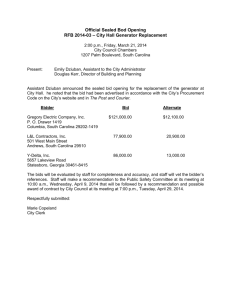

CEYLON PETROLEUM CORPORATION B/34/2014

advertisement

CEYLON PETROLEUM CORPORATION (Established by Parliamentary Act Number 28 of 1961) BIDDING DOCUMENT SUPPLY & INSTALLATION OF 800 kVA GENERATOR AT AVIATION FUNCTION, BANDARANAYKE INTERNATIONAL AIRPORT – KATUNAYAKE B/34/2014 CHAIRMAN CEYLON PETROLEUM CORPORATION NO. 609, DR. DANISTER DE SILVA MAWATHA COLOMBO 09 SRI LANKA CONTENTS Invitation for Bids 01 02 03 04 05 06 . Instructions to Bidders . Conditions of Contract (COC) . Technical Specifications . Bill of Quantities (BOQ) . Drawings . Technical Schedule 1-5 6-8 9-23 24-28 29-31 32-37 Annexes A – Declaration of Bidder B – Format of Manufacturer’s Authorization C – Form of Compliance / Deviation Sheet D – Form of Bid E – Format of Bid Security Guarantee F – Form of Agreement G – Format for Performance Guarantee H – Format of Advance Payment Bank Guarantee 38 39 40 41-42 43 44-45 46 47 INVITATION FOR BIDS CEYLON PETROLEUM CORPORATION (CPC) B/34 /2014 SUPPLY & INSTALLATION OF 800 KVA GENERATOR The Chairman, Departmental Procurement Committee, Ceylon Petroleum Corporation, No. 609, Dr. Danister De Silva Mawatha, Colombo 09 Sri Lanka will receive sealed Bids from manufacturers or their Agents in Sri Lanka for the Supply & Installation of 800 KVA Generator for the Aviation Function of CPC at Katunayake. Bid documents can be obtained between 0900 hrs. and 1500 hrs. up to 02.10.2014 from the office of Manager (Procurement & Stores), Ceylon Petroleum Corporation, 1st. Floor, No. 609, Dr. Danister De Silva Mwt., Colombo 09, on a written request and payment of a non-refundable fee of Rs. 1,142.40 (Rs. 1,000.00 + 2% NBT + 12% VAT) per set. The Bid will be closed at 1400 hrs. on 03.10.2014 and opened at the Office of Manager (Procurement & Stores), Ceylon Petroleum Corporation, at the above address, immediately after closing time of the Bid. Bidders or their authorized representatives will be permitted to be present at the opening of the Bid. Bids may be sent by post under registered cover or may be deposited in the Tender Box kept in the Office of Manager (Procurement & Stores), Ceylon Petroleum Corporation, 01st Floor, No. 609, Dr. Danister De Silva Mwt, Colombo 09. Bid documents may be inspected at the Office of Manager (Procurement & Stores), or on the website www.ceypetco.gov.lk. . MANAGER (PROCUREMENT & STORES) CEYLON PETROLEUM CORPORATION NO. 609, DR. DANISTER DE SILVA MAWATHA COLOMBO 09. Tel.: 5455330/5666225 Email: rajapakse@ceypetco.gov.lk 01. INSTRUCTIONS TO BIDDERS 01. INTRODUCTION The Chairman, Departmental Procurement Committee (DPC), on behalf of the Ceylon Petroleum Corporation, No. 609, Dr. Danister De Silva Mawatha, Colombo 09, Sri Lanka will receive sealed Bids from Manufactures or their Local Agents in Sri Lanka with minimum of 10 years’ experience in the relevant field for the Supply & Installation of 800 kVA Generator conforming to the Terms & Technical Specifications indicated in the Bidding Document. 02. BIDDING DOCUMENT FEE & BID DEPOSIT Bidding Documents can be obtained up to 1500 hrs. on 02.10.2014. Any Bidder calling for Bidding Documents, shall pay a non-refundable fee of Rs. 1,142.20 for the Bidding Document to the Cashier, CPC Head office, No. 609, Dr. Danister de Silva Mawatha, Colombo – 09. 03. DOCUMENTS & DETAILS TO ACCOMPANY BID All Bids shall contain adequate particulars in respect of the items offered. A. Failure to furnish the following documents and details along with the Bid will result in the bid being rejected. 01. Make and model number 01. Name & the company profile of the Manufacturer and Country of manufacture. 03. Technical Catalogues, literature of the offered item 02. Declarations from the bidder that the equipment offered are currently in manufacture, conforming to CPC specification and standards referred. 03. Declarations from the bidder for the availability of spares for equipment offered for minimum of 10 years period. 04. Company profile of the bidder & copies of financial statements for the past these years 05. Details of the maintenance staff intended to be deployed for the installation work & availability of workshop facility to provide after sales services. 06. Declaration of Bidder – Annex ‘A’ 07. Letter of Authorization from the principals–Annex ‘B’ 08. Form of Compliance/ Deviation Sheet – Annex ‘C’ 09. Form of Bid - Annex ‘D’ 10. Format of Bid Security - Annex ‘E’ 11. Form of Agreement - Annex ‘F’ 12. Format of Performance Guarantee - Annex ‘G’ 13. Format for Advance Payment Guarantee - Annex ‘H’ All documents shall be in English Language. 04. (A) SUBMISSION OF BID Bidder is strictly advice to visit the site before the pricing. Bidder who submits the bid without prior site visit may cause for rejection of his bid. Location of site: Aviation Function, BIA, Katunayake Contact Person: Manager (Aviation - Operations) Contact Number: 0112253039 Page 1 of 47 A local firm acting as Agent for more than one Principal Bidder should get each of his Principal Bidders he represents to tender on separate sets of Bidding Documents purchased from the Ceylon Petroleum Corporation for such purpose. Note: Alternative Bids / Options Multiple bids from same manufacturer can be submitted indication one offer as the main offer. (B) SUBMISSION OF A BID GUARANTEE Bid Security obtained from a Bank or Treasury approved Insurance Company to a value of Rs. 250,000.00 shall be submitted along with the Bid. Any bid not accompanied by an acceptable Bid Security will be “REJECTED” by the Procurement Committee considering the Bid as non-responsive. The Bid Security shall be valid form a period of 105 days from the date of closing of the Bid. 05. SEALING, MARKING & RECEIPT OF BIDS Bids shall be submitted in Duplicate as per annexed schedule of Prices. The original & duplicate copy of the Bid shall be placed in separate envelopes marked “ORIGINAL” & “DUPLICATE”. Envelopes shall be enclosed in one securely sealed cover, which shall be marked for the Supply & Installation of 800 kVA Generator–CLOSING DATE 1400 hrs. on 03.10.2014 on the top left-hand corner & the Bidder’s name & address on the bottom left-hand corner. Bids sealed, enclosed, marked and addressed as aforesaid, shall be sent under Registered Cover to reach the Chairman, DPC, Ceylon Petroleum Corporation, No. 609, Dr. Danister De Silva Mawatha, Colombo 09, Sri Lanka, not later than 1400 hrs on 03.10.2014 If, the Bidders choose not to send their Bids under Registered Cover, they could deposit such Bids in the Tender Box provided for this purpose at the Office of Manager (Procurement & Stores), 1st. floor, CPC Head Office, No. 609, Dr. Danister De Silva Mawatha, Colombo 09. 06. MINIMUM VALIDITY PERIOD OF BIDS (a) All bids shall necessarily be valid for acceptance for a minimum period of 77 days from the closing date of the Tender. (b) All prices indicated in the schedule of prices shall be firm and shall not be subject to any price variation within the validity period of offer specified in (a) above. (c) On acceptance of the offer within the period of 77 days the validity of offer should be extended by another 14 days for the purposes of a issuing of purchase order and other required documentation. Bids that do not comply with the above requirements will be rejected. 07. (a) CLOSING & OPENING OF BIDS Bids will be closed at 1400 hrs on 03.10.2014 & will be opened immediately thereafter at the Tender Opening room of Supplies Function. Bidder/s or their duly authorized representative/s may be present at the opening of bids. The officer who opens the Bids will read out the total price, as indicated in the schedule of prices/ Pro-forma to those who are present. Technical Data, Specifications or similar particulars will not be divulged. Page 2 of 47 (b) LATE BIDS Any Bid received after the deadline for submission of Bid will be rejected and returned unopened to the Bidder. 