Other - Indium Corporation

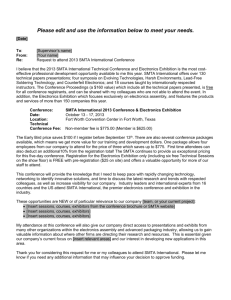

advertisement