In-situ MOKE along with RHEED, MR and XRR - UGC

advertisement

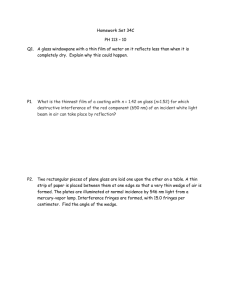

UGC-DAE Consortium for scientific Research New Versatile facility at UGC-DAE CSR, Indore In-situ thin film Lab Strength and Capabilities In-situ characterization techniques i. Magneto optical Kerr effect (MOKE) ii. Magnetoresistance (MR) iii. Small angle X-ray reflectivity (XRR) iv. Reflection high energy electron diffraction (RHEED) Deposition using e-beam evaporation Magnetic field for MOKE ~0.25 T Sample temperature ranging from ~50K to 1200K RHEED: 30 KeV electron gun Other important points Base pressure in the UHV chamber ~2x10-10 mbar Sample temperature ranging from ~50K to 1200K, which can be precisely controlled during all in- Chamber is equipped with a facility for thin film deposition using electron beam evaporation with in-situ measurement of magneto optical Kerr effect (MOKE), reflection high energy electron diffraction (RHEED) and magnetoresistance (MR) measurements. -Whole set-up is attached with a lab x-ray source coupled with a multilayer optics, which provides a beam of sufficient collimation and intensity to perform in-situ small angle x-ray reflectivity (XRR) experiments in the laboratory. -All the measurements in the present system can be done simultaneously during and after the deposition of the film, thus making it possible to study the evolution of magnetic, transport and structural properties with parameter such as film thickness, annealing temperature etc. -In contrast to the earlier in-situ systems in the literature, where measurements with each technique are performed separately and results are interpreted by combining the data, in the present set-up, combination of these techniques as in-situ measurements seems to be promising in surface and interface analysis of magnetic thin films and multilayer nanostructures. Page 1 situ measurements Ion gun at an oblique angle for sample cleaning Residual gas analyzer (RGA) to monitor residual gasses present before and during the deposition Mass flow controller to create partial pressure of the gases such as O2 N2 Ar etc. Dr. Dileep K. Gupta Scientist In-situ thin film Lab UGC-DAE CSR, Indore-452001 dkumar@csr.res.in; dileep.esrf@gmail.com Phone: +91-731-2463913 (ext.176) To use other facilities at the center visit: http://csr.res.in An illustration of the versatility of the set-up In-situ thin film Lab In-situ MOKE, RHEED and XRR measurements of Co/CoO bilayer during Growth Co/CoO bilayer structure was grown in UHV chamber at the base pressure of ~10-10 mbar using e-beam evaporation technique. Growth of the bilayer sample was done on a silicon substrate in two steps; (i) deposition of Co film at room temperature (ii) and formation of uniform oxide layer at the surface by heating it at 3000C in a partial oxygen pressure 5 ×10-6 mbar. During the growth of the bilayer, magnetic and structural properties were investigated in-situ using magnetooptical Kerr effect (MOKE), Reflection high energy electron diffraction (RHEED) and X-ray reflectivity (XRR) measurements. 10 Intensity (a.u) 5 X-Ray Intensity (a.u.) Co film as prepared Co on Si Si Subs 4 10 0, 45, 90 degree 3 10 -150 -100 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 -50 RHEED image of Co 0 50 100 150 H(Oe) Angle (Theta) 15 min Loop measurements during surface oxidation process 25 min 10 min heating 50 min heating 35 min Intensity (a.u) Reflectivity (arb. units.) As prepared 50 min 60 min 75 min 75 min heating 0.4 RHEED image of top CoO layer 0.8 1.2 2 theta 1.6 2.0 2.4 -150 -100 -50 0 50 100 150 H (Oe) First row: RHEED, XRR and MOKE measurements after deposition of Co film on Si substrate. Hysteresis loops in the