Leaflet corrosion_EN

advertisement

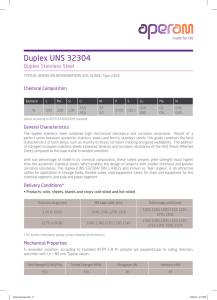

Stainless Steel and Corrosion What is corrosion? Metals, with the exception of the precious metals such as gold and platinum, that are found in their natural state are always extracted from ores; metals have therefore a tendency to revert to their stable state, which corresponds to their original state, that is to say their oxide form. Metal corrosion is essentially an electro-chemical reaction at the interface between metal and surrounding environment . Stainless Steel and the passive layer Steel is an alloy of iron and carbon. Contrary to carbon steel, the presence of a minimum of 10.5 % chromium in the stainless steel gives it the property of corrosion resistance. What are the major factors of corrosion? Medium Design Chemical nature Surface state Concentration Shape Oxidising power Assembly (welds, rivets) pH (acidity) Mechanical stresses Temperature Pressure Proximity to other metals Contact with a medium Viscosity (partial or total immersion) Solid deposits Methods of protection Agitation Composition Manufacturing Metallurgical state (thermal or mechanical treatment) Additives Impurities Material Chromium >10,5% factors Time What are the 5 principal types of corrosion linked with the surrounding environment ? Carbon <1,2% Iron Corrosion Ageing of the structure Evolution of stresses Temperature variability Modification of coatings Maintenance frequency Fe+C=steel Fe+C+Cr=stainless steel generalised localised Pitting Indeed, on contact with oxygen, a chromium oxide layer is formed on the surface of the material. This passive layer protects it and has the particular ability to self repair. neutral chloride environment Reaction of steel and stainless steel in contact with moisture in the air or water. Steel Stainless Steel Formation of iron oxide (rust) Formation of chromium oxide Fe + C O2 Crevice Under stress Fe + C + Cr > 10,5 % Rust Passive layer However if this protective layer is damaged, the start of corrosion can appear Intergranular Generalised acid medium Generalised corrosion is noticed when stainless steel is in contact with an acid medium and localised corrosion is seen in the majority of cases when stainless steel is placed in a neutral chloride environment La corrosion par piqûre In the document which follows we describe the 5 principal types of corrosion and we rank the majority of Stainless Europe grades from standard laboratory tests However, the phenomena of corrosion in real life are always specific, the data described does not exclude extra trials to choose the optimal material. Pitting Corrosion To understand the phenomenon Pitting corrosion is a local break in the passive layer of the stainless steel provoked by an electrolyte rich in chloride and or sulphides. At the site of the pitting, where the metal is unprotected, corrosion will develop if the pit does not re-passivate, in other words if the speed of metal dissolution enables to maintain a sufficiently aggressive environment to prevent its re-passivation. Passive layer Metal METAL ATTACK Chlorides > If the potential of the stainless steel in the given medium is superior to the pitting potential =>the stainless steel corrodes Note: the higher the pitting potential, better shall be the corrosion resistance of the grade. Outside the pits, the passive layer is always present to protect the stainless steel. Figure 1 shows pitting potentials obtained for different stainless steels in water containing 0.02M NaCl (710mg/l Cl-) at 23°C. It shows the influence on the resistance to pitting corrosion with the content of chromium and molybdenum for the ferritics, and chromium, molybdenum and nitrogen content for the austenitics. mV/SCE Passive layer Figure 1 800 K44 Corrosion of the base metal The metal re-passivates Passive Layer Metal This dissolution gives rise to metal ions and electrons and thus the passage of current (of dissolution) which gives rise to an electrical potential difference between the anodic zone (pitting) and the cathodic zone (the rest of the metal). To simulate this type of corrosion under laboratory circumstances, a sample is immersed in a corrosive electrolyte to which an increasing potential