08. LETTER OF AUTHORIZATION a. Offers from agents representing their Principals abroad, will not be considered unless they hold the Letter of Authorization from the Principals empowering the agents to offer on their behalf, to enter into a valid agreement on behalf of the Principals to fulfill all the terms and conditions of the contract, in the event of the bid being awarded. b. The agent signing the Bidding Document on behalf of the Principal shall state the Principal’s name, address, telephone, fax numbers & e-mail address if any. c. Nomination of Agents after the Bid has been submitted will not be valid. d. In the event that the Principal is not the Manufacturer, the Principal should furnish documentary proof of his arrangements with the Manufacturer. e. Principal means the seller with whom CPC enters into an agreement as per the tender. In case of an order, purchase order is placed with the principal. 09. BUSINESS REGISTRATION Local Agents in Sri Lanka, submitting the Bid should register with the Registrar of Companies and shall produce a copy of the valid Certificate of Registration issued by the Registrar of Companies together with the offer & a copy of the respective company registration of principal bidders shall be forwarded along with the bid. 10. VARIATIONS Bid price shall not be adjusted unless there is arithmetical error. 11. BILL OF QUANTITIES (BOQ) 11.1. Should indicate the prices in Rupees with taxes separately. 11.2. If any taxes are not mentioned separately such taxes will be considered as not relevant for the bid. 11.3. Where there is a discrepancy between the amount in figures and in words, the amount in words will govern. 11.4 Where there is a discrepancy between the unit rate and the line item total resulting from multiplying the unit rate by the quantity. a. The unit rate as quoted will govern b. Unless in the opinion of the Procurement Committee/TEC there is an obviously gross misplacement of the decimal point in the unit rate, in which case the line item total as quoted will govern and the unit rate will be corrected. 11.5 The amount stated in the Bidding Document adjusted in accordance with the above procedure with the concurrence of the bidder shall be considered as binding upon the Tender. If the bidder does not accept the corrected amount of bid, his bid will be rejected. Page 3 of 47 12. CORRECTION OF ERRORS a. Where there is a discrepancy between the amount in figures and in words, the amount in words will govern; and b. Where there is a discrepancy between the unit rate and the line item total resulting from multiplying the unit rate by the quantity. i. The unit rate as quoted will govern ii. Unless in the opinion of the Procurement Committee/TEC there is an obviously gross misplacement of the decimal point in the unit rate, in which case the line item total as quoted will govern and the unit rate will be corrected. c. The amount stated in the Bidding Document adjusted in accordance with the above procedure with the concurrence of the bidder shall be considered as binding upon the Tender. If the bidder does not accept the corrected amount of bid, his bid will be rejected. 13. EVALUATION OF BIDS All offers received will be examined to determine the eligibility of bidder’s responded and substantial responsiveness of bids received. Substantially responsive bid is one, which conforms to the terms, conditions and specifications of the Bidding Document. Incomplete bids will be rejected. Arithmetical errors in the Bidding Document will be corrected. Only the bids determined to be substantially responsive will be evaluated and compared. Award will be made to the lowest responsive evaluated bid. 14. POWER TO ACCEPT OR REJECT OFFERS (a) The Departmental Procurement Committee will not be bound to make the award to the Bidder submitting the lowest offer. (b) The Departmental Procurement Committee reserves the right to reject any or all Bids, or any part thereof, without adducing any reasons. 15. ANY OTHER INFORMATION 15.1. Any other information or clarification required could be obtained from the Manager (Procurement & Stores), Supplies Function, 1st Floor, Ceylon Petroleum Corporation, No. 609, Dr. Danister De Silva Mawatha, Colombo 09 Sri Lanka not later than 12 days before the closing date of tender given in clause No. 05. Telephone E-mail : : 5455330/5666225 raja@ceypetco@gov.lk Fax - 5455424 15.2. Where the Bidders have not sought any clarifications / information such Bidders shall be deemed to have accepted the Bidding Document in full. CPC reserves the right to issue amendments to the Bidding document if and when deemed necessary, up to 08 days before the closing date of the bid given in Clause 05 and such amendments will be notified to all Bidders who have collected the Bidding documents. Page 4 of 47 16. ABREVIATIONS DPC CPC ICLP ICTAD - Departmental Procurement Committee Ceylon Petroleum Corporation Institute for the Development of Commercial Law & Practice Institute of Construction Training and Development 17. PRE-BID MEETING 17.1 Bidder’s designated representative(s) is invited to attend a pre-Bid meeting, which will take place at the Aviation Function Katunayake at 11 a.m on 7 days before the tender opening date. 17.2 The purpose of the meeting will be to clarify issues and to answer questions on any matter that may be raised at that stage. 17.3 The Bidders are requested, as far as possible, to submit any questions in writing or by facsimile, to reach the Employer not later than one week before the meeting. It may not be practicable at the meeting to answer questions received late. All questions raised at the prebid meeting will be responded to in writing by the Employer. Page 5 of 47 02. CONDITIONS OF CONTRACT 01. NOTICE OF ACCEPTANCE Acceptance of bid will be communicated by fax / E-mail and confirmed in writing by registered post to the successful bidder to the address given by him, soon after the receipt of DPC decision. Any change of address of the bidder should be promptly notified to the Manager Supplies, Supplies Function, 1st Floor, Ceylon Petroleum Corporation, No. 609, Dr. Danister De Silva Mawatha, Colombo 09. , Sri Lanka. 02. PERIOD COMPLETION The successful contractor should supply install and commission the 800 kVA Generator within a period of six months from the date of receipt of the “Notice of Acceptance”. 03. SUBMISSION OF A PERFORMANCE SECURITY GUARANTEE Within a period of fourteen (14) on receipt of the Letter of Acceptance the successful bidder shall deliver to the employer a Performance Security in the amount equal at 10% of the contract price and in the form of a Bank Guarantee or a fixed deposit in the name of Ceylon Petroleum Corporation. If the Performance Security is provided by the bidder from a Bank operating in Sri Lanka the Bank Guarantee issued should be in the format given in “Annex G”. Note: Performance Guarantee from Insurance Companies will not be accepted by CPC for this contract. 04. MODE OF PAYMENT An advance payment of sum equivalent to a maximum of 20% of the total contract value could be released upon submission of a bank guarantee as per Annex ‘H’. The bank guarantee shall be valid for entire duration until the commissioning of the Generator. Repayment of the advance payment will be made from the subsequent claims. Advance payment shall be recovered fully when total invoice amount reaches 90% of the contract price. Subsequent payment shall be carried out in following Manner (i) (ii) (iii) (iv) Upto 70% of the assessed value of material and equipment at site will be paid on invoices. Upto 95% of the contract price on satisfactory completion and taking over. The retention from each payment shall be 10% percent of the certified work done. The limit of retention shall be 5% percent of the Initial Contract Price and will be release after one (1) month by completion of defect liability period. 05. DEFAULT BY SUCCESSFUL BIDDER 5.1 If for any reason in the opinion of the Ceylon Petroleum Corporation, the successful Bidder becomes incapable or unable to supply & install 800 kVA Generator offered in his Bid within the specified delivery period, the Ceylon Petroleum Corporation shall have the right to obtain the goods from other sources without being liable in any manner, whatsoever, to the successful Bidder. Page 6 of 47 5.2 If the successful Bidder defaults in the supply or otherwise commits a breach of any of the provisions in the Contract with the Ceylon Petroleum Corporation for the supply & install 800 kVA Generator conforming with the Specifications the Performance Guarantee will be forfeited. Further, he shall be liable to pay to the Ceylon Petroleum Corporation, all losses, damages and expenses incurred by the Ceylon Petroleum Corporation in consequence of such default of breach. 