WAN_0118

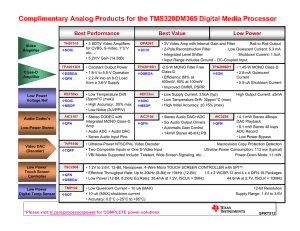

advertisement

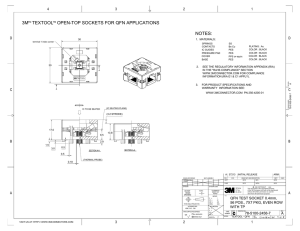

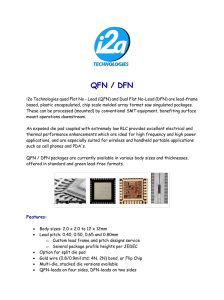

WAN_0118 w Guidelines on How to Use QFN Packages and Create Associated PCB Footprints INTRODUCTION The Quad Fine Pitch No Leads (QFN) package is a leadless plastic package, which obtains electrical contact via lands on the bottom surface of the device. Its compact nature and low profile makes the QFN package ideal for designs where space considerations are at a premium. This small size is one of the main reasons why the QFN package is chosen for Wolfson Microelectronics devices for portable applications. In addition to the bottom surface mounted pins, the other distinguishing feature of this package type is the exposed die paddle on the bottom side of the device. This paddle can be used to add extra strength in PCB mounting and to conduct heat more efficiently away from the die. The paddle may in future be bonded as a further analogue ground and so it is recommended that it be connected to the analogue ground of the PCB it is mounted to. The Chip On Lead Quad Fine Pitch No Leads (COL QFN) package has no paddle. This Application note sets out to explain some of the issues related to the design of a PCB footprint for the QFN package and then goes on to describe practical considerations when soldering the device to a PCB. PACKAGE DIMENSIONS The first thing to consider when creating a QFN footprint is the package drawing for the device. Wolfson uses a number of different QFN packages based on JEDEC specifications as follows: SIZE PIN WOLFSON TYPE 4MM×4MM 24 C 4MM×4MM 28 A AND C 5MM×5MM 28 A 5MM×5MM 32 A AND C 6MM×6MM 40 C 7MM×7MM 48 C 9MM×9MM 64 C Figure 1 QFN Package Range WOLFSON MICROELECTRONICS plc To receive regular email updates, sign up at http://www.wolfsonmicro.com/enews/ August 2006, Rev 2.2 Copyright ©2006 Wolfson Microelectronics plc WAN_0118 The Wolfson QFN package currently has two types of lead termination features, these are as follows. WOLFSON TYPE A The Wolfson Type A package is based on the JEDEC MO-220 specification with a slight modification on the pad design. In the Type A package there is mould compound round the bottom corner of the package (see arrow). After reflow a solder fillet between the PCB and the side of the package is not required; the side of the package is not required to be solderable. This is as defined in international standard IPC-A-610D. Refer to extract in the Appendix. Figure 2 Type A QFN Package WOLFSON TYPE C The Type C package is based on the JEDEC MO-220 specification with pads that are extended up the side of the package. After reflow a solder fillet between the PCB and the side of the package is not required; the side of the package is not required to be solderable. This is as defined in international standard IPC-A-610D. Refer to extract in the Appendix. Figure 3 Type C QFN Package The package type is dependant on the types of the part supplied and product family and can be found in the product data sheet. The dimension of the packages are, at time of document release, as follows. Please refer to the individual datasheets for the most current issue of the package dimensions. w August 2006, Rev 2.2 2 WAN_0118 FL: 24 PIN QFN PLASTIC PACKAGE 4 X 4 X 0.9 mm BODY, 0.50 mm LEAD