University of Massachusetts Amherst, Paige

advertisement

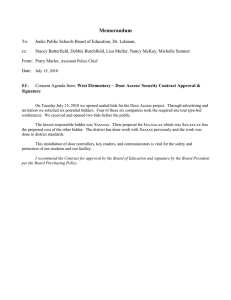

University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 University of Massachusetts Procurement Department 140 Hicks Way 407 Goodell Building Amherst, MA 01003 May 2, 2013 Addendum #5 Contract Number: UMA 13-43 Project Number: 10-000916 Speedtype: 137715 Title: Paige Laboratory Renovations The attention of the bidders submitting proposals for the above subject project is called to the following addendum to the specifications and drawings. The items set forth herein, whether of omission, addition, substitution, or clarifications, are all to be included in and form a part of the proposal submitted. The number of this Addendum (5) must be entered in the appropriate space “B. This bid includes addenda numbered (list all addenda) ______” found on Page 51 – Form For General Bid, and/or Page 59 - Form for Sub-Bid “B. This sub-bid includes addenda numbered (list all addenda)_____. CHANGES TO THE DRAWINGS: 1. General: DRAWINGS Reissued: New: None None SKETCHES Issued: Reissued: ASK029, ASK030, ASK031, SSK001 None 2. Structural: The following changes relate to Bidder Question #75: A. Section 2/ S-301: - Change title to read: “SECTION FOR EXISTING OPENINGS WITH A MAXIMUM WIDTH OF 12” ONLY”. - Revise note to read: “PLACE FORM AND SHORING BELOW & INFILL EXISTING OPENING w/ NW CONCRETE (OPTION TO USE A 22 GA-9/16" GALV. FORM DECK TO BE ATTACHED TO THE UNDERSIDE OF THE EXISTING SLAB w/ POWER DRIVEN PINS @ 6" MAX. SPACING AROUND THE OPENING)”. University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 B. Key Note 2 on drawings S-201, S-202 and S-203 shall be revised to read: “INFILL EXISTING FLOOR OPENING WITH S7. SEE 7/ S-300 SIMILAR.” C. Key Note 3 on drawings S-201, S-202 and S-203 shall be revised to read: “INFILL EXISTING FLOOR OPENING WITH NORMAL WEIGHT CONCRETE SLAB PER TYPICAL INFILL DETAILS 2 OR 11 /S-301 AS APPLICABLE.” D. Section 7/S-300: Note 1 shall be revised to read: “SEE FRAMING NOTES ON CORRESPONDING FRAMING PLAN FOR TYPE OF SLAB INFILL. PLACE DECK TO SPAN BETWEEN EXIST. PRIMARY SUPPORTS BELOW. FASTEN FORM DECK TO PERIMETER STEEL FRAME BY #12 SELF TAPPING SCREWS @ 12" O.C. (4 SCREWS MIN. ALONG EA. DECK EDGE).” E. Section 12/ S-301: Note 1 shall be revised to read: “SEE FRAMING NOTES ON CORRESPONDING FRAMING PLAN FOR TYPE OF SLAB INFILL. PLACE DECK TO SPAN BETWEEN EXIST. PRIMARY SUPPORTS BELOW. FASTEN FORM DECK TO PERIMETER STEEL FRAME BY #12 SELF TAPPING SCREWS @ 12" O.C. (4 SCREWS MIN. ALONG EA. DECK EDGE).” 3. Structural: The following changes relate to Bidder Question #63: a. Section 14/ S-301: Note specifying metal roof deck shall be revised to read: “3”-18ga. GALV. METAL ROOF DECK TO BE FIELD WELDED TO W10 STEEL BEAMS BELOW (2 SPAN TYPICAL).” University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 REVISIONS TO EXISTING SPECIFICATION SECTIONS: 1. Section 23 00 00, add the following paragraph 2.04. D. DIRECT BURIED PIPING “D. DIRECT BURIED PRE-INSULATED PIPING 1. For direct-buried piping, pre-insulated, drainable, dryable systems are required. The following systems are currently permitted to be bid on UMass Amherst projects: a. Perma-Pipe / Ricwil Inc., Multi — Therm 500 System b. Rovanco Piping Systems, Inc. — Insul 800 System c. Tricon Piping Systems, Inc., Steel-Con Plus System d. Thermacor Process, L.P., Duotherm 505 (HDPE) System 2. Service pipe and outer conduit miters may be implemented by the contractor in accordance with the manufacturer’s recommendations but under no circumstances may the miter exceed 10 degrees. 3. The service pipe insulation for the pre-insulated direct-buried piping shall incorporate an additive which makes it water repellent and water wicking resistant. Insulation product shall be tested in affirmative compliance with the U.S. Navy’s “96 Hour Conduit Boiling Test” requirements. Each service pipe shall be in a separate steel outer conduit. The conduit shall be ASTM A — 139 smooth wall, spiral or ERW welded steel, of sizes 10 gauge for up to 26” diameter, 6 gauge for 28-36” diameter, and 4 gauge for 38-42” diameter. 