Self-sensing cantilevers with integrated conductive coaxial tips for

advertisement

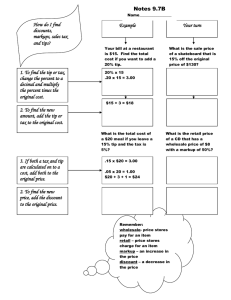

Self-sensing cantilevers with integrated conductive coaxial tips for high-resolution electrical scanning probe metrology Alexandre J. Haemmerli, Nahid Harjee, Markus Koenig, Andrei G. F. Garcia, David Goldhaber-Gordon, and Beth L. Pruitt Citation: Journal of Applied Physics 118, 034306 (2015); doi: 10.1063/1.4923231 View online: http://dx.doi.org/10.1063/1.4923231 View Table of Contents: http://scitation.aip.org/content/aip/journal/jap/118/3?ver=pdfcov Published by the AIP Publishing Articles you may be interested in Self-heating in piezoresistive cantilevers Appl. Phys. Lett. 98, 223103 (2011); 10.1063/1.3595485 Study of sensitivity and noise in the piezoelectric self-sensing and self-actuating cantilever with an integrated Wheatstone bridge circuit Rev. Sci. Instrum. 81, 035109 (2010); 10.1063/1.3327822 Current integration force and displacement self-sensing method for cantilevered piezoelectric actuators Rev. Sci. Instrum. 80, 126103 (2009); 10.1063/1.3244040 Quasistatic displacement self-sensing method for cantilevered piezoelectric actuators Rev. Sci. Instrum. 80, 065102 (2009); 10.1063/1.3142486 Parylene cantilevers integrated with polycrystalline silicon piezoresistors for surface stress sensing Appl. Phys. Lett. 91, 083505 (2007); 10.1063/1.2772189 [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 171.66.208.134 On: Thu, 01 Oct 2015 23:42:51 JOURNAL OF APPLIED PHYSICS 118, 034306 (2015) Self-sensing cantilevers with integrated conductive coaxial tips for high-resolution electrical scanning probe metrology Alexandre J. Haemmerli,1,a) Nahid Harjee,2,a) Markus Koenig,3 Andrei G. F. Garcia,3 David Goldhaber-Gordon,3 and Beth L. Pruitt1,b) 1 Department of Mechanical Engineering, Stanford University, 440 Escondido Mall, Stanford, North Carolina 94305, USA 2 Department of Electrical Engineering, Stanford University, 350 Serra Mall, Stanford, North Carolina 94305, USA 3 Department of Physics, Stanford University, 382 Via Pueblo Mall, Stanford, North Carolina 94305, USA (Received 4 March 2015; accepted 7 June 2015; published online 20 July 2015) The lateral resolution of many electrical scanning probe techniques is limited by the spatial extent of the electrostatic potential profiles produced by their probes. Conventional unshielded conductive atomic force microscopy probes produce broad potential profiles. Shielded probes could offer higher resolution and easier data interpretation in the study of nanostructures. Electrical scanning probe techniques require a method of locating structures of interest, often by mapping surface topography. As the samples studied with these techniques are often photosensitive, the typical laser measurement of cantilever deflection can excite the sample, causing undesirable changes electrical properties. In this work, we present the design, fabrication, and characterization of probes that integrate coaxial tips for spatially sharp potential profiles with piezoresistors for self-contained, electrical displacement sensing. With the apex 100 nm above the sample surface, the electrostatic potential profile produced by our coaxial tips is more than 2 times narrower than that of unshielded tips with no long tails. In a scan bandwidth of 1 Hz–10 kHz, our probes have a displacement resolution of 2.9 Å at 293 K and 79 Å at 2 K, where the low-temperature performance is limited by amplifier noise. We show scanning gate microscopy images of a quantum point contact obtained with our probes, highlighting the improvement to lateral resolution resulting from the coaxial tip. C 2015 AIP Publishing LLC. [http://dx.doi.org/10.1063/1.4923231] V I. INTRODUCTION Building on the principles of atomic force microscopy (AFM), researchers have developed a wide range of electrical scanning probe techniques to measure and manipulate the local electronic properties of materials. These techniques include scanning gate microscopy, electrostatic force microscopy, and Kelvin probe force microscopy which together enable mapping of current flow, surface potential, and work function. Common to each of these techniques is the need for a conductive probe with a sharp tip that is used to produce an electrostatic potential perturbation at the sample. The affect of this perturbation on the sample or the probe itself is recorded as the probe is raster scanned to produce an image. For example, in scanning gate microscopy (SGM), the conductance through the sample is measured as the tip modulates energy barriers or backscatters current carriers. In this way, SGM has been used to map branched current flow in two-dimensional electron gases (2DEGs)1–4 and to identify energy barriers in carbon nanotubes (CNTs).5–9 The lateral resolution of AFM is limited by the tip geometry, as features in the image plane are a spatial convolution between the tip and sample. Sharper tips (i.e., those that approach a spatial delta function) produce more accurate images of the sample. Similarly, the lateral resolution of electrical a) A. J. Haemmerli and N. Harjee contributed equally to this work. Electronic mail: pruitt@stanford.edu b) 0021-8979/2015/118(3)/034306/10/$30.00 scanning probe techniques is limited by the spatial extent of the electrostatic potential profile produced by the conductive probe. Often, the shape of the potential profile is controlled by the tip shape. However, the method of fabricating the conductor also plays a role. Consider the most commonly used conductive probes, commercially available metal-coated AFM probes. Because the conductor blankets the entire cantilever and tip cone and is completely unshielded, it produces a broad potential profile. Thus, while these probes have been used to study nanostructures such as CNTs, the features in the resulting images often appear larger than the nanostructures themselves, blurring