Vieques sustainable farming - English[1]

advertisement

![Vieques sustainable farming - English[1]](http://s2.studylib.net/store/data/018655334_1-652fb1399af5c98b6337154bf370b02e-768x994.png)

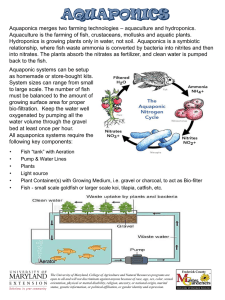

Vieques Sustainable Farming Resources Potential Projects Costs and Benefits Hydroponics and aquaponics: Hydroponics and aquaponics are methods of raising vegetables and/or fish without soil. Aquaponics is the symbiotic cultivation of plants and aquatic animals in a re-­‐circulating system using algae eating fish to fertilize a variety of crops and herbs using aquaponics. By using gravity as a transport, water is drained from the fish tank into a gravel bed. Here, beneficial bacteria break down the toxic ammonia in fish waste to Nitrite and then to Nitrogen, a key nutrient for plant development. On the gravel bed watercress is also used as a secondary means of water filtration. The filtered water is pumped from the gravel bed to the growing beds, where a variety of crops from specialty salad greens to tomatoes are raised. The water is wicked up to the crops roots with the help of coir, a by-­‐product of coconut shells and a sustainable replacement for peat moss. Finally, the water flows from the growing beds back into the tank of fish. This type of aquaponics system is easy to build and only needs a small pump and heat to get the system running. There is one operating aquaponics facility on Vieques presently http://www.hydroorganicspr.com/, and there is an opportunity to expand the operation at the underutilized hydroponics facility located adjacent to the recycling center.1 Recycling Center Hydroponics greenhouses 1 A commercial aquaponic system utilizing maximum floor space and a strict, balanced diet for the fish are the mark of a successful system. Such system can produce an extremely high numbers of final food stuffs. For example, a greenhouse approximately 37 feet wide by 100 feet long (3700 sq. ft.) can house an aquaponic system capable of producing 50 to 60 thousand heads of premium lettuce and approximately 11,000 pounds of fresh Tilapia per year. An aquaponic system of this size can be a rewarding and profitable business and could be operated successfully by a small number of persons or a family. One person can operate a 10,000 square foot facility but would need help harvesting fish. Yearly production from Portable Farms™ Aquaponics Systems. http://www.portablefarms.com/. A 90′ x 120′ unit produces 60,000 vegetables and 23,000 pounds of fish. A 1,024 square foot “small” commercial aquaponics system for $15,000 in materials. Each module is 7.5’ X 50’ and includes everything but fish tank and clarifier. A 30 module facility in a greenhouse (already constructed) would be about $40,000 with a one-time license. For an additional fee of $18,000. The engineer will help build the first 3 modules and train the interested parties or business owner to build the rest. The facility can be powered by a 200 watt solar collector with 4 marine batteries for back up. Hydroponics and Recycling Center Biodiesel and cooking oil (yellow grease) recycling: Although this is only peripherally related to agriculture, bio-­‐diesel made from used cooking fat is a sustainable fuel and scalable enough for a small plant to be built on Vieques to supply fuel for municipal vehicles and for diesel powered boats, or ferries. Edelca(r) Inc. http://edelcarpr.com/index.htm, collects cooking oil from businesses in and around San Juan, and either has built or is building a biodiesel plant on their premises. Jatrodiesel http://www.jatrodiesel.com/ provides consulting and construction services for biodiesel producers, and Tri State Biodiesel http://www.tristatebiodiesel.com/home.htm, is a start up cooking oil collector, consolidator and producer of biodiesel in the New York Metropolitan area. And the Doe Fund http://www.rwaresourcerecovery.org/, a non-­‐profit hires previously unemployed persons to collect oil and is building a biodiesel plant in Brooklyn. A small biodiesel collection facility and plant could be constructed at the recycling center. A small plant capable of producing 450 gallons a day will cost about $85002 2 http://homebiodieselkits.com/150gadewdr.html Our new 150 Gallon Deluxe processor with our patent pending drywash system built in will convert any used cooking oil into high grade biodiesel in as little as 7 hours without water washing! With a batch size of 150 gallons this system will easily produce 450 gallons of biodiesel per day. Features: • • • • • • • • • • • • • • Deluxe Starter Kit BioKleen Drywash System Built In 200 Gallon Reactor tank 4000 watt Exclusive In-Tank Heating System included. One-Piece Powder Coated Steel Frame Two 720 Ga. per hour mixing pumps. Hands Free Methoxide Mixing System. No hand pumps. Small air compressor needed. New digital process timer with on/off and even planning. All steel plumbing with 18 inch ground clearance. Exclusive 