4. The steel outer conduit shall be insulated with spray applied polyurethane foam on all straight lengths and fittings. The urethane foam shall meet ASTM C591 and have the minimum characteristics of .18 K-factor, density of 2 pcf and a closed cell content of 90 to 95% with a compressive strength of 40 psi. Quality assurance procedures for the foam insulation shall include either a visual check prior to jacketing, infrared, or radiographic (x-ray) testing to insure there are no insulation voids. Manufacturer shall provide documented test results, to include interpretation, for infrared or radiographic testing for a minimum of all the piping on the first truckload delivered to the project site. Testing shall be provided on at least one length of each size pipe as well as at least one of each size pipe elbow and anchor. Additional truckloads shall not be shipped until the University has accepted the test results. If the test results are rejected, insulation must be corrected and new test results submitted. If any test is rejected, all product associated with this project must be tested accordingly. 5. High density polyethylene (HDPE) factory installed jackets are required for all preinsulated piping systems. HDPE jacket shall be a minimum of 150 mils thick for all pipe sizes. 6. Joint sealing system shall be CANUSA SuperCase CSC — X joint sealing system. Where service pipe and outer conduit field miters between 3 and 10 degrees are necessary and are permitted by the manufacturer, instead apply the CANUSA CSC—X WA wrap around joint sealing system over the foam. The joint sealing system shall be fully certified to EN 489 requirements. 7. Keep the pipe system interior clean and dry at all times during installation. Grade top perimeter of excavations to prevent surface water run-off into excavation. Maintain bottom of all excavations stable, dry and free of water on a continual basis. Pipe shall be laid in the dry trench conditions. At no time shall water in the trench be permitted to flow into the pipe system interior. Contractor University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 8. 9. 10. 11. 12. PERKINS+WILL UMA 13-43 May 2, 2013 shall anticipate the potential for existing water main breaks. At any time that Work is not in progress, or the trench is unattended, the end of the pipe(s) shall be suitably closed to prevent the entry of animals, earth, water etc. THE UNIVERSITY WILL NOT ACCEPT ANY PRE INSULATED PIPING INTO WHICH WATER HAS ENTERED DURING CONSTRUCTION. DRYING PROCEDURES ARE NOT ACCEPTABLE. ALL WET PIPING SHALL BE REMOVED. Piping manufacturer shall submit a written warranty to the University, with copy to the installing contractor, for the piping to be executed upon installation by the installing contractor from the date of substantial completion for a period of ten years to repair piping systems and replace components damaged by failure. Likewise, the installing contractor shall submit a written warranty to the University for the field joints to be executed upon installation from the date of substantial completion for a period of five years to repair field joints and replace field joints damaged by failure. a. A factory employed and certified field technician shall be required on site to provide inspection during the critical periods of installation defined as: b. Unloading of the first load of material. c. Inspection of the initial trench and bedding. d. Initial hydrostatic test for at least one section of piping. e. Pouring of at least the first anchor blocks. f. Final verification of pipe pitch. g. Initial backfill of at least one area, but not necessarily all compacting. h. Any other observations required by the manufacturer to provide required Warranty. Provide two days of instruction on field joint construction to include both demonstration of field joint construction methods as well as observation of at least the first two field joint installations by construction staff Factory Field Technician requirements: a. Technically qualified, factory trained piping system installation instructor with a minimum of five years of