06. PENALTY ON DELAYED COMPLETION If the successful bidder could not supply & install the generator within the delivery period stipulated in above clause No. 15, a penalty charge of 0.05% of the total order value per calendar day or part thereof up to a total value of 10% of the total order value will be recovered from the payment to the bidder. However, CPC reserves the right to cancel the award of the tender, if the Generator is not supplied & installed within the period given in clause 15. 07. WARRANTY 7.1 Supplier should give a manufacturer’s warranty for all the equipment Supplied by him for a minimum period of 12 months form the date of commissioning. Warranty Conditions shall be clearly indicated in the quotation. 7.2 Any defect found during this warranty period should be attended by the supplier at his own cost (labour & spare parts), and any defective parts should be replaced with new parts free of charge. 7.3 All equipment and machinery offered should be brand new and proven models and no Prototype models should be offered. 08. FORCE MAJEURE Except as regards an act of God, war, strike, invasion, Civil War, rebellion, Tsunami, revolution, insurrection, military power, earth-quake, plagues, the Bidder shall undertake all risks and liabilities of whatsoever kind arising out of incidentals or connected with the supply. 09. BIDDER'S STANDARD CONDITIONS OF SALE Bidder's standard conditions of sale, usually printed on the reverse side of the Pro-forma Invoice or in a separate format will not be accepted. The Conditions of Tender of CPC will prevail. 10. ARBITRATION 17.4 All the disputes arising out of this agreement will be settled in accordance with the provisions of the Arbitration Act No. 11 of 1995. 17.5 All proceedings and hearings by the Arbitrator shall be held in Sri Lanka Arbitration will be conducted under the rules of the ICLP Arbitration Center and the Arbitration Act No. 11 of 1995. Page 7 of 47 11. DECLARATION Bidders should declare that they have read the Conditions and that they make the offer in compliance with and subject to all the Conditions thereof and agree to execute the contract / perform the services in accordance with the said Conditions in the manner therein set out. Page 8 of 47 3.0 Technical Specification 800 kVA Diesel Generator 1. General 1.1 Scope of Work The Contractor shall carry out the supply, delivery, erection, connection, testing, commissioning of brand new 800kVA Diesel engine driven Generator including the supply & installation of all the relevant equipment and material mentioned as per the requirements indicated in this bid document to establish an emergency LV Electrical Power Supply System to the premises. The engine driven generator shall be fully automatic and shall constitute a unified and coordinated system ready for operation once it is commissioned. The supplier shall service & maintain the Generator during the defects liability period which is one year stating from date of issuance of Take Over Certificate (TOC) by CPC. The location of the works is Aviation Refueling Terminal, Ceylon Petroleum Corporation, Bandaranayke International Airport (BIA) Katunayake. The installation shall include but not be limited to the following: 1. Remove the existing 75 kVA Generator and temporarily mount it adjacent to the switch room and provide required cabling to ATS panel for the normal stand by operation until completion of the works. 2. Modify and extend existing generator room (Size: 4.5 m*7.5m) to accommodate the installation of 800 kVA generator, day fuel tank and other necessary accessories. The concrete plinth shall be designed and constructed to withstand the new generator installation. 3. Supply and installation of Generator incoming breaker panel complete with suitably rated circuit breaker ATF/ATS, indicators, measuring equipment and necessary interlocks to communicate with existing CEB incoming breaker for fully automatic operation. Existing main incoming breaker details; Brand : Siemens Model : 3WN6473-OHG58-4KK1 Ratings : 1600A, 4P 4. Diesel Engine complete with; Lubrication Oil System Fuel Oil System Cooling System Speed governing system Intake and Exhaust Air Systems Starting System Page 9 of 47 1.2 5. AC Generator complete with; Control panel Automatic voltage regulating system Monitoring/supervision Circuit breaker Cabling/Bus bar connections to existing bus bars at switch room 6. Main storage tank of fuel, fuel transfer pumps, pipes and valves 7. Engine Generator set should be mounted inside of Sound attenuated weatherproof enclosure 8. LV Power cables/Bus bars 9. Spare Parts. 10. Witness of FAT(Factory Acceptance Test) by CPC Engineers Standby Power Supply Scheme There is no standby power supply for the pump room at present. Stand-by power supply for administration building and control room is provided by 75 KVA Diesel Generator. CPC intends to install new 800 kVA Diesel generator, electrical switchgear, AMF/ATS panel and other accessories under this contract. The existing 75 kVA generator and electrical power supply system shall not be permanently removed from the service until the new 800 kVA diesel generator is commissioned and connected to the system. The Generator shall be capable of providing required current for the operation of 02 nos. of 160 kW pump motors which are connected to fuel hydrant pumps used for in-to plane operations at BIA. The motors have star-delta starting method. The single line diagram of the existing electrical installation is given in Drg: No-01. All the loads connected to the main bus bars (i.e. after 1600 A, ACB) shall be considered as essential loads and the ATS panel output shall be connected to the main bus bars. The proposed procedure for the modification is as follows. 1. Remove existing 75 kVA generator and temporary place it adjacent to the switch room as directed by the engineer and provide temporary connections to the existing ATS panel 2. Modify existing generator room (Size: 4.5 m*7.5m) to accommodate the installation of 800 kVA generator, fuel day tank and other necessary accessories. The concrete plinth shall be designed and constructed to withstand the new generator installation. 3. Supply and install new 800kVA diesel generator with a suitable canopy in the existing generator room after necessary modifications and extension. 4. Supply and installation of a suitable size diesel day tank for 12 hour operation and bulk tank for 48 hour including necessary pumps, pipes, hoses and valves etc. Page 10 of 47 1.3 5. Supply and installation of new electrical switchgear to facilitate generator incoming breaker, AMF/ATS and necessary provisions to connect existing main bus bar 6. Supply and install new LV power cables/Bus bars to connect the new 800kVA diesel generator and CEB supply to the new electrical switchgear through main bus bars. The cabling and installation work of the generator shall be done without interruption of regular operations and other day to day works. Always two nos. of hydrant pumps shall be dedicated for the operational requirements while installation works are being carried out. 7. Testing and commission the new standby power supply system after completion of all equipment under this contract. 8. Training of CPC staff. General Requirements The Diesel Generator will be used as standby/emergency power supply source for the CPC aviation refuelling terminal and hence it shall be suitable for automatic quick start upon receiving ‘start’ signal from the automatic transfer switch (ATS) enabling switch on the full load. The diesel generator set shall be supplied complete with all ancillary equipment necessary for starting and running, including cooling system, sound attenuation system, fuel storage and supply system, instrumentation, interlock systems, control and protection arrangements, spares and special tools. Tenderer shall visit the site to ensure that proposed engine-generator set can be placed in the location proposed by CPC. Tenderer shall confirm that existing generator room area is sufficient for the installation and proper functioning of the generator after extension. Tenderer may propose alternative arrangements based on existing site conditions. 