last figure are taken at different azimuthal angle to get information of magnetic anisotropy in the Co film. Second raw: all above mentioned measurements after surface oxidation of Co film. XRR and MOKE measurements were carried also out during process of oxidation (after different time interval). It may be noted that MOKE and XRR measurements can be performed simultaneously whereas RHEED measurements is performed after MOKE measurement in order to avoid deflection in electron due to magnetic field generated by electromagnet during MOKE measurements. Page 2 An illustration of the versatility of the set-up In-situ thin film Lab Effect of Substrate Roughness on Growth of Thin Nanocrystalline Cobalt film Growth of Co film on glass substrates with surface roughness of 0.5 nm and 1.6 nm has been studied in-situ using magnetooptical Kerr effect (MOKE), reflection high energy electron diffraction (RHEED) and four probe resistivity methods. 0.9 nm (d) (e1) 2.5 nm (d1) 2.4 nm sub= 0.5 nm 1.4 RCo (k/k) 1.1 nm (e) 1.6 Variation of sheet resistance as a function of Co growth on rough and smooth substrate (B) (A) sub= 1.6 nm 1.2 (c1) 0.7 nm (c) 1.0 2.2 nm 0.8 (b1) (b) 0.6 2.0 nm 0.5 nm 0.4 0.2 (a) 0.0 (a1) 1.8 nm 0.0 0.5 1.0 1.5 2.0 2.5 Substrate 3.0 d (nm) -110 -55 Representative loops with increasing Co layer thickness on [A] =0.5nm and [B] =1.6nm substrate 0 -110 -55 55 110 0 55 110 H (Oe) H (Oe) In-situ measurements jointly suggested that the films grow via Volmer-Weber growth process and proceed via a nonmagnetic, superparamagnetic and a ferromagnetic phase on both the substrates. Islands were found to coalesce at film thicknesses of ~ 0.6 nm and at ~ 1.5 nm for smooth and rough substrate respectively and films become continuous and fully covering after the film thickness of ~1.5 nm and ~ 3.0 nm. Thermal stability of W/Si and W/B4C/Si multilayers: In order to study the mechanism of diffusion in W/Si and W/B4C/Si multilayer, in-situ XRR measurements were carried out upto high temperature annealing under UHV conditions. The temperature of the samples was increased in the steps of ~200C from 2000C to 8000 C. Sample structure NOTE: These samples were prepared using ion beam sputtering technique in a different chamber and finally transferred to the UHV system for in-situ reflectivity. Page 3 X-Ray Intensity (a.u.) It may be note that in case of W/B4C/Si multilayer the height of the Bragg peak does not change significantly even up to 8000C, whereas as in case of W/Si multilayer it is significantly influenced after thermal annealing. The present measurements revealed that the addition of very thin layer of B4C at interface of W and Si reduces interdiffusion between W and Si significantly. W/Si Multilayer W/B4C/Si Multilayer X-Ray Intensity (a.u.) 1. Si substrate W /B4C/Si- 10 bilayers – bilayer thickness 4.3 nm 2. Si substrate W (1.7nm)/Si(2.4 nm)10 bilayers- bilayer thickness 4.1nm 0.0 0.4 0.8 1.2 1.6 Angle (Theta) 2.0 2.4 0.0 0.4 0.8 1.2 1.6 2.0 2.4 Angle (Theta) In-situ XRR pattern of a) W/B4C/Si multilayer and b) W/Si multilayer at various temperatures ranging from 2000C to 8000C An illustration of the versatility of the set-up In-situ thin film Lab Attachment of Magneto-resistance (MR) option; growth of Ni film of Si substrate In order to perform in-situ transport measurements, sample holder for four probe resistivity measurement has been modified and tested by performing resistivity measurement during growth of Ni film. MR measurements were also performed with increasing thickness of Ni layer. Experiments performed are shown below. Schematic view of sample holder prepared Thin film Au contacts d= 20nm 0 300 H (Oe) 0.4 0.2 0 H (Oe) Continious film Island