2 micron biodiesel pre-filter. Exclusive In-line Static Mixer with over 10 times the mixing power of other processors. New built-in temperature guage for easy process temperature readings. One piece welded steel frame mounted on a skid with no assembly required. Biodiesel & Oil Collection Guide e-Books included. An $80 value. Composting: Composting is a valuable tool for eliminating waste from the landfill and creating a product that can be used as a soil amendment for farmers or gardeners. Home composting should be suggested (and the bins made available at a reasonable rate or for free) to private home owners and commercial property owners. However the most efficient way of dealing with compost is to have a collection center where restaurants, hotels, guest house owners who generate organic or wet paper waste can bring, (or contract with someone to bring) to a central location for composting. In Puerto Rico’s climate this process can be done in the open or under a roof to keep excess moisture out of the piles. Many municipalities now offer this service. (I can provide more information about municipal composting if necessary). Anaerobic digestion http://www.energysavers.gov/your_workplace/farms_ranches/index.cfm/mytopic=30003 takes composting to the next step. It is a mechanical, commercial application that takes organic waste including green waste, wet paper, cardboard, and even sewage sludge and converts it to a soil amendment and methane gas that can be bottled and used for fuel for cooking, heating, or for vehicle fuel. Anaerobic digesters are scalable. Many dairy, pork, or chicken farms use the manure to generate gas to operate the farm machinery and for household use. A significant amount of municipal waste that is going to the landfill could be feed stock for an anaerobic digester at the recycling plant. Bottled gas purveyors could become stakeholders or investors in this facility, and there may be Departments of Energy or Agriculture grants for building such a facility.3 Wastewater Garden: A 52 square meter wastewater garden serves all the greywater and blackwater at the homestead building of the Las Casas de la Selva rainforest enrichment and forestry project near Patillas. The Department of Natural Resources funded the project as a demonstration of an ecological approach to recycle sewage and to protect mountain streams that feed water reservoirs for local populations. Water quality testing showed over 90% reduction of biological oxygen demand, total suspended solids, and total nitrogen; total phosphate reduced by 83% and a 99.9% reduction of coliform bacteria.4 http://www.eyeontherainforest.org/wwgatlascasas.php Restoring Shaded Coffee Plantations in Puerto Rico Location: Southeastern Region: Puerto Rico 3 Anaerobic digester: A small scale horizontal plug flow, 3.5-4 thousand tons per year, used in front of a composting operation needs a footprint of 80’ X 160’ will cost from $1.6-2 million. The compost and methane gas produced will offset the purchase price. Methane can be used as a cooking and heating fuel, to generate electricity, or power gasoline engine vehicles after it is “scrubbed” and compressed. An additional important benefit is that anaerobic digestion reduces by 80% the methane (a greenhouse gas) escaping to the atmosphere compared to traditional composting. This digester can accept any organic waste including food, paper, farm waste, and sewage sludge. One company producing this size digester is http://www.eisenmann.com/en/products-and-services/environmental-technology/biogas-plants/agriculture.html 4 Andres Rua from Las Casas de la Selva forwarded me your enquiry about the constructed wetland system they have at their project. Wastewater Gardens (WWG), as I call our approach because we include a diversity of beautiful, efficient and if possible harvestable shrubs/trees in our system, have four major factors which influence cost. a. Liner: We often use EPDM (which is usually used in water gardens, ponds), a heavy-duty geo-membrane material; if the site has impermeable clay, that can be compacted and used; third choice is concrete. b. Gravel: generally the depth is 0.55 or 0.6 meters; and sizing of the system depends on quantity and strength/concentration of the wastewater. The gravel needs to be screened and clean (to maximize porosity).Are there quarries and a source of gravel on the island? c. Excavation of constructed wetland and leach drains (which serve as subsoil irrigation for additional greenery d. Plants: wetland-tolerant plants for the WWG and wider choice of plants/trees for the final subsoil irrigation excepting root crops and plants with invasive root systems I annually go to help with research at the project in Puerto Rico and could arrange a consulting trip to Vieques. Project Summary: Project provides incentives and assistance to coffee growers to return “sun” coffee plantations to shade, improving environment and wildlife