their true location and size. Furthermore, even when these probes are used to image mesoscale samples such as 2DEGs, non-trivial measurement techniques and data post-processing are often required to separate the data of interest from the background influence of the broad profile. To facilitate accurate, high-resolution electrical imaging of nanostructures, a tip capable of producing a spatially sharp electrostatic potential profile is needed. Electrical scanning probe techniques require a means of locating structures of interest, typically accomplished by mapping surface topography. As the samples studied with these techniques are often photosensitive, the conventional laser measurement of cantilever deflection can excite the sample and cause undesirable changes electrical properties. At cryogenic temperatures, photoexcited carriers can take hours or days to relax. Thus, the ideal electrical scanning probe should have a built-in sensor that enables electrical 118, 034306-1 C 2015 AIP Publishing LLC V [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 171.66.208.134 On: Thu, 01 Oct 2015 23:42:51 034306-2 Haemmerli et al. readout of cantilever deflection. Self-sensing probes provide additional benefits including faster setup (no optical alignment required) and reduced system size, complexity, and cost. Using a tip with a coaxial structure, it is possible to produce a highly localized potential perturbation. Such a tip consists of an inner conductor, insulator, and outer shield. At the tip apex, a small aperture in the shield allows electric field lines from the inner conductor to reach the sample. Coaxial tips were first explored for scanning near-field optical microscopy.10–16 However, these tips were rudimentary in construction. More recently, several microfabricated coaxial tips have been reported17–20 and some applied to electrical scanning probe techniques.21–27 Self-sensing cantilevers have been demonstrated using capacitors,28 piezoelectrics,29 quartz tuning forks,30 and piezoresistors.31,32 Piezoresistors are attractive as sensors because they can be readily fabricated using CMOScompatible processes, their resistance change can be detected with a simple Wheatstone bridge circuit, and they provide linear response to stress with large dynamic range (>140 dB (Ref. 33)). Researchers have continued to improve piezoresistive cantilevers by integrating actuators,34 enabling measurement of lateral forces,35 integrating on-chip signal conditioning,36 and optimizing force resolution.37–41 In this paper, we present new scanning probes that integrate coaxial tips for spatially sharp electrostatic potential profiles with piezoresistive cantilevers for self-contained, electrical displacement sensing. Like commercial AFM probes, the probes are batch fabricated using standard semiconductor manufacturing methods. We describe the design, fabrication, and characterization of this new probe. We show scanning gate microscopy images of a quantum point contact obtained with our probes, highlighting the improvement to lateral resolution resulting from the coaxial tip. J. Appl. Phys. 118, 034306 (2015) II. DESIGN FIG. 1. Simulations of the electrostatic potential profiles produced by (a) an unshielded tip and (b) a coaxial tip with a grounded shield. The tips are 100 nm and 20 nm above a GaAs/AlGaAs heterostructure containing a twodimensional electron gas (2DEG) 57 nm below the surface. They are biased at 1 V and have an opening half angle of 33 . The unshielded tip has a radius of curvature of 10 nm, while the coaxial tip has an opening radius of 30 nm. In (a), the potential decays slowly with distance while in (b), the potential drop is localized at the tip apex. Our scanning probe design is based on the results of a previously reported numerical optimizer39,42,43 and was adapted for displacement resolution and 4-leg cantilevers. Cantilever mechanical properties predicted by the optimizer, including spring constant and resonant frequency, were verified by finite element analysis (FEA) with COMSOL Multiphysics. We also used FEA to compare the electric field distributions produced by an unshielded tip and a coaxial tip, Figs. 1 and 2. There are several differences between the current scanning probes and our previous design.44 First, the piezoresistor and inner conductor to the coaxial tip are n-type, formed by phosphorus diffusion into p-type silicon. We selected this process as it allows us to easily fabricate dopant profiles with high surface concentration and shallow junction depths. Second, we moved the compensation piezoresistor from the die, where it was not released, to a separate cantilever with the same geometry as the active cantilever. This more closely matches the environments of the two piezoresistors and improves rejection of common mode signals (e.g., fluctuations in ambient temperature) when differential readout is employed. Last, we included a design variation in which the silicon between electrical traces is removed to minimize leakage paths and better defined piezoresistor geometry. This results in a cantilever with four legs as seen in Fig. 3. With less current leakage between n-type diffusions, sensitivity to tip displacement is improved and cross-talk between the coaxial tip and the piezoresistor is reduced. The numerical optimizer we used is written in Matlab and can calculate the performance of a user-specified design or, given an optimization goal (for example, minimize the resolvable force at the tip) and constraints (power consumption, bandwidth, etc.), can vary the parameters of an initial design to arrive at a more optimized probe. In this design, the optimized parameters were cantilever and piezoresistor geometries as well as doping time and temperature. The optimizer uses a recursive method to optimize and find the optimal displacement resolution while keeping the parameters within the defined design bounds. More details