1.4 Site Conditions All equipment and materials used shall be suitable for operation in the site conditions given below. 1.4.1 Site Environmental Conditions All equipment shall be tropicalized and suitable for prolonged operation in tropical site environmental conditions. Prime rating of the diesel generator shall be suitable for the site environmental conditions. Altitude of site above sea level Ambient temperature Average relative humidity : not exceeding 10m : 320C : 80% Page 11 of 47 1.4.2 Electrical System Nominal system voltage: 400 V±6% Wiring system Earthing of system System frequency Three phase, four wire, Solid earthing, TT system 50 Hz 2. General Specifications of Engine Generator Set 2.1 General Diesel Generator set shall consist of one engine including radiator, exhaust system, one alternator with exciter and one flywheel with flywheel housing, mounted on a steel base. The voltage regulator, switchgear, control system and accessories shall be mounted on a control panel. The generator set shall be factory assembled and aligned accurately on the steel base which shall be strong and rigid enough to ensure permanent alignment of all rotating units and prevent vibration build up and shall permit skidding in any direction during installation. 2.2 Standards Diesel Generator set and the Control Panel shall comply with the applicable requirements of the following standards/publications or equivalent other national/international standards. Engine: ISO 3046 BS 5514 Generator: BS 5000 IEC 60034 Instruments: BS 89 IEC 60051 Switchgear: IEC 60947 Power Cables BS 5467 IEC 60502 Page 12 of 47 2.3 Qualifications 2.3.1 Manufacturers Engine Manufacturer: Shall be a renowned company specialized in manufacture of diesel engines with minimum 10 years documented experience. (European or equivalent brands only) Generator Manufacturer: Shall be a renowned company specialized in manufacture of generators with minimum 10 years documented experience. (European or equivalent brands only) Assembly of Engine-Generator Set: If the assembly of engine-generator set is carried out neither by engine manufacturer nor generator manufacturer, then assembling party shall be done by a reputable company. 2.3.2 Supplier / Agent There shall be an authorized distributor of proposed engine-generator make in Sri Lanka who shall have adequate stock of spare parts at all the time. The incumbent shall produce documentary evidence with proven track records to verify the fact that he is providing a very good service to the clients in this respect. 2.4 Sound and Vibration Reduction The engine-generator set shall be provided with sound attenuated canopy with proper vibration dampers fitted to the base mountings and a proper exhaust silencer so that the noise level will not be more than the following levels. i. ii. At the premises boundary not more than 63 dB (A) when running at full load, to meet the statutory requirements. At 1m from the gen-set, not more than 80 dB (A), when running at full load. The sound attenuation design shall include layers sound absorbing materials for the canopy and fresh air intake attenuators and hot air discharge attenuators. Flexible connection shall be provided to all exhaust, water, air, fuel and oil piping that leave the engine to prevent the transmission of vibration and the fracture of the piping due to movement of the set. The choice of connections and their installation is to be such as to give long life under normal operating condition of the set. 2.5 2.6 Engine-Generator Set – Ratings Prime power Not less than 800 kVA at 0.8 power factor Rated speed 1500 rpm Overload capacity 10% for 1 hour in every 12 hours Engine-Generator Set Features Generator set shall have the following features: Page 13 of 47 2.7 Factory-mounted on a common, rigid, welded, structural steel base. Automatic start, accelerate to the rated speed and deliver the specified KW/kVA output at 50 Hz within 10 seconds after a single pole contact closes in a remote device. Recover rapidly from instantaneous changes between no load and the specified KW/KVA rating, and the reverse changes of load, without damage. Engine-generator set shall be statically and dynamically balanced at the factory. Canopy The canopy shall be sound attenuating weatherproof type and manufactured from high quality Zinc coated steel sheeting not less than 16 SWG or other approved material. The canopy shall be base frame mounted and lined with sound absorbing materials retained by steel perforated sheet or other suitable arrangement. Entering of air to the enclosure shall be via acoustic intake louvers at the generator end and discharge shall be acoustic louvers at the engine end. Access to the genset shall be provided by side opening doors with lockable recessed handles. The acoustic lining shall be applied to the doors, discharge and inlet louvers and roof. 2.8 Engine 2.8.1 General Engine shall be a general purpose continuous service heavy duty diesel engine for stationary applications. The engine shall be the standard product of manufacturer (European or equivalent only), a current production model complete with all auxiliaries normally furnished and shall provide sufficient power to drive the coupled alternator. The engine shall be compression ignition type, water-cooled turbo-charged with intercooler, direct injection, multi cylinder designed for industrial use.(European or equivalent brands only) 2.8.2 2.8.3 Engine Parameters No. of cylinders Not less than 6 Rated speed 1500 rpm Cycle 4 stroke Type of fuel Lanka Super Diesel (Refer Annex I) Engine Cooling System Shall have the following features: Water-cooled, closed loop, with radiator mounted on the engine generator set and integral engine driven circulating pump. Cooling capacity shall not be less than the cooling requirements of the engine-generator set and its lubricating oil while operating continuously at 110 percent of its specified rating. Coolant shall be extended life antifreeze solution, with corrosion inhibitor additive as recommended by the manufacturer. Radiator core tubes material shall be as recommended by the engine manufacturer. Radiator with cooling fan complete with protection guards, designed to cool the engine at full output in air-on temperature up to 400C. Page 14 of 47 2.8.4 Exhaust System Shall be complete with separate system for engine and shall include a flexible section. A muffler and exhaust piping graded away from the engine to the outside. Exhaust system shall include heavy duty industrial capacity exhaust silencer. Stainless steel exhaust bellows. To release exhaust gases at appropriate elevation, additional exhaust pipes shall be supplied and installed. Material and diameter of the additional pipes shall be the same as of engine manufacturer’s standard length exhaust pipes. 