 4C12B7MC 12 4 12 .030 .710 290 2C10B7MC 10 2 10 .030 .694 275 3C10B7MC 10 3 10 .030 .722 320 4C10B7MC 10 4 10 .030 .768 380 3C8B7MC 8 3 10 .045 .843 440 4C8B7MC 8 4 10 .045 .915 535 3C6B7MC 6 3 8 .045 .942 590 4C6B7MC 6 4 8 .045 1.016 795 3C4B7MC 4 3 8 .045 1.093 850 4C4B7MC 4 4 8 .045 1.193 1060 3C3B7MC 3 3 6 .045 1.169 1035 3C2B7MC 2 3 6 .045 1.209 1170 4C2B7MC 2 4 6 .045 1.337 1510 Color Coding: For sizes 14, 12, 10 use ICEA Method 1, Table K.2 with printed numbers. For sizes 8 and larger use ICEA Appendix K, Method 4 with printed numbers. www.ptsupply.com marketing@ptsupply.com 800-238-7514 13 Instrumentation & Tray Thermocouple and Thermocouple Extension Wire Construction Thermocouple Wire Conductor material determined by the thermocouple type. Teflon insulated and jacketed parallel constructions. Teflon Thermocouple Wire is inert to chemical attack and is flame retardant. Thermocouple Wire is made to a certain requirement as defined by the National Bureau of Standards. These standards designate temperature versus voltage levels for certain thermocouple types. Thermocouple Extension Wire Conductor material determined by the Thermocouple extension wire type. FEP teflon or PVC insulated with FEP teflon or PVC jacket. CL3/PLTC multipair thermocouple extension cables contain a 22 AWG (7x30) bare copper orange PVC insulated communication wire. PVC insulation/PVC jacketed cable specifications: • UL Subject 13 • UL 1685 Vertical Tray Flame Test • NEC® Type PLTC Listed, approved for cable tray use in Class 1, Division 2, hazardous areas and non-hazardous areas, cable trays, raceways, conduit and supported by messenger wires FEP insulated/FEP jacketed cable specifications: • UL Subject 13 • UL 910 Steiner Tunnel Flame Test • NEC® Type CL3P/PLTC Listed, approved for use in ducts, plenums and other space used for environmental air Applications Unshielded Parallel non-shielded extension wire may be utilized in low-noise environments when recommended by the instrument manufacturer. Overall Shield Recommended for use in applications where signals in excess of 100 millivolts are transmitted except in areas where high voltage and current sources create excessive noise interference. Individually Shielded Individually shielded pairs are recommended for use in applications where optimum noise rejection is required. Individual pair shields are fully isolated from each other and contain a separate drain wire for grounding to provide maximum protection from crosstalk and common mode interference. 14 www.ptsupply.com marketing@ptsupply.com See referenced page in the Hardware & Supplies section: Suggested Prep Tool • 721 Multi-Wire Stripper/Cutter - I-9 800-238-7514 Instrumentation & Tray Physical Characteristics: Thermocouple and Thermocouple Extension Wire A thermocouple is a temperature measurement sensor that consists of two dissimilar metals joined together at one end (a junction) that produces a small thermoelectric voltage when the junction is heated. The change in thermoelectric voltage is interpreted by thermocouple thermometers as a change in temperature. Thermocouple Identification and Limits of Error - †Reference Junction 0°C Insulation Color Code Conductor ID ISA Symbol Temperature Range °C Limits of Error Standard °C Jacket Color Overall Positive (+) Negative (-) Positive (+) Negative (-) E 0 to 340 ± 1.7°C Brown Purple Red Chromel* Constantan E 340 to 540 ± .5% - - - Non-magnetic Silver Color J 0 to 293 ± 2.2°C Brown White Red Iron Constantan J 293 to 480 ± .75% - - - Magnetic Non-magnetic K 0 to 293 ± 2.2°C Brown Yellow Red Chromel* Alumel* K 293 to 980 ± .75% - - - Non-magnetic Magnetic T 0 to 133 ± 1.0°C Brown Blue Red Copper Constantan T 133 to 260 ± .75% - - - Copper Color Non-magnetic EX 0 to 200 ± 1.7°C Purple Purple Red Chromel* Constantan JX 0 to 200 ± 2.2°C Black White Red Iron Constantan KX 0 to 200 ± 2.2°C Yellow Yellow Red Chromel* Alumel* TX 0 to 100 ± 1.0°C Blue Blue Red Copper Constantan * Hoskins Manufacturing Company Trade Mark † The Temperature Range and Limits of Error are for standard grade thermocouples. Reference ANSI MC96.1-1982 for special grade thermocouples. The Temperature Ranges for type E, J, K and T thermocouple wires listed above pertain to 20 AWG wire. www.ptsupply.com marketing@ptsupply.com 800-238-7514 15 Instrumentation & Tray SDN® Flexible Control Cable UL Listed Type TC Tray Cable, 600V, 90°C Polymer/Nylon Insulation, Neoprene Outer Jacket Construction Conductors Insulation Inside Jacket Overall Jacket Bare, soft annealed copper per ASTM