on the design and operation of the optimizer can be found in Ref. 39. We made the following enhancements to the code to enable optimization of ntype piezoresistive cantilevers for contact mode AFM. [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 171.66.208.134 On: Thu, 01 Oct 2015 23:42:51 034306-3 Haemmerli et al. J. Appl. Phys. 118, 034306 (2015) dmin ¼ Vnoise ; SdV (2) where SdV is the voltage displacement sensitivity. The sensitivities SFV and SdV are related by k, the cantilever spring constant, such that SdV ¼ kSFV. B. Cantilevers with four legs The code previously assumed a cantilever with uniform width. We modified the expression for SFV, applicable for a quarter-active Wheatstone bridge readout circuit, for cantilevers with four legs SFV ¼ FIG. 2. Simulations of the induced charge density Dn in the 2DEG for the conditions in Figure 1, where solid and dashed lines are for a tip 100 nm and 20 nm above the surface, respectively. The full width at half maximum (FWHM) of the perturbation produced by the coaxial tip is 2–3 narrower than that of the unshielded tip. Moreover, the perturbation from the unshielded tip exhibits a long tail. At a distance of 1 lm from the tip, it is still 17% of its maximum value whereas the perturbation from the coaxial tip is negligibly small. A. Displacement resolution The code was originally written to optimize cantilevers for force-sensing applications. Thus, the optimization goal was to minimize Fmin, the minimum resolvable force, given by Fmin ¼ Vnoise ; SFV (1) where Vnoise is the root mean square noise voltage and SFV is the voltage force sensitivity as defined in Ref. 40. For contact mode AFM, where we are sensing tip displacements, we added to ability to minimize dmin, the minimum resolvable displacement, given by 3ðlc 0:5lp Þpl;max cVbridge b : 8wp t2c (3) Here, lc and tc are the length and thickness of the cantilever, lp and wp are the length and width of the piezoresistor (with equivalent dimensions for the legs), l;max is the maximum piezoresistance coefficient, Vbridge is the voltage across the bridge, and c and b are the geometry and efficiency factors as defined in Ref. 40. In the denominator, we replaced wc, the width of the cantilever, with 4wp , the effective width at its root. To calculate SdV, we derived k for a cantilever with four legs k¼ Et3c ; l3c 1 4 2 2 lp 3lc lp þ 3lc 4 þ lp wc wp wc (4) where E is the elastic modulus of the cantilever material. Although the cantilever is made of silicon with silicon dioxide and aluminum thin films on top, a single E is a good approximation as the silicon layer is 40 thicker. To arrive at this expression, we equated the internal and external torques from a force at the tip, using a piecewise function for the cantilever moment of inertia corresponding to the regions with and without legs. C. Piezoresistance factor and dopant activation To calculate b in (3), we need the relationship between piezoresistance factor and carrier concentration.40 Because our piezoresistors are n-type, we replaced the p-type relationship reported by Harley38 with the n-type relationship of Tufte and Stelzer.45 The code uses Tsais model46 to predict phosphorus concentration profiles for a given diffusion time and temperature. Instead of assuming complete dopant ionization, we now convert the dopant concentration profiles into carrier concentration profiles using activation data from Fair and Tsai.47 D. Ambient temperature FIG. 3. Schematic of our cantilever probes in (a) plan and (b) cross-section views. The silicon between electrical traces was etched to minimize current leakage paths, resulting in a cantilever with four legs. The inner conductor runs under the outer shield to the coaxial tip (dotted line). As SGM is often performed at cryogenic temperatures, we now permit a user-specified ambient temperature instead of fixing it at 300 K. Currently, changing the temperature only affects the calculation of Johnson noise. We are working on adding the temperature dependence of mobility and dopant activation.48 [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 171.66.208.134 On: Thu, 01 Oct 2015 23:42:51 034306-4 Haemmerli et al. J. Appl. Phys. 118, 034306 (2015) E. Inactive resistance The factor in (3) is the ratio of the active resistance of piezoresistor, specifically the resistance of the two longitudinal legs, to the total measured resistance. Previously, this factor was determined by FEA and entered into the code. Instead, we derived an expression for using an equivalent resistance model c¼ 2Rlong Rshunt ; Rloop Rshunt þ Rloop (5) where Rloop ¼ 2Rlong þ Rtrans þ 2Rc . Rlong and Rtrans are the longitudinal and transverse resistances of the piezoresistor, Rshunt is the effective resistance due to leakage between the piezoresistor legs and Rc is the contact resistance from the metal electrodes to the piezoresistor. The latter two resistances can be determined with test structures fabricated alongside the scanning probes. We assume that the resistance of the metal traces and wire bonds is negligible. If Rshunt is large, as is the case when the silicon between neighboring traces is removed, the fraction on the right of 5 approaches unity. thicknesses of 6.5 lm, 0.5 lm, and 400 lm and a nominal resistivity of 1–5 X cm. Our process is illustrated in Figure 4. We first etched alignment marks in the device layer silicon with CHF3/O2 plasma. Our next sequence of steps produced sharp silicon tips. We oxidized the wafers at 1100 C for 39 min in pyrogenic steam to grow a 5000 Å hard mask. We patterned the oxide into discs with CHF3/O2 plasma. We etched the unmasked silicon isotropically in SF6 plasma, undercutting the discs to form conical tip precursors. We observed the tops of the precursors through the transparent discs, and stopped the etching when they could no longer be resolved with an optical microscope. We chose a disc diameter of 4 lm to yield tip heights of 