Boron Removal by Nanofiltration and Reverse

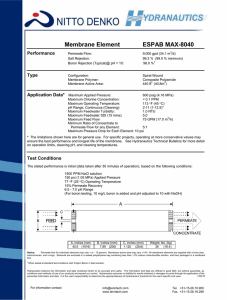

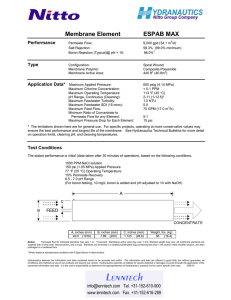

advertisement