2.8.5 Starting System The engine shall be equipped with an electronic starting system which is arranged for fully automatic starting upon receiving the signal from AMF/ATS on failure of any phase of the main power supply. Engine starting System shall start the engine at any position of the flywheel. Electric cranking motor: Rating shall be adequate for cranking the cold engine at the voltage provided by the battery system, and at the required speed during five consecutive starting attempts of 10 seconds cranking each at 10 second intervals, for a total of 50 seconds of actual cranking without damage. Batteries: 12 volt or 24 volt with the following features: Batteries shall be nickel-cadmium high discharge rate type. Each battery cell shall have minimum and maximum electrolyte level indicators. Batteries shall have connector covers for protection against external short circuits. With the charger disconnected, the batteries shall have sufficient capacity so that the total system voltage does not fall below 85 percent of the nominal system voltage with the following demands: Five consecutive starting attempts of 10 seconds cranking at 10 second intervals for a total of 50 seconds of actual cranking. Battery racks shall be metal with an alkali resistant finish and thermal insulation, and secured to the floor. Battery shall operate continuously for 12 hours and be able to provide the cranking power described in above without charging. External Battery Charger: 2.8.6 Charger shall be provided with both AC and DC transient protection. Charger shall be able to recharge a fully discharged battery without tripping AC protective devices. AC circuit breaker shall not trip under any DC load condition including short circuit on output terminals. The charger shall be capable of recharging the fully discharged battery in 12 hours and simultaneously power the Supervisory and Control panel. The charger shall have fused AC input and DC output protection, and shall not discharge the batteries when AC power fails. Engine Filtration System Shall consist of sealed paper mesh type dry air filters, cartridge type fuel filters and full blow lube oil filters. All filters shall have replaceable elements. Page 15 of 47 2.8.7 Governor Shall have the following features: It shall be electronic type. Steady-state speed band at 50 Hz shall not exceed plus or minus 1/3 of one percent. At 50 Hz, when load changes equal to 25 percent of the specified KW/kVA rating, frequency change shall not exceed two percent and it shall recover to 50 Hz within three seconds. At 50 Hz, when load changes equal to 100 percent of the specified KW/kVA rating, frequency change shall not exceed eight percent and it shall recover to 50 Hz within five seconds. While the engine is running, manual speed adjustments may be made. 2.8.8 Engine Generator Starting and Stopping Controls: The following controls shall be provided. a. A three-position, maintained-contact type selector switch with positions marked "AUTOMATIC", "OFF" and "MANUAL". b. A momentary contact pushbutton switch with positions marked "MANUAL START" and "MANUAL STOP". c. Selector switch in "AUTOMATIC" position shall cause the engine to start automatically when a signal from AMF/ATS panels arrives. d. Selector switch in "OFF" position shall prevent the engine from starting either automatically or manually. Selector switch in "MANUAL" position shall cause the engine to start when the manual start pushbutton is also depressed momentarily. e. With selector switch in "MANUAL" position, depressing the "MANUAL STOP" pushbutton momentarily shall stop the engine after a cool down period. f. A maintained contact, red mushroom head pushbutton switch marked "EMERGENCY STOP" will cause the engine to stop without a cool down period independent of the position of the selector switch. 2.9 Generator 2.9.1 Generator Parameters Rated Output - Not less than 800 kVA prime power Power Factor - 0.8 Frequency 50 Hz - Rated Voltage - 400/230 V, 3 phase & neutral Insulation Class H - Generator shall be synchronous, brushless type with fully interconnected damper windings. Generator shall have low waveform distortion with non-linear loads and shall have been designed for sustained short circuit currents. Generator shall be of screen protected and dripproof type (European and equivalent only). Nameplates attached to the generator and exciter shall show the manufacturer's name, equipment identification, serial number, voltage ratings, field current ratings, KW/KVA output ratings, power factor rating, temperature rise ratings, RPM ratings, full load current rating, number of phases and frequency, and date of manufacture. Page 16 of 47 At full load, the efficiency shall be not less than 92%. The neutral shall be electrically isolated from equipment ground and terminated in same terminal box as the phase conductors. 2.9.2 Automatic Voltage Regulator A fully sealed automatic voltage regulator shall maintain the voltage within the limits of +/1.5% from no load to full load at any power factor between 0.8 lagging and unity. It shall correct voltage fluctuations rapidly and restore the output voltage to the predetermined level with a minimum amount of hunting. 2.9.3 Generator Control Board Generator control board shall be provided which incorporated complete controls for all functions of the set. The control board shall be free standing, floor mounting, suitably ventilated, bottom or top entry with front access and constructed with heavy gauge, corrosion resisting material coated steel sheet. Control board shall include but not be limited to the following: 2.9.4 Circuit breaker Oil pressure gauge Water temperature gauge Battery charge Ammeter Voltmeters and selector switches for generator & mains Ammeters Frequency meter Tachometer kW meter kWH meter Power factor meter Hours run counter Selector switch Auto/Manual/Off Alarms and controls Relays, contactors etc. Alarm System Complete visual and audible alarms shall be provided which shall include but not be limited to the following. (a) Lub Oil Pressure Gauge (b) Water Temperature Gauge (c) Duty Selector Switch (d) Emergency Stop Push Button (e) Lamp Test Button (f) Trickle Charge Complete with A/meter Page 17 of 47 (g) Low Oil Pressure Shut Down Indication (h) High Water Temp Shut Down Indication (i) Over Speed Shut Down Indication (j) Over Current Trip Indication (k) Over Voltage Trip Indication (l) Fail to Start Indication (m) Mains Available Indication (n) Mains on Load Indication (o) Generator on Load Indication (p) Indication Reset Button 2.9.5 Control System A control system comprising of a microprocessor incorporated with relays, switching and other devices and necessary wiring shall be provided for fully automatic and manual operation of generator set. It shall provide total genset system integration, including automatic remote starting/stopping, automatic load transfer, precise frequency and voltage regulation, alarm and status message display, protections, output metering, auto-shutdown at fault detection. An emergency stop button shall be provided. All devices shall be mounted on the generator control board. 2.9.6 Circuit Breaker Power switching and over-current protection shall be accomplished with a moulded case circuit breaker or air circuit breaker. Circuit Breaker shall have the following features: 1) Solid state adjustable trip type circuit breakers. 2) Shall be in accordance with IEC 947-2. 3) Trip unit shall have field adjustable tripping characteristics as follows: a) Long-time current setting (continuous). b) Long-time delay c) Short-time trip point. d) Short-time time delay. e) Instantaneous trip point. 4) Shall be 100 percent rated. 6) Electrically and mechanically trip free. 7) Manual operating handle with lock-open padlocking provisions, and position indicators on the front of the breaker. 8) Rear stud connection for both line and load sides. 2.10 Fuel System Fuel oil service tank and bulk storage shall be provided by the contractor and shall be either set mounted or free-standing with fixings, as specified. Page 18 of 47 The capacity of the service tank shall be selected for adequate capacity to operate generator 12 hr at full load. Capacity of the Diesel bulk tank should be selected for adequate capacity to operate generator 12 hr at full load for 4 days. The fuel tanks shall be manufactured and installed to comply with the requirements of BS 799: Part 5. The day tanks shall feed the generator set by gravity and shall be installed elevated on angle iron supports by at least 300 mm above the fuel inlet of the engine. The service tank shall be rectangular and manufactured from minimum 3 mm thick grade CR4 carbon steel plates with welded seams and suitable stiffened internally. All welding shall comply with the requirements of BS 5135. The inside and outside to be painted with oilresistant primer and externally finished with oil resistant paintwork. The tanks shall be supplied complete with all necessary pipe work, valves, connections, and shall be clearly marked with the type of fuel oil to be used. The tanks shall incorporate: 50 mm dia fill opening and filler pipe extension Oil strainer on filler pipe Filler cap 50 mm dia goose-neck vent pipe with S.S. mesh 10 wire gauge covered opening Dial-type contents gauge (graduated in liters and gallons) 25 mm dia screwed socket for fuel supply to generator set with gate valve and strainer filter 25 mm dia connections for engine leak-off return pipe 20 mm dia lockable drain valve and hose connection Float switch for overfill alarm Float switch for low-level alarm 300*300 inspection opening hinged cover 1 no M10 bolt for earthling terminal 50 mm dia screwed socket for fuel overflow Audio visual alarm provisions shall be made on the main control panel. A hand operated fuel transfer pump of the self-priming type shall be supplied complete with flexible hose and installed by the contractor in the position specified. The hand pump should have a capacity of 20 times the rate of fuel consumption of the engine. 