Fiber Optic Cables - Seacoast Electric Company

advertisement

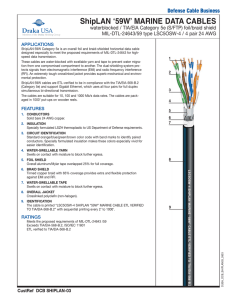

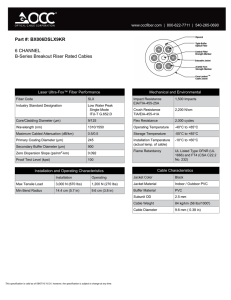

(MIL-PRF-85045F Qualified) SHIPBOARD •• •• •• •• •• •• •• •• Fiber Optic Cables MANUFACTURER OF CHROMATIC TECHNOLOGIES CABLE PRODUCTS (MIL-PRF-85045F Qualified) SHIPBOARD FIBER OPTIC CABLES raka Comteq USA, Inc.’s, qualified fiber optic shipboard cables provide superior optical performance in a craftfriendly and flexible cable design. D Draka Comteq USA, Inc.’s, shipboard fiber optic cables are designed using a tight buffered, water-blocked construction with low smoke, zerohalogen jacketing materials. Adhering to the United States Department of Defense MIL-PRF85045F specification document, Draka Comteq USA, Inc., offers these cables in one, four and eight fiber configurations. The optical fiber cable component (OFCC) consists of an optical fiber with a 900µm diameter tight buffer, reinforced with aramid yarns, and encased in a 2.0mm flexible zero-halogen jacket. In addition, Draka Comteq manufactures optical fibers that are radiation resistant and qualified per the applicable MIL-F-49291 specification document to insure system survivability in the event of radiation exposure. This family of cables has passed a stringent qualification program to insure full compliance to the MIL-PRF-85045F document and the applicable specification sheets. The program includes tests such as acid gas generation, halogen content, smoke generation and flame propagation, toxicity, fluid immersion, thermal shock, humidity, electromagnetic resistance, low/high pressure salt water blocking and many other highly demanding requirements. In addition to the qualification program, the U.S. Department of Defense closely monitors the manufacturing process, the final cable testing and the periodic re-qualification tests to insure the highest degree of product quality. These cables are available with either a thermoplastic or a cross-linked, thermoset LSZH outer jacket. The thermoplastic jacketing system offers good resistance to chemicals, fluids, fungus and abrasion; offers low smoke, low toxic fumes and acid gas generation. The cross-linked, thermoset jacket is more rugged and offers improved thermal aging and fluid resistance,improved abrasion, scrape and cut through resistance and better flexibility at cold temperature extremes. Draka Comteq USA, Inc.’s, unique thermoset jacketing process provides an extremely rugged and cost effective cable design while maintaining superior optical performance and long term reliability. ISOMETRIC VIEW OF 4-FIBER SHIPBOARD CABLE Chromatek™ Zero Halogen Outer Jacket Waterblocking Aramid Yarn Waterblocking Inner Wrap Waterblocking Central Member Buffer Optical Fiber Cable Component Waterblocking Yarn Aramid Yarn Fiber SPECIFICATIONS INSTALLATION MIL Spec P/N Draka Comteq P/N Number of Fibers Cable Dia. mm (in Cable Weight Kg/Km (lb/1000ft) M85045/13-01N,P S458T-08-62G 8 11.3 (.445) 115 (77) 2775 (625) M85045/13-02N,P S458T-08-010N 8 11.3 (.445) 115 (77) 2775 (625) M85045/15-01N,P S458T-04-62G 4 8.26 (.325) 60 (40) 2015 (454) 6.6 (2.6) 418 (94) 13.2 (5.2) M85045/15-02N,P S458T-04-010N 4 8.26 (.325) 60 (40) 2015 (454) 6.6 (2.6) 418 (94) 13.2 (5.2) M85045/16-01 S458T-01-62G 1 2.0 (.079) 4.5 (3.0) 220 (50) 1.6 (.63) 100 (22) 3.2 (1.26) M85045/16-02 S458T-01-010N 1 2.0 (.079) 4.5 (3.0) 220 (50) 1.6 (.63) 100 (22) 3.2 (1.26) M85045/17-01N,P S454T-08-62G 8 11.3 (.445) 115 (77) 2775 (625) 9.0 (3.5) 555 (125) 18.0 (7.0) M85045/17-02N,P S454T-08-010N 8 11.3 (.445) 115 (77) 2775 (625) 9.0 (3.5) 555 (125) 18.0 (7.0) M85045/18-01N,P S454T-04-62G 4 8.26 (.325) 60 (40) 2015 (454) 6.6 (2.6) 418 (94) 13.2 (5.2) M85045/18-02N,P S454T-04-010N 4 8.26 (.325) 60 (40) 2015 (454) 6.6 (2.6) 418 (94) 13.2 (5.2) THERMOPLASTIC JACKETED CABLES Tensile Strength Bend Diameter N (lbs) cm (in) LONG TERM THERMOSET JACKETED CABLES M85045/13-01N,P M85045/15-02N,P M85045/17-01N,P M85045/13-02N,P M85045/16-01 M85045/17-02N,P M85045/15-01N,P M85045/16-02 M85045/18-01N,P Strength Member Water blocked aramid yarn Water blocked aramid yarn OFCC Jacket 9.0 (3.5) 555 (125) 18.0 (7.0) 9.0 (3.5) 555 (125) 18.0 (7.0) The above cables are listed on Qualified Products List (QPL) 85045 per United States Department of Defense, Defense Logistics Agency, Defense Electronic Supply Center. Notification letters on file at Draka Comteq USA, Inc. OPTICAL FIBER SPECIFICATIONS CABLE SPECIFICATIONS Thermoset (/17 AND /18) Bend Diameter cm (in) Note: "N" cables are rated for pressures up to 300psi "P" cables are rated