PITCH DM035.C DETAIL 1 D D2 19 24 1 18 EXPOSED GROUND 6 PADDLE A INDEX AREA (D/2 X E/2) 4 E2 E SEE DETAIL 2 13 6 2X 12 7 b e 1 bbb M C A B 2X aaa C aaa C TOP VIEW BOTTOM VIEW DETAIL 1 A 0.08 C 45 degrees A1 SIDE VIEW C DETAIL 2 5 0.32mm DETAIL 2 SEATING PLANE L L1 Datum 1 ccc C A3 EXPOSED GROUND PADDLE W Terminal tip e/2 e R T A3 G H b Exposed lead Half etch tie bar DETAIL 2 Symbols A A1 A3 b D D2 E E2 e G H L L1 T MIN 0.80 0 0.18 2.00 2.00 0.30 0.03 Dimensions (mm) NOM MAX NOTE 0.90 1.00 0.02 0.05 0.20 REF 1 0.30 0.25 4.00 2.15 4.00 2.15 0.50 BSC 0.213 0.1 0.40 2.25 2 2.25 2 0.50 0.15 7 0.1 0.2 W Tolerances of Form and Position aaa bbb ccc REF: 0.15 0.10 0.10 JEDEC, MO-220, VARIATION VGGD-2. NOTES: 1. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.15 mm AND 0.30 mm FROM TERMINAL TIP. 2. FALLS WITHIN JEDEC, MO-220, VARIATION VGGD-2. 3. ALL DIMENSIONS ARE IN MILLIMETRES. 4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO JEDEC 95-1 SPP-002. 5. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS. 6. REFER TO APPLICATIONS NOTE WAN_0118 FOR FURTHER INFORMATION REGARDING PCB FOOTPRINTS AND QFN PACKAGE SOLDERING. 7. DEPENDING ON THE METHOD OF LEAD TERMINATION AT THE EDGE OF THE PACKAGE, PULL BACK (L1) MAY BE PRESENT. 8. THIS DRAWING IS SUBJECT TO CHANGE WITHOUT NOTICE. Figure 4 24 pin 4x4 QFN Package Wolfson Type C w August 2006, Rev 2.2 3 WAN_0118 DM043.D FL: 28 PIN COL QFN PLASTIC PACKAGE 4 X 4 X 0.75 mm BODY, 0.45 mm LEAD PITCH DETAIL 1 D D2 28 22 21 1 INDEX AREA (D/2 X E/2) 4 E2 A E SEE DETAIL 2 15 7 2X 8 14 1 bbb M C A B b e 2X aaa C aaa C TOP VIEW BOTTOM VIEW DETAIL 1 A 0.08 C A1 SIDE VIEW C 5 PIN 1 IDENTIFICATION 0.150MM SQUARE L Datum L1 0.275MM DETAIL 2 SEATING PLANE DETAIL 2 0.275MM 1 ccc C A3 Terminal tip e/2 e R W T A3 H G b Exposed lead DETAIL 2 Symbols A A1 A3 b D D2 E E2 e G H L L1 T W MIN 0.725 0 0.18 3.95 3.95 Dimensions (mm) NOM MAX NOTE 0.75 0.775 0.02 0.05 0.203 REF 1 0.23 0.28 4.00 2.70 REF 4.00 2.70 REF 0.45 BSC 0.535 REF 0.100 REF 0.40 REF 0.05 REF 0.100 REF 0.230 REF 4.05 2 4.05 2 7 Tolerances of Form and Position aaa bbb ccc REF: 0.15 0.10 0.10 JEDEC, MO-220 NOTES: 1. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.15 mm AND 0.30 mm FROM TERMINAL TIP. 2. FALLS WITHIN JEDEC, MO-220, VARIATION VGGD-2. 3. ALL DIMENSIONS ARE IN MILLIMETRES. 4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO JEDEC 95-1 SPP-002. 5. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS. 6. REFER TO APPLICATIONS NOTE WAN_0118 FOR FURTHER INFORMATION REGARDING PCB FOOTPRINTS AND QFN PACKAGE SOLDERING. 7. DEPENDING ON THE METHOD OF LEAD TERMINATION AT THE EDGE OF THE PACKAGE, PULL BACK (L1) MAY BE PRESENT. 8. THIS DRAWING IS SUBJECT TO CHANGE WITHOUT NOTICE. Figure 5 28 pin 4x4 COL QFN Package Wolfson Type A w August 2006, Rev 2.2 4 WAN_0118 FL: 28 PIN QFN PLASTIC PACKAGE 4 X 4 X 0.75 mm BODY, 0.45 mm LEAD PITCH DM042.B DETAIL 1 D D2 28 22 21 1 EXPOSED GROUND 6 PADDLE A INDEX AREA (D/2 X E/2) 4 E2 E SEE DETAIL 2 15 7 0.226 Ref. 2X 8 14 b e 1 bbb M C A B 2X aaa C aaa C TOP VIEW BOTTOM VIEW DETAIL 1 A 0.08 C 45 degrees A1 SIDE VIEW C DETAIL 2 DETAIL 2 SEATING PLANE Datum 0.30mm EXPOSED GROUND PADDLE A3 L 5 1 ccc C A3 Terminal tip e/2 e R G b Exposed lead DETAIL 2 Symbols A A1 A3 b D D2 E E2 e G L aaa bbb ccc REF: MIN 0.70 0 0.175 3.95 2.55 3.95 2.55 0.375 Dimensions (mm) NOM MAX NOTE 0.75 0.80 0.02 0.05 0.203 REF 1 0.185 0.18 4.00 4.05 2.6 2.65 2 4.05 4.00 2 2.6 2.65 0.45 BSC 0.560 0.425 0.475 Tolerances of Form and Position 0.15 0.10 0.10 JEDEC, MO-220 NOTES: 1. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.15 mm AND 0.30 mm FROM TERMINAL TIP. 2. FALLS WITHIN JEDEC, MO-220. 3. ALL DIMENSIONS ARE IN MILLIMETRES. 4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO JEDEC 95-1 SPP-002. 5. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS. 6. REFER TO APPLICATIONS NOTE WAN_0118 FOR FURTHER INFORMATION REGARDING PCB FOOTPRINTS AND QFN PACKAGE SOLDERING. 7. DEPENDING ON THE METHOD OF LEAD TERMINATION AT THE EDGE OF THE PACKAGE, PULL BACK (L1) MAY BE PRESENT. 8. THIS DRAWING IS SUBJECT TO CHANGE WITHOUT NOTICE. Figure 6 28 pin 4x4 QFN Package Wolfson Type C w August 2006, Rev 2.2 5 WAN_0118 FL: 28 PIN QFN PLASTIC PACKAGE 5 X 5 X 0.9 mm BODY, 0.50 mm LEAD PITCH CORNER TIE BAR 5 SEE DETAIL A D2 B D2/2 27 22 DM023.G D 28 INDEX AREA (D/2 X E/2) L 21 1 EXPOSED GROUND 6 PADDLE 2 E2/2 A A 15 E2 E 7 SEE DETAIL B 14 8 13 aaa C 2X b ccc M C A B B e aaa C 2X BOTTOM VIEW TOP VIEW DETAIL A ccc C DETAIL B 0.210mm 0. 56 6 m m EXPOSED GROUND PADDLE R e L A1 1 e/2 TERMINAL TIP SIDE VIEW CORNER TIE BAR 5 0. 15 28x b bbb M C A B 0.08 C SEATING PLANE DATUM C 1 A 28x K (A3) 1 0.3 8m m Symbols A A1 A3 b D D2 E E2 e L L1 R K aaa bbb ccc REF: MIN 0.85 0 0.18 3.2 3.2 0.35 Dimensions (mm) NOM MAX 0.90 1.00 0.02 0.05 0.2 REF 0.23 0.30 5.00 BSC 3.3 3.4 5.00 BSC 3.3 3.4 0.5 BSC 0.4 0.45 0.1 1 L1 R L1 NOTE 1 2 2 1 b(min)/2 0.20 Tolerances of Form and Position 0.15 0.10 0.10 JEDEC, MO-220, VARIATION VHHD-1 NOTES: 1. DIMENSION b APPLIED TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.25 mm AND 0.30 mm FROM TERMINAL TIP. DIMENSION L1 REPRESENTS TERMINAL PULL BACK FROM PACKAGE SIDE WALL. MAXIMUM OF 0.1mm IS ACCEPTABLE. WHERE TERMINAL PULL BACK EXISTS, ONLY UPPER HALF OF LEAD IS VISIBLE ON PACKAGE SIDE WALL DUE TO HALF ETCHING OF LEADFRAME. 2. FALLS WITHIN JEDEC, MO-220 WITH THE EXCEPTION OF D2, E2: D2,E2: LARGER PAD SIZE CHOSEN WHICH IS JUST OUTSIDE JEDEC SPECIFICATION 3. ALL DIMENSIONS ARE IN MILLIMETRES 4. THIS DRAWING IS SUBJECT TO CHANGE WITHOUT NOTICE. 5. SHAPE AND SIZE OF CORNER TIE BAR MAY VARY WITH PACKAGE TERMINAL COUNT. CORNER TIE BAR IS CONNECTED TO EXPOSED PAD INTERNALLY 6. REFER TO APPLICATION NOTE WAN_0118 FOR FURTHER INFORMATION REGARDING PCB FOOTPRINTS AND QFN PACKAGE SOLDERING. Figure 7 28 pin 5x5 QFN Package Wolfson Type A w August 2006, Rev 2.2 6 WAN_0118 FL: 32 PIN QFN PLASTIC PACKAGE 5 X 5 X 0.9 mm BODY, 0.50 mm LEAD PITCH CORNER TIE BAR 5 SEE DETAIL A D2 B D2/2 25 DM030.E D 32 L 1 24 INDEX AREA (D/2 X E/2) EXPOSED GROUND 6 PADDLE E2/2 A E2 17 E SEE DETAIL B 8 16 aaa C 2X 15 9 b 2X B e aaa C TOP VIEW BOTTOM VIEW DETAIL A ccc C (A3) 1 1 0.08 C SEATING PLANE SIDE VIEW CORNER TIE BAR 5 32x b bbb M C A B A1 L C A 0.4 1 e/2 TERMINAL TIP m m 0. 56 1 e L1 0.35 L1 R aaa bbb ccc REF: 0.18 4.90 3.2 4.90 3.2 EXPOSED GROUND PADDLE R A A1 A3 b D D2 E E2 e L L1 R K MIN 0.85 0 m Symbols m 32x K 6 DATUM 3 DETAIL B Dimensions (mm) NOM MAX 0.90 1.00 0.02 0.05 0.2 REF 0.23 0.30 5.00 5.10 3.3 3.4 5.00 5.10 3.3 3.4 0.5 BSC 0.4 0.45 0.1 NOTE 1 2 2 1 b(min)/2 0.20 Tolerances of Form and Position 0.15 0.10 0.10 JEDEC, MO-220, VARIATION VHHD-2 NOTES: 1. DIMENSION b APPLIED TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.25 mm AND 0.30 mm FROM TERMINAL TIP. DIMENSION L1 REPRESENTS TERMINAL PULL BACK FROM PACKAGE SIDE WALL. MAXIMUM OF 0.1mm IS ACCEPTABLE. WHERE TERMINAL PULL BACK EXISTS, ONLY UPPER HALF OF LEAD IS VISIBLE ON PACKAGE SIDE WALL DUE TO HALF ETCHING OF LEADFRAME. 