3 lm with this etch recipe. We stripped the masks in 6:1 buffered oxide etch (BOE) and oxidized the wafers at 900 C for 43 min in steam. At temperatures below 950 C, the build-up of stress inhibits oxidation at regions of high curvature. Thus, the oxidation sharpened the precursors into final tips.50 Next, we created the piezoresistors and inner conductors by phosphorus diffusion. We used the 1000 Å of oxide grown during the sharpening process as a hard mask, patterning it in 6:1 BOE. We avoided dry etching in order to maintain tip sharpness. We F. Tip offset The code previously assumed that the cantilever is loaded at its free end. However, in the case of scanning probes, the sharp tip interacts with the sample. This tip is typically offset from the free end of the cantilever by a distance we define as loffset. To calculate the cantilever properties at the tip location, we replaced all occurrences of lc with le where le ¼ lc lo ff set. The design parameters and predicted performance of our scanning probes resulting from the optimizer with the enhancements discussed above are provided in (1). As the devices presented here are intended for room temperature operation, we specified an ambient temperature of 300 K. In addition, we restricted power dissipation in the piezoresistor to 2 mW to keep the cantilever self-heating below 100 C,49 selected a measurement bandwidth of 10 kHz (1 Hz–10 kHz) for reasonable scan times, and placed an upper bound of 10 N/m on the cantilever spring constant to minimize damage to the sample while scanning. To facilitate fabrication, we specified a minimum diffusion time tdiff of 15 min and a range for the diffusion temperature Tdiff of 1073 K–1173 K. The remaining parameters were determined by the optimizer. III. FABRICATION We fabricated the scanning probes using a batch process that produces >100 devices per wafer. We then opened the shield and insulator at the apex of each tip, exposing the inner conductor, using focused ion beam (FIB) milling. These methods are described in detail below. A. Batch Fabrication of cantilever probes We fabricated the scanning probes from 4-in. (100) double-side polished p-type silicon-on-insulator (SOI) wafers with device, buried oxide (BOX), and handle layer FIG. 4. Batch process used to fabricate our cantilever probes from siliconon-insulator wafers: (a) Etch alignment marks, grow thermal oxide, and pattern oxide into discs at the tip locations. Etch device layer Si in SF6 plasma, undercutting the discs to form tip precursors. Remove discs. (b) Grow thermal oxide to sharpen tips, then pattern oxide and perform phosphorus diffusion to create piezoresistors and inner conductors. (c) Strip oxide mask and deposit low-temperature oxide to form insulator. Open contacts to diffusions. (d) Sputter and pattern Al into outer shields and bond pads. (e) Define and (f) release cantilevers with deep reactive ion etching. Clear buried oxide in CHF3/O2 plasma. [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 171.66.208.134 On: Thu, 01 Oct 2015 23:42:51 034306-5 Haemmerli et al. J. Appl. Phys. 118, 034306 (2015) FIG. 5. SEM images of a representative device at increasing magnification: (a) entire die, (b) scanning cantilever (front) and matched cantilever for differential readout (back), (c) scanning cantilever, highlighting the four leg design, and (d) close-up of the unopened tip. performed the diffusion at 850 C for 15 min (parameters calculated by the numerical optimizer) in a POCl3 ambient. We stripped the phosphosilicate glass deposited during the diffusion and the oxide mask in 6:1 BOE. To passivate the piezoresistors and create the insulator for the coaxial tips, we deposited 400 Å of low-temperature oxide (LTO) at 400 C. This film thickness withstands 10 V between the inner conductor and outer shield before electrical breakdown but does not round the tip apex significantly. We used LTO instead of thermal oxide to mitigate dopant diffusion which would degrade piezoresistor performance. We etched contact vias to the n-type silicon using 20:1 BOE and immediately sputtered 400 Å of aluminum. We patterned the metal into the outer shield for the coaxial tips and the bond pads for the piezoresistors and the inner conductors with AL-11 wet etchant at 40 C. Again, we selected the film thickness to minimize tip rounding. We defined the cantilevers and die outlines by etching the device layer silicon in HBr/Cl2 plasma, stopping on the BOX. To release the cantilevers, we etched through the handle layer with deep reactive ion etching (DRIE), again stopping on the BOX, then cleared the BOX in CHF3/O2 plasma. During this process, the frontside of the wafer was protected with 7 lm of SPR220–7 resist. Finally, we cleaned the wafers in PRS-1000 at 40 C. Scanning electron microscope (SEM) images of a completed device are presented in Figure 5. I-beam to mill the rectangle one line at a time, ending at the overlapping edge, instead of raster scanning the entire pattern for the duration of the etching. The line-by-line approach is known as a cleaning cross-section and produces a high-quality surface at the end of the tip. We used a 1 pA Gaþ beam current to achieve a slow milling rate and to limit damage to the probe while imaging. We milled until clear contrast could be observed between the exposed inner conductor and outer shield in E-beam images. With this method, we could repeatably produce apertures of 30 nm in radius. SEM images of a tip before and after milling are shown in Figure 7. IV. RESULTS AND DISCUSSION Figure 8 shows a representative topography scan using our tips. We measured the vertical displacement resolution of our scanning probes at 293 K and 2 K for the corresponding designs. At room-T, we mounted the probe in a Witec Alpha300A AFM system and placed the active and compensation piezoresistors in a Wheatstone bridge configuration B. Opening the coaxial tip We used FIB milling to