experience. If this instructor does not have experience installing the specified CANUSA joint sealing system, a CANUSA factory trained joint sealing system installation instructor shall also be provided for the duration of the field joint construction inspection and instruction activity described above. b. A resume shall be submitted to the Owner for approval. If the Owner does not approve the proposed Technician, the Manufacturer shall submit an alternate for approval. c. A substitute Technician shall not be provided unless approved in advance by the Owner. At the Owners discretion, removal of the Technician may be requested, which will require the Manufacturer to submit an alternate Technician for approval. d. All costs associated with the Technician shall be included in the bid. Manufacturer’s Sales Representative requirements. Either the Factory Field Technician or the Manufacturer’s Sales Representative shall provide the following additional inspections: a. Unloading of remaining loads of material. b. Hydrostatic test for all other piping. c. Pouring of remaining anchor blocks. A daily field report shall be required from the factory technician and sales representative detailing work observed while on site. Field reports shall be submitted to the Installing Contractor and University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 Owners representative. Field reports shall include the condition and quality of materials used in accordance with the contract documents and manufacturer’s written instructions. Field reports shall also include any discrepancies, installation concerns, unsatisfactory work performed and the Technician’s/Representative’s recommendations for appropriate and corrective action to be taken. 13. Upon completion of the pipe installation the contractor shall deliver to the Owners Representative, a notarized certificate from the manufacturer stating that the installation has been made in accordance with the manufacturer’s recommendations and warranty requirements. Manufacturer’s Sales Representatives will not be acceptable to perform pipe installation inspections identified above as being performed by the Factory Field Technician. 14. Pre-insulated piping manufacturers shall also include Thermal Stress Analysis as part of their Scope of Services for the piping they provide. The thermal stress analysis shall be performed using industry recommended software and an accompanying report shall be submitted to the University prior to piping fabrication. Submittals shall include required concrete anchor sizes. 15. Pipe hangers, supports, anchors, alignment guides, expansion loops, expansion joints, and flexible ball joints shall be specified and shown on design drawings. In steam manholes, tunnels, and vaults it is preferred that pipe supports be attached to walls or to 4” high concrete pads, to keep them above any liquid on the floor. Pipe supports may be suspended from cast in place manhole roofs. Anchors shall be welded to the pipe, but anchor connection to the building structure must be bolted. Provide structural support for all kinetic forces including seismic and wind loads.” University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 RESPONSE TO BIDDER QUESTIONS: 60. BIDDER QUESTION 060: On detail 4 -S-302 parapet bracing. Is this part of sub bid 051200 or 055100? Parapet bracing is part of 05 12 00 Structural Steel Framing. 61. BIDDER QUESTION 061: In specifications section 055100 pg. 1 summary section A-20 stair nosings, are nosing to be used for all exterior concrete treads and what is the design intent – aluminum, galv? No metal nosings at exterior stairs are required, see details on A11-21 and A11-22. 62. BIDDER QUESTION 062: Who supplies sump pit steel & grating? 