2. FALLS WITHIN JEDEC, MO-220 WITH THE EXCEPTION OF D2, E2: D2,E2: LARGER PAD SIZE CHOSEN WHICH IS JUST OUTSIDE JEDEC SPECIFICATION 3. ALL DIMENSIONS ARE IN MILLIMETRES 4. THIS DRAWING IS SUBJECT TO CHANGE WITHOUT NOTICE. 5. SHAPE AND SIZE OF CORNER TIE BAR MAY VARY WITH PACKAGE TERMINAL COUNT. CORNER TIE BAR IS CONNECTED TO EXPOSED PAD INTERNALLY. 6. REFER TO APPLICATION NOTE WAN_0118 FOR FURTHER INFORMATION REGARDING PCB FOOTPRINTS AND QFN PACKAGE SOLDERING. Figure 8 32 pin 5x5 QFN Package Wolfson Type A w August 2006, Rev 2.2 7 WAN_0118 FL: 32 PIN QFN PLASTIC PACKAGE 5 X 5 X 0.9 mm BODY, 0.50 mm LEAD PITCH DM033.D D DETAIL 1 D2 32 25 L 1 24 4 EXPOSED GROUND 6 PADDLE A INDEX AREA (D/2 X E/2) E2 17 E 8 16 2X 15 9 b B e 1 bbb M C A B 2X aaa C aaa C TOP VIEW BOTTOM VIEW ccc C A3 A 5 0.08 C C SEATING PLANE R = 0.3MM A1 SIDE VIEW EXPOSED GROUND PADDLE DETAIL 2 W T A3 b Exposed lead DETAIL 1 G H Half etch tie bar DETAIL 2 Symbols A A1 A3 b D D2 E E2 e G H L T W MIN 0.80 0 0.18 3.30 3.30 0.30 Dimensions (mm) NOM MAX NOTE 0.90 1.00 0.02 0.05 0.20 REF 1 0.25 0.30 5.00 3.45 5.00 3.45 0.50 BSC 0.213 0.1 0.40 0.1 0.2 3.55 2 3.55 2 0.50 Tolerances of Form and Position aaa bbb ccc REF: 0.15 0.10 0.10 JEDEC, MO-220, VARIATION VHHD-5. NOTES: 1. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.15 mm AND 0.30 mm FROM TERMINAL TIP. 2. FALLS WITHIN JEDEC, MO-220, VARIATION VHHD-5. 3. ALL DIMENSIONS ARE IN MILLIMETRES. 4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO JEDEC 95-1 SPP-002. 5. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS. 6. REFER TO APPLICATION NOTE WAN_0118 FOR FURTHER INFORMATION REGARDING PCB FOOTPRINTS AND QFN PACKAGE SOLDERING. 7. THIS DRAWING IS SUBJECT TO CHANGE WITHOUT NOTICE. Figure 9 32 pin 5x5 QFN Package Wolfson Type C w August 2006, Rev 2.2 8 WAN_0118 FL: 40 PIN QFN PLASTIC PACKAGE 6 X 6 X 0.9 mm BODY, 0.50 mm LEAD PITCH D2 31 DM037.B DETAIL 1 40 D 1 30 EXPOSED GROUND 6 PADDLE INDEX AREA (D/2 X E/2) 4 A E E2 21 10 aaa C 2X 11 20 e b BOTTOM VIEW 1 bbb M C A B aaa C 2X TOP VIEW ccc C A3 AA A 0.08 C 7 DD CC BB A1 SIDE VIEW C 5 DETAIL 2 SEATING PLANE L L1 W T A3 b Exposed lead Symbols A A1 A3 b D D2 E E2 e G H L T W MIN 0.80 0 0.18 4.00 4.00 0.30 DETAIL 1 G H Half etch tie bar DETAIL 2 Dimensions (mm) NOM MAX 0.90 1.00 0.02 0.05 0.20 REF 0.25 6.00 BSC 4.15 6.00 BSC 4.15 0.50 BSC 0.213 0.1 0.40 0.1 Dimensions (mm) Symbols NOTE 0.30 1 4.25 2 4.25 2 AA BB CC DD L1 MIN 0.235 0.235 0.181 0.181 0.03 NOM MAX NOTE 7 7 7 7 0.15 0.50 0.2 Tolerances of Form and Position aaa bbb ccc REF: 0.15 0.10 0.10 JEDEC, MO-220, VARIATION VJJD-2. NOTES: 1. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.15 mm AND 0.30 mm FROM TERMINAL TIP. 2. FALLS WITHIN JEDEC, MO-220, VARIATION VJJD-2. 3. ALL DIMENSIONS ARE IN MILLIMETRES. 4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO JEDEC 95-1 SPP-002. 5. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS. 6. REFER TO APPLICATION NOTE WAN_0118 FOR FURTHER INFORMATION REGARDING PCB FOOTPRINTS AND QFN PACKAGE SOLDERING. 