B-3 18 AWG: Bunch stranded Class K (16 x 30 AWG strands), ASTM B-174 and UL-62 paragraph 10.2 16, 14 and 12 AWG: Concentric stranded Class C (19 strands), ASTM B-8 and UL-83 table 13. Flame-retardant polymer Nylon Black neoprene (polychloroprene) Specifications UL Subject 1277 NEC® Article 318 “Cable Trays” and Article 340 “Power and Control Cable Type TC.” Meets the requirements of the 70,000 BTU “Cable Tray Propagation Test” per IEEE-383. Cables pass the CSA FT4 flame tests and are CSA rated as Type CIC TC, 90°C, 600V. Applications SDN cables are designed for control, power, lighting, telemetering, signals and relay control systems. They are especially suitable for flexible applications such as cranes, hoists and some robotic applications, at temperatures down to -55°C. Conductor Data Class Insulation Thick. (in) Nylon Jacket Thick. (in) Nominal O.D. (in) 16 x 30 K .015 .004 .088 19 x 29 C .015 .004 .097 14 19 x 27 C .015 .004 .113 12 19 x 25 C .015 .004 .132 AWG Strands 18 16 Type Installations Inside: Recognized for use in Class 1 or 2, Division 2 hazardous locations and for installation in trays, raceways, troughs, channels, ducts and conduit. Outside: Specifically recommended for direct earth burial in wet or dry locations. The Arctic-grade neoprene jacket resists abrasion, sunlight, oil, chemicals, acids, alkalies and flames. 16 www.ptsupply.com marketing@ptsupply.com See referenced page in the Hardware & Supplies section: Suggested Prep Tool • 721 Multi-Wire Stripper/Cutter - I-9 800-238-7514 Instrumentation & Tray Physical Characteristics: SDN® Flexible Control Cable See conductor color chart on page 8. No. Cond. Jacket Thick. (in) Nominal O.D. (in) Weight (lbs/M-ft) 3 .045 .385 115 4 .045 .420 146 No. Cond. Jacket Thick. (in) Nominal O.D. (in) Weight (lbs/M-ft) 3 .045 .340 84 4 .045 .375 104 14 AWG 12 AWG 5 .045 .460 177 5 .045 .410 127 6 .045 .500 209 6 .045 .440 147 8 .060 .610 294 8 .045 .510 200 12 .060 .685 395 10 .060 .590 246 12 .060 .605 290 16 .060 .665 354 51 24 .060 .820 510 .080 .905 660 .080 .990 785 50 16 AWG 2 .045 .295 3 .045 .305 62 30 4 .045 .335 77 37 5 .045 .360 92 6 .045 .390 107 18 AWG 7 .045 .415 123 3 .045 .290 8 .045 .450 137 5 .045 .335 71 9 .045 .480 165 6 .045 .365 83 10 .045 .490 165 8 .045 .420 109 12 .045 .500 188 10 .045 .455 126 14 .060 .555 240 12 .045 .470 142 16 .060 .590 258 14 .045 .490 165 19 .060 .630 296 16 .045 .515 175 24 .060 .715 367 19 .060 .590 240 30 .060 .750 432 24 .060 .665 321 37 .060 .870 556 37 .060 .775 386 www.ptsupply.com marketing@ptsupply.com 800-238-7514 17 Instrumentation & Tray Flexible Cables, 10 - 20 AWG Unshielded and Shielded Multi-Purpose Flexible Cables • General purpose electronic cables where flexibility is required, providing three times the flexibility of ordinary PVC cable • Ease of installation that standard PVC or Polyurethane cables cannot provide • Outstanding oil and chemical resistant jacket that meets the stringent requirements of the VDE 0472, Section 803 oil test • UL recognition and CSA certification • Black numbered conductors and standard green/yellow ground conductor on the outer layer • Stocked in 600V unshielded and shielded constructions Applications Multi-Purpose Flexible Cables are designed for applications requiring increased flexibility or intermittent motion. They also are used for machine tools and rebuilding, CNC machine centers, data processing, automation and material handling equipment. Clifford offers Flexible Cables from Alpha Wire Company and OLFLEX® Continuous Use Flexible Cable • Unmatched flexibility and durability in continuous motion cable track applications • Twice the flexibility of ordinary PVC cable • Super-flexible cables which have been tested to MIL-C-13777G for flex life • For prolonged use in heavy-duty, high speed cable track applications • Outstanding oil and chemical resistant jacket that meets the stringent requirements of the VDE 0472 Section 803 oil test • UL recognition and CSA certification • Red numbered conductors and standard green/yellow ground conductor on the outer layer See referenced pages in the Hardware & Supplies section: • Stocked in 600V unshielded and shielded constructions Applications Continuous Use Flexible Cables are designed for applications requiring continuous flexing, robotics, installation in cable track, assembly lines and automation and material handling equipment. 18 www.ptsupply.com marketing@ptsupply.com Suggested Prep Tools • MK01A Outer Jacket Cable Stripper - I-11 • 721 Multi-Wire Stripper/Cutter - I-9 800-238-7514