055100 or others? Sump pit steel and grating should be provided by 05 51 00 Miscellaneous Metal Fabrications and Ornamental Iron. 63. BIDDER QUESTION 063: On drawing A11.23 detail 4 who provides canopy steel & framing? See “Addendum 5 CHANGES TO THE DRAWINGS: 2. Structural” and ASK029, ASK030, ASK031 and SSK-001 for revisions to North Canopy. Steel indicated in Structural Drawings is part of 05 12 00 Structural Steel Framing. All other steel shown exclusively in Architectural drawings to be in 05 51 00 Miscellaneous Metal Fabrications and Ornamental Iron. 64. BIDDER QUESTION 064: Who supplies c10 ledger framing at new elevator? Steel indicated in Structural Drawings is part of 05 12 00 Structural Steel Framing. All other steel shown exclusively in Architectural drawings to be in 05 51 00 Miscellaneous Metal Fabrications and Ornamental Iron. 65. BIDDER QUESTION 065: On drawing S-201, 202, 203, 204, col line D & E & G & F. Key notes 4/5 Detail 4 S-301 OWJ framing – who supplies angles and plates? Angles and plates in referenced locations shall be provided as part of 05 12 00 Structural Steel Framing. 66. BIDDER QUESTION 066: In specifications 055100 pg.1 summary section A-6, 7 includes supply and install wood rails, These will be supplied and installed by Section 062023 wood only? Wood rails at interior stairs shall be provided and installed by 06 20 23 Interior Finish Carpentry. University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 67. BIDDER QUESTION 067: On drawing S-202, Framing notes 9 – is this typical for all windows? And what size angles are existing? See Head Details on A00-61 and Exterior Elevations on A11-01 for locations of removal and replacement of angles. Assume angles are 4” x 3 1/2” x 5/16”, field verify to match existing. 68. BIDDER QUESTION 068: On drawing A12-03, detail 1 specified on drawing A00-70, CODE mtl2, what is the color intent of panels? Clear anodized finish for Aluminum panels, see specification for more information 69. BIDDER QUESTION 069: Question regarding masonry infills in corridor – is toothing required @ the C04 locations? Yes, C04 indicates infill with terra cotta tile to match adjacent wall conditions, so toothing is required. 70. BIDDER QUESTION 070: Could you please confirm that roof curbs for mechanical equipment are provided by the HVAC sub? Note 1 for the roof detail on M04-03 calls for the GC to provide roof curbs and flashing. Roof curbs and flashing for duct penetrations as noted on M04-03 shall be provided by the General Contractor. The GC shall also provide and coordinate the sleepers for the condensing units to be installed on the roof. 71. BIDDER QUESTION 071: Who is responsible for removing the masonry, including toothing, and existing lintels to be replaced at exterior locations noted on A11-01? It makes sense for the mason to be responsible for all work associated with this detail. This is also shown on page S-302 and 2 and 5/ A00-61. Masonry is responsible. 72. BIDDER QUESTION 072: Please clarify the extent of existing to remain metal bar joists that get cleaned and painted. The only references to this work we can find are in 1 & 11/A10-53. Is this limited to Lobby/ Lounge 299B? Also, who is responsible for the cleaning? Cleaning and painting of Existing to Remain Bar Joists is limited to Lobby/Lounge 299B and Elevator Lobby 199B. See Room Finish Schedule. Section 09 91 23 Interior Painting is responsible for cleaning and preparation of bar joists to be painted. 73. BIDDER QUESTION 073: Detail 1/A10-53 shows 1” acoustic spray. Detail 11/A10-53 shows 1 ½” acoustic spray. Please clarify where it changes from 1” to 1 ½” thickness? Detail 11/A10-53 is revised to indicate 1” of acoustic spray insulation. Provide 1” thickness of acoustic spray insulation at both locations. University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 74. BIDDER QUESTION 074: Addendum #2, Changes to Drawings, Item 5 references drawing A10-20. That page is not in our set or listed on the Index of Drawings. Please clarify? Item 5 of Addendum #2 is revised to reference A11-20. 75. BIDDER QUESTION 075: There is no metal deck shown for the concrete deck infills. Would it make sense for either the misc. metals or structural steel sub to tack decking to the new support steel at the perimeters of these infills instead of trying to form the concrete from below with plywood? See “Addendum 5 CHANGES TO THE DRAWINGS: 2. Structural” for clarification relating to this question. 