7. DEPENDING ON THE METHOD OF LEAD TERMINATION AT THE EDGE OF THE PACKAGE, PULL BACK (L1) MAY BE PRESENT. 8. THIS DRAWING IS SUBJECT TO CHANGE WITHOUT NOTICE. Figure 10 40 pin 6x6 QFN Package Wolfson Type C w August 2006, Rev 2.2 9 WAN_0118 DM029.E FL: 48 PIN QFN PLASTIC PACKAGE 7 X 7 X 0.9 mm BODY, 0.50 mm LEAD PITCH D2 SEE DETAIL 1 D D2/2 48 37 L INDEX AREA (D/2 X E/2) 1 36 EXPOSED GROUND 6 PADDLE E2/2 E2 E SEE DETAIL 2 25 12 13 24 e aaa C 2X b 2X BOTTOM VIEW aaa C TOP VIEW ccc C (A3) A 0.08 C SIDE VIEW A1 DETAIL 1 DETAIL 3 DETAIL 2 R = 0.3MM W G H b Exposed lead Terminal tip e/2 EXPOSED GROUND PADDLE T (A3) Datum 1 C SEATING PLANE e R Half etch tie bar DETAIL 3 Symbols A A1 A3 b D D2 E E2 e G H L T W aaa bbb ccc REF Dimensions (mm) NOM MAX 0.90 1.00 0.05 0.02 0.20 REF 0.18 0.25 0.30 7.00 BSC 5.00 5.15 5.25 7.00 BSC 5.00 5.15 5.25 0.5 BSC 0.213 0.1 0.50 0.30 0.4 0.1 0.2 Tolerances of Form and Position 0.15 0.10 0.10 MIN 0.80 0 NOTE 1 JEDEC, MO-220, VARIATION VKKD-2 NOTES: 1. DIMENSION b APPLIED TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.15 mm AND 0.30 mm FROM TERMINAL TIP. 2. ALL DIMENSIONS ARE IN MILLIMETRES 3. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO JESD 95-1 SPP-002. 4. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS. 5. THIS DRAWING IS SUBJECT TO CHANGE WITHOUT NOTICE. 6. REFER TO APPLICATION NOTE WAN_0118 FOR FURTHER INFORMATION REGARDING PCB FOOTPRINTS AND QFN PACKAGE SOLDERING. Figure 11 48 pin 7x7 QFN Package Wolfson Type C w August 2006, Rev 2.2 10 WAN_0118 DM039.B FL: 64 PIN QFN PLASTIC PACKAGE 9 X 9 X 0.9 mm BODY, 0.50 mm LEAD PITCH D2 SEE DETAIL 1 D2/2 49 D 64 L 1 48 EXPOSED GROUND 6 PADDLE INDEX AREA (D/2 X E/2) E2/2 E2 E SEE DETAIL 2 16 33 aaa C 2X 32 17 e 2X b BOTTOM VIEW aaa C TOP VIEW ccc C (A3) A 0.08 C SEATING PLANE SIDE VIEW DETAIL 1 DETAIL 2 DETAIL 3 W 45 degrees T (A3) Terminal tip e/2 0.35mm G H b Exposed lead Datum 1 C A1 e R Half etch tie bar DETAIL 3 Symbols A A1 A3 b D D2 E E2 e G H L T W aaa bbb ccc REF Dimensions (mm) NOM MAX 0.90 1.00 0.05 0.02 0.20 REF 0.18 0.25 0.30 9.00 BSC 7.00 7.15 7.25 9.00 BSC 7.00 7.15 7.25 0.5 BSC 0.165 0.1 0.50 0.30 0.40 0.1 0.2 Tolerances of Form and Position 0.15 0.10 0.10 MIN 0.80 0 NOTE 1 JEDEC, MO-220, VARIATION VMMD-2 NOTES: 1. DIMENSION b APPLIED TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.15 mm AND 0.30 mm FROM TERMINAL TIP. 2. ALL DIMENSIONS ARE IN MILLIMETRES 3. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO JESD 95-1 SPP-002. 4. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS. 5. THIS DRAWING IS SUBJECT TO CHANGE WITHOUT NOTICE. 6. REFER TO APPLICATION NOTE WAN_0118 FOR FURTHER INFORMATION REGARDING PCB FOOTPRINTS AND QFN PACKAGE SOLDERING. Figure 12 64 pin 9x9 QFN Package Wolfson Type C w August 2006, Rev 2.2 11 WAN_0118 PCB DESIGN CONSIDERATIONS The PCB design rules when using the QFN packages are fundamentally no different to those for other more well known packages. The most important considerations are those effects that occur during the PCB assembly process, which do affect the PCB land layout. The most obvious difference is the presence of a large thermal die paddle on the bottom side of the device. Concern is also often shown to the pull-off strength of the QFN device when