obtain small, controlled apertures at the tip apex. We performed the milling with an FEI Strata 235DB dual-beam FIB/SEM in which the electron beam (E-beam) and ion-beam (I-beam) are coincident on the sample and separated by 52 . We aligned the I-beam parallel to the cantilever and opened the tip from the side using a rectangular milling pattern, as shown in Figure 6. We drew the pattern such that one edge overlaps the tip apex. We set the FIG. 6. Focused ion beam (FIB) process used to open the coaxial tips. A 1 pA Gaþ ion beam (I-beam) is used for milling and an electron beam (Ebeam) is used for imaging. We attached the probes to a 45 mount, tilted the stage 7 to align the I-beam parallel to the cantilevers and opened the tips from side with a rectangular milling pattern. We configured the I-beam to scan the pattern line-by-line in the direction of the arrow, producing a highquality surface at the tip apices. [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 171.66.208.134 On: Thu, 01 Oct 2015 23:42:51 034306-6 Haemmerli et al. J. Appl. Phys. 118, 034306 (2015) FIG. 7. SEM images of a representative tip (a) before and (b) after FIB milling. The opening radius is 30 nm. The inner conductor and outer shield are separated by 400 Å of oxide. The scale bars are 500 nm. FIG. 8. Topographic image of an aluminum test pattern on glass taken with our probe in contact mode using piezoresistive feedback. The sample was fabricated by spin-coating polystyrene beads on a glass slide, evaporating Al and removing the beads in solvent. Aluminum not in contact with the glass lifted off with the beads, leaving an inverted hexagonal close-packed lattice with 10 nm step heights. with two matched metal-film resistors. We connected the output of the bridge to a Texas Instruments INA103 amplifier with 1000 gain. For low-T measurements, we used a home-built scanning system contained within a top-loading 3 He cryostat. The readout circuit consisted of a Wheatstone bridge followed by two Stanford Research Systems SR560 TABLE I. Design parameters and predicted AFM performance of scanning probes. Measurements bandwidth is 1 Hz–10 kHz. Temperature (K) Bridge voltage (V) Cantilever dimensions Piezoresistor dimensions Spring constant (N/m) Resonant frequency (kHz) Power dissipation (lW) Displacement sensitivity (kV/m) pffiffiffiffiffiffi Johnson noise (nV/ Hz) pffiffiffiffiffiffi Hooge noise (nV/ Hz) at 10 Hz Total noise (nV) Displacement resolution (Å) lc (lm) wc (lm) tc (lm) lp (lm) wp (lm) Room-T Low-T 293 2 145.5 35 3 42.5 5 7.40 154 638 3.57 5 35 581 1.63 2 0.2 145.5 35 3 96 5 6.42 154 3.52 0.298 4 20 422 14.2 amplifiers in series, with gains of 100 and 500. The compensation piezoresistor was not used because the temperature in the cryostat is well controlled. During operation, the three matched resistors in the bridge are at the same temperature as the probe; while the amplifiers remain at room-T. In either systems, the probes were mounted at a 12 angle with respect to the sample. At both temperatures, we first measured the voltage noise with the tip out of contact and then measured the output voltage as the cantilever was deflected with a hard sample, giving displacement sensitivity. We calculated displacement resolution by dividing the integrated noise in 1 Hz–10 kHz by the sensitivity. We also measured the resonant frequency by vibrating the probes with an external piezoelectric actuator and identifying a sharp peak in the output voltage as we swept the excitation frequency. Our results are summarized in Tables I and II, where the predicted values have been updated to reflect actual probe geometry as measured by SEM (lc ¼ 174.5 lm and tc ¼ 2.5 lm). At room-T, the scanning probe is able to resolve displacements of 2.94 Å. The predicted and measured values all agree within 5% with a resolution variation over measured devices of 5%. At low-T, the measured displacement sensitivity is 18% lower than predicted. We calculated the predicted sensitivity using room-T values for the piezoresistive coefficient pl as we did not have data for n-type diffusions at 2 K. Thus, the discrepancy between the measured and predicted values can be explained by the variation of pl with TABLE II. AFM performance of two fabricated scanning probes. Two separate designs are presented optimized for room or low temperature. Boldface values are measured, others are predicted. Measurements bandwidth is 1 Hz–10 kHz. Temperature (K) Bridge voltage (V) Spring constant (N/m) Resonant frequency (kHz) Displacement sensitivity (kV/m) Total noise (nV) Displacement resolution (Å) Room-T Low-T 293 2 2.96 105 100 2.00 2.03 587 581 2.94 2 0.2 2.67 114 103 0.146 0.178 1150 422 78.8 2.86 23.7 [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 171.66.208.134 On: Thu, 01 Oct 2015 23:42:51 034306-7 Haemmerli et al. FIG. 9. Variation of piezoresistor coefficient pl with temperature for n-type diffusions with different surface concentrations ns . The measured value of pl is a conductivity-weighted average of the piezoresistive coefficient over the thickness of the diffusion. Below 100 K, pl shows a decrease with temperature. Data from this work fits well with that of Tufte and Stelzer.45 J. Appl. Phys. 118, 034306 (2015) temperature. In Figure 9, we plot pl for n-type diffusions with different surface concentrations ns down to 77 K, taken from Tufte and Stelzer.45 Because the carrier concentration varies with depth in diffused piezoresistors, the pl values presented here are conductivity-weighted averages over the thickness. We see that below 100 K, pl decreases with temperature. The pl values extracted from our piezoresistors (ns ¼ 1.3 1020 cm3, verified by spreading resistance analysis) show good agreement with the existing data. We also see that the measured noise is 2.7 larger than predicted. At low-T operating conditions, the two main sources of noise 2 ). from the piezoresistor are small (VJ2 / T and