2.10.1 Pipes, Valves Etc. All pipes, valves and other accessories required for the entire fuel transfer system – from main fuel storage tank to daily fuel tank, from daily fuel tank to diesel generator - shall be supplied. Piping System shall be Black steel, standard weight, ASTM A-53 pipe and with necessary valves and pressure gauges. Page 19 of 47 2.11 Tests 2.11.1 Factory Acceptance Test (FAT) The following tests and checks shall be carried out in the manufacturer's plant and test certificates shall be attested by an approved third party inspection authority. - All tests as required by the manufacturer's practice or by applicable standards during the manufacturing stage. - Factory Test: Manufacturer shall furnish load banks, testing instruments and all other equipment as necessary to perform these tests to be witnessed by representatives of the Employer. 1. Performance Load Test: Four (04) hours running at full rated load One (01) hour running at 110% full rated load One (01) hour running at 75%, 50% and 25% full rated load During this test record the following data at 30-minute intervals: Time KW Voltage Amperes Engine RPM Water Temperature In Water Temperature Out Oil Temperature In Oil Temperature Out Fuel Pressure Oil Pressure Ambient Temperature FAT shall be witnessed by two (02) CPC officials together with an internationally recognized independent third party inspector approved by CPC. The cost of witness of third party inspection and factory test performance inspection of the Generator prior to delivery shall be included separately in the Bill of quantities (BOQ). 2. Quick Start Test: Record time required for the engine generator set to develop specified voltage, frequency and KW load from a standstill condition. - Performance tests on the assembled diesel generating set (with voltage regulator) - Check of fuel consumption at different loads Measurement of vibration Measurement of sound level at 1 m and 5 m distance. - Functional tests on the fuel transfer pump - Dielectric and insulation tests - Routine tests on voltage regulator 2.11.2 Site Tests The following tests shall be carried out after installation at the Site: - Operational tests (including instantaneous loading and load rejection) - Measurement of the output Page 20 of 47 - Functional testing of all alarm and control devices - Checking of the starting time and of the time up to taking-over full load. - Testing of noise levels at 1m & 5m distances. 3. Automatic Transfer Switch Panel 3.1 General One automatic mains failure (AMF) and load transfer (ATS) switchgear panel shall be supplied for the purpose of automatic transfer of the entire electrical load from the normal CEB supply to standby diesel generator, when a failure of CEB supply occurs. When the CEB supply is restored, the load shall be automatically transferred back to the CEB supply. 3.2 Ratings Rated Voltage : 400 Volts ±6%, 3-phase Rated Current : Not less than 1600 A Short-circuit rating : Not less than 40 kA Automatic Transfer Switch Panel shall be a 4-pole unit suitable for 3 phase and neutral system. 3.3 Construction Automatic Transfer Switch panel shall be of freestanding cubicle type. The panel shall be painted with the manufacturer’s standard painting procedure to insure suitability for environmental conditions. It shall consist of completely enclosed contact assembly and a separate control logic unit. The contact assembly shall be operated by a motor operator or stored energy mechanism, and be energized only momentarily during transfer providing inherently double throw switching action. Control power for all transfer operation shall be derived from the line side of the source to which the load is being transferred. Transfer switch shall also be capable of being operated manually under full load condition. Transfer switch shall be positively interlocked mechanically and electrically to prevent simultaneous closing of both sources under either automatic or manual operation. Main contacts shall be mechanically locked in position in both Normal and Emergency positions. A neutral position shall not be possible under normal electrical operation. A Transfer Switch position indicator shall be visible from the front of the panel to show to which source the Transfer Switch is connected. A solid state sensing and control logic unit shall be separately mounted from the power switching portion on the panel. 3.4 Sequence of Operation (a) Upon loss of phase-to-phase voltage of the Normal source (i.e. CEB supply) to 90% (adjustable) of nominal, and after an adjustable time delay of 0.5 – 180 seconds to override momentary dips and/or outages, a contact shall close to initiate starting of the Emergency/Standby source (i.e. Diesel Generator). Transfer to the Alternate Source (Diesel Generator) shall take place immediately upon attainment of 95% of rated voltage and frequency of the Diesel Generator. Page 21 of 47 (b) When the Normal source has been restored to 95% of rated voltage, and after a time delay adjustable from 0.5 –10 minutes (to insure the integrity of the Normal power source), the load shall be transferred to the Normal source. (c) A time delay, adjustable 0.5 – 10 minutes, shall delay shutdown of the Emergency/Standby power source (i.e. Diesel Generator) after retransfer to 80 (d) Allow the generator to run unloaded for cool down, after which the generator shall be automatically shut down. (e) If the Diesel Generator fails while carrying the load, transfer to the Normal power source shall be made instantaneously upon restoration of the Normal source to satisfactory conditions. Full details of equipment manufacturer’s standard sequence of operation shall be submitted with the offer, if it is different from the above. 4. LV Power Cables LV power cable required for connection of diesel generator to ATS panel shall be supplied and installed. LV power cable shall be copper conductor, XLPE insulated PVC sheathed steel wire armoured copper conductor four-core cables and shall be of 600/1000 volt grade complying with BS 5467 or IEC 60502. Conductor size of the cable shall be decided by considering the total allowable voltage drop in the cable and current rating. These cables shall be installed in cable ducts/trench. All cable ducts/trench shall be covered with galvanized steel checker plate or grill. All ducts/trenches shall be leak proof so that any fuel that would seep in the trench does not leach to the surrounding ground. 5. Miscellaneous 5.1 Surge Arresters Sure Arresters of rating not less than 20 kA shall be provided each phase and neutral to divert lightning electrical surges without damaging to the components. 5.2 Spares and Tools Essential tool and spares shall be supplied with the engine-generator set, which shall include the following. A. For the engine-generator set: 1. Three lubricating oil filters. 2. Three primary fuel oil filters. 3. Three secondary fuel oil filters. 4. Three intake air filters. B. For battery charger: 1. Three complete sets of fuses. 2. One complete set of indicating lamps. Page 22 of 47 C. For control and supervisory panel: 1. Three complete sets of fuses. 2. One complete set of indicating lamps. 