simply using the pads to fix the package. For added strength and improved thermal dissipation characteristics, the die paddle should ideally be soldered to the PCB in addition to the pins. ROUTING OF TRACES Traces should be routed straight out from the peripheral pads to a minimum of 500um beyond the device extremities. Traces should not be routed inwards to a via at the expense of all or part of the thermal die paddle as there would be a strong possibility of the via shorting to the die paddle. For QFN Type A packages (see Figures 5 & 6 above) traces from the corner pads should not be routed perpendicularly as there would be a strong possibility of the trace shorting to the corner tie bars. This corner area should also be free of other signal traces or copper plane areas that are connected to different ground planes than that of the die paddle. Figure 21 below, shows a good example layout where all of the above and below recommendations have been considered and adhered to. THERMAL DISSIPATION To allow the heat generated through this large pad to dissipate, the area under the device may require the inclusion of a thermal landing on the component side of the PCB equal in size to the maximum size of the device thermal die paddle (it is also recommended to place a thermal landing on the opposite side of the PCB) connected to analogue ground using a number of thermal vias, approximately 0.33mm (0.013 inches) diameter. These thermal vias should be completely connected (flooded over) to the thermal landing(s) (as well as internal ground planes if using a multilayer PCB) and should not be confused with “thermal relief” or “web-constructed” vias which are designed with “spokes” to decrease thermal transfer through the PCB. The number of vias will depend upon device package size, but as a guide the pitch between the vias should be between 0.74mm and 1.27mm. In Figures 13 – 19 below, 3x3 vias are used for the packages. In Figure 20, the 9X9 package’s size allows an additional 8 vias. Figures 13 - 20 are not to scale for the purpose of clarity. w August 2006, Rev 2.2 12 WAN_0118 QFN FOOTPRINTS DIMENSIONS Figure 13 24 Pin 4x4 QFN Footprint Figure 14 28 Pin 4x4 COL QFN Footprint Figure 15 28 Pin 4x4 QFN Footprint w August 2006, Rev 2.2 13 WAN_0118 Figure 16 28 Pin 5x5 QFN Footprint Figure 17 32 Pin 5x5 QFN Footprint Figure 18 40 Pin 6x6 QFN Footprint w August 2006, Rev 2.2 14 WAN_0118 Figure 19 48 Pin 7x7 QFN Footprint Figure 20 64 Pin 9x9 QFN Footprint w August 2006, Rev 2.2 15 WAN_0118 SOLDER MASK AND STENCIL DESIGN CONSIDERATIONS The greater complexity of the QFN footprint due to the inclusion of the die paddle also means that the solder mask used during assembly will be of equal complexity. To prevent the solder of the die paddle transgressing onto the land pads during reflow, the solder mask should overlap the thermal pad outer edges by at least 100um. This overlap will prevent transgression to the land pads even in the worst case scenario. As per Figure 21, the vias should be left bare or untented. This minimizes the presence of voids and prevents outgassing during reflow. Additionally, if the application permits the use of plated through hole vias, then the bottom side soldermask should have a clearance around the vias equal in size to the one on the top side. Figure 