VH2 / Vbridge Total noise is determined by the amplifier noise floor. We verified that the total noise did not change when the inputs of the first-stage amplifier were disconnected from the bridge and grounded. Thus, although the scanning probe is only able to resolve displacements of 78.8 Å, the resolution isp limffiffiffiffiffiffi ited by the amplifier. Switching p from the SR560 (4 nV/ Hz ffiffiffiffiffiffi at 1 kHz) to the INA103 (1 nV/ Hz at 1 kHz) should allow displacements of 7.19 Å to be resolved. We measured the electrostatic potential profile produced by our coaxial tips using a quantum point contact. At 2 K, we first obtained a plot of conductance Gds through the QPC versus voltage VG FIG. 10. QPC measurements of a coaxial tip: (a) Topography of the surface gates that defines the QPC. (b) Two-dimensional maps of Gds collected as the tip are scanned 100 nm above the sample surface. Inner conductor voltage Vic varies along rows and outer shield voltage Vsh varies along columns. The nominal conductance (Gds ¼ 2.56 e2 =h, determined with the tip absent) is shown in white, while suppression and enhancement are shown as red and blue, respectively. The scale bar is 2 lm, valid for all images. When Vic and Vsh have the same polarity (bottom left and top right), the tip behaves as if it is unshielded, resulting in long-range conductance modulation. The benefit of the coaxial tip is apparent when the shield is grounded (middle column). In this case, the tip only modulates conductance when it is above the QPC and the long-range effect is almost completely nulled. [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 171.66.208.134 On: Thu, 01 Oct 2015 23:42:51 034306-8 Haemmerli et al. on the surface gates. To measure Gds , we applied a small AC voltage (4 lV) across the ohmic contacts and recorded the resulting current using a DL 1211 current preamplifier and an EG&G 124A lock-in amplifier. Then, we selected VG such that the QPC was between the first and second conductance plateaus. In this region, dGds =dVG is approximately linear. When the tip is placed in proximity to the QPC, it acts as a third gate and the tip potential modulate the channel conductance. Thus, by recording Gds as the tip is scanned over the QPC, a spatial map of the tip potential can be obtained. In Figure 10, we present 8 lm 8 lm maps of Gds acquired at a lift height of 100 nm above the semiconductor surface as in Figure 11. We set VG ¼ 0.730 V, yielding a nominal Gds ¼ 2.56 e2 =h. We varied the inner conductor voltage Vic from 2 V to þ2 V in steps of 2 V and the outer shield voltage Vsh from 1 V to þ1 V in steps of 1 V, producing a 3 3 array of maps (see linecuts in Figure 12). The maps show that we can independently address the inner conductor and outer shield and that both are capable of gating the QPC. Qualitatively, we see that by tuning Vsh , we can narrow the perturbation created by the inner conductor and eliminate the slow decay in potential that is characteristic of an unshielded tip. Consider the bottom row of images where Vic ¼ 2 V. When Vsh ¼ 1 V, Gds is suppressed in the entire scan window. Even when the tip is several microns from the QPC, the long range fields from the inner conductor and shield result in a negative DGds . When Vsh ¼ 0 V, the region of strong suppression from the inner conductor is reduced. Furthermore, with this biasing, when the tip is not directly above the QPC, Gds returns to its nominal value. Finally, when Vsh ¼ þ1 V, the perturbation produced by the inner conductor is even narrower. However, the potential on the shield now enhances Gds . Two surprising features are apparent in the maps. First, when Vic and Vsh are 0 V, we intuitively expect that the tip will have no effect on QPC conductance. However, centered above the QPC, we see a small region of suppression FIG. 11. Experimental setup to measure the tip potential profile with a quantum point contact (QPC). The sample is a GaAs/AlGaAs heterostructure containing a buried two-dimensional electron gas (2DEG). A negative voltage VG is applied to the surface gates which depletes the 2DEG below and forms the QPC. Conductance through the QPC Gds is determined by applying a small AC excitation Vds across the ohmic contacts and measuring the resulting current via a lock-in amplifier. The bias on the gates is selected such that Gds is a linear function of VG , between conductance plateaus. As the probe is scanned above the QPC, the tip potential couples to the surface gates and the 2DEG below, modulating Gds . A spatial map of Gds reveals the shape of the potential profile. J. Appl. Phys. 118, 034306 (2015) surrounded by a halo of enhancement. Poggio et al. also observed a change in Gds in response to a grounded cantilever when they used a QPC as a displacement sensor.51 The authors hypothesized that the modulation of conductance was a result of trapped charge on the cantilever or differences in work function between the cantilever and sample materials. Here, we believe the latter explanation is valid. By tuning the Vic and Vsh , we can null the differences in work function and minimize the tip effect. For example, the halo is caused by the work function difference between the Al FIG. 12. Linecuts of Gds along the dashed line in Figure 10(a). Top: Vic ¼ 0 V and Vsh ranging from 1 V to þ1 V in steps of 0.2 V. Bottom: Vsh ¼ 0 V and Vic is ranging from 2 V to þ2 V in steps of 2 V. The dashed line in top plot indicates the nominal value of Gds when the tip is absent. When Vsh ¼ þ1 V or 1 V, the shield dominates the effect of the tip and the probe behaves like a conventional metal-coated AFM probe. In either case, the potential profile is broad and has a long tail (Gds has yet to return to its nominal value at x ¼ 4 lm). When Vic ¼ Vsh ¼ 0 V, the effect of the tip on Gds results from the work function differences between the materials in the tip and in the sample. The n-type Si inner