76. BIDDER QUESTION 076: The detail for the elevator penthouse slab does not show a pour stop (5 & 6/S-300). Please advise if required and who provides it? Yes, provide pour stop at elevator penthouse slab per Pour Stop Schedule 10/S101. 05 12 00 Structural Steel Framing shall be responsible for pour stop. 77. BIDDER QUESTION 077: Is the mason responsible for making the site seating in detail 10/A11-22? Yes. 78. BIDDER QUESTION 078: Who is responsible for removing and modifying the existing bar joists at the new elevator shaft location? 05 12 00 Structural Steel Framing shall be responsible for removing and modifying the existing bar joists at the new elevator shaft locations. See Detail 4/S301. 79. BIDDER QUESTION 079: Please clarify who is responsible for salvaging and reinstalling granite shown in detail 7/A11-21. Is this the work of the filed sub-bid mason? Yes. Masonry. 80. BIDDER QUESTION 080: Please provide specs for the following: LPS piping 2-1/2”& larger? LPC piping 2-1/2”& larger? MPS piping 2"& smaller? MPS piping 2-1/2"& larger? MPC piping 2"& smaller? LPS piping shall be schedule 40, ASTM A-53, Type E, Grade B. On piping 2.5” and larger, joints shall be Class 150 flanged or butt welded. On piping 2” and smaller, joints shall be Class 150 flanged or butt welded. Threaded fittings and joints are allowed on piping 2” and smaller, but schedule 80 piping must be used. MPS piping shall be schedule 40, ASTM A-53, Type E, Grade B. On piping 2.5” and larger, joints shall be Class 300 flanged or butt welded. On piping 2” and smaller, joints shall be Class 300 flanged or butt welded. Shutoff duty valves 2” and small shall be socket weld, 800lb, gate valves. University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 All low pressure and medium pressure condensate piping shall be schedule 80, ASTM A-53, Type E, Grade B with schedule 80 butt welding fittings of seamless steel or forged steel socket weld fittings 2000 pounds WOG. Malleable iron unions and threaded fittings and joints are allowed on piping 2” and smaller. Shutoff duty valves 2” and smaller shall be socket weld, 800lb, gate valves. 81. BIDDER QUESTION 081: Is there a spec for the HVAC pipe insulation per 230000 2.6 for LPS, MPS, LPC, MPC? Refer to piping system types and temperatures in Table A in specification section 23 00 00 paragraph 2.06. To clarify, all steam and condensate pipe insulation on pipe 2” and larger shall be 3” thickness. All steam and condensate pipe insulation on pipe 1.5” and smaller shall be 1.5” thickness. 82. BIDDER QUESTION 082: Is there a spec for the buried 6”CHWS&R on C-100? Refer to the added specification section 23 00 00 paragraph 2.04.D, included in this Addendum 5. 83. BIDDER QUESTION 083: Does the 230000 HVAC filed-sub bidder own the buried 6”CHWS&R on C-100? Per Drawing M02-01, the HVAC contractor shall own buried 6” CHW&R piping 10’ from building. 84. BIDDER QUESTION 084: Has most demolition been completed and/or awarded under a separate contract? If most demolition has been awarded separately, how does the abatement Appendix A&B in back of book 3 of 3 refer to this contract? Required demolition is indicated on Demolition Drawings. There was an early Demo Package that will be complete by early May. Demolition to be performed as indicated on Demolition Drawings such as Window Removal is called for in the Abatement Report Appendix A. 85. BIDDER QUESTION 085: Please clarify which section/trade owns epoxy floor type EP-1 as indicated in room finish schedule in A00/70? Finish legend shows vendor/manufacturer option as Stonehard, who's product and specification is described in Section 092763-Resinuos Flooring, 2.1, A, 34. This Section not being part of Section 09 00 03 - Painting. Please direct? Epoxy Floor type EP-1 shall be provided by 09 67 23 Resinous Flooring. 86. BIDDER QUESTION 086: Please confirm exposed steel column shown in Mechanical Room 113 / A04-01 (F-2A Level 1) will not require intumescent painting or ptd gwb enclosure? University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 Construction Note 01 applies to Stl Column at F-2A on Level 1 (see Addendum 2 Changes to the Drawings, Item 2.a.) Yes, Provide Ptd GWB enclosure at Stl Column at F-2A on Level 1. 