21 32 Pin 5x5 QFN Design Guide STENCIL DESIGN FOR PERIMETER PADS The stencil should be 1:1 or 90% of the PCB pad size and should be laser cut for accuracy and electro-polished which helps in smoothing the stencil sidewalls. The recommended stencil thickness used is 0.075mm to 0.127mm (0.003in to 0.005in) and the sidewalls of the stencil openings should be tapered approximately 5 degrees to facilitate better paste release. DISSECTION OF THE DIE PADDLE SOLDER PASTE STENCIL If the solder paste coverage of the thermal landing is too big, out-gassing occurs during the reflow process which may cause defects (splatter, solder balling). As per Figure 21, dividing the thermal landing into smaller screen openings reduces the risk of solder voiding and allows the solder joints for the smaller terminal pads to be at the same height as the larger ones. Figure 21 also shows how the solder paste stencil pattern can minimize the risk of the solder paste wicking down untented vias. The COL QFN package has no Die Paddle. w August 2006, Rev 2.2 16 WAN_0118 SOLDER PASTE RECOMMENDATIONS AND REFLOW PROFILE Due to the size, pitch and depth of the stencil apertures for the QFN package it is recommended that type 3 no-clean solder pastes be used for printing. For reflow it is recommended an IR or Forced Convection system be used or a combination system of IR and Forced Convection. For further information on soldering, please refer to Wan_0158. INSPECTION OF SOLDER JOINTS AFTER REFLOW Due to the pad layout of the QFN the solder joints are formed underneath the package and are not visible. It is recommended that to ensure the joints are soldered sufficiently x-ray inspection be utilized whenever possible. Visual inspection may be used for a cursory inspection to ensure that there is no obvious solder bridging. Shown below in Figure 22 is a typical x-ray inspection of the Wolfson 32pin QFN. Figure 22 X-Ray Inspection of 5mm×5mm 32 pin QFN As can be seen the solder has reflowed to form acceptable joints and there is minimal voiding in the thermal die paddle and pad solder joints, also there is no bridging visible between the joints. X-Ray inspection can also be useful in highlighting possible process problems such as solder balling and voiding which are often an indication of poorly optimized reflow profiles. For a cursory visual inspection it should be noted that Wolfson currently provides its packages with two different QFN package types as mentioned. However it should be noted that solder fillets up the side of the QFN package are not required for acceptability of soldering; as specified in international standard IPC-A-610D; whether fillets are formed or not does not affect the mechanical strength and reliability of the solder joints. There is no difference in the mechanical strength and reliability between the two packages; the differences are only cosmetic. w August 2006, Rev 2.2 17 WAN_0118 APPENDIX: Extract from IPC-A-610D (Copyright IPC, Bannockburn, IL. Used by permission) w August 2006, Rev 2.2 18 WAN_0118 w August 2006, Rev 2.2 19 WAN_0118 APPLICATION SUPPORT If you require further information or require technical support, please contact Wolfson Microelectronics Applications group through the following channels: Email: Telephone: Fax: Mail: apps@wolfsonmicro.com (+44) 131 272 7070 (+44) 131 272 7001 Applications at the address on the last page. or contact your local Wolfson representative. Additional information may be made available from time to time on our web site at: http://www.wolfsonmicro.com w August 2006, Rev 2.2 20 WAN_0118 IMPORTANT NOTICE Wolfson Microelectronics plc (“Wolfson”) products and services are sold subject to Wolfson’s terms and conditions of sale, delivery and payment supplied at the time of order acknowledgement. Wolfson warrants performance of its products to the specifications in effect at the date of shipment. Wolfson reserves the right to make changes to its products and specifications or to discontinue any product or service without notice. Customers should therefore obtain the latest version of relevant information from Wolfson to verify that the information is current. Testing and other quality control techniques are utilised to the extent Wolfson deems necessary to support its warranty. Specific testing of all parameters of each device is not necessarily performed unless required by law or regulation. In order to minimise risks associated with customer applications, the customer must use adequate design and operating safeguards to minimise inherent or procedural hazards. Wolfson is not liable for applications assistance or customer product design. The customer is solely responsible for its selection and use of Wolfson products. Wolfson is not liable for such selection or use nor for use of any circuitry other than circuitry entirely embodied in a Wolfson product. Wolfson’s products are not intended for use in life support systems, appliances, nuclear systems or systems where malfunction can reasonably be expected to result in personal injury, death or severe property or environmental damage. Any use of products by the customer for such purposes is at the customer’s own risk. Wolfson does not grant any licence (express or implied) under any patent right, copyright, mask work right or other intellectual property right of Wolfson covering or relating to any combination, machine, or process in which its products or services might be or are used. Any provision or publication of any third party’s products or services does not constitute Wolfson’s approval, licence, warranty or endorsement thereof. Any third party trade marks contained in this document belong to the respective third party owner. Reproduction of information from Wolfson datasheets is permissible only if reproduction is without alteration and is accompanied by all associated copyright, proprietary and other notices (including this notice) and conditions. Wolfson is not liable for any unauthorised alteration of such information or for any reliance placed thereon. Any representations made, warranties given, and/or liabilities accepted by any person which differ from those contained in this datasheet or in Wolfson’s standard terms and conditions of sale, delivery and payment are made, given and/or accepted at that person’s own risk. Wolfson is not liable for any such representations, warranties or liabilities or for any reliance placed thereon by any person. ADDRESS: Wolfson Microelectronics plc 26 Westfield Road Edinburgh EH11 2QB United Kingdom Tel :: +44 (0)131 272 7000 Fax :: +44 (0)131 272 7001 Email :: apps@wolfsonmicro.com w August 2006, Rev 2.2 21