conductor suppresses conductance, while the Al outer shield enhances it. These biasing conditions can be used to produce a sharp perturbation with no long tail (Gds returns to its nominal value at x ¼ 4 lm). If undesirable, the enhancement peaks produced by the Al shield (arrows) can be compensated with slightly negative Vsh , completely disappearing at Vsh ¼ 0.6 V. The bottom plot further displays how the tip inner conductor can be independently biased to produce the desired tip effect. [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 171.66.208.134 On: Thu, 01 Oct 2015 23:42:51 034306-9 Haemmerli et al. shield and the AlGaAs/GaAs heterostructure. It is eliminated when we set Vsh ¼ 0:6 V. The same voltage was reported by other researchers to null the work function difference between the Al island of a single-electron transistor scanning electrometer and an AlGaAs/GaAs heterostructure.52 The map of Gds tells us that the work function difference between the n-type Si inner conductor and the heterostructure has the opposite polarity of that between the Al outer shield and the heterostructure. In general, for SGM imaging with the coaxial tip, Vsh should be tuned to null the work function difference between the outer shield and the sample such that the perturbation to the sample results strictly from the inner conductor. Second, we see that the electrostatic potential profile from the tip appears elliptical instead of circular, with the long axis of the ellipse perpendicular to the surface gates. The QPC does not sample the tip potential at a single point in space. It responds to the potential in a nearby volume, which can be represented by a point spread function (PSF). The PSF sets the spatial resolution of QPC when it is used as a sensor. The maps of Gds are convolutions of the tip J. Appl. Phys. 118, 034306 (2015) potential profile with the PSF. The shape of the resulting convolution is controlled by the broader of these two inputs. From our modeling, we expect that the FWHM of the potential profile produced by the coaxial tip is below the spatial resolution of the QPC, which is determined primarily by the channel width (300 nm). Thus, when the QPC is used to measure this profile, the map of Gds takes the shape of the PSF. We believe that the PSF of the QPC is elongated in the axis perpendicular to the surface gates because the gates screen the tip potential. When the tip is scanned along the length of the gates, its effect decays more rapidly than when it is scanned along the QPC channel. In addition, the flow of electrons through the QPC is collimated,1 with the maximum flow occurring through the center of the channel. The flow decreases at larger angles from the straight-line trajectory. Because fewer electrons are backscattered at large angles, the tip has less of an effect in these locations. To calculate the FWHM of the convolution, which gives an upper bound on the FWHM of the tip potential profile, we considered maps of Gds with Vsh ¼ 0.6 V. We subtracted the map with Vic ¼ 0 V from the map with Vic ¼ 2 V to eliminate the effect of work function differences and measured the FWHM of the result. Because the convolution is elliptical, we measured the FWHM in the x and y axes, yielding 350 nm and 240 nm, respectively. As expected, the FWHM values roughly correspond to the QPC channel width. In Figure 13, we showed that the FWHM of the perturbation induced by an unshielded tip at hlift ¼ 100 nm is 560 nm. Using the QPC, we demonstrated that the FWHM of the potential profile coaxial tip at the same lift height is 240 nm. Thus, under these conditions, our coaxial tips improve the lateral resolution of SGM by 2.3. V. CONCLUSIONS FIG. 13. (a) FWHM of Dn versus lift height for unshielded (•) and coaxial (䊏) tips. For both tips, rc ¼ 10 nm and for the coaxial tip, ro ¼ 100 nm. FWHM increases with hlift as there is a larger distance between the tip and sample over which the electric field can diverge. (b) FWHM of Dn versus shield opening for a coaxial tip with rc ¼ 10 nm and hlift ¼ 100 nm. FWHM increases with ro as shielding of the inner conductor is less effective. Scanning gate microscopy enables measurement of local current flow, carrier density, and potential barriers, but the lateral resolution of the technique has been limited by existing probes. We have demonstrated a new scanning probe that integrates a coaxial tip on a piezoresistive cantilever. By shielding the inner conductor up to the tip apex, the coaxial tip minimizes stray capacitance and produces tightly confined potential profiles. The piezoresistor provides selfsensing capability, allowing cantilever deflection to be measured electrically, without the traditional optical lever setup that can disturb photosensitive samples. We designed the piezoresistive cantilevers with the aid of a numerical optimizer and used finite element analysis to compare the electrostatic potential profiles from unshielded and coaxial tips. We showed that lift height and shield opening radius have the largest effect on profile width. We developed a 7-mask process to fabricate scanning probes with both a piezoresistor and a coaxial tip. We used FIB milling to open the shield metal at the tip apex. The smallest apertures we produced were 30 nm in radius. We characterized the AFM performance of the probes by measuring the total system noise with the tip out of contact and then recording the readout circuit output while deflecting the cantilever with a hard sample to [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 171.66.208.134 On: Thu, 01 Oct 2015 23:42:51 034306-10 Haemmerli et al. calculate displacement sensitivity. The probes can self-sense tip displacements of 2.9 Å at 293 K and 79 Å at 2 K in a 10 kHz bandwidth, where the low-T performance is limited by amplifier noise. Finally, we imaged the potential profiles produced by the coaxial tips using a quantum point contact. At a lift height of 100 nm, the coaxial tips produce profiles that are 2.3 narrower than those of unshielded tips. We are currently using our self-sensing coaxial-tip probes to investigate carbon nanotube field effect transistors. ACKNOWLEDGMENTS This work was supported by the National Science Foundation (NSF) under Grant No. ECCS-0708031, NSF NSEC Center for Probing the Nanoscale (CPN) Grant No. PHY-0425897, and a CPN fellowship to NH. Fabrication work was performed in part at the Stanford Nanofabrication Facility (a member of the National Nanotechnology Infrastructure Network) supported by the NSF under Grant No. ECS-9731293, its lab members, and the industrial members of the Stanford Center for Integrated Systems. The authors would like to thank Keji Lai and Worasom Kundhikanjana for helpful discussions. 