film 0 -300 0 300 H (Oe) Connecting islands Resistance (k-ohm) -300 0.6 4 8 12 16 20 d (nm) Resistance and MOKE with Ni growth up to 20 nm thickness Voltage of the sample(V) d= 2nm d= 0.5nm 0.8 0 0 30 10 0 60 -225 0 40 0 0 70 0 20 50 0 225 -225 80 0 225 0 0 0 -225 0 225 Magnetic Field(Oe) Magneto-resistance of Ni 20 nm thin film at different azimuthal angle First figure gives the thickness dependence of film resistance (R). Initially up to a thickness of about 1.5 nm the sheet resistance remains almost constant and essentially represents resistance of Si substrate. At this thickness, the separation between Ni islands would be quite large and the conduction of electrons from one island to another will not take place. With further increase in the thickness, as the islands come closer, hopping conduction can take place, which results in a gradual decrease in the sheet resistance with thickness. Around a thickness of about 2 nm a rapid decrease in the resistivity is observed, which signals the formation of a percolating cluster. In the thickness range of 12–15 nm a continuous film is formed, and beyond this resistance exhibits a slow decrease because of decreasing contribution of surface and interface scattering. Inset of Figure represents hysteresis loops of Ni thin film at film thickness of 0.5, 2 nm and 20nm. One may note that at a thickness of 0.5 nm, hardly any loop developed whereas a faint hysteresis loop starts appearing at around 2 nm thickness. The combined information with MOKE revealed that near the film thickness of 2-3 nm, as the islands become multi-domain, the coercivity starts developing. At very low thickness loop may be absent due to very small islands, which may be in single magnetic domain and exhibit superparamagnetism. The present set-up also provides the capability to do MR measurements at different azimuthal direction by rotating sample holder between the poles of the magnetic field. Magneto-resistance (MR) measurements at thickness of 20 nm are also shown in figure. Page 4 Related Publications In-situ thin film Lab 1. “Interface induced perpendicular magnetic anisotropy in a Co/CoO/Co thin-film structure: an in situ MOKE investigation” Dileep Kumar, Ajay Gupta, P. Patidar, A Banerjee, K K Pandey, T. Sant and S. M. Sharma, J. Phys. D: Appl. Phys. 47 (2014) 105002; doi:10.1088/0022-3727/47/10/105002 2. “In situ surface magneto-optical Kerr effect (s-MOKE) study of ultrathin soft magnetic FeCuNbSiB alloy films” Dileep Kumar, Pooja Gupta, and Ajay Gupta, Materials Research Express 1 (2014) 046405; doi:10.1088/2053-1591/1/4/046405. 3. “Correlation between iron self-diffusion and thermal stability in doped iron nitride thin films” Akhil Tayal, Mukul Gupta, Dileep Kumar, V. R. Reddy, Ajay Gupta, S. M. Amir, Panagiotis Korelis, and Jochen Stahn, Journal of Applied Physics 116, 222206 (2014); doi: 10.1063/1.4902962. 4. “Study of ultrathin magnetic cobalt Films on MgO(001)” Gagan Sharma, U.P. Deshpande, Dileep Kumar and Ajay Gupta Journal of Applied Physics 112, 023910 (2012). 5. “In-situ study of magnetic thin films on nanorippled Si (1 0 0) substrates” Sarathlal K.V., Dileep Kumar, V. Ganesan, Ajay Gupta, Applied Surface Science 258 (2012) 4116 6. “Study of Co90Fe10 magnetic thin Film on MgO substrate using In-situ MOKE Technique” Gagan Sharma, Dileep Kumar, Ajay Gupta Journal of Physics: Conference Series 365 (2012) 012038 7. “Growth study of Co thin film on nanorippled Si(100) substrate” Sarathlal K. V., Dileep Kumar, and Ajay Gupta, Appl. Phys. Lett 98, 123111 (2011) Dr. Dileep K. Gupta Scientist In-situ thin film UGC-DAE CSR, Indore-452001 dkumar@csr.res.in; dileep.esrf@gmail.com Phone: +91-731-2463913 (ext.176) Page 45 Page