Bourns® Power Resistors

advertisement

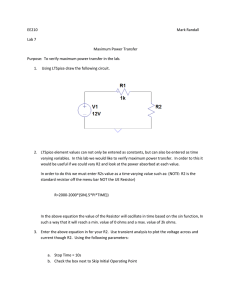

& *R AE oH C- SC Q2 O 00 MP Q LI UA A N LI T FI ED Ro VE LEA HS RS D C ION FRE OM S PL AR IA E NT * 2 62 1 Features Applications n TO-220 housing n Power supplies n Low inductance n Motor drives n Resistor electrically isolated from the n Test and measurement AE C * A P Ro P R HS OV C ED OM (S PL el IAN ec T tM od el s) backplate n High power rating n AEC-Q200 qualified n RoHS compliant* n Rectifiers PWR220T-35 Series Power Resistor General Information Bourns® PWR220T-35 Series is a TO-220 DPAK style power resistor. Manufactured using thick film on alumina ceramic technology, it is used in current measurement, snubber, bleeder and discharge circuits. Popular Resistance Values Electrical & Thermal Characteristics Parameter Resistance (See Popular Resistance Values table) Power Rating @ 25 ˚C Case Temperature Tolerance TCR 0.02 Ω<R<130.0K Ω Thermal Resistance - Rthj Inductance Operating Voltage Dielectric Strength Insulation Resistance Operating Temperature Value(s) 0.02 Ω to 130 KΩ 35 W ±1 %**, ±5 % Code ±100 PPM/˚C 3.7 ˚C/W 0.1 µH maximum √P*R with a maximum of 250 V 2 KV AC 10 GΩ -55 ˚C to 155 ˚C ** Available for most values. Check Popular Resistance Values table. Reliability Characteristics Parameter Short Term Overload (2x Pr for R < 2 Ω, 1.6 x Pr for R ≥ 2 Ω, V < 1.5 x Operating Voltage) Load Life (1000 hours at rated power) Thermal Shock (-55 ˚C to 155 ˚C, 5 cycles) Resistance to Soldering Heat (10 seconds at 270 ˚C) Vibration (20 G 10-2000 Hz .06 ” D.A.) Terminal Strength (MIL-STD-202, Method 211 Test A1) Shock (Saw Tooth: 100 g/6 ms) Humidity (Steady State) 1000 hrs. 85 °C/85 % RH High Temperature Exposure (100 hrs - 40 % Pr @ +125 °C) Material Characteristics Resistor....................................Thick film Substrate...................... Alumina (AL203) Housing.........................................Epoxy Pins....................Tinned Copper (Sn/Cu) Flammability......... Conforms to UL-94V0 Specification ΔR ±0.25 % ΔR ΔR ±1.0 % ±0.5 % ΔR ±0.5 % ΔR ±0.25 % ΔR ±0.2 % ΔR ±0.5 % ΔR ±0.5 % ΔR ±0.5 % Typical Part Marking RESISTANCE CODE MANUFACTURER'S TRADEMARK Packaging 220 35 R500 1% YYWW COSTA RICA MODEL NUMBER TOLERANCE DATECODE R020 R025 R030 R033 R040 R050 R075 R100 R150 R200 R250 R300 R330 R400 R500 R750 1R00 1R50 2R00 2R50 3R00 3R30 4R00 5R00 7R50 8R00 10R0 12R0 15R0 20R0 25R0 27R0 30R0 33R0 40R0 47R0 50R0 56R0 75R0 Resistance Value 0.02 Ω*** 0.025 Ω*** 0.03 Ω*** 0.033 Ω*** 0.04 Ω*** 0.05 Ω*** 0.075 Ω*** 0.1 Ω 0.15 Ω 0.2 Ω 0.25 Ω 0.3 Ω 0.33 Ω 0.4 Ω 0.5 Ω 0.75 Ω 1Ω 1.5 Ω 2Ω 2.5 Ω 3Ω 3.3 Ω 4Ω 5Ω 7.5 Ω 8Ω 10 Ω 12 Ω 15 Ω 20 Ω 25 Ω 27 Ω 30 Ω 33 Ω 40 Ω 47 Ω 50 Ω 56 Ω 75 Ω Code 1000 1200 1500 2000 2500 3000 3300 4000 4700 5000 5600 7500 1001 1501 2001 2501 3001 3301 4001 5001 7501 1002 1502 2002 2502 3002 3302 4002 4702 5002 5602 6802 7502 8202 1003 1153 1203 1253 1303 Resistance Value 100 Ω 120 Ω 150 Ω 200 Ω 250 Ω 300 Ω 330 Ω 400 Ω 470 Ω 500 Ω 560 Ω 750 Ω 1.0 KΩ 1.5 KΩ 2.0 KΩ 2.5 KΩ 3.0 KΩ 3.3 KΩ 4.0 KΩ 5.0 KΩ 7.5 KΩ 10 KΩ 15 KΩ 20 KΩ 25 KΩ 30 KΩ 33 KΩ 40 KΩ 47 KΩ 50 KΩ 56 KΩ 68 KΩ 75 KΩ 82 KΩ 100 KΩ 115 KΩ 120 KΩ 125 KΩ 130 KΩ *** 5 % Tolerance COUNTRY OFORIGIN ............................................ 50 pcs./tube *RoHS Directive 2002/95/EC Jan. 27, 2003 including annex and RoHS Recast 2011/65/EU June 8, 2011. Specifications are subject to change without notice. The device characteristics and parameters in this data sheet can and do vary in different applications and actual device performance may vary over time. Users should verify actual device performance in their specific applications. PWR220T-35 Series Power Resistor Product Dimensions How to Order 3.6 DIA. (.142) 10.1 (.398) 6.0 (.236) PWR 220 T - 35 - 10R0 F 4.0 (.158) Model PWR = Power Resistor 1.23 (.049) Package 220 = TO-220 Style Pin Style T = Through-hole 2.5 (.098) Power 35 = 35 W 14.6 (.575 Resistance Value <100 ohms.... “R” represents decimal point (examples: 7R50 = 7.5 Ω; R500 = 0.5 Ω) 8.63 (.340) ≥100 ohms..... First three digits are significant, fourth digit represents number of zeros to follow (examples: 2000 = 200 ohms; 3002 = 30K ohms) Absolute Tolerance J=5% F=1% 28.3 (1.12) REF. 13.72 (.540) Derating Curve 120 5.08 (.200) Power Ratio (%) 100 0.72 (.029) 2.25 (.089) DIMENSIONS: MM (INCHES) 0.38 TOLERANCE: ± UNLESS OTHERWISE NOTED (0.015) 60 40 20 0 -20 Pulse Power Rating 25 35 45 55 65 75 85 95 105 115 125 135 145 155 Temperature of Backplate (°C) 100 Energy in Joules 80 10 1 0.1 0.01 10 -7 10 -6 10 -5 10 -4 10 -3 10 -2 10 - 1 Overload Duration in Seconds The energy absorbed by the resistor expressed in Joules can be calculated by multiplying the peak power of the pulse in watts times the length of the pulse in seconds. The energy should not exceed the limits shown in the graph. The overload voltage should not exceed 1.5 times the maximum operating voltage. REV. 07/16 Specifications are subject to change without notice. The device characteristics and parameters in this data sheet can and do vary in different applications and actual device performance may vary over time. Users should verify actual device performance in their specific applications.