is applied until the passive layer is broken. During this dynamic potential (intensity/potential) scan the sudden increase in intensity corresponds to the pitting potential Epitting IntensitY I =50µA/cm2 Epitting POTENTIAL Passive Field The pitting potential corresponds to the potential necessary to initiate stable pits. > If the potential of the stainless steel in the given medium is inferior to the pitting potential => pitting does not start 700 17-11MT 18-11ML 600 18-9E/L 18-10T 17-7A/C/E K41 500 K45 K36 18-7L 17-4Mn 16-4Mn 16-5MnL 2 cases Pitting potential in water containing 0.02MNaCI pH=6,6 at 23°C (mV/SCE ) Metal K39 400 K30-K31 K03 K09 K10 300 Martensitic 200 10 12 14 16 18 20 22 24 PREN (%Cr+3,3%Mo+16%N) Commercial Designations Martensitic K09+ K03 K10 K30-K31 K39 K41 K36 K45 K44 16-4Mn 16-5Mn 17-4Mn 17-7A/C/E 18-7L 18-9L 18-11 ML 17-11MT Standards ASTM Designation: Type 420 409 410S 430 439 441 436 445 444 201.2 201LN 201.1 301 301LN 304L 316 - 316 L 316Ti EN 1.4021 1.4512 1.4003 1.4000 1.4016 - 1.4017 1.4510 1.4509 1.4526 1.4621 1.4521 1.4372 1.4371 1.4618 1.4310 1.4318 1.4307 1.4401 - 1.4404 1.4571 26 As figures 2 and 3 show, this pitting potential can only be used to rank the grades in a given medium. It diminishes notedly when the temperature (figure 2) or the concentration of chlorides in the medium increases. (figure 3) 500 K44 600 18-11ML 500 18-9E/L 400 K36 K41 K39 300 K30 200 K03-K09-K10 100 Pitting potential in water containing 0.5M NaCI pH=6,6 at 50°C (mV/SCE) Pitting potential in water containing 0.02M NaCI pH=6,6 at 23°C (mV/SCE) 700 450 400 350 300 18-9E/L K36 K41 250 K39 200 150 K30 100 50 0 K03-K09-K10 0 10 12 14 16 18 20 22 24 K44 18-11ML 26 10 12 14 PREN (%Cr+3,3%Mo+16%N) 16 18 20 22 24 26 PREN (%Cr+3,3%Mo+16%N) Figure 2 Figure 3 In order to map the duplex range, tests in the most severe medium, 0.5M NaCl (17.75g/l Cl-) at 50°C, were carried out. The results obtained are shown below. 23° 50° 23° 700 23° Standards No pits 500 No pits 600 No pits Pitting potential in water containing 0.5M NaCl, at 23°C and 50°C (mV/SCE) Figure 4 1200 50° Commercial Grades 23° 23° ASTM Designation Type 400 23° 300 50° 50° 200 50° EN UNS DX2202 2202 UNS 32202 1.4062 DX2304 2304 UNS 32304 1.4362 DX2205 2205 UNS 32205 1.4462 50° 100 0 DX2202 DX2205 DX2304 304 316 K44 > Usually we use the PREN (Pitting Resistance Equivalent Number) of the grades to rank their general piting behaviour. The PREN, %Cr+3.3%Mo+16%N , demonstrates the major influence of these alloy elements. Our recommandation To avoid pitting corrosion: > We would look to see if it is possible to lower the corrosiveness by lowering the temperature of the medium, limiting contact time, avoiding stagnant areas and reducing the concentration of halogens and the presence of oxidants. > We would choose a grade high in chromium or containing molybdenum. Crevice Corrosion To understand the phenomenon A/Initiation of corrosion In an electrolyte high in chloride, a confined (occluded) zone linked for example to bad design, favours the accumulation of chloride ions. The progressive acidification of the medium in this zone facilitates the de-stabilisation of the passive layer. When the pH in this zone reaches a critical value called « depassivation pH »,corrosion starts. The depassivation pH or pHd is used to characterize the resistance to crevice corrosion initiation. WHY? Confined zone (acidification) HOW? Break in the passive layer and metal attack Some pHd values for our stainless steels are given in figure 5. The lower the value pHd the better the resistance to crevice corrosion. Figure 5: Depassivation pH of various stainless steels in NaCl 2M (71g/l Cl-) de-aerated and acidified with HCl at 23°C This value is sensitive to the alloy elements which improve the passivity and limit active dissolution, principally molybdenum, nickel and chromium (see figure 6 ). The speed of propagation is also a function of local aggressiveness and temperature of the medium. 