6. Submittals The following documents shall be submitted by the Contractor at the appropriate time. A. Shop Drawings: 1. Sufficient information, clearly presented, shall be included to determine compliance with specifications. 2. Prior to fabrication, submit for approval the following data for the engine-generator set, transfer device and control and supervisory equipment: a. Engine generator set b. Engine jacket water heaters c. Muffler assembly d. Day tank and pumps e. Batteries, racks and charger g. Control and Supervisory Equipment f. Performance: 1) Voltage regulating equipment 2) Frequency regulating equipment 3) Voltage and frequency dips and recovery times due to motor loading 4) Ambient derating g. Fuel oil system h. Cooling system B. Manuals: 1. Submit, simultaneously with the shop drawings, companion copies of complete maintenance and operating manuals of the engine generator set and auxiliaries including technical data sheets, wiring diagrams, and information, such as telephone number, fax number, and web sites, for ordering replacement parts. 2. Two weeks prior to the final inspection, submit four copies of the updated maintenance and operating manual to the Engineer: a. Include complete "As built" diagrams, which indicate all items of equipment and their interconnecting wiring. b. Include complete diagrams of the internal wiring for each of the items of equipment, including "As installed" revisions of the diagrams. c. The wiring diagrams shall identify the terminals to facilitate installation, maintenance, operation and testing. d. Complete lists of spare parts and special tools recommended for two years of normal operation of the complete system. 7. Warranty Warranty period of the Diesel Generator and all the equipment supplied under this contract shall be 365 days from the date of commissioning. Page 23 of 47 4. Bill of Quantities (BOQ) Page 24 of 47 Page 25 of 47 Page 26 of 47 Page 27 of 47 Page 28 of 47 5. Drawings Drg No-1: Existing Single Line Diagram Drg No-2: Existing Main Substation Drawing Page 29 of 47 Page 30 of 47 Page 31 of 47 6. Technical Schedule Page 32 of 47 Page 33 of 47 Page 34 of 47 Page 35 of 47 Page 36 of 47 Page 37 of 47 ANNEX – “A” DECLARATION OF BIDDER Chairman, Departmental Procurement Committee, Ceylon Petroleum Corporation. Dear Sir, TENDER FOR SUPPLY & INSTALLATION OF 800 KVA GENERATOR We hereby tender for the supply & installation of 800 KVA Generator in conformity with the specifications as stated in the tender document. Having perused the Instructions to Bidders for the supply & installation of 800 KVA Generator and the Schedule of Prices referred to therein, I / We hereby agree to comply with the Conditions of the said Tender. I / We undertake to conform to all the Terms & Conditions in the said Tender and the Schedule of Prices within the time specified. I / We am / are fully aware that the acceptance of any Tender will be at the sole discretion of the Departmental Standing Procurement Committee, Ceylon Petroleum Corporation. ……………………………………… Signature of Bidder Date : ……………………. …………………………………… ……… Company Stamp Page 38 of 47 ANNEX “B” Format of Manufacturer’s Authorization [The Bidder shall require the Manufacturer to fill in this Form in accordance with the instructions indicated. This letter of authorization should be on the letterhead of the Manufacturer and should be signed by a person with the proper authority to sign documents that are binding on the Manufacturer.] Date: ………………………………………… Tender No.: ……………………………………………. To: Chairman – Departmental Procurement Committee WHEREAS We ………………………………………………………………………………[insert complete name of Manufacturer], who are official manufacturers of ………………………………………………[insert type of goods manufactured],having factories at………………………………………………………………… ……………………………………………………………………………[insert full address of Manufacturer’s factories], do hereby authorize ……………………………………………………………………………….[insert complete name of Bidder]to submit a bid the purpose of which is to provide the following Goods, manufactured by us ……………………………………………………………………………. [Insert name and or brief description of the Goods],and to subsequently negotiate and sign the Contract. We hereby confirm goods offered are in good condition & conforming to the specifications as mentioned Technical Specifications of the Bidding Document. ……………………………………………………………………… Signature of authorized representative of the Manufacturer Company Address: ………………………………………… ………………………………………… ………………………………………………… ……… Company Stamp Title: Duly authorized to sign this Authorization on behalf of: [insert complete name of Manufacturer] Date : ……………………. Page 39 of 47 ANNEX “C” COMPLIANCE / DEVIATIONS SHEET Please mark “ ” if complied with the tender requirement or mark “X” if there is any deviation and indicate the deviation in the cage provided. Specification / Condition 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Complied Deviations if any Document Fee & Bid deposit Paid for each Principal Bidder Cost breakdown per BOQ. Offer Validity – 77 Days BOQ Duly Filled, Stamped, Signed & Forwarded Agreed with Payment Terms & Other Requirements as per clause No. 4,Conditions of Contract Letter of Authorization – Annex ‘B’ Specifications & Other Conditions Agreed with project completion Period per Clause No 2, COC Agreed with Penalty on Delayed Completion per Clause No. 6 of COC Literature / Catalogues & Other Technical Data Given Country of manufacturing Given If Relevant, VAT Registration No. Given Deviations from Specifications, terms & conditions, if any, indicated Documentary proof for recent supplies made to customers in similar magnitude Declaration per Annex-“A” Copy of Business registration per Clause 09 Complete Spare parts list with their current prices provided List of recommended spare parts for 05 year operation of the equipment given Company profile indicating the experience in the relevant field & financial statements provided Other Deviation If Any …………………………………………… Signature of the Bidder ……………………………… Company Stamp Page 40 of 47 ANNEX “D” Form of Bid To: The Chairman Procurement Committee, Ceylon Petroleum Corporation, No. 609, Dr. Danister De Silva Mwt., Colombo 09. SRI LANKA From: ………………………………. ……………………………… ……………………………… Sir, A-1 Having familiarized ourselves with the formal request for Instruction to Bidders and Conditions of Contract for supply & installation of 800 kVA Generator we offer to complete the whole of said services in conformity with the said document. A-2 Unless and until a formal Agreement is prepared and executed this Tender together with your written acceptance thereof shall constitute a binding contract with us. A-3 We understand you are not bound to accept the lowest or any Tender you may receive. A-4 The Bid we are offering is complete and fulfils the requirements discussed in the Bid document. A-5 We agree to abide by this Tender for the period of 77 days from the date of opening of the Tender. Conditions and prices quoted shall remain binding upon us and may be accepted at any time before the expiration of the period.. A-6 We agree to be bound by the Bid, Bid Conditions and Performance Guarantee. A-7 We affirm that the said items will be delivered within …….. months after we receive notice acceptance of our Tender from the CPC. A-8 We offer the lump sum fixed price of Sri Lanka Rupees ………………………… (in words) ……………............ …………………………………………………………… for Supply, of…………………………………….………….., as detailed out in this Bid document and details of Page 41 of 47 the lump sum price is as given in the schedule of prices. We agree that it is open to the Procurement Committee to reject this offer or to accept. Dated this ………………………… day of ………………………………2013. Signature ………………………….. in the capacity of ………………………………………………… ………………………………………… duly authorized to sign tenders for and on behalf of : Name ……………………………………………………………. Address ……………………………………………………………. ……………………………………………………………. ……………………………………………………………. Witnesses: 1. Signature: …………………………………… Name: ……..………………….