1 M. A. Eriksson, R. G. Beck, M. Topinka, J. A. Katine, R. M. Westervelt, K. L. Campman, and A. C. Gossard, Appl. Phys. Lett. 69, 671 (1996). 2 M. Topinka, B. LeRoy, S. Shaw, E. Heller, R. Westervelt, K. Maranowski, and A. Gossard, Science 289, 2323 (2000). 3 M. Topinka, B. LeRoy, R. Westervelt, S. Shaw, R. Fleischmann, E. Heller, K. Maranowski, and A. Gossard, Nature 410, 183 (2001). 4 M. P. Jura, M. A. Topinka, L. Urban, A. Yazdani, H. Shtrikman, L. N. Pfeiffer, K. W. West, and D. Goldhaber-Gordon, Nat. Phys. 3, 841 (2007). 5 Y. W. Fan, B. R. Goldsmith, and P. G. Collins, Nat. Mater. 4, 906 (2005). 6 Y. Kim, Y. M. Oh, J.-Y. Park, and S.-J. Kahng, Nanotechnology 18, 475712 (2007). 7 M. Freitag, A. Johnson, S. Kalinin, and D. Bonnell, Phys. Rev. Lett. 89, 216801 (2002). 8 M. Bockrath, W. Liang, D. Bozovic, J. H. Hafner, C. M. Lieber, M. Tinkham, and H. Park, Science 291, 283 (2001). 9 A. Bachtold, M. S. Fuhrer, S. Plyasunov, M. Forero, E. H. Anderson, A. Zettl, and P. L. McEuen, Phys. Rev. Lett. 84, 6082 (2000). 10 M. Fee, S. Chu, and T. W. Hansch, Opt. Commun. 69, 219 (1989). 11 U. C. Fischer and M. Zapletal, Ultramicroscopy 42–44, 393 (1992). 12 F. Keilmann, Infrared Phys. Technol. 36, 217 (1995). 13 R. C. Davis, C. C. Williams, and P. Neuzil, Appl. Phys. Lett. 66, 2309 (1995). 14 C. Mihalcea, W. Scholz, S. Werner, S. Muenster, E. Oesterschulze, and R. Kassing, Appl. Phys. Lett. 68, 3531 (1996). 15 D. Drews, W. Ehrfeld, M. Lacher, K. Mayr, W. Noell, S. Schmitt, and M. Abraham, Nanotechnology 10, 61 (1999). 16 T. Leinhos, O. Rudow, M. Stopka, A. Vollkopf, and E. Oesterschulze, J. Microsc. 194, 349 (1999). 17 I. W. Rangelow and S. Biehl, J. Vac. Sci. Technol., B 19, 916 (2001). 18 P. Pingue, V. Piazza, P. Baschieri, C. Ascoli, C. Menozzi, A. Alessandrini, and P. Facci, Appl. Phys. Lett. 88, 043510 (2006). J. Appl. Phys. 118, 034306 (2015) 19 G. Valdre, D. Moro, D. Lee, C. G. Smith, I. Farrer, D. A. Ritchie, and R. T. Green, Nanotechnology 19, 045304 (2008). 20 K. A. Brown, J. A. Aguilar, and R. M. Westervelt, Appl. Phys. Lett. 96, 123109 (2010). 21 D. van der Weide, Appl. Phys. Lett. 70, 677 (1997). 22 I. W. Rangelow, F. Shi, P. Hudek, P. Grabiec, B. Volland, E. I. Givargizov, A. N. Stepanova, L. N. Obolenskaya, E. S. Mashkova, and V. A. Molchanov, J. Vac. Sci. Technol., B 16, 3185 (1998). 23 B. Rosner, T. Bork, V. Agrawal, and D. van der Weide, Sens. Actuators, A 102, 185 (2002). 24 M. Tabib-Azar and Y. Wang, IEEE Trans. Microwave Theory Tech. 52, 971 (2004). 25 K. A. Brown, J. Berezovsky, and R. M. Westervelt, Appl. Phys. Lett. 98, 183103 (2011). 26 K. A. Brown, K. J. Satzinger, and R. M. Westervelt, Nanotechnology 23, 115703 (2012). 27 N. R. Wilson and D. H. Cobden, Nano Lett. 8, 2161 (2008). 28 J. Brugger, R. A. Buser, and N. F. de Rooij, J. Micromech. Microeng. 2, 218 (1992). 29 S. Watanabe and T. Fujii, Rev. Sci. Instrum. 67, 3898 (1996). 30 P. G€ unther, U. Fischer, and K. Dransfeld, Appl. Phys. B: Lasers Opt. 48, 89 (1989). 31 M. Tortonese, R. C. Barrett, and C. F. Quate, Appl. Phys. Lett. 62, 834 (1993). 32 T. Gotszalk, P. Grabiec, and I. W. Rangelow, Ultramicroscopy 82, 39 (2000). 33 J. R. Mallon, A. J. Rastegar, A. A. Barlian, M. T. Meyer, T. H. Fung, and B. L. Pruitt, Appl. Phys. Lett. 92, 033508 (2008). 34 S. R. Manalis, S. C. Minne, and C. F. Quate, Appl. Phys. Lett. 68, 871 (1996). 35 B. W. Chui, T. W. Kenny, H. J. Mamin, B. D. Terris, and D. Rugar, Appl. Phys. Lett. 72, 1388 (1998). 36 T. Akiyama, U. Staufer, N. F. de Rooij, D. Lange, C. Hagleitner, O. Brand, H. Baltes, A. Tonin, and H. R. Hidber, J. Vac. Sci. Technol., B 18, 2669 (2000). 37 J. A. Harley and T. W. Kenny, Appl. Phys. Lett. 75, 289 (1999). 38 J. A. Harley and T. W. Kenny, J. Microelectromech. Syst. 9, 226 (2000). 39 J. C. Doll, S.-J. Park, and B. L. Pruitt, J. Appl. Phys. 106, 064310 (2009). 40 S.-J. Park, J. C. Doll, and B. L. Pruitt, J. Microelectromech. Syst. 19, 137 (2010). 41 S.-J. Park, J. C. Doll, A. J. Rastegar, and B. L. Pruitt, J. Microelectromech. Syst. 19, 149 (2010). 42 J. C. Doll and B. L. Pruitt, Piezod (2012). 43 J. C. Doll and B. L. Pruitt, Piezoresistor Design and Applications: Springer, 2013. 44 N. Harjee, A. G. F. Garcia, M. K€ onig, J. C. Doll, D. Goldhaber-Gordon, and B. L. Pruitt, in Proceedings of International Conference on Micro Electro Mechanical Systems (2010), p. 344. 45 O. Tufte and E. Stelzer, J. Appl. Phys. 34, 313 (1963). 46 J. C. C. Tsai, Proc. IEEE 57, 1499 (1969). 47 R. Fair and J. Tsai, J. Electrochem. Soc. 124, 1107 (1977). 48 D. B. M. Klaassen, Solid-State Electron. 35, 961 (1992). 49 J. C. Doll, E. A. Corbin, W. P. King, and B. L. Pruitt, Appl. Phys. Lett. 98, 223103 (2011). 50 T. Ravi, R. Marcus, and D. Liu, J. Vac. Sci. Technol., B 9, 2733 (1991). 51 M. Poggio, M. P. Jura, C. L. Degen, M. A. Topinka, H. J. Mamin, D. Goldhaber-Gordon, and D. Rugar, Nat. Phys. 4, 635 (2008). 52 M. J. Yoo, T. A. Fulton, H. F. Hess, R. L. Willett, L. N. Dunkleberger, R. J. Chichester, L. N. Pfeiffer, and K. W. West, Science 276, 579 (1997). [This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded to ] IP: 171.66.208.134 On: Thu, 01 Oct 2015 23:42:51