4 3,5 3 Figure 6: Critical current «icrit» at the peak of activity for various stainless steels in NaCl 2M (71g/l de Cl-) deaerated and acidified with HCl at 23°C. 2,5 2 1,5 DX2205 1 0,5 10 15 20 25 30 35 PREN (%Cr+3,3%Mo+16%N) B/ Propagation of corrosion Once corrosion is initiated, its propagation occurs by active dissolution of the material in the crevice. In the laboratory, we simulate this type of corrosion by recording the potentiodynamic scans in chloride mediums of increasing acidity. Critical current «icrit» at the peak of activity for various stainless steels in NaCl 2M +(71g/l de Cl-) Depassivation pH of various stainless steels in NaCl 2M ( 71g/l Cl-) de-aerated and acidified with HCl at 23°C If on a recording we detect a current peak (activity), crevice corrosion is starting , in the opposite case repassivation takes place. Activity peak measurement for a pH lower to the depassivation pH can then be considered to quantitatively compare the speed of crevice corrosion propagation for different grades. 2500 K03/K09/K10 2000 Martensitic K30/K31 K41 K39 1500 K45 1000 164Mn 165MnL 500 174Mn K44 DX2202 187L DX2304 177A 0 1 3 5 189E 1810T 7 1711MT 1810L 1811ML 1812MS 1813MS 9 DX2205 11 0,2%Cr+%Mo+0,4%Ni > Our recommandation Our first recommendation to avoid crevice corrosion is to optimise the design of the piece to avoid all artificial crevices. An artificial crevice can be created by a badly made joint, a rough or bad weld, deposits, gaps between two plates etc., If the confined zone is unavoidable, it is preferable to enlarge this zone and not to make it smaller. If the design of the pièce is not modifiable or if the fabrication process makes difficult to avoid confined zones, the risk of crevice corrosion is very high . We recommend, in this case, choosing an appropriate grade, in particular a stainless steel austenitic or duplex when the product will be in contact with corrosive media or part of the process equipment. If ferritics with 20% chromium limit the risk of crevice corrosion initiation, they do not, with the exception of K44 containing 2% molybdenum, curb its propagation unlike austenitic or duplex more highly nickel and / or molybdenum alloyed. Intergranular Corrosion To understand the phenomenom At temperatures greater than 1035°C , the carbon is in solid solution in the matrix of the austenitic stainless steels. However, when these materials are cooled slowly from these temperatures or even heated between 425 and 815 °C, chromium carbides precipitate at the grain boundaries. These carbides have a higher chromium content in comparison to the matrix. Consequently, the zone directly adjacent to the grain boundaries is greatly impoverished. The sensitisation state takes place in a lot of environments by privileged initiation and the rapid propagation of corrosion on the de-chromed sites. For unstabilized ferritic stainless steels, the sensitisation temperature is greater than 900°C. 13 > Our recommandation In practice , this case of corrosion can be encountered in the welded zones . The solution for the austenitic consists of using a low carbon grade called « L » (Low C%<0.03%) or a stabilized grade, and the titanium or niobium stabilized ferritic grades. The volume of the piece permiting a thermal treatment of the quenching type (rapid cooling) at 1050/1100°C or a tempering of the welded piece can be done. Stress Corrosion To understand the phenomenon We mean by « stress corrosion » the formation of cracks which start after a period of long incubation and which afterwards can propagate very rapidly and provoke downtime of the equipment by cracking . This particularly dangerous phenomenon is the result of the combined effects of 3 parameters: - temperature, since stress corrosion rarely develops under 50°C - the applied or residual stresses - the corrosiveness of the medium : presence of Cl-, H2S or caustic media NaOH Aggressive medium Chlorides Temperature effects > Although stress corrosion of ferritics can be provoked by particularly aggressive tests in the laboratory , their body cubic centred structure rarely renders them subject to this type of phenomena in practice . > The face cubic centred structure of austenitic stainless steels can present a risk. In effect , it favours a mode of planar deformation which can generate very strong stress concentrations locally. As shows the graph below, this is particularly true for classic austenitic stainless steels with 8% nickel; an increase in nickel above 10% is beneficial . > In austenitic stainless steels, the austenitic stainless steels with manganese perform worse. > The austeno-ferritic structure of the duplex gives them an intermediate behaviour, very close to the ferritics in the chloride medium and even better in the H2S medium . 