…………. …………………………………………… 2. Signature: ………………………………... Name: ………………………………... …………………………………………… Address : …………………………………… Address: ……………………………… . ………………………………………………. …………………………………………… ………………………………………………. …………………………………………….. Page 42 of 47 ANNEX “E” Format for Bid Security Guarantee [This Bank Guarantee form shall be filled in accordance with the instructions indicated in brackets] …………………[insert issuing agency’s name and address of issuing branch or office]……………… Beneficiary : ………………. [ insert (by PE) name and address of Employer/ Purchaser] Date : ………………. [ insert (by issuing agency) date] BID GUARANTEE NO. : ………………[insert (by issuing agency) number] We have been informed that ………………[insert (by issuing agency) name of the Bidder; if a joint venture, list complete legal names of partners] (hereinafter called “ the Bidder”) has submitted to you its bid dated ………………[insert (by issuing agency) date] (hereinafter called “the Bid”) for execution/ supply [select appropriately) of [insert name of Contract] under Invitation for Bids No. ……………….. [insert IFB number] (“the IFB”) Furthermore, we understand that, according to your conditions, Bids must be supported by a Bid Guarantee. At the request of the Bidder, we ……………[insert name of issuing agency] hereby irrevocably undertake to pay you any sum or sums not exceeding in total an amount of ………………[insert amount in figures] ……………..[insert amount in words] upon receipt by us of your first demand in writing accompanied by a written statement stating that the Bidder is in breach of its obligation(s) under the bid conditions, because the Bidder. (a) has withdrawn its Bid during the period of bid validity specified; or (b) does not accept the correction of errors in accordance with the Instructions to Bidders (hereinafter “the ITB”) of the IFB; or (c) having been notified of the acceptance of its Bid by the Employer/ Purchaser during the period of bid validity, (i) fails or refuses to execute the Contract Form, if required, or (ii) fails or refuses to furnish the Performance Guarantee, in accordance with the ITB. This Guarantee shall expire: (a) if the Bidder is the successful bidder, upon our receipt of copies of the Contract signed by the Bidder and of the Performance Guarantee issued to you by the Bidder; or (b) if the Bidder is not the successful bidder, upon the earlier of (i) our receipt of a copy of your notification to the Bidder that the Bidder was unsuccessful, otherwise it will remain in force up to ……………[insert date]Consequently, any demand for payment under this Guarantee must be received by us at the office on or before that date ………………………………….[signature(s) of authorized representative(s)] Page 43 of 47 ANNEX “F” Form of Agreement This Agreement made this ________________ day of _________________ 2013, by and between CPC established by an Act of Parliament namely Act No. 28 of 1961 & having its registered Office at No. 609, Dr. Danister De Silva Mwt., Colombo 09 in the Government of the Democratic Socialist Republic of Sri Lanka (hereinafter called and referred to as the “CPC” which terms of expression as herein used shall where this context so requires and admits mean & include the CPC & its Successors & assigns) of the one part and ____________________ of ________________________ a Company duly incorporated & having its registered Office at _______________________________ (hereinafter called the “Agent” which terms of expression as herein used shall where this context so requires and admits mean & include the ________________ & its successors & assigns) of the other part . Whereas the CPC is desirous that the goods known as the supply & installation of the 800 KVA Generator should be supplied by the Agent, and has accepted a Tender by the Agent for the supply of such Generator. The CPC and the Agent agree, as follows: 1. In the agreement words and expressions shall have the same meanings as are respectively assigned to them in the Conditions of Contract and Contractor’s scope of work hereinafter referred to. 2. The following documents shall be deemed to form and be read and construed as a part of this Agreement. Letter of Acceptance dated _______________. The Bid dated _______________________. The Conditions of Contract Technical Specifications The Completed Schedules and The Contractor’s Proposal Page 44 of 47 3. In consideration of the payments to be made by the CPC to the Agent as hereinafter mentioned, the Agent hereby covenants with the CPC to supply and remedy any defects therein, fit for purpose in conformity in all respect according to the provisions of the Agreement.. 4. The CPC hereby covenants to pay the Agent in consideration of the Supply and the remedying of defects therein, the agreed Price or such other sum as may become payable under the provisions of the Contract at the times and in the manner prescribed by the Agreement. In Witness whereof the parties have hereunto caused this Agreement to be executed the day, month & year afore written. Authorized Signatureof CPC Authorized Signature of the Agent In the presence of In the presence of Name Name Signature Signature Address Address Page 45 of 47 ANNEX “G” FORMAT FOR PERFORMANCE GUARANTEE ……………………………………[issuing Agency’s Name and Address of issuing Branch or Office]……………. Beneficiary : ……………………..[Name and Address of Employer] ………………………… Date : …………………………….. PERFORMANCE GUARANTEE NO : ………………………………. We have been informed that ………………….[name of Contractor/ Supplier] (hereinafter called “the Contractor”) has entered into Contract No. …………………….[reference number of the contract] dated ………………..with you, for the ……………….. [insert “ construction”/ “Supply”] of …………………..[name of contract and brief description of Works] (hereinafter called “the Contract”) Furthermore, we understand that, according to the conditions of the Contract, a performance guarantee is required. At the request of the Contractor, we ………………………. [name of Agency] hereby irrevocably undertake to pay you any sum or sums not exceeding in total an amount of …………….[amount in figures] (…………………) [amount in words], such sum being payable in the types and proportions of currencies in which the Contract Price is payable, upon receipt by us of your first demand in writing accompanied by a written statement stating that the Contractor is in breach of its obligation(s) under the Contract, without your needing to prove or to show grounds for your demand or the sum specified therein. This guarantee shall expire, no later than the ………….day of ……….., 2012 [insert date, 28 days beyond the scheduled contract completion date] and any demand for payment under it must be received by us at this office on or before that date. …………………………… [ Signature(s)] Page 46 of 47 ANNEX “H” FORMAT FOR ADVANCE PAYMENT GUARANTEE ……………………………………………………………………………[Name and address of Agency, and Address of Issuing Branch or Office] Beneficiary: ……………………………………………………..[Name and Address of Employer] Date : ……………………………………. ADVANCE PAYMENT GUARANTEE NO.:……………………………… We have been informed that …………………………………………......[name of Contractor](hereinafter called “the Contractor”) has entered into Contract No……………….(reference number of the contract] dated……………………………….with you, for the ………………Construction of ………………………....[name of contract and brief description] (hereinafter Called “the Contract). Furthermore, we understand that, according to the conditions of the Contract, an advance payment in the sum……………..[amount in figure] (………………………………..[amount in words] is to be made against an advance payment guarantee. At the request of the Contractor, we…………………………………[name of issuing agency]Hereby irrevocably undertake to pay you any sum or sums not exceeding in total an amount of…………………..[amount in figures] (…………………………………………….) [amount in words] upon receipt by us of your first demand in writing accompanied by a written statement stating that the Contractor is in breach of its obligation in repayment of the advance payment under the Contract. The maximum amount of this guarantee shall be progressively reduced by the amount of the advance payment repaid by the Contractor. This guarantee shall expire on……………………[Insert the date, 28 days beyond the Intended Completion date] Consequently, any demand for payment under this guarantee must be received by us at this office on or before that date. --------------------------------------[Signature(s)] Page 47 of 47 Page 48 of 47