for pressures up to 1,100psi M85045/18-02N,P Thermoplastic (/13 AND /15) Tensile Strength N (lbs) Multimode Singlemode Fiber Designator 62G 010N 2.0mm (0.079in) nom. diameter 2.0mm (0.079in) nom. diameter Fiber Type Multimode, Graded Index Singlemode Low smoke, zero halogen thermoplastic Low smoke, zero halogen thermoset Applicable Specifications MIL-F-49291/6 MIL-F-49291/7 Core Diameter 62.5µm ± 3µm 8.3µm Nominal Applicable Specification M85045/13 & /15 M85045/17 & /18 Cladding Diameter 125µm ± 1µm 125µm ± 1µm Storage Temperature -40°C to +75°C -40°C to +75°C Coating Diameter 250µm ± 15µm 250µm ± 15µm Operating Temperature -28°C to +65°C -28°C to +65°C Buffer Diameter 900µm ± 50µm 900µm ± 50µm Life Aging 240 hrs @ 110°C 240 hrs @ 110°C Numerical Aperture 0.275 Nominal N/A Smoke Index, NES 711 < 25 < 25 Mode Field Diameter N/A 9.3µm ± 0.5µm @ 1300nm Toxicty, NES 713 <5 <5 Attenuation Halogen Content by Weight < 0.2% < 0.2% 3.5 dB/Km Max. @ 850nm 1.5 dB/Km Max. @ 1300nm 1.0 dB/Km Max. @ 1310nm 1.0 dB/Km Max. @ 1550nm Flammability UL-1685 UL-1685 NFPA 262 (Modified) NFPA 262 (Modified) Bandwidth (overfilled) 350 MHz/Km Min. @ 850nm N/A 800 MHz/Km Min. @ 1300nm N/A Crush Resistance 2,000N per cm of outer cable diameter 2,000N per cm of outer cable diameter Dispersion N/A N/A 3.2ps/nm- Km @ 1310nm 22ps/nm-Km @ 1550nm Abrasion Resistance 250 cycles 750 cycles Proof Test 100,000 Psi 100,000 Psi Low Temperature Flexibility -28°C -40°C Radiation Resistance per MIL-F-49291 per MIL-F-49291 Tempest Comply Comply Fluid Immersion Draka Comteq USA, Inc.'s, MIL-PRF-85045F shipboard cables meet the requirements of IEEE Lubricating Oil 24 hrs @ 75°C 24 hrs @ 100°C Fuel Oil 24 hrs @ 35°C 24 hrs @ 100°C 802.3 Gigabit Ethernet standard (3.5dB/Km @ 850nm and 1.5dB/Km @ 1300nm) and surpass the attenuation requirements of the MIL-PRF-85045F specification (4.5dB/Km @ 850nm and 2.0dB/Km @ 1300nm) Integrated Cable Solutions for the Reel World developing new cables for unique markets, W hether researching raw materials for specialty applications or designing new manufacturing and process equipment for unique fiber and copper cable requirements, Draka Comteq USA, Inc., taps into Draka's worldwide resources to ensure high quality and innovative results. Draka Comteq USA, Inc., is part of the global Draka Comteq alliance through Draka Holding, N.V. In addition, Draka Comteq USA, Inc., is a partner with the North American subsidiaries of Draka Holding's Draka USA. Since 1905, Draka USA has been answering the unique requirements of military and defense applications. Draka USA's Defense Cables Business (DCB) has provided a multitude of cable designs including acoustic and minesweeper assemblies, towed cables, Corona-Free (EMI Reducing) cables, severe waterblocked cables, fiber optic, category twisted pair, coaxial communications cables and next generation circuit integrity cables. A comprehensive 10,000 square-foot testing facility is an integral part of research and development to serve all Draka USA companies and available to all worldwide Draka Holding Group members. This laboratory hosts an extreme range of test equipment, where rigorous testing and analysis is performed on all cable designs in a variety of environments to meet all industry standards, approvals and certifications. The other members of Draka USA are dedicated to producing a broad range of special-purpose cables. These companies are: BIW Cable Products for offshore, transit and commercial marine products; Tamaqua Cable Products which produces cables for industrial control, signaling, irrigation and airport lighting as well as cable-in-duct; and Draka Elevator Products for hoistway and elevator cable products. Draka Holding, N.V., the parent company to Draka Comteq and Draka USA is headquartered in Amsterdam, and has over 60 operating companies in 25 countries in Europe, The Americas and Asia and employs 8,100 worldwide employees. With decades of experience in providing integrated cable solutions, Draka Holding N.V., together with all its members, is solely engaged and dedicated to worldwide development of superior quality cable products and systems to become a global forerunner in all industries. Data is for informational purposes only and is subject to change. Please contact our sales department or refer to our website for current information. Draka Comteq USA, Inc. www.drakausa.com www.drakacomteq.com Shipboard cables distributed by: Manufacturing & Corporate Headquarters: 20 Forge Park Franklin, MA 02038 Tel: 508/541-7100 Toll Free: 888/541-7100 Fax: 508/541-8122