87. BIDDER QUESTION 087: Please clarify the work required for connecting to the existing Acid Waste System? Answer: The acid waste neutralizing system located on the lower level is an existing to remain system. During the demolition phase, piping draining to this system was disconnected at the 4” inlet to the tank and removed entirely. The piping is now capped. The scope of work includes all new acid waste piping shown on the drawings in its entirety. This piping will connect to the 4” capped connection. There is also an existing acid waste sump pit in the same room as the neutralizing system. This pit received waste underground from all fixtures on the lower level and then pumped it up into the neutralizing tank. This pit will now receive new underground acid waste piping as shown on the drawings. Finally, the sump pit pump, acid neutralization system, and all appurtenances will need to be restarted and tested to ensure proper working functionality. 88. BIDDER QUESTION 088: Please find out what UMass wants for a transformer. The spec header says dry type and that is the norm @ UMASS but the spec reads as an oil filled unit. Please advise which one they want? Answer: Dry Type 89. BIDDER QUESTION 089: There was added gas piping in one of the addendums, but there is no spec for turrets. Please provide. Answer: The gas turrets to be located on the walls adjacent to the lab benches shall be a Chicago Faucets model #986-937CHAGVCP, wall mounted single needle valve with wall flange or equal. 90. BIDDER QUESTION 090: Please provide specs for the following items related to the RO system: RO faucet/outlet, RO pipe and fittings. Answer: RO pipe and fittings shall be unpigmented Type 1 homopolymer polypropylene with socket fusion fittings or equal. RO faucet shall be a Chicago Faucets model #869BPVC, deck mounted type. 91. BIDDER QUESTION 091: Is the RO water system existing? Please clarify the work required for the installation of the RO system. Answer: The RO water system is an existing system that is currently located on the lower level. Drawing P01-01 notes the location and that it is to be relocated. The scope of work includes all new RODI water piping shown on the drawings in its entirety. This piping will connect to the existing relocated RODI water system as shown on the plans. Finally, the University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 existing RODI water system shall be restarted and tested to ensure proper working functionality. 92. BIDDER QUESTION 092: Detail 6/A10.60 shows three tiers of shelving at the typical mobile benches when viewed from the front, but only two tiers when viewed form the side. Which is correct? Provide 2 tiers of adjustable shelving above mobile workbenches. 93. BIDDER QUESTION 093: Card readers have been shown for all perimeter doors except for the east exterior entrance on level 2, it is next to the east stairwell 299D. Do you want a reader to control access on this perimeter door as well? See Door Schedule. Hardware Set 01 is indicated for Door 299G-1 at East Entry, which includes a Card Reader. 94. BIDDER QUESTION 094: Are all readers and access control equipment to be the UMass Amherst standard SOFTWARE HOUSE? Yes. 95. BIDDER QUESTION 095: Door contacts have been shown but Rex Pir motion detectors used to shunt alarms on exit are missing, the standard is model DS150i do you want them included for each door? Motion Detectors are not required. 96. BIDDER QUESTION 096: Are any of the card access doors going to be equipped with handicap door operators? Yes, Hardware Set 05 is indicated for Door 199F-1. See Door Schedule. 97. BIDDER QUESTION 097: Door 101-1 is shown on the Door Schedule to receive a new frame. It is not shown on the demolition plan to remove the existing frame. Please clarify. Existing frame at Door 101-1 location shall be removed. 98. BIDDER QUESTION 098: Door 101-2 is shown on the floor plans as a pair of doors. Door 1012 is indicated on the Door Schedule to receive frame Type 2 – a single door with a side-lite. Which is correct? Door 101-2 is a pair of doors and should be Frame Type 1. 