1000 cracking Fissuration PASSIVE LAYER No cracking STAINLESS contraintes PASSIVE LAYER 100 Time to crack (hours) contraintes 10 STAINLESS CRACKs The metallurgical structure of stainless steels influences their behaviour in this type of configuration. 1 0 > 20 40 60 80 Nickel content, wt.% Effect of nickel content on the resistance to stress corrosion of Stainless steel containing from 18-20% chromium in magnesium chloride at 154°C [ From a study by Copson [ref] . Physical Metallurgy of Stress Corrosion Cracking, Interscience, New York, 247 (1959).] Our recommandation To avoid this type of corrosion: > Suppress the stresses or have a better redistribution, by optimising the design or by , of the pieces concerned. a stress relieving treatment after forming and welding , > lower the temperature if possible > If not practicable, choose the grade most adapted, favouring as a solution a ferritic or duplex but bearing in mind the other corrosion problems encountered . Uniform Corrosion To understand the phenomenon The maximum current reading of the activity peak allows us to classify the resistance of different grades to this type of corrosion (see figure 7). Generally, the higher the current, the faster and greater the dissolution, thus the less the grade will be resistant. We see this corrosion in acid mediums. Indeed, below a critical pH value, the passive layer protecting the stainless steel is no longer stable and the material suffers a generalised active dissolution. The more acid the medium, the faster the corrosion and the loss of thickness of the stainless steel. In the laboratory, we measure this speed of corrosion in an acid medium by graphing the polarisation curve (see below). An increasing potential scan is imposed on the metal and the corresponding intensity is recorded. 100 10 Polarization curve in an acidic medium Potential U 1 Transpassivity 0.1 Passivity 0.01 K09 Pre-passivity Up B K03 K30 K41 K39 K45 K44 16-4 18-9E 17-4 18-11 Mn Mn ML Figure 7: Critical current «icrit» at the peak maximum in H2SO4 2M de-aerated at 23°C Activity Immunity M UP = Current density (I) Cathodic Curve Anodic Curve Pitting Potential In a low oxidising medium, the cathodic curve (M) cuts the anodic curve below the pitting potential: metal remains intact. In a strong oxidising medium, the cathodic curve (B) cuts the anodic curve above the pitting potential: pits appear on the surface of metal. Aperam Stainless Europe Le Cézanne - 30, Avenue des Fruitiers Aperam Stainless Europe FR-93212 La Plaine Saint Denis Cedex Le Cézanne - 30, Avenue des Fruitiers FR-93212 La Plaine Saint Denis Cedex > Our recommandation To avoid this type of corrosion, choose the appropriate grade in regard to the acid medium used. We note the favourable impact of chromium and molybdenum which reinforce the existing passive film but also the combined effect of noble alloys (nickel, molybdenum and copper) which slow down the dissolution of the material when the stability of its passive layer is broken. Information Information Tel. : +33 1 71 92Information 06 66 www.aperam.com/stainlesseurope Fax : +33 1 71 92 07: 98 Tel. +33 1 71 92 06 66 stainless.europe@aperam.com www.aperam.comFax : +33 1 71 92 07 98 stainless.europe@aperam.com www.aperam.com stainless.europe@aperam.com September 2013, Aperam Stainless Europe. FT-Corrosion.en. While everycare has been taken to ensure that the information contained in this publication is as accurate as possible, Aperam Stainless Europe cannot guarantee that it is complete nor that it is free from error. KARA® is a brand of Aperam Stainless Europe, registered in numerous countries. © Aperam. This is the dissolution of all the affected points on the surface of the material which are attacked by the corrosive medium. On the micrographic scale,this corresponds to a regular uniform loss of thickness or loss of weight (uniform or generalised corrosion as opposed to localised corrosion).