habitat. See the end note about the feasibility of growing coffee in Vieques. However Silmarie Padrón Fish and Wildlife Biologist Branch of Habitat Restoration of the U.S. Fish and Wildlife Service 4401 North Fairfax Drive, Room 700H Arlington, VA 22203, believes that other forms of agriculture in Vieques are sustainable. i http://www.cooperativeconservation.org/viewproject.asp?pid=121 Ridge to Reef sustainable farming: A potential project of the Virgin Island Sustainable Farming Institute (VISFI), and the Vieques Conservation and Historical Trust (VCHT) partnership in sustainable farming called Ridge to Reef or La Cresta Hasta el Arrecife. Barbara Hyland from VCHT was in St. Croix last February, and met with Nate Olive from VISFI to talk about this collaboration. http://www.visfi.org/about/, http://www.vcht.com/ There are Permaculture books and course materials available in Spanish from Las Cañadas in Mexico http://www.bosquedeniebla.com.mx/hacperint.htm. Caribbean Lobster Hatchery for Vieques: Ted Ames, fisherman and MacArthur Fellow is a co-­‐founder of Penobscot East Resource Center. Ted has expressed interest in helping to develop a Caribbean lobster hatchery with the Vieques Fishermen’s Cooperative (Cooperativo de Pescadores de Vieques). The process is similar to the hatchery described in the following link. http://www.penobscoteast.org/hatchery.asp. The references below5 clearly indicate that Spiny (Caribbean) lobster aquaculture is feasible. The costs depend on the size and production of the facility. A small lobster hatchery in Stonington ME was built for $200,000 plus some volunteer fishermen labor. Ted Ames’ fee would be $200 a day plus expenses to come to Vieques to help plan, design, and help the fishermen build the facility. i Our office has been working for over a decade in the high mountain region of the main island with farmers through our voluntary habitat restoration programs (Partners for Fish and Wildlife and Coastal Program) to convert sun coffee orchards back to the more traditional shade coffee. This was initially to restore forest canopy habitat for migratory birds, threatened and endangered species, and other native wildlife; but we quickly recognized the benefits to stream and coastal water quality from the shade coffee practice. It also has direct benefits for the farmer as it reduces the need for fertilizers and other chemical (herbicides and pesticides), reduces the frequency of pruning and replanting the coffee bushes, and produces a higher quality coffee. 5 http://www.thefishsite.com/articles/355/candidate-species-for-aquaculture-caribbean-spiny-lobster-ipanulirus-argus-i Hatchery design considerations Samia Sarkis Department of Conservation Services Bermuda E-mail: scsarkis@gov.bm Sarkis, S. 2011. Hatchery design considerations. In A. Lovatelli and S. Sarkis (eds). A regional shellfish hatchery for the Wider Caribbean: Assessing its feasibility and sustainability. FAO Regional Technical Workshop. 18–21 October 2010, Kingston, Jamaica. FAO Fisheries and Aquaculture Proceedings. No. 19. Rome, FAO. 2011. pp. 147–152. The cultivation of marine invertebrates indigenous to the Wider Caribbean Region established culture techniques and research needs for crustacean: Roger Leroy Creswell University of Florida Sea Grant Fort Pierce, Florida, United States of America E-mail: creswell@ufl.edu Creswell, R.L. 2011. The Cultivation of marine invertebrates indigenous to the Wider Caribbean Region: established culture techniques and research needs for crustaceans. In A. Lovatelli and S. Sarkis (eds). A regional shellfish hatchery for the Wider Caribbean: Assessing its feasibility and sustainability. FAO Regional Technical Workshop. 18–21 October 2010, Kingston, Jamaica. FAO Fisheries and Aquaculture Proceedings. No. 19. Rome, FAO. 2011. pp. 105–117. It is important to understand that this is a crop that needs the cooler temperatures of higher altitudes (generally over 200 meters) and a lot of water. Basically all of the coffee growing region is in the moist to wet forest ecological zone. Like the U.S. Virgin Islands, Vieques and Culebra are very dry islands with very few or no perennial streams--they lie in the dry forest ecological zone with the exception of the western portion of Vieques which has moist forest. Also, with the exception of Monte Resaca, which lies within the National Wildlife Refuge, Vieques is under 150 meters in elevation (most of it well under 100 meters). Fresh water sources on the island are also very limited with a very limited aquifer, and essentially all intermittent streams (some may be very marginally perennial--with some persistent pools). Fresh water for the island is supplied through a pipeline that also supplies Culebra. Culebra is also very dry and has relatively low altitudes. For these reasons, I strongly question whether coffee is a viable crop for these islands. Information: Beverly Yoshioka (787) 851-7297 ext. 224