99. BIDDER QUESTION 099: Door 207, 210 and 218 are shown on the Door Schedule to receive a new frame. It is not shown on the demolition plan to remove the existing frame. Please clarify. Existing frame at Door 207, 210, and 218 shall be removed. University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 100. BIDDER QUESTION 100: There is not a metal frame indicated on the Door Schedule for the cased openings to 299N and 299M, from Lounge 299B. Please clarify what is required for “Metal Frames” at these locations. See Detail 2/A10-51 for typical detail at opening into 299 M and 299N. 101. BIDDER QUESTION 101: Door 307 and 318 are shown on the Door Schedule to receive a new frame. It is not shown on the demolition plan to remove the existing frame. Please clarify. Existing frame at Door 307, and 318 shall be removed. 102. BIDDER QUESTION 102: Addendum 2 changed the door frame type at Door #316 to Type 3. Should it have been Door #315? Door 316 shall be Frame Type 1. Door 315 shall be Frame Type 3. 103. BIDDER QUESTION 103: There is not a metal frame indicated on the Door Schedule for the new cased openings to 399N and 399M, from Lobby 399B. Please clarify what is required for “Metal Frames” at these locations? See Detail 2/A10-51 for typical detail at opening into 399 M and 399N. 104. BIDDER QUESTION 104: Series of related questions regarding Louver infill Details: a. Structural Detail 5/S-302 indicates to use 8” CMU back-up. Architectural detail 3/A11-24 indicates to use “Clay Tile”. Which is correct? Yes. CMU is acceptable where not visible (Updates Response to Bidder Question 53 in Addendum 3). b. Structural Detail 4/S-302 indicates to “Remove the Lintel”. Architectural detail 3/A11-24 shows the lintel to remain. Which is correct? Architectural detail 3/A11-24 is revised to show lintel to be removed. c. If the louver lintel is to be removed, is this by the Mason FSB? Yes. 105. BIDDER QUESTION 105: Typical structural wall infill details indicate to use CMU. This contradicts some of the architectural details. Which is correct? CMU is acceptable where not visible. See Architectural Drawings for locations of Terra Cotta Tile infill to match existing adjacent walls. University of Massachusetts Amherst, Paige Laboratory 161 Holdsworth Way, Amherst, MA 01003 Addendum #5 PERKINS+WILL UMA 13-43 May 2, 2013 106. BIDDER QUESTION 106: Addendum 1 deleted glass type GL-6, fire rated glazing. The door schedule on page A00-50 of the drawings show many type G doors having a 45 minute rating. Please advise as to what type of glass is to be used in the doors with a fire rating considering the fire rated product listed in the specifications was deleted? Fire Rated glass is not required for Lites in Door Type G (lites shall be 4” x 24” which is under 100 square inches) 107. BIDDER QUESTION 107: None of the doors, hollow metal frames or storefront specify a glass type to be used. Please provide information regarding what glass type is used in each door, frame and storefront? Door Type A: GL-2 Door Type B: GL-2 Door Type E: GL-2 Door Type G: GL-2 Sidelites in Frame Type 2 and 3: GL-2 Window Type N, M, P: GL-1 Glazing in Storefront shown on A11-30 (Vestibule 299H): GL-2 108. BIDDER QUESTION 108: Please clarify the flexible membrane strips at masonry openings in spec. section 072100 Thermal Insulation vs. the modified bituminous strip air barriers in spec. section 072713. For example, we are looking at details 5 and 6/ A11-24: is it your intent to have the membrane strip shown here installed by the insulation contractor or by the filed sub-bid waterproofer. Also referring to details 1 and 2/A11-24 is it your intent to have the peel and stick new AV barrier installed by the filed sub-bid waterproofer? Membrane strip shown in details 5 and 6 on A11-24 shall be installed by the filed sub-bid waterproofer. Peel and Stick AV barrier shown in details 1 and 2 on A11-24 shall be installed by the filed sub-bid waterproofer. End of Addendum #5 By: John O. Martin Director of Procurement P E R KI NS + WILL 225 Franklin Street, Suite 1100 Boston, MA 02110 t 617.478.0300 f 617.478.0321 www.perkinswill.com E D UNIVERSITY OF MASSACHUSETTS DESIGN AND CONSTRUCTION MANAGEMENT 5 PAIGE LABORATORY RENOVATIONS A11-23 3 4 5' - 4" A10-52 A11-24 DEMO EXISTING 161 Holdsworth Way Amherst, MA 01003 LEVEL 02 111' - 0" FINISHED METAL PANEL, FLAT & CORRUGATED SURFACE DEMO RAIN LEADER, BEHIND SCREEN WALL 2' - 6" PTD GALV STEEL BEAMS, SEE STRUCTURAL 5/1/2013 2:29:51 PM c:\temp\155081.000 - Paige Laboratory (CENTRAL)_currans.rvt ALUM STOREFRONT ENTRY DOORS & FRAME 8 Sheet Information A11-23 Date 05.02.13 Project Number 10-000916 Contract Number Drawn UMA 13-43 Author Checked Checker Approved Approver Reference Sheet A11-23 Title LEVEL 01 100' - 0" 1 NORTH ENTRY - ELEVATION 3/8" = 1'-0" NORTH ENTRY ELEVATION Sheet ASK029 Copyright © 2012 Perkins+Will P E R KI NS + WILL 225 Franklin Street, Suite 1100 Boston, MA 02110 t 617.478.0300 f 617.478.0321 www.perkinswill.com UNIVERSITY OF MASSACHUSETTS 6' - 10 6' - 10 DESIGN AND CONSTRUCTION MANAGEMENT 1/2" PAIGE LABORATORY RENOVATIONS 1/2" 161 Holdsworth Way Amherst, MA 01003 PTD GALV STEEL BEAMS, SEE STRUCTURAL EXPOSED, PTD GALV METAL DECK c:\temp\155081.000 - Paige Laboratory (CENTRAL)_currans.rvt 4 Sheet Information 05.02.13 Project Number 10-000916 Contract Number Drawn UMA 13-43 Author Checked Checker Approved Approver Reference Sheet A11-23 Title NORTH ENTRY CANOPY REFLECTED CEILING PLAN D 5/1/2013 2:29:51 PM Date 1 E ENLARGED REFLECTED CEILING PLAN @ NORTH ENTRY CANOPY 3/8" = 1'-0" F Sheet ASK030 Copyright © 2012 Perkins+Will P E R KI NS + WILL 225 Franklin Street, Suite 1100 Boston, MA 02110 t 617.478.0300 f 617.478.0321 www.perkinswill.com UNIVERSITY OF MASSACHUSETTS DESIGN AND CONSTRUCTION MANAGEMENT PAIGE LABORATORY RENOVATIONS 3 1 ASK029 A11-23 5 6' - 10 1/2" 161 Holdsworth Way Amherst, MA 01003 A11-23 1/2" 6' - 10 EQ EQ EQ EQ 3 7/8" / 12" " 13' - 9 EQ EQ EQ 3 7/8" / 12" PTD GALV STEEL BEAM & STL PLATE, BOLT CONNECTION AT MASONRY WALL & BEAM, SEE STRUCTURAL 6 A11-23 RD FLAT SEAM METAL ROOFING METAL PANEL INTEGRAL GUTTER CAP PIECE, CAULK IN PLACE c:\temp\155081.000 - Paige Laboratory (CENTRAL)_currans.rvt 9 A11-23 EQ EQ 4 Sheet Information Date 05.02.13 Project Number 10-000916 Contract Number Drawn UMA 13-43 Author Checked Checker Approved Approver Reference Sheet A11-23 Title NORTH ENTRTY CANOPY ENLARGED PLAN VIEW D E F 5/1/2013 2:29:52 PM Sheet 1 ENLARGED PLAN VIEW OF NORTH CANOPY 3/8" = 1'-0" ASK031 Copyright © 2012 Perkins+Will PE RKI NS + WI L L D E F 225 Franklin Street, Suite 1100 Boston, MA 02110 t 617.478.0300 f 617.478.0321 www.perkinswill.com 14 H.D. GALV. W10x22 CANTILEVERS (3 TOTAL) S-301 UNIVERSITY OF MASSACHUSETTS CONT. H.D. GALV. W14x13 SEE ARCH DWG S6 x13 T CON W4 ALV. CONT. H.D. GALV. MC4x13.8 H.D. GALV. MC10x15.3 .G . H.D 1/2" x 9"x9" HD GALV. STEEL PLATE w/ (4) 3/4" DIA. GALV. EPOXY ANCHOR w/ 8" EMBEDMENT. DESIGN AND CONSTRUCTION MANAGEMENT PAIGE LABORATORY RENOVATIONS 161 Holdsworth Way Amherst, MA 01003 4 (2) W8x24 STEEL LINTEL ABOVE NEW OPENING BELOW KEY NOTE 5 NEW C8x13.7 SUSPEND END OF W10x22 TO EXIST. 12WF31 (F.V.) SEE 15/ S-301 SUSPEND END OF W10x22 TO EXIST. 6 I 12.5 (F.V.) EXIST. 6I 12.5 EXIST. 12WF31 S5 NEW MC10x25 KEY NOTE 4 7 S-300 Sheet Information 10-000916 UMA 13-43 Author Checked Checker Approved Approver Reference Sheet F 8W 58 05.02.13 Project Number Drawn S3 EXIST. 14WF38 Date Contract Number S7 S1 S-201 Title NORTH ENTRY CANOPY 58 8W F EXIST. 14WF34 L6x4x3/8 HANGER EA. END NEW MC10x25 NEW MC10x25 40 EXIST. 14WF34 S1 NEW MC10x25 BELOW F 8W 3 EXIST. STEEL OWJ (F.V.) NEW MC10x25 NEW MC10x25 C12x25 NOTES: 1. 1 PARTIAL EXISTING LEVEL 2 FRAMING PLAN & ALTERATIONS Scale: 3/16" = 1'-0" 0 2 4 6 8 10 FT 2. THIS PARTIAL FRAMING PLAN PROVIDES FRAMING INFORMATION FOR THE NORTH CANOPY ONLY. SEE DRAWING S-201 FOR ALL OTHER INFORMATION NOT SHOWN OR NOTES. S6 INDICATES NEW 3" - 18 Ga GALVANIZED METAL ROOF DECK. THE ORIENTATION OF DOUBLE ARROWS INDICATES THE DIRECTION OF THE SPAN OF THE METAL ROOF DECK. Sheet SSK 001 Date: 5/1/13 File name: Paige-S-Plans_May01-13.vwx © LY Consulting Engineers, Inc. 2013